SpaceX

SpaceX’s Crew Dragon and Falcon 9 Block 5 rocket are almost ready for astronauts

In a Commercial Crew update presented by Program Manager Kathy Lueders to the NASA Advisory Council (NAC), the agency has confirmed that SpaceX is deep into the final stages of hardware preparation and testing ahead of their first uncrewed and crewed demonstrations launches of Crew Dragon.

Barring a miracle for Commercial Crew Program partner Boeing’s Starliner spacecraft program or serious faults leading up to SpaceX’s own debuts, SpaceX is all but guaranteed to become the first private company in history to design, build, and launch a spacecraft into Earth orbit with real astronauts onboard.

PICTURE OF B1051!!! It will ship to the Cape from McGregor soon.

Solar panel array on the trunk for the DM-1 capsule will take place in Hawthorne. pic.twitter.com/K82GANn5zr

— Michael Baylor (@MichaelBaylor_) August 27, 2018

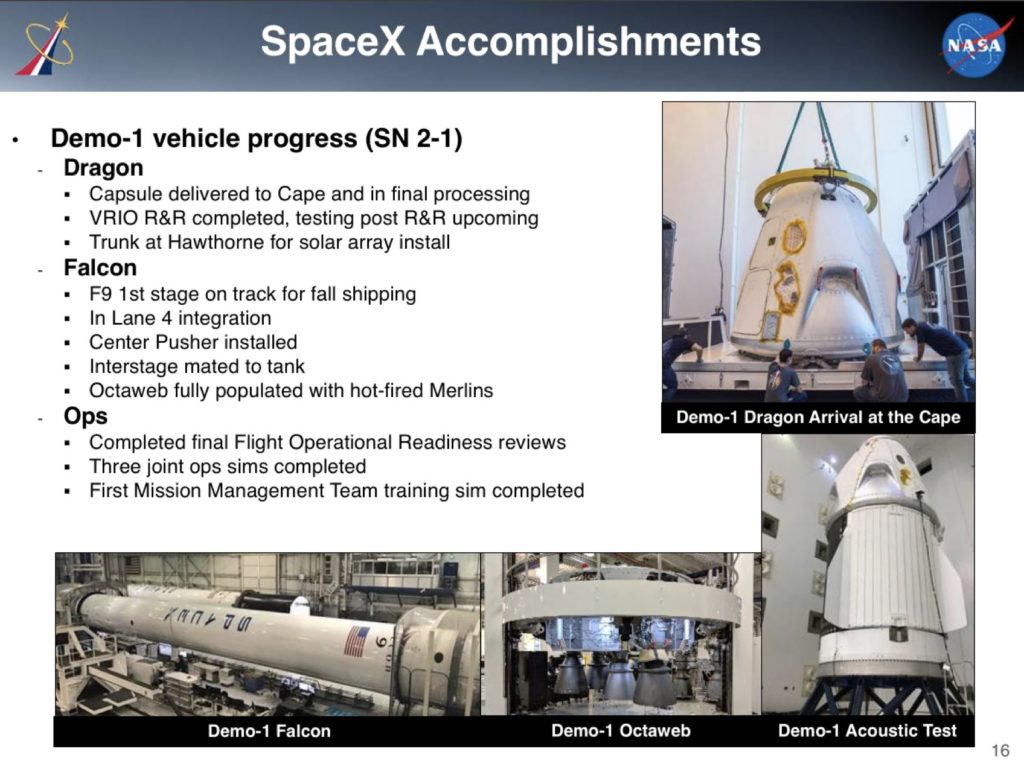

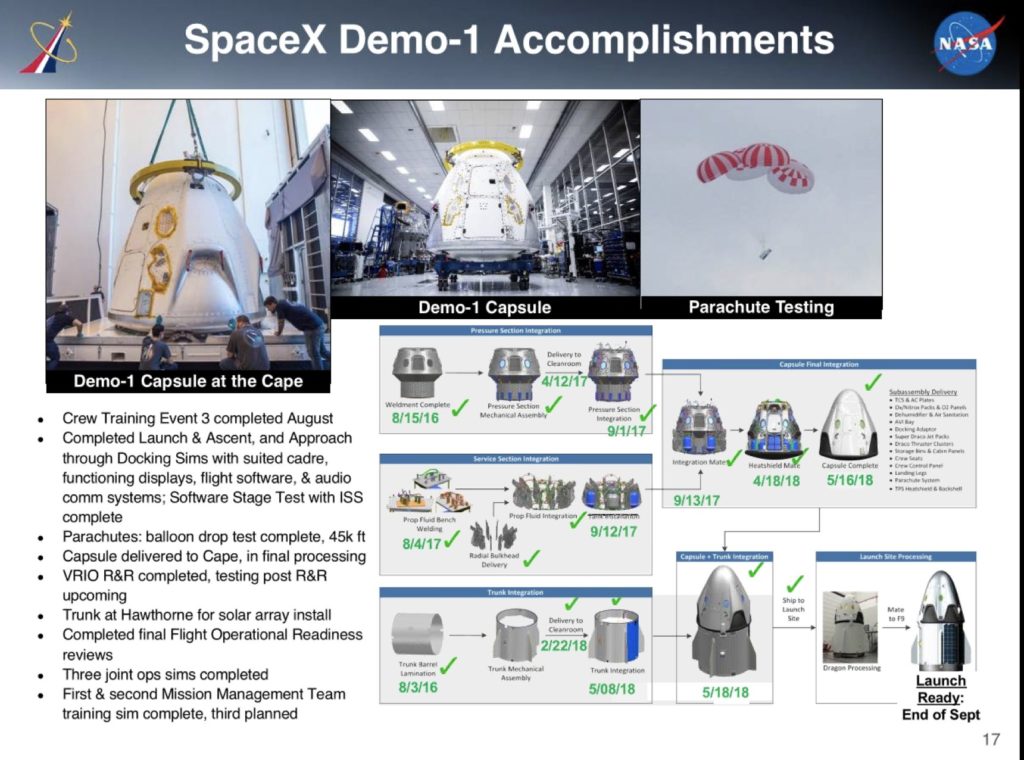

SpaceX’s DM-1 Crew Dragon (serial number C201; “C” for capsule, “2” for Dragon 2, and “01” for capsule #1) capsule is already in Florida at one of the company’s spacecraft processing facilities, while that vehicle’s trunk segment – a module mounted below the capsule responsible for providing power (solar arrays), thermal regulation (radiator panels), and external cargo lift capacity – is scheduled to ship from Hawthorne, CA to Florida by the end of September. Demonstration Mission-1 (DM-1) is currently targeting a launch debut no earlier than November 2018.

DM-1’s Falcon 9 launch vehicle, booster B1051 and an expendable second stage, are also making significant progress towards the Crew Dragon’s uncrewed debut launch. NASA’s report noted that B1051 was on track for shipment (presumably to the Cape) sometime in the fall (technically anytime after August 31st) and that the upper stage would likely find its way to Florida soon after, sometime in September. Due to the fact that Merlin Vacuum engine qualification has not yet been completed, that milestone is likely the only thing standing between S2 shipment to FL, as SpaceX typically builds and tests both Falcon 9 segments near-simultaneously.

