SpaceX

SpaceX’s first Starship engine suffers “expected” damage during Raptor test fire

SpaceX CEO Elon Musk says that the first full-scale Starship engine to be tested has already been pushed to the point of damage less than three weeks after the campaign began, setting the stage for the second full-scale Raptor to take over in the near future.

According to Musk, while most of the damaged pathfinder Raptor’s components should still be easily reusable, the assembly of the second finalized engine is “almost done” and that Raptor will take over near-term testing rather than waiting for repairs to the first engine. This is undoubtedly an extraordinarily aggressive test program, particularly for such a new and cutting-edge rocket propulsion system, but these latest developments are ultimately far more encouraging than they are concerning.

Merlins. The max chamber pressure run damaged Raptor SN 1 (as expected). A lot of the parts are fine for reuse, but next tests will be with SN 2, which is almost done.

— Elon Musk (@elonmusk) February 21, 2019

Although the Raptor engine family began integrated subscale static fires way back in September 2016, SpaceX’s propulsion team finalized Raptor’s baseline design and completed assembly, shipment, and an integrated static fire of the first full-scale engine on February 3rd, considerably less than three weeks before Musk took to Twitter. Aside from confirming that the new Raptor had been damaged during its most recent static fire several days prior, Musk indicated that the failure (unsurprisingly) was primarily attributed to the engine reaching the highest chamber pressures yet.

Raptor’s main combustion chamber (the bit directly above the nozzle) has been designed to nominally operate at and reliably withstand extraordinary pressures of 250+ bar (3600+ psi), performance that demands even higher pressures in the components that feed hot methane and oxygen gas into Raptor’s combustion chamber. One prime example hinted at by Musk in a 2018 tweet is its oxygen preburner, used to convert liquid propellant into a high-velocity gas that can then feed a dedicated oxygen turbopump. Aside from the absurdly corrosive environment created by extremely hot gaseous oxygen, the preburner must also survive pressures that could peak as high as 800+ bar, or 12,000 psi.

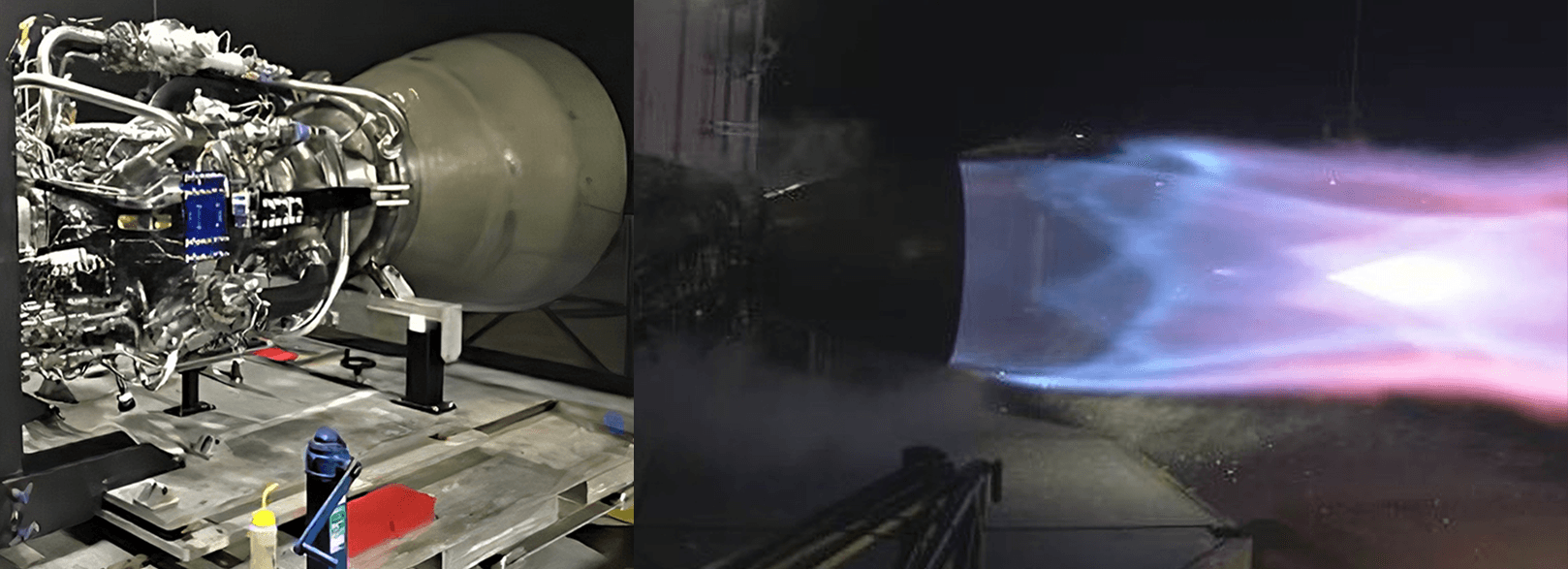

- SpaceX’s world-class rocket propulsion team has been progressing through early full-scale Raptor tests at an incredible speed. (SpaceX)

