News

SpaceX’s next-gen Falcon Heavy closer to reality as side booster leaves factory

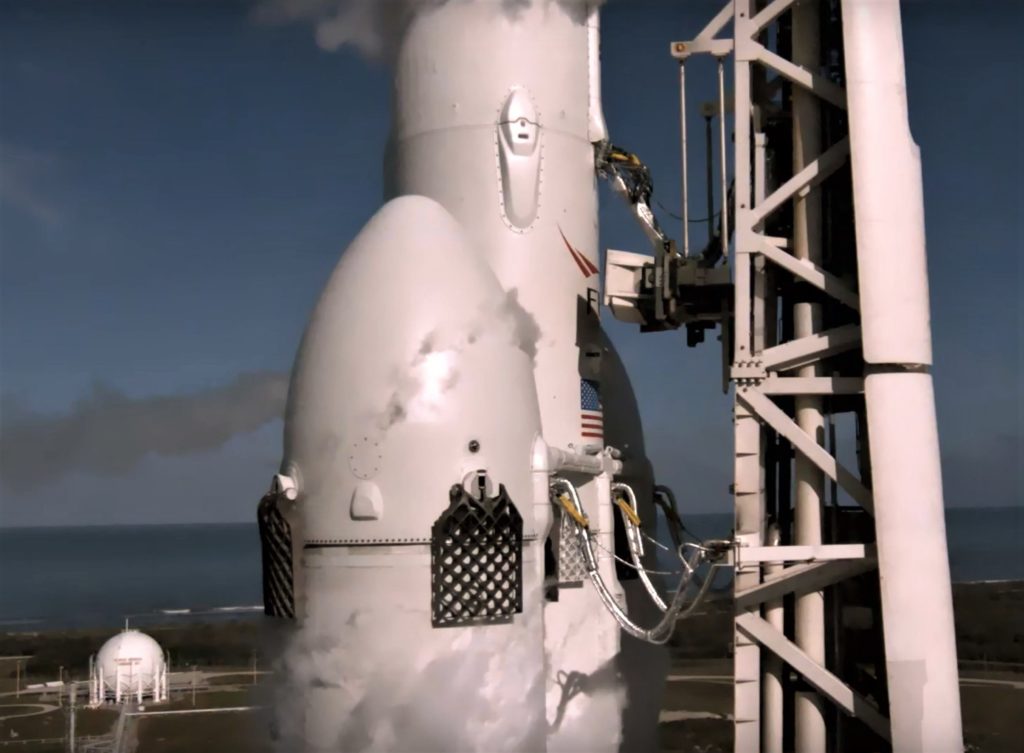

A duo of rocket spottings on November 9th and 10th confirm that SpaceX’s next Falcon Heavy rocket – an amalgamation of three Falcon 9 boosters, an upper stage, and extensive modifications – is already in the late stages of manufacturing and is nearing the beginning of integrated structural and static fire testing.

As of now, this Falcon Heavy side booster could end up supporting either or both of two near-term launch contracts in place for the rocket, communications satellite Arabsat 6A or the US Air Force’s second Space Test Program (STP-2) launch

SpaceX's second Falcon Heavy is slowly but surely coming together 😀 https://t.co/AYJsQ8Mld5

— Eric Ralph (@13ericralph31) November 13, 2018

The question of the hour – at least for Falcon Heavy – is which of those two available payloads will be atop the rocket on its first truly commercial launch. While suboptimal, a few general characteristics of each payload, SpaceX’s history of commercial launches, and Falcon Heavy itself can offer a hint or two.

Triple the rocket, triple the trouble

Thanks in large part to the fact that the first integrated Falcon Heavy was composed of two relatively old Falcon 9 booster variants and a center core that was quite literally a one-off rocket, the process of reenginering and building another Falcon Heavy rocket off of the family’s newest Block 5 variant has likely been far harder than simply building another Falcon Heavy. Although all three original Falcon Heavy boosters (B1023, B1025, and B1033) were in the same league as Block 5, their Block 2 and Block 3 hardware was designed for approximately 10% less thrust and are almost entirely different vehicles from the perspective of structures and avionics.

Perhaps even more importantly, it’s unknown whether Falcon Heavy Block 1 (for lack of a better descriptor) was designed with serious reusability in mind, at least in the same sense as Falcon 9 Block 5 was. For instance, a major portion of the rocket’s extreme complexity and difficulties lies in the basic need to transmit three times as much thrust through the center core. To do that and do it without rocket-powered separation mechanisms, SpaceX had to develop structural attachments and connections capable of surviving unbelievable mechanical and thermal stresses for minutes on end.

