News

Drone successfully flies human organ transplant between hospitals

For the first time, a human organ has been successfully transported between medical facilities by a drone. A team of scientists from the University of Maryland Baltimore used a research-qualified donor kidney as a test subject to shuffle back and forth on a remotely piloted hexacopter, testing the organ for changes throughout 14 flights. Its longest journey was 3 miles at a maximum speed of 40 mph, the duration and distance of which were suitable for demonstrating transportation between inner city hospitals.

Currently, organs have few options for transportation, and the process for moving them involves a network of couriers and commercial aircraft that are dependent on schedules and traffic patterns. When normal commercial schedules aren’t available, the cost of private charter transportation can be prohibitive. Even when cost isn’t a factor, the time involved in the process altogether can prevent a transplant from being completed as organs are very sensitive cargo.

To best ensure a successful transplant procedure, organs must be moved quickly between the donor and the recipient. The amount of time an organ can spend chilled after removal and when it’s warmed up and the blood supply restored, called cold ischemia time (CIT), is very limited. Some organs, such as the heart, only have as few as 4 hours available to be transported before they are no longer eligible for transplant. Up against airplane flight availability and traffic patterns, an improvement like what drone transportation could provide might have life saving implications.

Shortening CIT times with faster organ transportation could also expand the availability of organs across regions currently out of range. According to the Journal article detailing the results of the drone test, the national average CIT is 16-18 hours. With a fast enough drone, even a cross-country trip could be cut down to around 8 hours, potentially expanding the availability of organs such as the liver and pancreas to such a distance. Regional expansion would be especially helpful for harder to reach areas where CITs are routinely longer than 30 hours for kidneys, the recommended maximum CIT being about 24 hours.

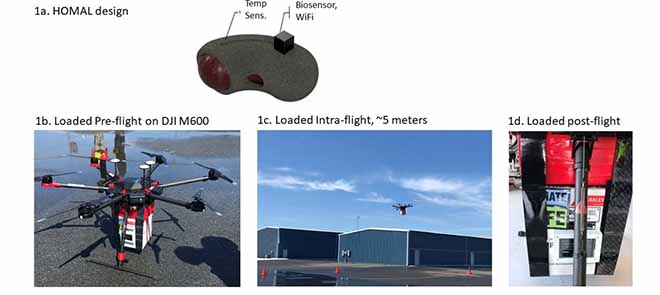

The research scientists used a specially designed device for this experiment called a HOMAL (Human Organ Monitoring and Quality Assurance Apparatus for Long-Distance Travel) to measure temperature, barometric pressure, altitude, vibration, and location via GPS during the organ’s transportation. Once the project was complete, the kidney’s temperature and travel environment were shown to have remained stable. Further biopsies also did not reveal any flight-related impact on its structural integrity.

The drone used in this research was a commercially available DJI Matrice 600 Pro Hexacopter, the specifications of which include 6 vertically oriented motors, around 20 minutes of flight time, a maximum flight speed of 40 mph, and a payload capability of about 13 pounds. For long-distance organ transport, upgraded equipment would be necessary as well as revised regulations on drone activity. A mandatory line of sight is required for drone pilots under current laws, thus precluding any major travel distances. Also, as with most aircraft, drones would also be subject to weather constraints.

Despite the limitations of drone transportation, the team involved in this study remain optimistic as technological developments progress. The fastest drone on record can reach a speed of about 160 mph, and 22 pound payloads are already possible on commercially available craft. As these and other developments continue to expand and overcome other challenges, so could their potential use for medical transportation. As improvements also expand the regional reach of transplants to potential donor recipients, the medical benefits of the technology could prompt revision of current drone restrictions.

