News

SpaceX stacking two Starships at once for the first time in ten months

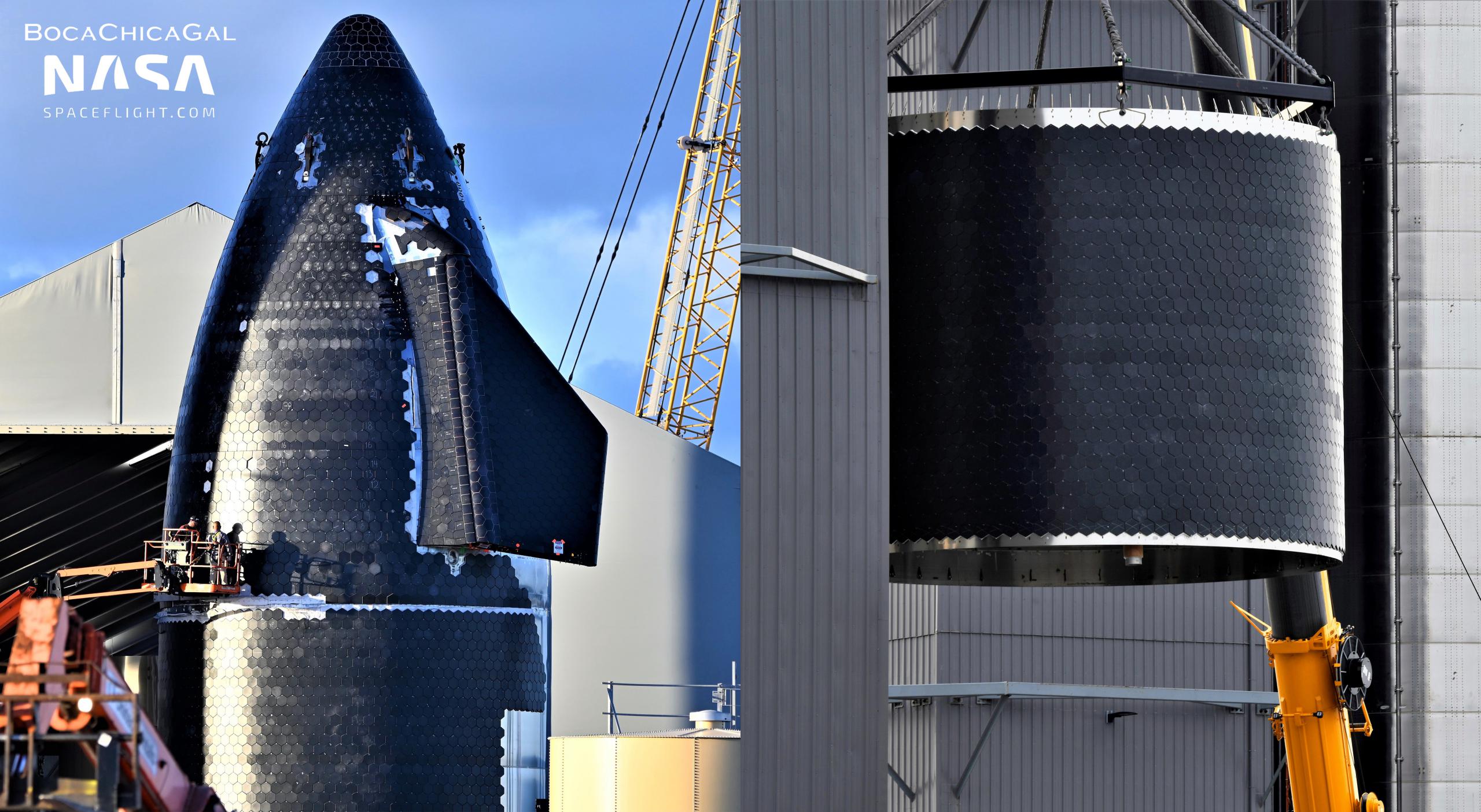

As of late November, SpaceX has begun stacking two Starship prototypes simultaneously for the first time in ten months.

Known as Starship S21 and S22, SpaceX began stacking the latter prototype inside Starbase’s ‘midbay’ in mid-October – the first Starship assembly work seen in more than two and a half months. For about half a year, SpaceX has been significantly more focused on Super Heavy production as it works to thoroughly test a booster for the first time. In the interim, the assembly of Starships – which already have an impressive history of ground and flight tests – slowed to a halt, though the production of Starship parts did not.

