News

SpaceX Starship factory eyes cutting-edge industry solutions for inspiration [updated]

Update: In a Twitter response to this article, SpaceX CEO Elon Musk says that the reality of things is unsurprisingly a bit more complex. As noted, the standards and requirements for aerospace hardware are much stricter than those needed for the water towers, storage tanks, and other utilities that existing commercial solutions are commonly used to build.

As such, it’s inaccurate to suggest that those off-the-shelf solutions are capable of building rockets right out of the box. Still, several pieces of commercial fabrication equipment from providers like IMCAR have been spotted in use at SpaceX’s Boca Chica, Texas Starship facilities. With “substantial capital and engineering” investments into making those solutions more precise, however, SpaceX may still be able to use existing hardware – or at least the concepts they underly – to rapidly build high-quality Starships and Super Heavy boosters.

A SpaceX engineer says that the company wants to adopt commercially-available manufacturing equipment that could allow its Boca Chica, Texas team to build Starship tank parts in minutes and nearly-complete rocket bodies in a matter of days.

Originally created to meet the needs of a variety of different companies – typically oil and gas related – that need efficient, affordable, and standardized storage tanks, a small but growing niche exists for semi-automated tank production. While there is some clear uncertainty given that the quality and consistency required for oil and gas needs or even simple water storage likely isn’t the same needed to meet strict spaceflight margins, SpaceX has already acquired several production tools from existing contractors and is working around the clock to prove that those same tools can be used to build large, reusable rockets.

The gamble is simple: if it turns out that off-the-shelf (COTS) equipment can become an almost turnkey solution for manufacturing high-quality Starship spacecraft and Super Heavy boosters, SpaceX may have found a shortcut to orbit, avoiding the huge expense of finding and building its own custom production solutions. But is that COTS tank fabrication hardware truly up to the task?

At least right now, the simple answer is “yes”. Thanks to two highly successful destructive tests of Starship tank prototypes that wrapped up last month, SpaceX has confirmed that at least a subset of the available COTS solutions can be used to build Starships (theoretically) capable of orbital flight. To be clear, those tanks reached only the most basic kind of specification needed for a true orbital-class spacecraft, demonstrating that they can fairly easily survive the pressures required for Starship and its Super Heavy boosters to remain structurally sound from liftoff to touchdown.

For the most part, the only truly COTS aspect of those test tanks were the flat, cylindrical rings at their center – produced by cutting and welding together giant sheets of coiled steel. The tanks’ domes were more or less welded together by hand with the help of large jigs, while finished domes and rings were also welded together by hand. Given that the welds used to create the rings themselves have never obviously been a problem, the success of Starship’s two test tanks can thus be heavily attributed to skilled welders’ hands rather than any particular off-the-shelf solution.

Still, the fact of the matter is that automatic solutions like those currently available exist for good reason – aside from requiring far less labor to produce similar results, the consistency and quality of those results can actually be much better than anything that can be reliably achieved in a more boutique fashion. This is, at least, the promise of solutions like those shown below.

SpaceX certainly appears to be pursuing the best-case scenarios that could be made possible with some of the hardware shown above. Already, it looks like Starship ring segments – themselves formed and welded with semi-automated IMCAR hardware – are being stacked and tack welded (temporary welds used like clamps) inside one of SpaceX’s new tents before the stand holding those ring(s) rotates itself, automatically welding them together.

The three mated rings pictured above were assembled over the course of several days using some of those methods and COTS fabrication hardware. However, if SpaceX can refine its procedures – currently still in the oven, so to speak – and become an expert at modifying and using available tank fabrication hardware to fabricate rockets, the company could conceivably build entire Starship and Super Heavy bodies in a matter of days.

It might take a substantial amount of trial and error, but SpaceX is clearly well on its way.

Check out Teslarati’s Marketplace! We offer Tesla accessories, including for the Tesla Cybertruck and Tesla Model 3.

News

Tesla Australia confirms six-seat Model Y L launch in 2026

Compared with the standard five-seat Model Y, the Model Y L features a longer body and extended wheelbase to accommodate an additional row of seating.

Tesla has confirmed that the larger six-seat Model Y L will launch in Australia and New Zealand in 2026.

The confirmation was shared by techAU through a media release from Tesla Australia and New Zealand.

The Model Y L expands the Model Y lineup by offering additional seating capacity for customers seeking a larger electric SUV. Compared with the standard five-seat Model Y, the Model Y L features a longer body and extended wheelbase to accommodate an additional row of seating.