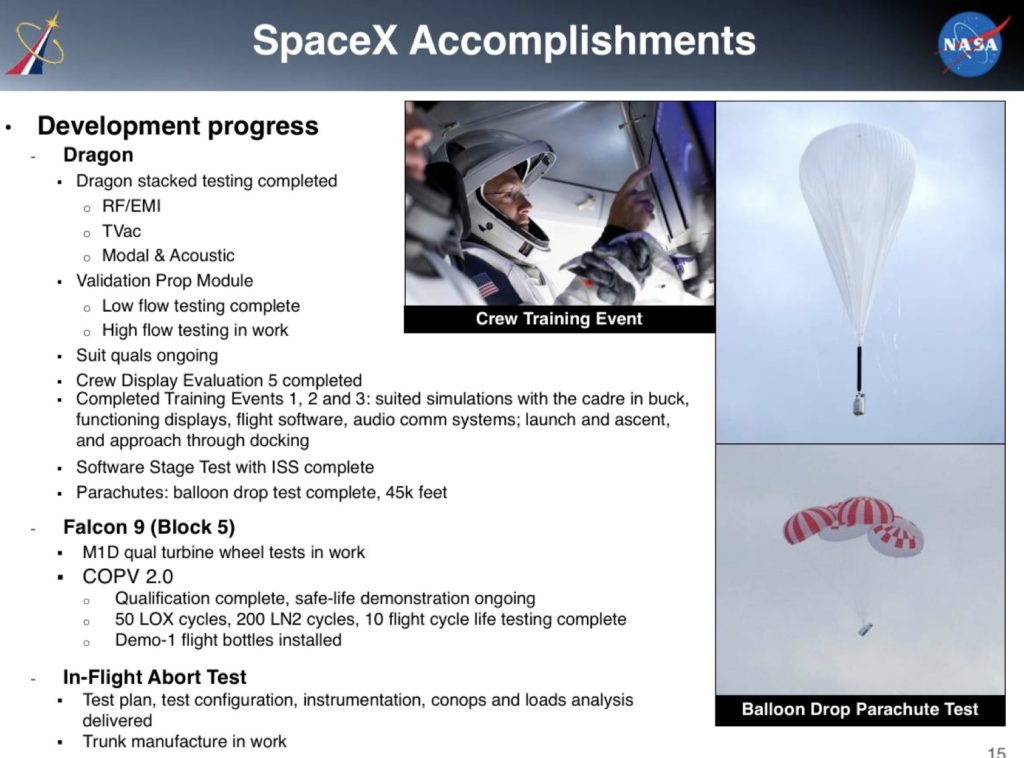

- One of the aforementioned balloon-drop parachute tests. (SpaceX)

- The DM-1 Crew Dragon capsule soon after completion. (SpaceX)

- DM-1 seen conducting acoustic testing in Ohio. (SpaceX)

- Falcon 9 B1051, DM-1’s rocket of choice, seen during construction in SpaceX’s Hawthorne factory. (SpaceX)

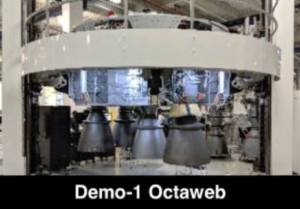

- B1051’s octaweb, the structure that Merlin engines attach to and thrust against. (SpaceX)

