News

SpaceX envisions massive rocket enclosure for military applications

SpaceX has published the first renders of a massive tower (MST) designed to fully enclose a Falcon Heavy rocket, giving the US military access to certain prized satellite payloads even when the vehicle is vertical at the launch pad.

Stretching some 70 m (230 ft) tall and 12.2 m (40 ft) wide, building a movable tower capable of fully enclosing SpaceX’s Falcon Heavy rockets is no mean feat. Known as a mobile service tower (MST), SpaceX has managed to avoid the need for the expensive, complex, and extremely unwieldy infrastructure for the first decade of Falcon 9 and Falcon Heavy launch operations. Instead, SpaceX has designed its launch vehicles around the concept of horizontal integration, meaning that its Falcon rockets can be entirely integrated and prepared for flight before going vertical for launch. This approach has ensured easy, cheap access to the entire rocket and payload up until the last few days of static fire and launch operations, lowering the cost of launch.

Beyond Russian spaceflight operations, SpaceX, and a handful of other companies around the world, nearly all other major launch providers and space agencies – including the United Launch Alliance (ULA), Arianespace, ISRO (India), and CNSA (China) – rely almost exclusively on vertical integration. With its new Pad 39A mobile tower, SpaceX will soon join that small club, giving it the ability to compete on completely even footing with ULA and others for lucrative military launch contracts.

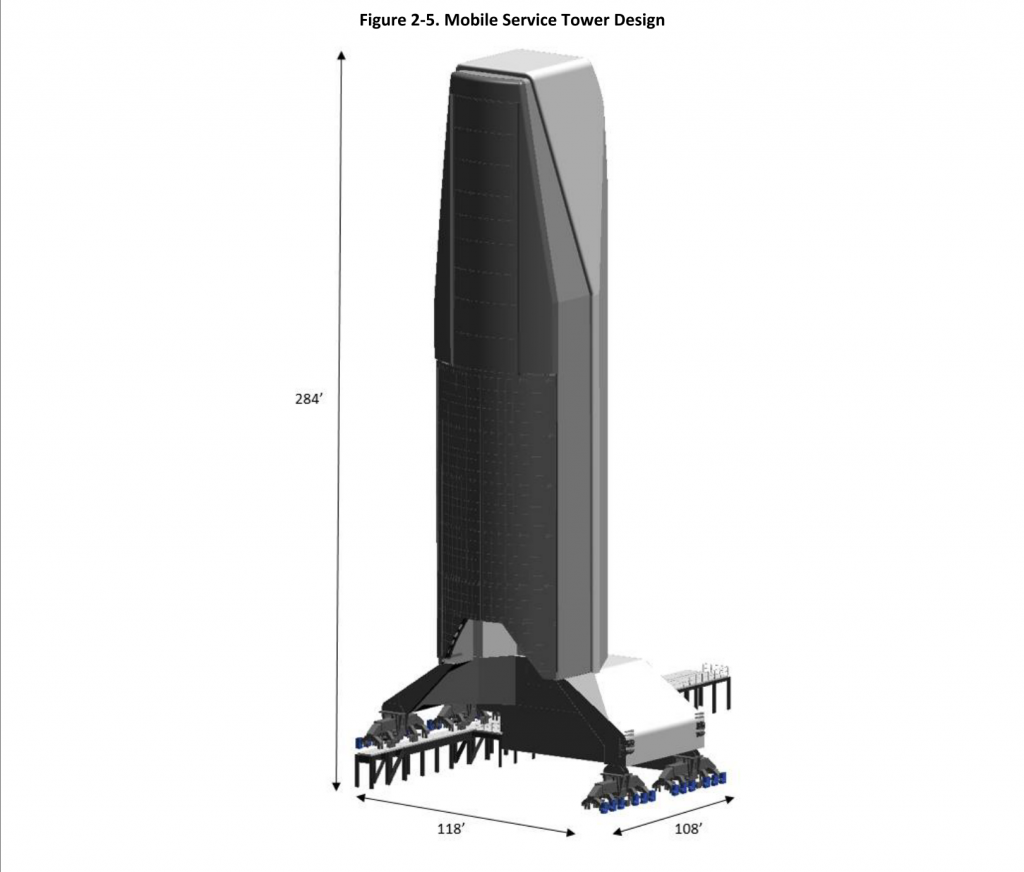

While one only has so much flexibility when designing a mobile skyscraper that needs to survive Florida’s hurricane seasons, SpaceX’s solution is still visually unique. According to the company, the mobile service tower (MST) it plans to build at its Kennedy Space Center (KSC) Launch Complex 39A (Pad 39A) facilities will measure 87m (284 ft) from its wheels to the top of its roof, while the tower’s ‘crawler’ base will be some 36m x 33m (118 ft x 108 ft) wide, a quarter of the area of a US football field.