The Model Y L is already being produced at Tesla’s Gigafactory Shanghai for the Chinese market, though the vehicle will be manufactured in right-hand-drive configuration for markets such as Australia and New Zealand.

Tesla Australia and New Zealand confirmed the vehicle will feature seating for six passengers.

“As shown in pictures from its launch in China, Model Y L will have a new seating configuration providing room for 6 occupants,” Tesla Australia and New Zealand said in comments shared with techAU.

Instead of a traditional seven-seat arrangement, the Model Y L uses a 2-2-2 layout. The middle row features two individual seats, allowing easier access to the third row while providing additional space for passengers.

Tesla Australia and New Zealand also confirmed that the Model Y L will be covered by the company’s updated warranty structure beginning in 2026.

“As with all new Tesla Vehicles from the start of 2026, the Model Y L will come with a 5-year unlimited km vehicle warranty and 8 years for the battery,” the company said.

The updated policy increases Tesla’s vehicle warranty from the previous four-year or 80,000-kilometer coverage.

Battery and drive unit warranties remain unchanged depending on the variant. Rear-wheel-drive models carry an eight-year or 160,000-kilometer warranty, while Long Range and Performance variants are covered for eight years or 192,000 kilometers.

Tesla has not yet announced official pricing or range figures for the Model Y L in Australia.

News

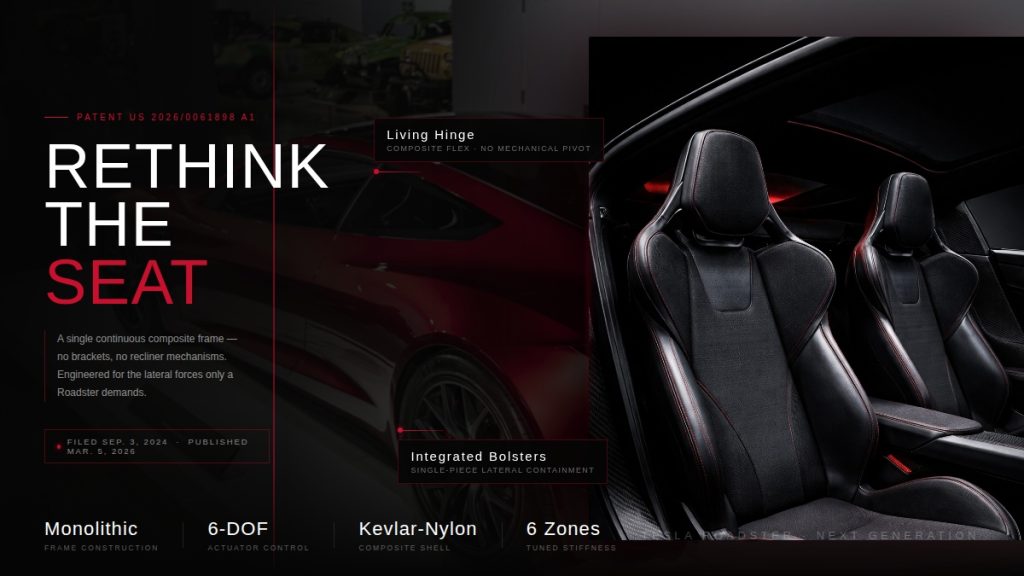

Tesla Roadster patent hints at radical seat redesign ahead of reveal

A newly published Tesla patent could offer one of the clearest signals yet that the long-awaited next-generation Roadster is nearly ready for its public debut.