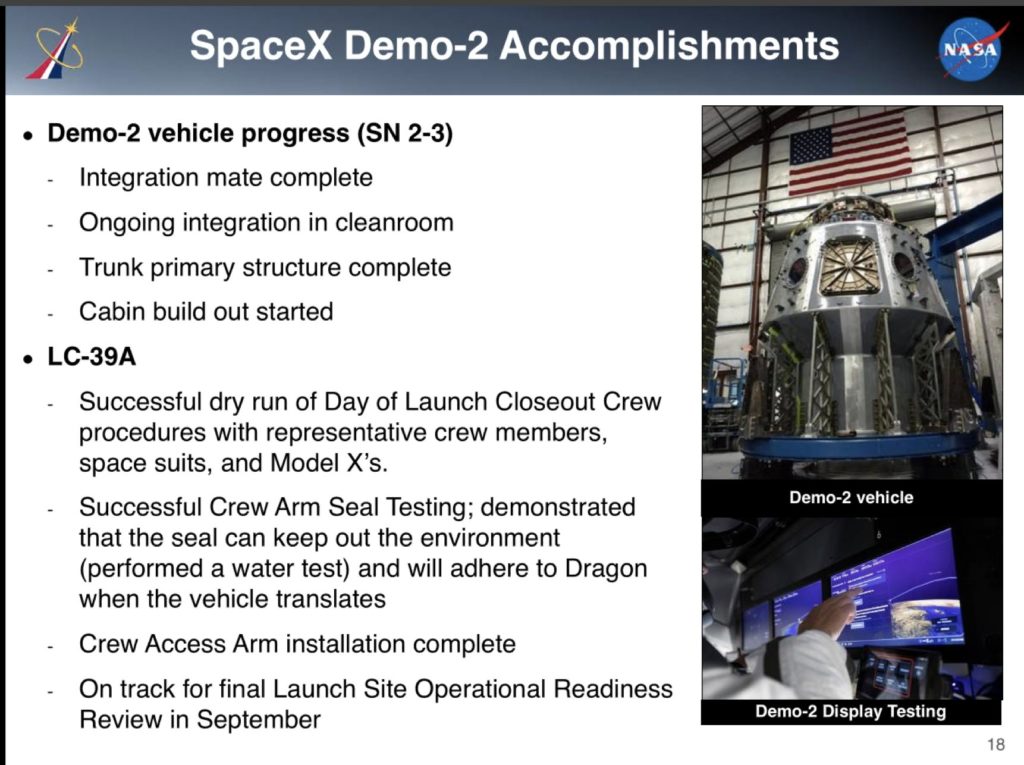

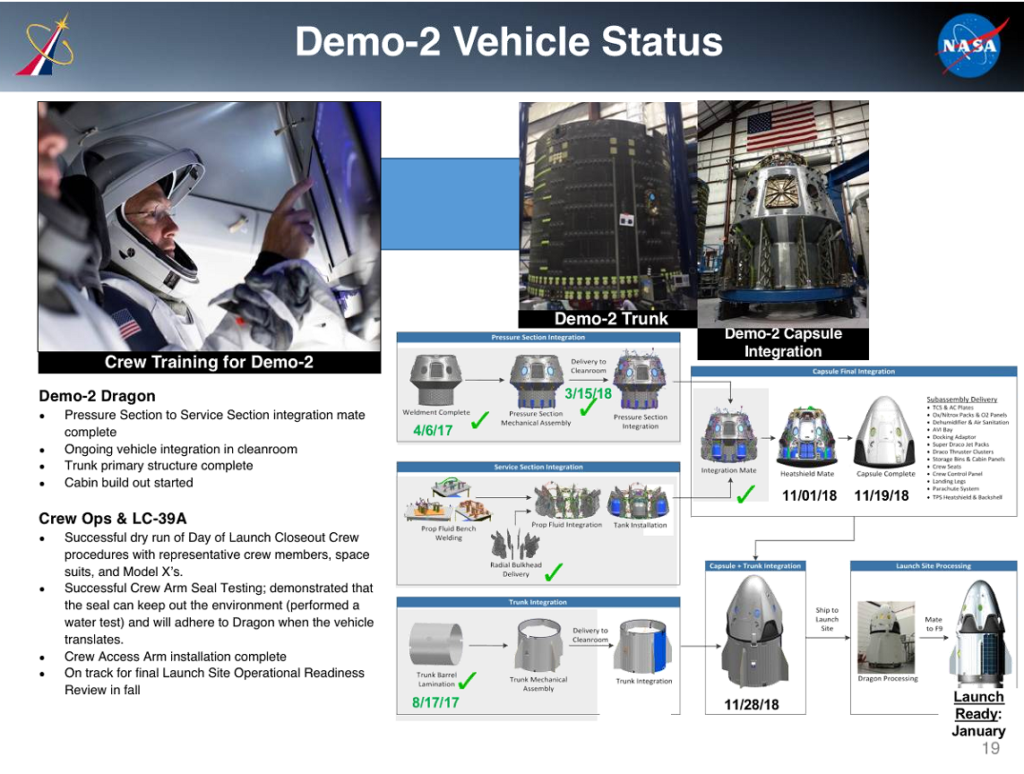

- The DM-2 Crew Dragon’s trunk module seen during production. (SpaceX)

- Crew Dragon astronauts test the capsule’s display controls. (SpaceX)

- SpaceX Crew Dragon capsule C203 – then assigned DM-2 – is seen here in August 2018. (Pauline Acalin)

Meanwhile, SpaceX has successfully completed a duo of unique and critical tests of Crew Dragon’s parachute systems, carrying a Crew Dragon mass simulator (i.e. boilerplate) up to 45,000 feet (13,700 m) under a huge balloon before dropping the mockup, a test series designed to prove out the ability of the parachute system to successfully deploy and function in the exact flight regimes the real hardware will experience while safely returning astronauts to Earth. As NASA Commercial Crew Program Manager Kathy Lueders herself noted, that type of testing is extremely difficult to pull off, but SpaceX has thus far completed two.

