SpaceX

SpaceX’s Starship reaches new heights as Elon Musk teases Q1 2019 hop tests

In a burst of activity that should probably be expected at this point but still feels like a complete surprise, SpaceX technicians took a major step towards completing the first Starship hopper prototype by combining the last two remaining sections (aft and nose) scarcely six weeks after assembly began.

SpaceX CEO Elon Musk also took to Twitter late last week to offer additional details and post what appears to be the first official render of Starship’s hopper prototype, which is now closer than ever before to looking like the real deal thanks to the incredible drive of the company’s southernmost employees. With the massive rocket’s rough aeroshell and structure now more or less finalized, Musk’s targeted February/March hop test debut remains ambitious to the extreme but is now arguably far from impossible.

A quiet day as #SpaceX workers were having lunch and enjoying a well deserved break under the shadows of their creation. The wings/legs of the vehicle are getting an aesthetic touch up. 😍🚀 #Starshiphopper #ElonMusk #RGV pic.twitter.com/Y0zNGUNily

— Austin Barnard🚀 (@austinbarnard45) January 7, 2019

Where there was literally just a tent and some construction equipment barely eight weeks ago, SpaceX’s Boca Chica facilities now sport one of the most bizarre developments in recent aerospace history — a vast, ~30 ft (9m) diameter rocket being built en plein air out of tubes and sheets of common steel. At the current pace of work, 24 hours is often enough for wholly unexpected developments to appear, and this Starship hopper (Starhopper) is beginning to look more and more like its concept art as each day passes.

Aside from a few well-earned slow days last weekend, SpaceX technicians, engineers, and contractors have spent the last week or so shaping Starhopper into a form more reminiscent of the conceptual render (clearly hand-painted) Musk posted on Saturday. This primarily involved stacking a tall conical nose section atop a separate cylindrical body section, followed by gradually cladding both the aft section’s legs and barrel in sheets of stainless steel, presumably intended to improve both its aesthetic and aerodynamic characteristics.

Starship test vehicle under assembly will look similar to this illustration when finished. Operational Starships would obv have windows, etc. pic.twitter.com/D8AJ01mjyR

— Elon Musk (@elonmusk) January 5, 2019

SpaceX's Big Falcon Hopper/Starship Hopper at Boca Chica now has the three sections mated:#Shiny

Photo from NSF's BocaChicaGal:https://t.co/4RG5vZW4rN pic.twitter.com/Sd6W0Jepro

— NSF – NASASpaceflight.com (@NASASpaceflight) January 8, 2019

Notably, technicians have installed two out of three (?) aerodynamic shrouds at the top of each steel tube leg, bringing Starhopper’s appearance even closer to the smooth and polished aesthetic of its conceptual sibling.

Starhopper’s hopped-up hop test ETA

Musk later replied to a question related to Starhopper’s near-term schedule and stated that the nominal target for its first flight test was – almost unfathomably – four weeks away, although he admitted in the same response that that would probably translate into eight weeks due to “unforeseen issues”, placing the actual launch target sometime between February and March 2019. Just to reiterate, the site Starhopper is currently located on was quite literally empty – aside from the temporary tent – in late November 2018, barely more than six weeks ago.

Another great and beautiful day at #spacex today and progress is being made. I hope you all enjoy them, and have an amazing day.😃❤️🚀📸 pic.twitter.com/A9ukmdbgZI

— Austin Barnard🚀 (@austinbarnard45) January 5, 2019

To plan to go from a blank slate to actual integrated flight tests of a rocket – no matter how low-fidelity – that is 9m (~30 ft) in diameter, at least 40m (~130 ft) tall, could weigh as much as 500 tons (1.1M lbs), and may produce ~600 tons (~1.35M lb/f) of thrust at liftoff is extraordinarily ambitious even for SpaceX. At the end of the day, significant delays to Musk’s truly wild timeline are very likely, but it seems entirely possible at this point that Starhopper really could begin its first hop tests in the first half of 2019, kicking off a test program currently aiming for flights as high as 5 km (3.1 mi) and as long as 6 minutes.

A whole range of things will have to go perfectly right for a timeline as ambitious as this to be realized, including but not limited to successfully acceptance-testing three brand new and recently-redesigned Raptor engines, the completion of Starhopper’s unfamiliar structures, propellant tankage, plumbing, and avionics, and the completion of a rough launch and landing pad and integration facilities, if needed. Aside from those big ticket items, many dozens of other smaller but no less critical tasks will have to be completed with minimal to no unforeseen hurdles if hop tests are to begin just a few months from now.

And follow up from NSF member "bocachicagal"

Mating complete! 🙂 pic.twitter.com/LbR0PKENII

— NSF – NASASpaceflight.com (@NASASpaceflight) January 4, 2019

Regardless, SpaceX has pulled off miraculous tasks much like this in its past, and the possibility that the company’s brilliant, dedicated, and admittedly overworked employees will do so again should not be discounted.

