News

SpaceX returns to Starship program roots with new ‘test tank’ prototype

It’s now clear that SpaceX is preparing to return to the roots of its Starship program with the latest in a series of one-off ‘test tanks’ meant to qualify upgrades to the rocket’s design and production.

Likely known as Starship SN7.2, the hardware will be the first standalone tank built and tested by SpaceX since SN7.1 was successfully pressurized to failure in a process known as burst testing in September 2020. Following in the footsteps of SN7.1, a simple test tank fully focused on qualifying a change in the steel alloy used to build Starships, SN7.2 was somewhat more complex, swapping one of two smooth forward domes with a thrust dome and adding a ‘skirt’ section.

Built out of the same steel alloy as SN7.1, SN7.2 went through similar testing but included the use of a hydraulic ram designed to simulate the thrust of one, two, or three Raptors on the ‘thrust puck’ those engines would otherwise attach to. Starship test tank SN7.2 appears to be quite similar to SN7.1 – but with one or two crucial differences.

The first difference, as noted above, is a reduction in the thickness of the steel rings that make up the outer walls and structure of SN7.2’s barrel-like tank section. SpaceX is believed to have reduced that skin thickness by 25% (4mm to 3mm) in an apparent effort to begin a weight reduction process necessary for Starships to eventually achieve their optimal payload goal of ~150 metric tons (~330,000 lb) to low Earth orbit.

From some angles, SN7.2’s steel rings do appear slightly flimsier or more liable to warp from the heat of welding than other test tanks in the SN7 range, but the differences are rather subtle. Regardless, a reduction from 4mm to 3mm steel rings could likely cut 5-10% from an orbit-capable Starship’s empty weight. When every gram of Starship mass reduction translates directly into an extra gram of payload, it’s safe to say that SpaceX is just getting started.

It’s unclear if a successful SN7.2 test campaign will result in similar reductions to the steel that makes up Starship tank domes and noses. SN7.2’s forward and thrust domes appear to be more or less identical to almost all prior Starship prototype hardware.

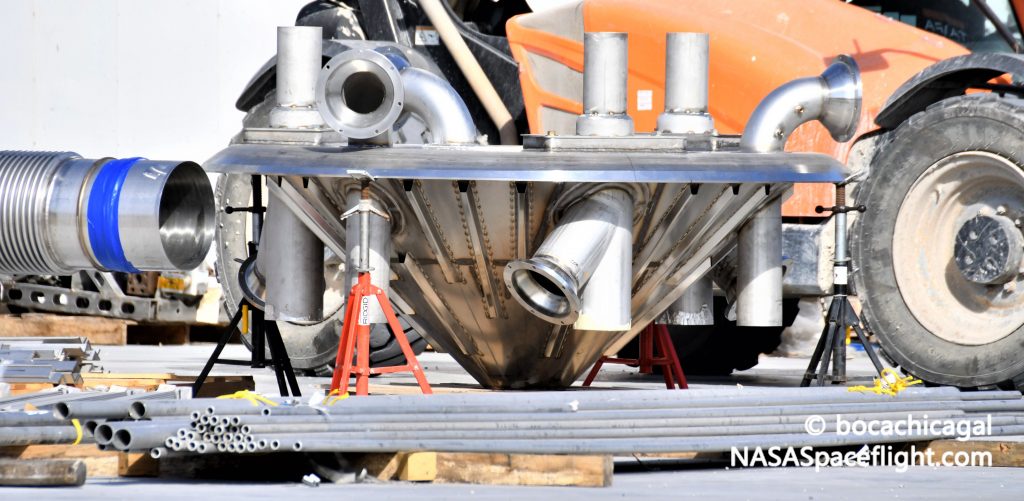

Aside from thinner steel skin, it’s also possible that SpaceX will attempt to hit two birds with one stone and test a second unproven change on SN7.2 – namely an upgraded ‘thrust puck’ design. That new puck design first appeared on a November 2020 shipment from SpaceX’s Hawthorne, CA headquarters. Referring to the cone-like structure Starship’s three central Raptor engines attach to and are fed propellant through, the new design simplifies plumbing complexity by allowing Starship’s fuel and fuel header tanks to attach directly to and feed methane through the puck.

It’s unclear which thrust puck design SN7.2 has settled on, though SpaceX’s decision to make SN7.2 an engine section test tank arguably points towards the new puck. Regardless, SpaceX will almost certainly install a skirt section – two reinforced rings – underneath SN7.2 once the tank is welded together, giving it the hold-down clamps needed to secure it to a launch mount while simulating Raptor thrust.

Cybertruck

Tesla confirms date when new Cybertruck trim will go up in price

Tesla has officially revealed that this price will only be available until February 28, as the company has placed a banner atop the Design Configurator on its website reflecting this.

Tesla has confirmed the date when its newest Cybertruck trim level will increase in price, after CEO Elon Musk noted that the All-Wheel-Drive configuration of the all-electric pickup would only be priced at its near-bargain level for ten days.

Last week, Tesla launched the All-Wheel-Drive configuration of the Cybertruck. Priced at $59,990, the Cybertruck featured many excellent features and has seemingly brought some demand to the pickup, which has been underwhelming in terms of sales figures over the past couple of years.

Tesla launches new Cybertruck trim with more features than ever for a low price

When Tesla launched it, many fans and current owners mulled the possibility of ordering it. However, Musk came out and said just hours after launching the pickup that Tesla would only keep it at the $59,990 price level for ten days.

What it would be priced at subsequently was totally dependent on how much demand Tesla felt for the new trim level, which is labeled as a “Dual Motor All-Wheel-Drive” configuration.