- The first Falcon Heavy was a Frankenstein’s monster of sorts. (SpaceX)

- Falcon Heavy is seen here lifting off during its spectacular launch debut. (SpaceX)

- A Falcon Heavy side booster was spotted eastbound in Arizona on November 10th. (Reddit – beast-sam)

Clearly, this was an unfathomably difficult problem to solve in such a manner that Falcon Heavy would work at all the first time. Factor in the strategic need for those same components to survive repeated cycles of those stresses with minimal refurbishment in between and the problem at hand likely becomes a magnitude more difficult, at least. In large part, this helps to explain why there will end up being a minimum of 11-12 months between Falcon Heavy’s first and second launches.

Arabsat or STP?

Over the course of SpaceX’s last 2-3 years of commercial launch activity, the company and its customers have demonstrated time and time again a reliable pattern: commercial customers (in the sense of private entities) are far more willing to take risks with new technologies than SpaceX’s government customers. NASA’s Commercial Resupply Services is the exception for the latter group but also has no Falcon Heavy launch contracts. For Falcon Heavy, there are thus main three options at hand.

- Arabsat 6A launches first with 1-2 flight-proven boosters; the Air Force’s STP-2 mission flies on an all-new Falcon Heavy 4-6 months later.

- SpaceX builds entirely new Falcon Heavy rockets for both customers, requiring four new side boosters and two new center cores.

- STP-2 launches first on an all-new Falcon Heavy; Arabsat 6A launches second on the first flight-proven Falcon Heavy after 6+ months of additional delays.

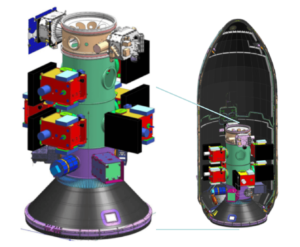

- The USAF’s STP-2, a combination of a few dozen different satellites. (USAF)

- The communications satellite Arabsat-6A. (Lockheed Martin)

- LZ-1 and LZ-2, circa February 2018. (SpaceX)

- A closeup of one of Falcon Heavy’s side boosters after landing. (SpaceX)

Arabsat is far more likely to accept – for a significant discount – a ride aboard the first flight-proven Falcon Heavy, especially if it means preventing more major launch delays. If the Falcon Heavy side booster spotted eastbound last week is a refurbished Block 5 booster rather than a new rocket, than option 1 is the easy choice for most probable outcome. The real pack leader for Falcon Heavy Flight 2, however, will be the completion of a new Block 5 center core and its shipment to Texas for structural and static fire testing.

Time will tell. For now, a completed Falcon Heavy side booster is the best sign yet that SpaceX may manage the rocket’s second launch in the first quarter of 2019, whichever launch that may be.

News

Tesla makes big Full Self-Driving change to reflect future plans

Tesla made a dramatic change to the Online Design Studio to show its plans for Full Self-Driving, a major part of the company’s plans moving forward, as CEO Elon Musk has been extremely clear on the direction moving forward.

With Tesla taking a stand and removing the ability to purchase Full Self-Driving outright next month, it is already taking steps to initiate that with owners and potential buyers.

On Thursday night, the company updated its Online Design Studio to reflect that in a new move that now lists the three purchase options that are currently available: Monthly Subscription, One-Time Purchase, or Add Later:

🚨 Check out the change Tesla made to its Online Design Studio:

It now lists the Monthly Subscription as an option for Full Self-Driving

It also shows the outright purchase option as expiring on February 14 pic.twitter.com/pM6Svmyy8d

— TESLARATI (@Teslarati) January 23, 2026

This change replaces the former option for purchasing Full Self-Driving at the time of purchase, which was a simple and single box to purchase the suite outright. Subscriptions were activated through the vehicle exclusively.

However, with Musk announcing that Tesla would soon remove the outright purchase option, it is clearer than ever that the Subscription plan is where the company is headed.

The removal of the outright purchase option has been a polarizing topic among the Tesla community, especially considering that there are many people who are concerned about potential price increases or have been saving to purchase it for $8,000.

This would bring an end to the ability to pay for it once and never have to pay for it again. With the Subscription strategy, things are definitely going to change, and if people are paying for their cars monthly, it will essentially add $100 per month to their payment, pricing some people out. The price will increase as well, as Musk said on Thursday, as it improves in functionality.

I should also mention that the $99/month for supervised FSD will rise as FSD’s capabilities improve.