For prompt updates, on-the-ground perspectives, and unique glimpses of SpaceX’s rocket recovery fleet check out our brand new LaunchPad and LandingZone newsletters!

Elon Musk

Starlink powers Europe’s first satellite-to-phone service with O2 partnership

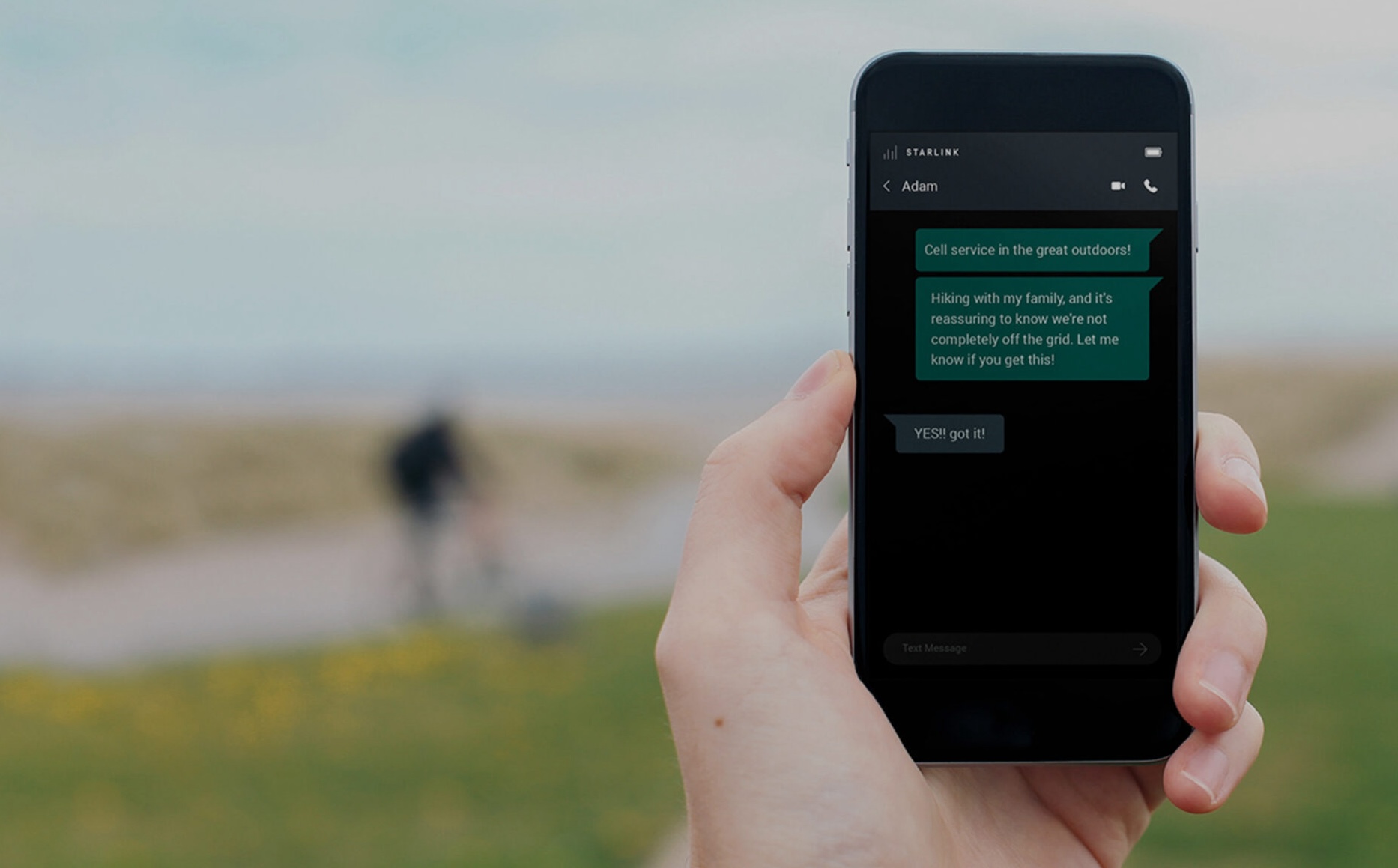

The service initially supports text messaging along with apps such as WhatsApp, Facebook Messenger, Google Maps and weather tools.

Starlink is now powering Europe’s first commercial satellite-to-smartphone service, as Virgin Media O2 launches a space-based mobile data offering across the UK.

The new O2 Satellite service uses Starlink’s low-Earth orbit network to connect regular smartphones in areas without terrestrial coverage, expanding O2’s reach from 89% to 95% of Britain’s landmass.

Under the rollout, compatible Samsung devices automatically connect to Starlink satellites when users move beyond traditional mobile coverage, according to Reuters.

The service initially supports text messaging along with apps such as WhatsApp, Facebook Messenger, Google Maps and weather tools. O2 is pricing the add-on at £3 per month.