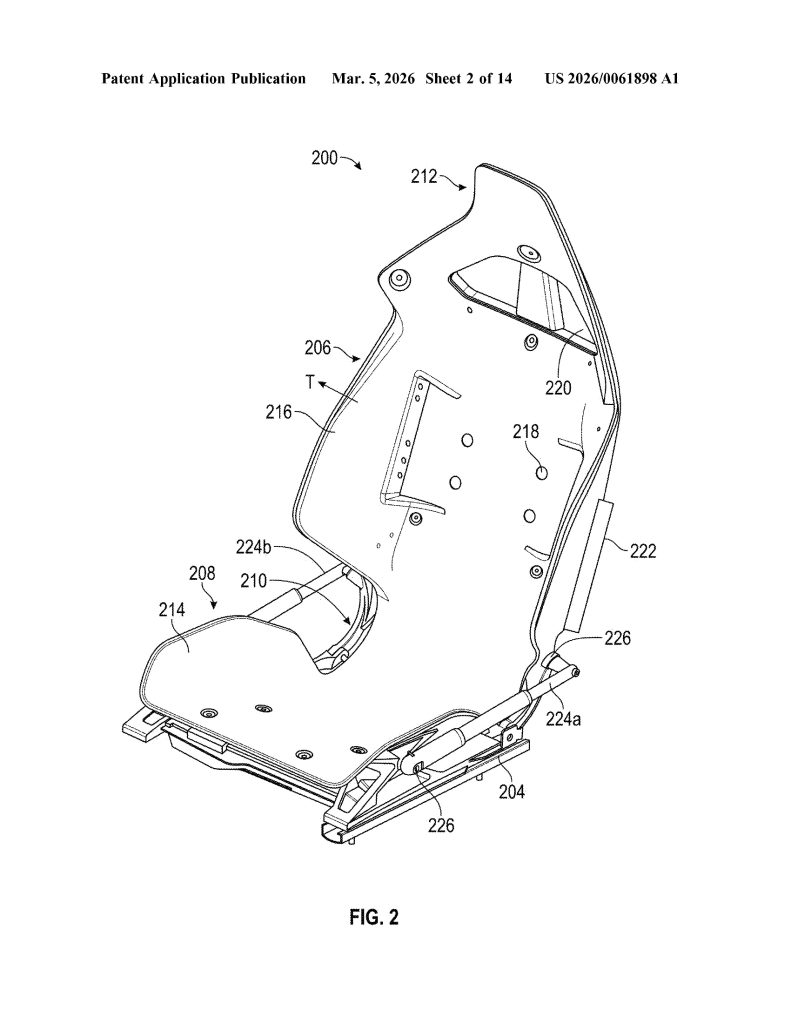

Patent No. US 20260061898 A1, published on March 5, 2026, describes a “vehicle seat system” built around a single continuous composite frame – a dramatic departure from the dozens of metal brackets, recliner mechanisms, and rivets that make up a traditional car seat. Tesla is calling it a monolithic structure, with the seat portion, backrest, headrest, and bolsters all thermoformed as one unified piece.

The approach mirrors Tesla’s broader manufacturing philosophy. The same company that pioneered massive aluminum castings to eliminate hundreds of body components is now applying that logic to the cabin. Fewer parts means fewer potential failure points, less weight, and a cleaner assembly process overall.

Tesla ramps hiring for Roadster as latest unveiling approaches

The timing of the filing is difficult to ignore. Elon Musk has publicly targeted April 1, 2026 as the date for an “unforgettable” Roadster design reveal, and two new Roadster trademarks were filed just last month. A patent describing a seat architecture suited for a hypercar, and one that Tesla has promised will hit 60 mph in under two seconds.

The Roadster, originally unveiled in 2017, has been one of Tesla’s most anticipated yet most delayed products. With a target price around $200,000 and engineering ambitions to match, it is being positioned as the ultimate showcase for what Tesla’s technology can do.

The patent was first flagged by @seti_park on X.

Tesla Roadster Monolithic Seat: Feature Highlights via US Patent 20260061898 A1

- Single Continuous Frame (Monolithic Construction). The core invention is a seat assembly built from one continuous frame that integrates the seat portion, backrest portion, and hinge into a single component — eliminating the need for separate structural parts and mechanical joints typical in conventional seats.