On the launch pad side of things, SpaceX will be exclusively conducting Crew Dragon missions from Pad 39A. The company completed installation of a strikingly modern-looking crew access arm (CAA) just days ago, marking a crucial milestone for the historic launch complex to be truly ready to support human spaceflight once more, a heritage represented physically by the tower the arm is installed on (Shuttle-era) and the pad’s foundation and thrust diverter (constructed to support Saturn V’s Apollo moon missions).

That’s right provided the two Crew Dragon test flights go well. Hardware will def be ready. https://t.co/KcAFArYn1x

— Elon Musk (@elonmusk) August 6, 2018

Further down the road, SpaceX has already entered into the late stages of hardware integration and preparation for the second Crew Dragon demonstration mission (DM-2), which will almost without a doubt see SpaceX become the first private entity in history to build, launch, and operate a crewed spacecraft in Earth orbit.

According to NASA’s SpaceX-derived schedule, that particularly historic spacecraft is expected to be ready for launch as early as January, a full three months prior to its current April 2018 launch date. CEO Elon Musk did note recently on Twitter that the hardware for both crewed and uncrewed demonstration missions would “def[initely] be ready” for the launch dates of November 2018 and April 2019.

Catch all the technical SpaceX-related slides below.

- August 27, 2018. (NASA)

- August 27, 2018. (NASA)

- August 27, 2018. (NASA)

- August 27, 2018. (NASA)

- August 27, 2018. (NASA)

For prompt updates, on-the-ground perspectives, and unique glimpses of SpaceX’s rocket recovery fleet check out our brand new LaunchPad and LandingZone newsletters!

News

SpaceX President Gwynne Shotwell details xAI power pledge at White House event

The commitment was announced during an event with United States President Donald Trump.

SpaceX President Gwynne Shotwell stated that xAI will develop 1.2 gigawatts of power at its Memphis-area AI supercomputer site as part of the White House’s new “Ratepayer Protection Pledge.”

The commitment was announced during an event with United States President Donald Trump.

During the White House event, Shotwell stated that xAI’s AI data center near Memphis would include a major energy installation designed to support the facility’s power needs.

“As you know, xAI builds huge supercomputers and data centers and we build them fast. Currently, we’re building one on the Tennessee-Mississippi state line. As part of today’s commitment, we will take extensive additional steps to continue to reduce the costs of electricity for our neighbors…

“xAI will therefore commit to develop 1.2 GW of power as our supercomputer’s primary power source. That will be for every additional data center as well. We will expand what is already the largest global Megapack power installation in the world,” Shotwell said.

She added that the system would provide significant backup power capacity.

“The installation will provide enough backup power to power the city of Memphis, and more than sufficient energy to power the town of Southaven, Mississippi where the data center resides. We will build new substations and invest in electrical infrastructure to provide stability to the area’s grid.”

Shotwell also noted that xAI will be supporting the area’s water supply as well.

“We haven’t talked about it yet, but this is actually quite important. We will build state-of-the-art water recycling plants that will protect approximately 4.7 billion gallons of water from the Memphis aquifer each year. And we will employ thousands of American workers from around the city of Memphis on both sides of the TN-MS border,” she noted.

The Ratepayer Protection Pledge was introduced as part of the federal government’s effort to address concerns about rising electricity costs tied to large AI data centers, as noted in an Insider report. Under the agreement, companies developing major AI infrastructure projects committed to covering their own power generation needs and avoiding additional costs for local ratepayers.