News

Tesla FSD (Supervised) fleet passes 8.4 billion cumulative miles

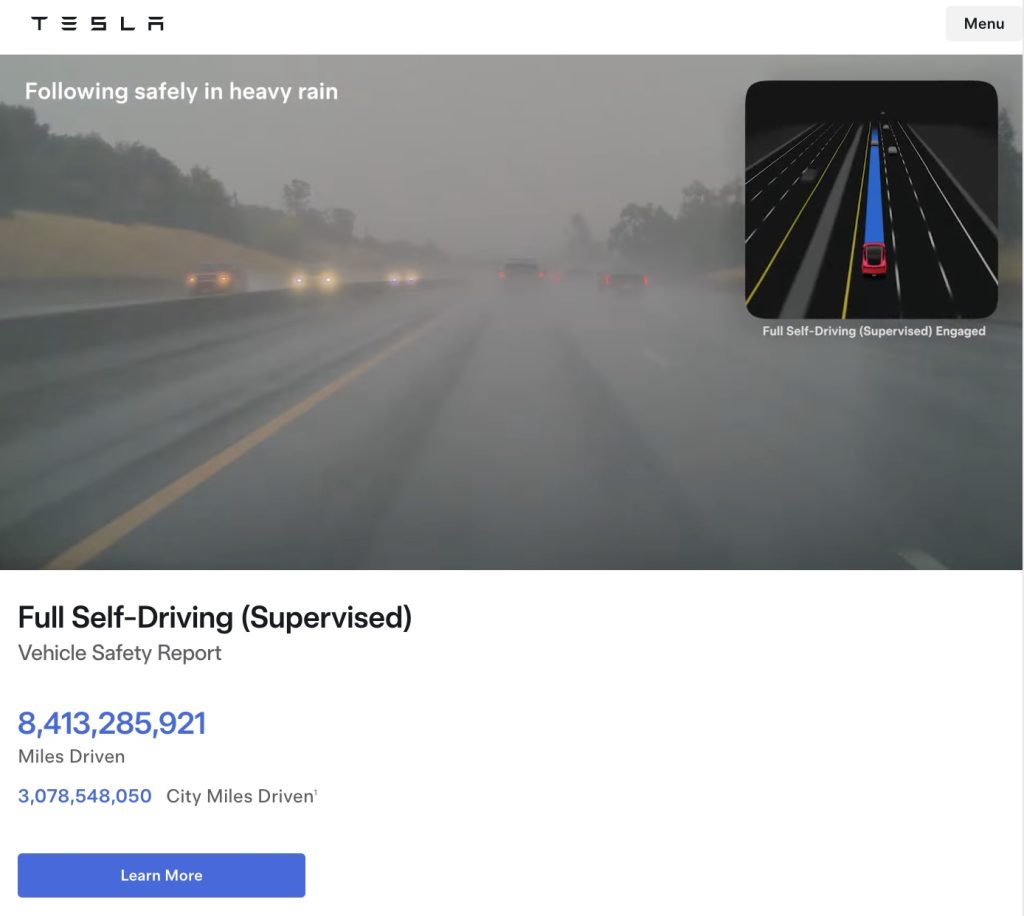

The figure appears on Tesla’s official safety page, which tracks performance data for FSD (Supervised) and other safety technologies.

Tesla’s Full Self-Driving (Supervised) system has now surpassed 8.4 billion cumulative miles.

The figure appears on Tesla’s official safety page, which tracks performance data for FSD (Supervised) and other safety technologies.

Tesla has long emphasized that large-scale real-world data is central to improving its neural network-based approach to autonomy. Each mile driven with FSD (Supervised) engaged contributes additional edge cases and scenario training for the system.

The milestone also brings Tesla closer to a benchmark previously outlined by CEO Elon Musk. Musk has stated that roughly 10 billion miles of training data may be needed to achieve safe unsupervised self-driving at scale, citing the “long tail” of rare but complex driving situations that must be learned through experience.

The growth curve of FSD Supervised’s cumulative miles over the past five years has been notable.

As noted in data shared by Tesla watcher Sawyer Merritt, annual FSD (Supervised) miles have increased from roughly 6 million in 2021 to 80 million in 2022, 670 million in 2023, 2.25 billion in 2024, and 4.25 billion in 2025. In just the first 50 days of 2026, Tesla owners logged another 1 billion miles.

At the current pace, the fleet is trending towards hitting about 10 billion FSD Supervised miles this year. The increase has been driven by Tesla’s growing vehicle fleet, periodic free trials, and expanding Robotaxi operations, among others.

With the fleet now past 8.4 billion cumulative miles, Tesla’s supervised system is approaching that threshold, even as regulatory approval for fully unsupervised deployment remains subject to further validation and oversight.

Elon Musk

Elon Musk fires back after Wikipedia co-founder claims neutrality and dubs Grokipedia “ridiculous”

Musk’s response to Wales’ comments, which were posted on social media platform X, was short and direct: “Famous last words.”