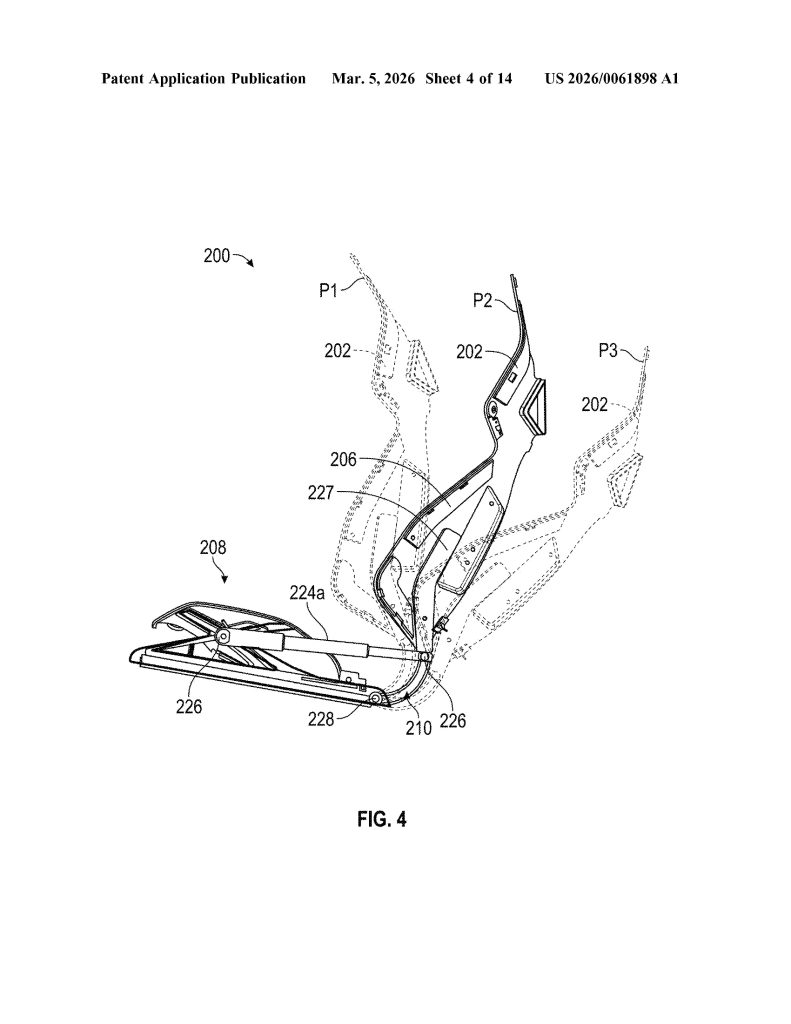

- Integrated Flexible Hinge. Rather than a traditional mechanical recliner, the hinge is built directly into the continuous frame and is designed to flex, and allowing the backrest to move relative to the seat portion. The hinge can be implemented as a fiber composite leaf spring or an assembly of rigid linkages.

- Thermoformed Anisotropic Composite Material. The continuous frame is manufactured via thermoforming from anisotropic composite materials, including fiberglass-nylon, fiberglass-polymer, nylon carbon composite, Kevlar-nylon, or Kevlar-polymer composites, enabling a molded-to-shape monolithic structure.

- Regionally Tuned Stiffness Zones. The frame is engineered with up to six distinct stiffness regions (R1–R6) across the seat, backrest, hinge, headrest, and bolsters. Each zone can have a different stiffness, allowing precise ergonomic and structural tuning without adding separate components.