Tesla has officially revealed that this price will only be available until February 28, as the company has placed a banner atop the Design Configurator on its website reflecting this:

NEWS: Tesla has officially announced that the price of the new Cybertruck Dual-Motor AWD will be increasing after February 28th. pic.twitter.com/vZpA521ZwC

— Sawyer Merritt (@SawyerMerritt) February 24, 2026

Many fans and owners have criticized Tesla’s decision to unveil a trim this way, and then price it at something, only to change that price a few days later based on how well it sells.

Awful way to treat customers – particularly when they already sent out a marketing email announcing the $59,990 truck…with zero mention of it being a limited-time offer.

— Ryan McCaffrey (@DMC_Ryan) February 24, 2026

It seems the most ideal increase in price would be somewhere between $5,000 and $10,000, but it truly depends on how many orders Tesla sees for this new trim level. The next step up in configuration is the Premium All-Wheel-Drive, which is priced at $79,990.

The difference between the Dual Motor AWD Cybertruck and the Premium AWD configuration comes down to towing, interior quality, and general features. The base package is only capable of towing up to 7,500 pounds, while the Premium can handle 11,000 pounds. Additionally, the seats in the Premium build are Vegan Leather, while the base trim gets the textile seats.

It also has only 7 speakers compared to the 15 that the Premium trim has. Additionally, the base model does not have an adjustable ride height, although it does have a coil spring with an adaptive damping suspension package.

Cybertruck

Tesla set to activate long-awaited Cybertruck feature

Tesla will officially activate the Active Noise Cancellation (ANC) feature on Cybertruck soon, as the company has officially added the feature to its list of features by trim on its website.

Tesla is set to activate a long-awaited Cybertruck feature, and no matter when you bought your all-electric pickup, it has the hardware capable of achieving what it is designed to do.

Tesla simply has to flip the switch, and it plans to do so in the near future.

Tesla will officially activate the Active Noise Cancellation (ANC) feature on Cybertruck soon, according to Not a Tesla App, as the company has officially added the feature to its list of features by trim on its website.

Tesla rolls out Active Road Noise Reduction for new Model S and Model X

The ANC feature suddenly appeared on the spec sheet for the Premium All-Wheel-Drive and Cyberbeast trims, which are the two configurations that have been delivered since November 2023.

However, those trims have both had the ANC disabled, and although they are found in the Model S and Model X, and are active in those vehicles, Tesla is planning to activate them.

In Tesla’s Service Toolbox, it wrote:

“ANC software is not enabled on Cybertruck even though the hardware is installed.”

Tesla has utilized an ANC system in the Model S and Model X since 2021. The system uses microphones embedded in the front seat headrests to detect low-frequency road noise entering the cabin. It then generates anti-noise through phase-inverted sound waves to cancel out or reduce that noise, creating quieter zones, particularly around the vehicle’s front occupants.

The Model S and Model X utilize six microphones to achieve this noise cancellation, while the Cybertruck has just four.

Tesla Cybertruck Dual Motor AWD estimated delivery slips to early fall 2026

As previously mentioned, this will be activated through a software update, as the hardware is already available within Cybertruck and can simply be activated at Tesla’s leisure.

The delays in activating the system are likely due to Tesla Cybertruck’s unique design, which is unlike anything before. In the Model S and Model X, Tesla did not have to do too much, but the Cybertruck has heavier all-terrain tires and potentially issues from the aluminum castings that make up the vehicle’s chassis, which are probably presenting some challenges.

Unfortunately, this feature will not be available on the new Dual Motor All-Wheel-Drive configuration, which was released last week.

News

Tesla Model S and X customization options begin to thin as their closure nears

Tesla’s Online Design Studio for both vehicles now shows the first color option to be listed as “Sold Out,” as Lunar Silver is officially no longer available for the Model S or Model X. This color is exclusive to these cars and not available on the Model S or Model X.

Tesla Model S and Model X customization options are beginning to thin for the first time as the closure of the two “sentimental” vehicles nears.

We are officially seeing the first options disappear as Tesla begins to work toward ending production of the two cars and the options that are available to those vehicles specifically.

Tesla’s Online Design Studio for both vehicles now shows the first color option to be listed as “Sold Out,” as Lunar Silver is officially no longer available for the Model S or Model X. This color is exclusive to these cars and not available on the Model S or Model X.

🚨 Tesla Model S and Model X availability is thinning, as Tesla has officially shown that the Lunar Silver color option on both vehicles is officially sold out

To be fair, Frost Blue is still available so no need to freak out pic.twitter.com/YnwsDbsFOv

— TESLARATI (@Teslarati) February 25, 2026

Tesla is making way for the Optimus humanoid robot project at the Fremont Factory, where the Model S and Model X are produced. The two cars are low-volume models and do not contribute more than a few percent to Tesla’s yearly delivery figures.

With CEO Elon Musk confirming that the Model S and Model X would officially be phased out at the end of the quarter, some of the options are being thinned out.

This is an expected move considering Tesla’s plans for the two vehicles, as it will make for an easier process of transitioning that portion of the Fremont plant to cater to Optimus manufacturing. Additionally, this is likely one of the least popular colors, and Tesla is choosing to only keep around what it is seeing routine demand for.

During the Q4 Earnings Call in January, Musk confirmed the end of the Model S and Model X:

“It is time to bring the Model S and Model X programs to an end with an honorable discharge. It is time to bring the S/X programs to an end. It’s part of our overall shift to an autonomous future.”

Fremont will now build one million Optimus units per year as production is ramped.