- Full-scale Raptor’s first static fire test, February 3rd. (SpaceX)

- Raptor’s business end with a Musk-for-scale. (Elon Musk)

- Starship revealed a trio of Raptor mockups when SpaceX technicians moved the assembly from stand to ground. (NSF – bocachicagal)

- A September 2018 render of Starship (then BFS) shows one of the vehicle’s two hinged wings/fins/legs. (SpaceX)

- BFR (2018) breaks through a cloud layer shortly after launch. (SpaceX)

A lack of technical detail means that it’s hard to know what thrust or main chamber pressure Musk had in mind when referring to exotic alloys that would be needed to survive those pressures, but the performance statistics of a Raptor with a preburner operating at 800+ bar would probably outstrip anything Musk has thus far described. In other words, it’s safe to assume that Raptor has probably not been pushed to those performance levels just yet, although it’s still a distant possibility. More likely is that 800+ bar in the oxygen preburner is an extreme stretch-goal that will take concerted research, development, and optimization to achieve, with Raptor having suffered damage somewhere below those levels while still reaching eye-watering performance figures.

— Elon Musk (@elonmusk) February 4, 2019

For an engine as complex as Raptor, there are countless dozens of potential failure modes the appearance of which would come as little surprise for an engine just days into full-scale testing. Above all else, the Raptor test schedule held by SpaceX’s world-class propulsion team – be it self-motivated or driven by reckless management-by-spreadsheet – has been fast-paced in the extreme, taking the first high-performance Raptor ever built from standstill to more than 90% thrust and chamber pressures of almost 270 bar (3900 psi) in – quite literally – less than one week. In the same period of time, more than half a dozen static fire tests (ranging from 1-10 seconds) were performed.

Within a few days of that February 10th milestone, in which Raptor reached chamber pressures comparable with the most advanced modern engines (namely RD-180/190/191), the engine was apparently pushed dramatically higher still, reaching a chamber pressure (and thus thrust) that wrought damage on some of the more sensitive parts of the engine’s plumbing. Despite the fact that the second production Raptor is apparently already “almost done”, Musk suggested that it would already feature changes (of unknown gravity) to mitigate the failure modes experienced by Raptor SN01.

SN2 has changes that should help

— Elon Musk (@elonmusk) February 21, 2019

In an industry where NASA and contractors like Aerojet-Rocketdyne will spend months between static fire tests of Space Shuttle engines that have each literally flown multiple (if not) dozens of missions to orbit and have a demonstrated performance and reliability record that is measured in the hundreds of thousands of seconds, the speed and agility of SpaceX’s Raptor development and test program is breathtaking. What remains to be seen is just how comparably reliable and successful the end results (i.e. operational Raptor) will be, but an attitude that actively accepts and even pursues testing to destruction can ultimately only serve to benefit the finished product at the cost of destroyed hardware and many on-ground lessons learned the hard ways.

Given the immense success of SpaceX’s Merlin family of engines and the aggressive strategy of development and continuous improvement that brought it from Merlin 1A to 1D and MVacD, SpaceX is clearly not fumbling around in the dark when it comes to Raptor R&D.

Check out Teslarati’s newsletters for prompt updates, on-the-ground perspectives, and unique glimpses of SpaceX’s rocket launch and recovery processes!

Elon Musk

Tesla CEO Elon Musk trolls budget airline after it refuses Starlink on its planes

“I really want to put a Ryan in charge of Ryan Air. It is your destiny,” Musk said.

Tesla CEO Elon Musk trolled budget airline Ryanair on his social media platform X this week following the company’s refusal to adopt Starlink internet on its planes.

Earlier this week, it was reported that Ryanair did not plan to install Starlink internet services on its planes due to its budgetary nature and short flight spans, which are commonly only an hour or so in total duration.

Initially, Musk said installing Starlink on the company’s planes would not impact cost or aerodynamics, but Ryanair responded on its X account, which is comical in nature, by stating that a propaganda it would not fall for was “Wi-Fi on planes.”

Musk responded by asking, “How much would it cost to buy you?” Then followed up with the idea of buying the company and replacing the CEO with someone named Ryan:

I really want to put a Ryan in charge of Ryan Air. It is your destiny.

— Elon Musk (@elonmusk) January 19, 2026

Polymarket now states that there is an 8 percent chance that Musk will purchase Ryanair, which would cost Musk roughly $36 billion, based on recent financial data of the public company.

Although the banter has certainly crossed a line, it does not seem as if there is any true reason to believe Musk would purchase the airline. More than anything, it seems like an exercise of who will go further.

Starlink passes 9 million active customers just weeks after hitting 8 million

However, it is worth noting that if something is important enough, Musk will get involved. He bought Twitter a few years ago and then turned it into X, but that issue was much larger than simple banter with a company that does not want to utilize one of the CEO’s products.