SpaceX builds Starships by forming structures and rings out of rolls, sheets, and billets of steel. For noses, domes, and header tanks, laser or waterjet-cut steel ‘gores’ (a bit like pizza slices) are welded together. Rolls of sheet metal are unspooled, cut into sections, and welded into individual rings that are then stacked on top of each other and robotically welded together around their circumference. Those ring sections – 9m (30 ft) wide and ranging from 2-4 rings tall (3.6-7.3m or 12-24 ft) – are then outfitted with stiffener rings and stringers to add rigidity and strength.

Once that basic structure is complete, parts are cut out or welded on to create structural supports, pass-throughs, and mounts for avionics (batteries, wiring, power, comms) hardware, plumbing, mechanical systems, and more. In the case of ships, robotic arms also weld on thousand of studs that eventually become anchors for heat shield tiles. At some point, certain partially-finished ring sections are ‘sleeved’ around tank domes, of which Starship and Super Heavy both have three. Finally, at some point in the early ‘life’ of a Starship or Super Heavy, SpaceX begins assembling the actual vehicle out of that collection of different sections. While weeks or even months of work always precede that milestone, the first stack is still the point at which SpaceX decides to turn those parts into an actual vehicle – never a guarantee, no matter how far along those parts appear to be.

— RGV Aerial Photography (@RGVaerialphotos) December 2, 2021

That’s where Starship S21 and Starship S22 found themselves around October 17th and November 21st. Six weeks later, now side by side in Starbase’s midbay, Ship 21’s tank section is fully stacked and Ship 22’s tank section is close to two-thirds complete. Ship 22’s nose assembly – a nosecone and section of four rings – is still in two pieces, while Ship 21’s nose is fully integrated – heat shield included.

In the very near future, Starship S21’s tank section will be rolled from midbay to high bay for nose installation and Starship S22’s tank section will be topped off with its engine section and leg skirt. Perhaps as early as January, both ships could be fully stacked and more or less waiting in line for qualification testing ahead of Starship’s first few orbital launch attempts. Meanwhile, SpaceX is simultaneously preparing sections of Starship S23 and Super Heavy boosters B6 and B7 for possible assembly late this year or early next.

Elon Musk

Tesla Giga Texas to feature massive Optimus V4 production line

This suggests that while the first Optimus line will be set up in the Fremont Factory, the real ramp of Optimus’ production will happen in Giga Texas.

Tesla will build Optimus 4 in Giga Texas, and its production line will be massive. This was, at least, as per recent comments by CEO Elon Musk on social media platform X.

Optimus 4 production

In response to a post on X which expressed surprise that Optimus will be produced in California, Musk stated that “Optimus 4 will be built in Texas at much higher volume.” This suggests that while the first Optimus line will be set up in the Fremont Factory, and while the line itself will be capable of producing 1 million humanoid robots per year, the real ramp of Optimus’ production will happen in Giga Texas.

This was not the first time that Elon Musk shared his plans for Optimus’ production at Gigafactory Texas. During the 2025 Annual Shareholder Meeting, he stated that Giga Texas’ Optimus line will produce 10 million units of the humanoid robot per year. He did not, however, state at the time that Giga Texas would produce Optimus V4.

“So we’re going to launch on the fastest production ramp of any product of any large complex manufactured product ever, starting with building a one-million-unit production line in Fremont. And that’s Line one. And then a ten million unit per year production line here,” Musk stated.

How big Optimus could become

During Tesla’s Q4 and FY 2025 earnings call, Musk offered additional context on the potential of Optimus. While he stated that the ramp of Optimus’ production will be deliberate at first, the humanoid robot itself will have the potential to change the world.

“Optimus really will be a general-purpose robot that can learn by observing human behavior. You can demonstrate a task or verbally describe a task or show it a task. Even show it a video, it will be able to do that task. It’s going to be a very capable robot. I think long-term Optimus will have a very significant impact on the US GDP.

“It will actually move the needle on US GDP significantly. In conclusion, there are still many who doubt our ambitions for creating amazing abundance. We are confident it can be done, and we are making the right moves technologically to ensure that it does. Tesla, Inc. has never been a company to shy away from solving the hardest problems,” Musk stated.