The massive value jump is when you can be on your phone or sleeping for the entire ride (unsupervised FSD). https://t.co/YDKhXN3aaG

— Elon Musk (@elonmusk) January 23, 2026

Those skeptics have grown concerned that this will actually lower the take rate of Full Self-Driving. While it is understandable that FSD would increase in price as the capabilities improve, there are arguments for a tiered system that would allow owners to pay for features that they appreciate and can afford, which would help with data accumulation for the company.

Musk’s new compensation package also would require Tesla to have 10 million active FSD subscriptions, but people are not sure if this will move the needle in the correct direction. If Tesla can potentially offer a cheaper alternative that is not quite unsupervised, things could improve in terms of the number of owners who pay for it.

News

Tesla Model S completes first ever FSD Cannonball Run with zero interventions

The coast-to-coast drive marked the first time Tesla’s FSD system completed the iconic, 3,000-mile route end to end with no interventions.

A Tesla Model S has completed the first-ever full Cannonball Run using Full Self-Driving (FSD), traveling from Los Angeles to New York with zero interventions. The coast-to-coast drive marked the first time Tesla’s FSD system completed the iconic, 3,000-mile route end to end, fulfilling a long-discussed benchmark for autonomy.

A full FSD Cannonball Run

As per a report from The Drive, a 2024 Tesla Model S with AI4 and FSD v14.2.2.3 completed the 3,081-mile trip from Redondo Beach in Los Angeles to midtown Manhattan in New York City. The drive was completed by Alex Roy, a former automotive journalist and investor, along with a small team of autonomy experts.

Roy said FSD handled all driving tasks for the entirety of the route, including highway cruising, lane changes, navigation, and adverse weather conditions. The trip took a total of 58 hours and 22 minutes at an average speed of 64 mph, and about 10 hours were spent charging the vehicle. In later comments, Roy noted that he and his team cleaned out the Model S’ cameras during their stops to keep FSD’s performance optimal.

History made

The historic trip was quite impressive, considering that the journey was in the middle of winter. This meant that FSD didn’t just deal with other cars on the road. The vehicle also had to handle extreme cold, snow, ice, slush, and rain.

As per Roy in a post on X, FSD performed so well during the trip that the journey would have been completed faster if the Model S did not have people onboard. “Elon Musk was right. Once an autonomous vehicle is mature, most human input is error. A comedy of human errors added hours and hundreds of miles, but FSD stunned us with its consistent and comfortable behavior,” Roy wrote in a post on X.

Roy’s comments are quite notable as he has previously attempted Cannonball Runs using FSD on December 2024 and February 2025. Neither were zero intervention drives.

Elon Musk

Tesla removes Autopilot as standard, receives criticism online

The move leaves only Traffic Aware Cruise Control as standard equipment on new Tesla orders.

Tesla removed its basic Autopilot package as a standard feature in the United States. The move leaves only Traffic Aware Cruise Control as standard equipment on new Tesla orders, and shifts the company’s strategy towards paid Full Self-Driving subscriptions.

Tesla removes Autopilot

As per observations from the electric vehicle community on social media, Tesla no longer lists Autopilot as standard in its vehicles in the U.S. This suggests that features such as lane-centering and Autosteer have been removed as standard equipment. Previously, most Tesla vehicles came with Autopilot by default, which offers Traffic-Aware Cruise Control and Autosteer.

The change resulted in backlash from some Tesla owners and EV observers, particularly as competing automakers, including mainstream players like Toyota, offer features like lane-centering as standard on many models, including budget vehicles.

That being said, the removal of Autopilot suggests that Tesla is concentrating its autonomy roadmap around FSD subscriptions rather than bundled driver-assistance features. It would be interesting to see how Tesla manages its vehicles’ standard safety features, as it seems out of character for Tesla to make its cars less safe over time.

Musk announces FSD price increases

Following the Autopilot changes, Elon Musk stated on X that Tesla is planning to raise subscription prices for FSD as its capabilities improve. In a post on X, Musk stated that the current $99-per-month price for supervised FSD would increase over time, especially as the system itself becomes more robust.

“I should also mention that the $99/month for supervised FSD will rise as FSD’s capabilities improve. The massive value jump is when you can be on your phone or sleeping for the entire ride (Unsupervised FSD),” Musk wrote.

At the time of his recent post, Tesla still offers FSD as a one-time purchase for $8,000, but Elon Musk has confirmed that this option will be discontinued on February 14, leaving subscriptions as the only way to access the system.