The insufferable, special needs chimp currently running Ryan Air is an accountant. Has no idea how airplanes even fly.

— Elon Musk (@elonmusk) January 20, 2026

In a poll posted yesterday by Musk, asking whether he should buy Ryanair and “restore Ryan as their rightful ruler.” 76.5 percent of respondents said he should, but others believe that the whole idea is just playful dialogue for now.

But it is not ideal to count Musk out, especially if things continue to move in the direction they have been.

Elon Musk

Lufthansa Group to equip Starlink on its 850-aircraft fleet

Under the collaboration, Lufthansa Group will install Starlink technology on both its existing fleet and all newly delivered aircraft, as noted by the group in a press release.

Lufthansa Group has announced a partnership with Starlink that will bring high-speed internet connectivity to every aircraft across all its carriers.

This means that aircraft across the group’s brands, from Lufthansa, SWISS, and Austrian Airlines to Brussels Airlines, would be able to enjoy high-speed internet access using the industry-leading satellite internet solution.

Starlink in-flight internet

Under the collaboration, Lufthansa Group will install Starlink technology on both its existing fleet and all newly delivered aircraft, as noted by the group in a press release.

Starlink’s low-Earth orbit satellites are expected to provide significantly higher bandwidth and lower latency than traditional in-flight Wi-Fi, which should enable streaming, online work, and other data-intensive applications for passengers during flights.

Starlink-powered internet is expected to be available on the first commercial flights as early as the second half of 2026. The rollout will continue through the decade, with the entire Lufthansa Group fleet scheduled to be fully equipped with Starlink by 2029. Once complete, no other European airline group will operate more Starlink-connected aircraft.

Free high-speed access

As part of the initiative, Lufthansa Group will offer the new high-speed internet free of charge to all status customers and Travel ID users, regardless of cabin class. Chief Commercial Officer Dieter Vranckx shared his expectations for the program.

“In our anniversary year, in which we are celebrating Lufthansa’s 100th birthday, we have decided to introduce a new high-speed internet solution from Starlink for all our airlines. The Lufthansa Group is taking the next step and setting an essential milestone for the premium travel experience of our customers.

“Connectivity on board plays an important role today, and with Starlink, we are not only investing in the best product on the market, but also in the satisfaction of our passengers,” Vranckx said.

Elon Musk

SpaceX gains favor as Pentagon embraces Musk-style defense reform

The remarks highlighted Musk’s improving relationship with the White House, as well as SpaceX’s growing role in U.S. defense.

SpaceX emerged as a clear beneficiary of the Trump administration’s renewed push to accelerate military innovation, as Defense Secretary Pete Hegseth openly praised Elon Musk’s private space enterprise during a visit to the company’s Starbase launch site in Texas.

The remarks highlighted Musk’s improving relationship with the White House, as well as SpaceX’s growing role in U.S. defense.

Hegseth embraces Elon Musk’s pace

Speaking at SpaceX’s Starbase facility in Brownsville, Texas, Hegseth criticized what he described as a “risk-averse culture” among traditional defense contractors and called for faster innovation modeled after Musk’s approach. He confirmed that the Department of Defense plans to integrate Musk’s Grok AI platform into Pentagon systems, which is part of the administration’s efforts to make the U.S. military an “AI-first warfighting force.”

Hegseth stated that the Pentagon intends to deploy AI models across both classified and unclassified networks, signaling a willingness to push past earlier efforts to limit military use of artificial intelligence. His comments aligned closely with President Donald Trump’s recent call for a $500 billion increase in defense spending, Bloomberg News noted. Trump has also warned major contractors that slower production and shareholder-focused practices could put future contracts at risk.

While Hegseth criticized legacy defense firms, SpaceX was held up as an example of how aggressive timelines, vertical integration, and iterative development could reshape defense strategies. “We need to be blunt here; we can no longer afford to wait a decade for our legacy prime contractors to deliver a perfect system. Winning requires a new playbook. Elon wrote it with his algorithm: question every requirement, delete the dumb ones and accelerate like hell,” Hegseth said.

SpaceX’s expanding defense role comes into focus

SpaceX has become one of the U.S. government’s most important aerospace partners. The company holds roughly $4 billion in NASA contracts to develop Starship into a lunar lander, while also serving as a key launch provider for sensitive national security payloads using its Falcon 9 and Falcon Heavy rockets.

During the visit, Musk highlighted that his ambitions extend beyond defense contracts, reiterating long-term goals of interplanetary travel and eventual exploration beyond the solar system. Still, the optics of the event reinforced how closely SpaceX’s capabilities now align with U.S. strategic priorities.

The appearance also marked another step in Musk’s political rehabilitation after a public falling-out with the White House last year. Since leaving his role leading the Department of Government Efficiency, Musk has gradually reengaged with the administration, reconnecting with U.S. President Donald Trump during slain conservative activist Charlie Kirk’s tribute and attending events at the White House. Trump’s also recently suggested that Starlink could help restore internet access in Iran.