By leveraging Starlink’s satellite infrastructure, O2 can deliver connectivity in remote and rural regions without building additional ground towers. The move represents another step in Starlink’s push beyond fixed broadband and into direct-to-device mobile services.

Virgin Media O2 chief executive Lutz Schuler shared his thoughts about the Starlink partnership. “By launching O2 Satellite, we’ve become the first operator in Europe to launch a space-based mobile data service that, overnight, has brought new mobile coverage to an area around two-thirds the size of Wales for the first time,” he said.

Satellite-based mobile connectivity is gaining traction globally. In the U.S., T-Mobile has launched a similar satellite-to-cell offering. Meanwhile, Vodafone has conducted satellite video call tests through its partnership with AST SpaceMobile last year.

For Starlink, the O2 agreement highlights how its network is increasingly being integrated into national telecom systems, enabling standard smartphones to connect directly to satellites without specialized hardware.

Elon Musk

Elon Musk’s Starbase, TX included in $84.6 million coastal funding round

The funds mark another step in the state’s ongoing beach restoration and resilience efforts along the Gulf Coast.

Elon Musk’s Starbase, Texas has been included in an $84.6 million coastal funding round announced by the Texas General Land Office (GLO). The funds mark another step in the state’s ongoing beach restoration and resilience efforts along the Gulf Coast.

Texas Land Commissioner Dawn Buckingham confirmed that 14 coastal counties will receive funding through the Coastal Management Program (CMP) Grant Cycle 31 and Coastal Erosion Planning and Response Act (CEPRA) program Cycle 14. Among the Brownsville-area recipients listed was the City of Starbase, which is home to SpaceX’s Starship factory.

“As someone who spent more than a decade living on the Texas coast, ensuring our communities, wildlife, and their habitats are safe and thriving is of utmost importance. I am honored to bring this much-needed funding to our coastal communities for these beneficial projects,” Commissioner Buckingham said in a press release.

“By dedicating this crucial assistance to these impactful projects, the GLO is ensuring our Texas coast will continue to thrive and remain resilient for generations to come.”

The official Starbase account acknowledged the support in a post on X, writing: “Coastal resilience takes teamwork. We appreciate @TXGLO and Commissioner Dawn Buckingham for their continued support of beach restoration projects in Starbase.”

The funding will support a range of coastal initiatives, including beach nourishment, dune restoration, shoreline stabilization, habitat restoration, and water quality improvements.

CMP projects are backed by funding from the National Oceanic and Atmospheric Administration and the Gulf of Mexico Energy Security Act, alongside local partner matches. CEPRA projects focus specifically on reducing coastal erosion and are funded through allocations from the Texas Legislature, the Texas Hotel Occupancy Tax, and GOMESA.

Checks were presented in Corpus Christi and Brownsville to counties, municipalities, universities, and conservation groups. In addition to Starbase, Brownsville-area recipients included Cameron County, the City of South Padre Island, Willacy County, and the Willacy County Navigation District.

Elon Musk

SpaceX targets 150Mbps per user for upgraded Starlink Direct-to-Cell

If achieved, the 150Mbps goal would represent a significant jump from the current performance of Starlink Direct-to-Cell.

SpaceX is targeting peak download speeds of 150Mbps per user for its next-generation Direct-to-Cell Starlink service. The update was shared by SpaceX Spectrum & Regulatory Affairs Lead Udrivolf Pica during the International Telecommunication Union’s Space Connect conference.

“We are aiming at peak speeds of 150Mbps per user,” Pica said during the conference. “So something incredible if you think about the link budgets from space to the mobile phone.”

If achieved, the 150Mbps goal would represent a significant jump from the current performance of Starlink Direct-to-Cell.

Today, SpaceX’s cellular Starlink service, offered in partnership with T-Mobile under the T-Satellite brand, provides speeds of roughly 4Mbps per user. The service is designed primarily for texts, low-resolution video calls, and select apps in locations that traditionally have no cellular service.

By comparison, Ookla data shows median 5G download speeds of approximately 309Mbps for T-Mobile and 172Mbps for AT&T in the United States, as noted in a PCMag report. While 150Mbps would still trail the fastest terrestrial 5G networks, it would place satellite-to-phone broadband much closer to conventional carrier performance, even in remote areas.

Pica indicated that the upgraded system would support “video, voice, and data services, clearly,” moving beyond emergency connectivity and basic messaging use cases.

To reach that target, SpaceX plans to upgrade its existing Starlink Direct-to-Cell satellites and add significant new capacity. The company recently acquired access to radio spectrum from EchoStar, which Pica described as key to expanding throughput.

“More spectrum means a bigger pipeline, and this means that we can expand what we can do with partners. We can expand the quality of service. And again, we can do cellular broadband basically, cellular broadband use cases, like AI or daily connectivity needs,” he stated.

SpaceX has also requested regulatory approval to deploy 15,000 additional Direct-to-Cell satellites, beyond the roughly 650 currently supporting the system. The upgraded architecture is expected to begin rolling out in late 2027.