Elon Musk fired back at Wikipedia co-founder Jimmy Wales after the longtime online encyclopedia leader dismissed xAI’s new AI-powered alternative, Grokipedia, as a “ridiculous” idea that is bound to fail.

Musk’s response to Wales’ comments, which were posted on social media platform X, was short and direct: “Famous last words.”

Wales made the comments while answering questions about Wikipedia’s neutrality. According to Wales, Wikipedia prides itself on neutrality.

“One of our core values at Wikipedia is neutrality. A neutral point of view is non-negotiable. It’s in the community, unquestioned… The idea that we’ve become somehow ‘Wokepidea’ is just not true,” Wales said.

When asked about potential competition from Grokipedia, Wales downplayed the situation. “There is no competition. I don’t know if anyone uses Grokipedia. I think it is a ridiculous idea that will never work,” Wales wrote.

After Grokipedia went live, Larry Sanger, also a co-founder of Wikipedia, wrote on X that his initial impression of the AI-powered Wikipedia alternative was “very OK.”

“My initial impression, looking at my own article and poking around here and there, is that Grokipedia is very OK. The jury’s still out as to whether it’s actually better than Wikipedia. But at this point I would have to say ‘maybe!’” Sanger stated.

Musk responded to Sanger’s assessment by saying it was “accurate.” In a separate post, he added that even in its V0.1 form, Grokipedia was already better than Wikipedia.

During a past appearance on the Tucker Carlson Show, Sanger argued that Wikipedia has drifted from its original vision, citing concerns about how its “Reliable sources/Perennial sources” framework categorizes publications by perceived credibility. As per Sanger, Wikipedia’s “Reliable sources/Perennial sources” list leans heavily left, with conservative publications getting effectively blacklisted in favor of their more liberal counterparts.

As of writing, Grokipedia has reportedly surpassed 80% of English Wikipedia’s article count.

News

Tesla Sweden appeals after grid company refuses to restore existing Supercharger due to union strike

The charging site was previously functioning before it was temporarily disconnected in April last year for electrical safety reasons.

Tesla Sweden is seeking regulatory intervention after a Swedish power grid company refused to reconnect an already operational Supercharger station in Åre due to ongoing union sympathy actions.

The charging site was previously functioning before it was temporarily disconnected in April last year for electrical safety reasons. A temporary construction power cabinet supplying the station had fallen over, described by Tesla as occurring “under unclear circumstances.” The power was then cut at the request of Tesla’s installation contractor to allow safe repair work.

While the safety issue was resolved, the station has not been brought back online. Stefan Sedin, CEO of Jämtkraft elnät, told Dagens Arbete (DA) that power will not be restored to the existing Supercharger station as long as the electric vehicle maker’s union issues are ongoing.

“One of our installers noticed that the construction power had been backed up and was on the ground. We asked Tesla to fix the system, and their installation company in turn asked us to cut the power so that they could do the work safely.

“When everything was restored, the question arose: ‘Wait a minute, can we reconnect the station to the electricity grid? Or what does the notice actually say?’ We consulted with our employer organization, who were clear that as long as sympathy measures are in place, we cannot reconnect this facility,” Sedin said.

The union’s sympathy actions, which began in March 2024, apply to work involving “planning, preparation, new connections, grid expansion, service, maintenance and repairs” of Tesla’s charging infrastructure in Sweden.

Tesla Sweden has argued that reconnecting an existing facility is not equivalent to establishing a new grid connection. In a filing to the Swedish Energy Market Inspectorate, the company stated that reconnecting the installation “is therefore not covered by the sympathy measures and cannot therefore constitute a reason for not reconnecting the facility to the electricity grid.”

Sedin, for his part, noted that Tesla’s issue with the Supercharger is quite unique. And while Jämtkraft elnät itself has no issue with Tesla, its actions are based on the unions’ sympathy measures against the electric vehicle maker.

“This is absolutely the first time that I have been involved in matters relating to union conflicts or sympathy measures. That is why we have relied entirely on the assessment of our employer organization. This is not something that we have made any decisions about ourselves at all.

“It is not that Jämtkraft elnät has a conflict with Tesla, but our actions are based on these sympathy measures. Should it turn out that we have made an incorrect assessment, we will correct ourselves. It is no more difficult than that for us,” the executive said.