Elon Musk

Rumored SpaceX-xAI merger gets apparent confirmation from Elon Musk

The comment follows reports that the rocket maker is weighing a transaction that could further consolidate Musk’s space and AI ventures.

Elon Musk appeared to confirm reports that SpaceX is exploring a potential merger with artificial intelligence startup xAI by responding positively to a post about the reported transaction on X.

Musk’s comment follows reports that the rocket maker is weighing a transaction that could further consolidate his space and AI ventures.

SpaceX xAI merger

As per a recent Reuters report, SpaceX has held discussions about merging with xAI, with the proposed structure potentially involving an exchange of xAI shares for SpaceX stock. The value, structure, and timing of any deal have not been finalized, and no agreement has been signed.

Musk appeared to acknowledge the report in a brief reply on X, responding “Yeah” to a post that described SpaceX as a future “Dyson Swarm company.” The comment references a Dyson Swarm, a sci-fi megastructure concept that consists of a massive network of satellites or structures that orbit a celestial body to harness its energy.

Reuters noted that two entities were formed in Nevada on January 21 to facilitate a potential transaction for the possible SpaceX-xAI merger. The discussions remain ongoing, and a transaction is not yet guaranteed, however.

AI and space infrastructure

A potential merger with xAI would align with Musk’s stated strategy of integrating artificial intelligence development with space-based systems. Musk has previously said that space-based infrastructure could support large-scale computing by leveraging continuous solar energy, an approach he has framed as economically scalable over time.

xAI already has operational ties to Musk’s other companies. The startup develops Grok, a large language model that holds a U.S. Department of Defense contract valued at up to $200 million. AI also plays a central role in SpaceX’s Starlink and Starshield satellite programs, which rely on automation and machine learning for network management and national security applications.

Musk has previously consolidated his businesses through share-based transactions, including Tesla’s acquisition of SolarCity in 2016 and xAI’s acquisition of X last year. Bloomberg has also claimed that Musk is considering a merger between SpaceX and Tesla in the future.

Cybertruck

Tesla analyst claims another vehicle, not Model S and X, should be discontinued

Tesla analyst Gary Black of The Future Fund claims that the company is making a big mistake getting rid of the Model S and Model X. Instead, he believes another vehicle within the company’s lineup should be discontinued: the Cybertruck.

Black divested The Future Fund from all Tesla holdings last year, but he still covers the stock as an analyst as it falls in the technology and autonomy sectors, which he covers.

In a new comment on Thursday, Black said the Cybertruck should be the vehicle Tesla gets rid of due to the negatives it has drawn to the company.

The Cybertruck is also selling in an underwhelming fashion considering the production capacity Tesla has set aside for it. It’s worth noting it is still the best-selling electric pickup on the market, and it has outlasted other EV truck projects as other manufacturers are receding their efforts.

Black said:

“IMHO it’s a mistake to keep Tesla Cybertruck which has negative brand equity and sold 10,000 units last year, and discontinue S/X which have strong repeat brand loyalty and together sold 30K units and are highly profitable. Why not discontinue CT and covert S/X to be fully autonomous?”

IMHO it’s a mistake to keep $TSLA Cybertruck which has negative brand equity and sold 10,000 units last year, and discontinue S/X which have strong repeat brand loyalty and together sold 30K units and are highly profitable. Why not discontinue CT and covert S/X to be fully…

— Gary Black (@garyblack00) January 29, 2026

On Wednesday, CEO Elon Musk confirmed that Tesla planned to transition Model S and Model X production lines at the Fremont Factory to handle manufacturing efforts of the Optimus Gen 3 robot.

Musk said that it was time to wind down the S and X programs “with an honorable discharge,” also noting that the two cars are not major contributors to Tesla’s mission any longer, as its automotive division is more focused on autonomy, which will be handled by Model 3, Model Y, and Cybercab.

Tesla begins Cybertruck deliveries in a new region for the first time

The news has drawn conflicting perspectives, with many Tesla fans upset about the decision, especially as it ends the production of the largest car in the company’s lineup. Tesla’s focus is on smaller ride-sharing vehicles, especially as the vast majority of rides consist of two or fewer passengers.

The S and X do not fit in these plans.

Nevertheless, the Cybertruck fits in Tesla’s future plans. Musk said the pickup will be needed for the transportation of local goods. Musk also said Cybertruck would be transitioned to an autonomous line.