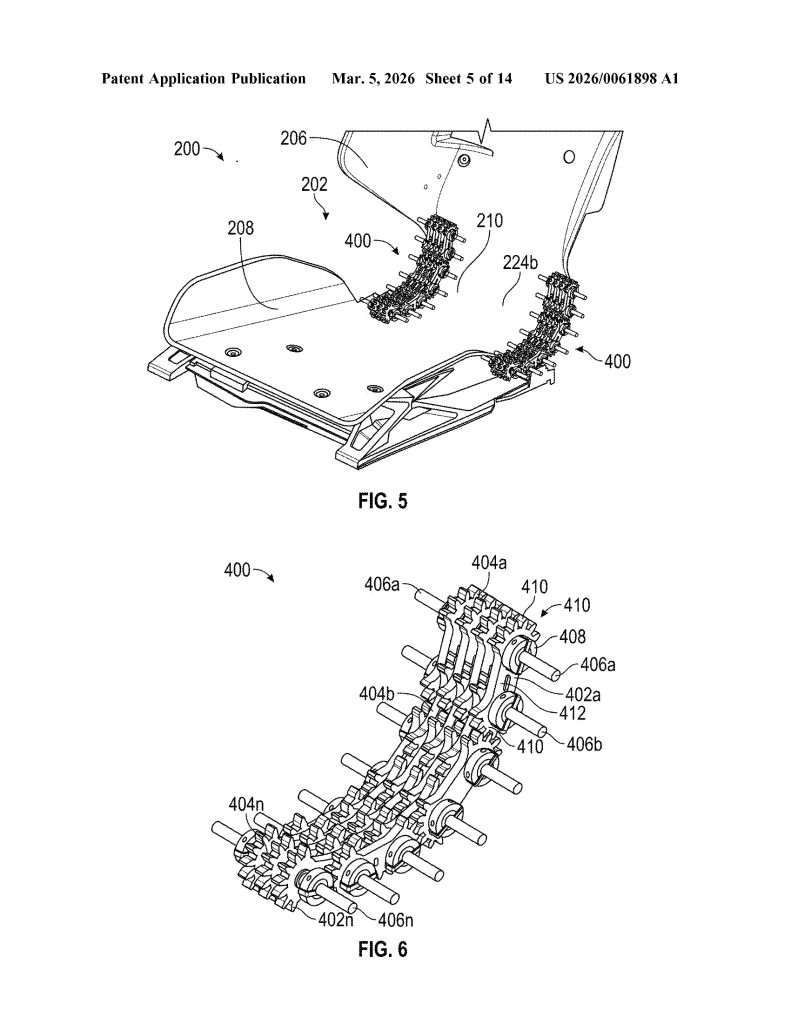

- Linkage Assembly Hinge Mechanism. The hinge incorporates one or more linkage assemblies consisting of multiple interlocking links with gears, connected by rods. When driven by motors or actuators, these linkages act as a flexible member to control backrest movement along a precise, ergonomically optimized trajectory.

- Multi-Actuator Six-Degree-of-Freedom Positioning System. The seat uses four distinct actuator pairs, all controlled by a central controller. These actuators work in coordinated combinations to achieve fore/aft, height, cushion tilt, and backrest rotation adjustments simultaneously.

- ECU-Based Controller Architecture. An Electronic Control Unit (ECU) and programmable controller manage all seat actuators, receive user input via a user interface (touchscreen, buttons, or switches), and incorporate sensor feedback to confirm and maintain desired seat positions, essentially making this a software-driven seat system.

- Airbag-Integrated Bolster Deployment System. The backrest bolsters (216) are geometrically shaped and sized to guide airbag deployment along a specific, pre-configured trajectory. Left and right bolsters can have different shapes so that each guides its respective airbag along a distinct trajectory, improving occupant protection.

- Ventilation Holes Formed into the Backrest. The continuous frame includes one or more ventilation holes formed directly into the backrest portion, configured to either receive airflow into or deliver airflow from the seat frame — enabling passive or active thermal comfort without requiring separate ventilation components.

- Soft Trim Recess for Tool-Free Integration. The headrest and backrest portions together define a molded recess, specifically designed to receive and secure a soft trim component (foam, fabric, or cushioning) directly into the continuous frame, eliminating the need for separate attachment hardware and simplifying final assembly.

Elon Musk

Elon Musk’s xAI plans $659M expansion at Memphis supercomputer site

The new building is planned for a 79-acre parcel located at 5414 Tulane Road, next to xAI’s Colossus 2 data center site.

Elon Musk’s artificial intelligence company xAI has filed a permit to construct a new building at its growing data center complex outside Memphis, Tennessee.

As per a report from Data Center Dynamics, xAI plans to spend about $659 million on a new facility adjacent to its Colossus 2 data center. Permit documents submitted to the Memphis and Shelby County Division of Planning and Development show the proposed structure would be a four-story building totaling about 312,000 square feet.

The new building is planned for a 79-acre parcel located at 5414 Tulane Road, next to xAI’s Colossus 2 data center site. Permit filings indicate the structure would reach roughly 75 feet high, though the specific function of the building has not been disclosed.

The filing was first reported by the Memphis Business Journal.

xAI uses its Memphis data centers to power Grok, the company’s flagship large language model. The company entered the Memphis area in 2024, launching its Colossus supercomputer in a repurposed Electrolux factory located in the Boxtown district.

The company later acquired land for the Colossus 2 data center in March last year. That facility came online in January.

A third data center is also planned for the cluster across the Tennessee–Mississippi border. Musk has stated that the broader campus could eventually provide access to about 2 gigawatts of compute power.

The Memphis cluster is also tied to new power infrastructure commitments announced by SpaceX President Gwynne Shotwell. During a White House event with United States President Donald Trump, Shotwell stated that xAI would develop 1.2 gigawatts of power for its supercomputer facility as part of the administration’s “Ratepayer Protection Pledge.”

“As you know, xAI builds huge supercomputers and data centers and we build them fast. Currently, we’re building one on the Tennessee-Mississippi state line… xAI will therefore commit to develop 1.2 GW of power as our supercomputer’s primary power source. That will be for every additional data center as well…

“The installation will provide enough backup power to power the city of Memphis, and more than sufficient energy to power the town of Southaven, Mississippi where the data center resides. We will build new substations and invest in electrical infrastructure to provide stability to the area’s grid,” Shotwell said.

Shotwell also stated that xAI plans to support the region’s water supply through new infrastructure tied to the project. “We will build state-of-the-art water recycling plants that will protect approximately 4.7 billion gallons of water from the Memphis aquifer each year. And we will employ thousands of American workers from around the city of Memphis on both sides of the TN-MS border,” she said.