Elon Musk

SpaceX to launch Starlink V2 satellites on Starship starting 2027

The update was shared by SpaceX President Gwynne Shotwell and Starlink Vice President Mike Nicolls.

SpaceX is looking to start launching its next-generation Starlink V2 satellites in mid-2027 using Starship.

The update was shared by SpaceX President Gwynne Shotwell and Starlink Vice President Mike Nicolls during remarks at Mobile World Congress (MWC) in Barcelona, Spain.

“With Starship, we’ll be able to deploy the constellation very quickly,” Nicolls stated. “Our goal is to deploy a constellation capable of providing global and contiguous coverage within six months, and that’s roughly 1,200 satellites.”

Nicolls added that once Starship is operational, it will be capable of launching approximately 50 of the larger, more powerful Starlink satellites at a time, as noted in a Bloomberg News report.

The initial deployment of roughly 1,200 next-generation satellites is intended to establish global and contiguous coverage. After that phase, SpaceX plans to continue expanding the system to reach “truly global coverage, including the polar regions,” Nicolls said.

Currently, all Starlink satellites are launched on SpaceX’s Falcon 9 rocket. The next-generation fleet will rely on Starship, which remains in development following a series of test flights in 2025. SpaceX is targeting its next Starship test flight, featuring an upgraded version of the rocket, as soon as this month.

Starlink is currently the largest satellite network in orbit, with nearly 10,000 satellites deployed. Bloomberg Intelligence estimates the business could generate approximately $9 billion in revenue for SpaceX in 2026.

Nicolls also confirmed that SpaceX is rebranding its direct-to-cell service as Starlink Mobile.

The service currently operates with 650 satellites capable of connecting directly to smartphones and has approximately 10 million monthly active users. SpaceX expects that figure to exceed 25 million monthly active users by the end of 2026.

Elon Musk

Starlink V2 to bring satellite-to-phone service to Deutsche Telekom in Europe

Starlink stated that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Starlink is partnering with Deutsche Telekom to roll out satellite-to-mobile connectivity across Europe, extending coverage to more than 140 million subscribers across 10 countries.

The service, planned for launch in 2028 in several Telekom markets, including Germany, will use Starlink’s next-generation V2 satellites and Mobile Satellite Service (MSS) spectrum to enable direct-to-device connectivity.

In a post on X, the official Starlink account stated that the agreement will be the first in Europe to deploy its V2 next-generation satellite-to-mobile technology using new MSS spectrum. The company added that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Abdu Mudesir, Board Member for Product and Technology at Deutsche Telekom, shared his excitement for the partnership in a press release. “We provide our customers with the best mobile network. And we continue to invest heavily in expanding our infrastructure. At the same time, there are regions where expansion is especially complex due to topographical conditions or official constraints,” he said.

“We want to ensure reliable connectivity for our customers in those areas as well. That is why we are strategically complementing our network with satellite-to-mobile connectivity. For us, it is clear: connectivity creates security and trust. And we deliver. Everywhere.”

Under the partnership, compatible smartphones will automatically switch to Starlink’s satellite network when terrestrial coverage is unavailable, enabling access to data, voice, video, and messaging services.

Telekom reports 5G geographic coverage approaching 90% in Germany, with LTE exceeding 92% and voice coverage reaching up to 99%. Starlink’s satellite layer is intended to extend connectivity beyond those terrestrial limits, particularly in topographically challenging or infrastructure-constrained areas.

Stephanie Bednarek, VP of Starlink Sales, also shared her thoughts on the partnership. “We’re so pleased to bring reliable satellite-to-mobile connectivity to millions of people across 10 countries in partnership with Deutsche Telekom. This agreement will be the first-of-its-kind in Europe to launch Starlink’s V2 next-generation technology that will expand on data, voice and messaging by providing broadband directly to mobile phones,” she said.

Starlink’s V2 constellation is designed to expand bandwidth and capacity compared to its predecessor. If implemented as outlined, the 2028 launch would mark one of the first large-scale European deployments of integrated satellite-to-phone connectivity by a major telecom operator.