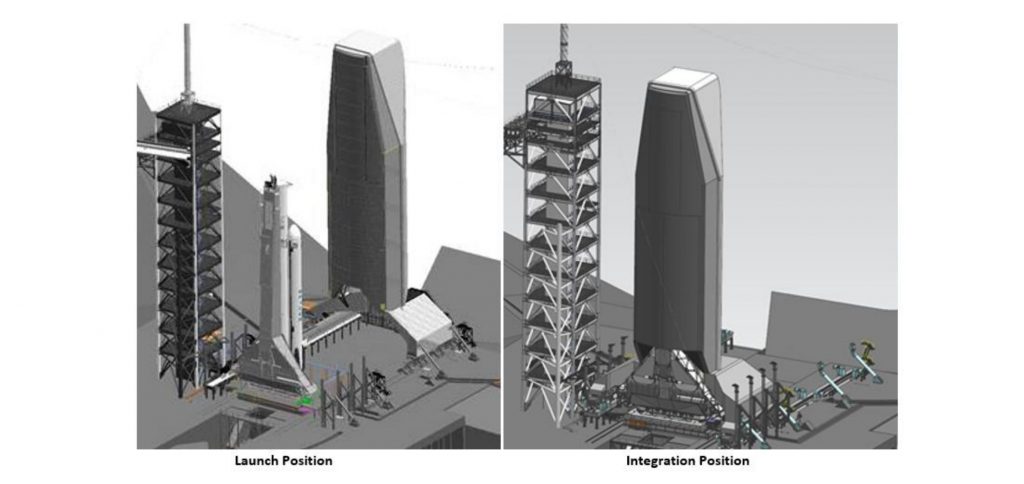

During launch preparations, SpaceX would integrate its Falcon Heavy and Falcon 9 rockets like usual, joining boosters, side boosters, upper stages, and recovery while still horizontal inside its Pad 39A hangar. The integrated rocket would be installed (still horizontal) on 39A’s transporter/erector (T/E) – the white steel structure seen backing the rocket above – and rolled out to the launch mount, where the T/E is effectively bolted into the ground before lifting the rocket vertical.

Once vertical, SpaceX’s new tower would slowly crawl about 40m (130 ft) to fully encompass a given Falcon Heavy or Falcon 9 rocket. Once safely inside the MST, 11 different levels would give SpaceX and customer technicians access to the vast majority of the rocket. Most importantly, the tower would allow SpaceX technicians to crane certain US military payloads – encapsulated inside a Falcon payload fairing – onto the top of the rocket.

At the end of the day, that’s really the only reason SpaceX needs such a tower – certain customers (the US military and, to a lesser extent, NASA) have certain payloads that they either can’t or won’t tweak to allow for horizontal integration. No schedule for the MST construction has been mentioned yet but knowing SpaceX, it’s safe to say it could be completed sooner than later once environmental impact studies are complete and construction permits have been secured.

Check out Teslarati’s Marketplace! We offer Tesla accessories, including for the Tesla Cybertruck and Tesla Model 3.

Elon Musk

Tesla Giga Berlin growth could stall if not “free from external influences”: Elon Musk

The comments were delivered in a pre-recorded video discussion.

Tesla CEO Elon Musk has reportedly warned that future expansion of Gigafactory Berlin could be jeopardized if the site does not remain “free from external influences.”

Musk’s comments were delivered in a pre-recorded video discussion with employees and came at a sensitive moment for the facility, where union representation has been a recurring issue.

According to reports from Handelsblatt and Der Spiegel, citing participants at the event, Musk suggested that if Giga Berlin is no longer “free from external influences,” further expansion would become unlikely. He did not, however, hint that the plant would shut down.

While Musk did not name IG Metall directly, his remarks were widely interpreted as referencing the union, which is currently the largest faction on the works council but does not hold a majority, as noted in an electrive report.

The video conversation was conducted between Musk in Austin and Grünheide plant manager André Thierig, then played back to the workforce in Germany. Works council elections are scheduled for early March, heightening the tension between management and organized labor.

The CEO has previously voiced concerns that stronger union influence could limit Tesla’s operational flexibility and long-term strategy in Germany.

Despite the warning on expansion, Musk praised the Giga Berlin site during the same address, describing it as one of the most advanced factories worldwide and highlighting its cleanliness and team culture.

The discussion also reportedly touched on battery cell production. According to attendees cited in German media, Musk indicated that Tesla has begun ramping cell production at the site. That would mark a notable shift from earlier expectations that large-scale cell manufacturing in Brandenburg would not begin until 2027.

Elon Musk

Tesla Full Self-Driving’s newest behavior is the perfect answer to aggressive cars

According to a recent video, it now appears the suite will automatically pull over if there is a tailgater on your bumper, the most ideal solution for when a driver is riding your bumper.

Tesla Full Self-Driving appears to have a new behavior that is the perfect answer to aggressive drivers.

According to a recent video, it now appears the suite will automatically pull over if there is a tailgater on your bumper, the most ideal solution for when a driver is riding your bumper.

With FSD’s constantly-changing Speed Profiles, it seems as if this solution could help eliminate the need to tinker with driving modes from the person in the driver’s seat. This tends to be one of my biggest complaints from FSD at times.

A video posted on X shows a Tesla on Full Self-Driving pulling over to the shoulder on windy, wet roads after another car seemed to be following it quite aggressively. The car looks to have automatically sensed that the vehicle behind it was in a bit of a hurry, so FSD determined that pulling over and letting it by was the best idea:

Tesla appears to be implementing some sort of feature that will now pull over if someone is tailgating you to let the car by

Really cool feature, definitely get a lot of this from those who think they drive race cars

— TESLARATI (@Teslarati) February 26, 2026

We can see from the clip that there was no human intervention to pull over to the side, as the driver’s hands are stationary and never interfere with the turn signal stalk.

This can be used to override some of the decisions FSD makes, and is a great way to get things back on track if the semi-autonomous functionality tries to do something that is either unneeded or not included in the routing on the in-car Nav.

FSD tends to move over for faster traffic on the interstate when there are multiple lanes. On two-lane highways, it will pass slower cars using the left lane. When faster traffic is behind a Tesla on FSD, the vehicle will move back over to the right lane, the correct behavior in a scenario like this.

Perhaps one of my biggest complaints at times with Full Self-Driving, especially from version to version, is how much tinkering Tesla does with Speed Profiles. One minute, they’re suitable for driving on local roads, the next, they’re either too fast or too slow.

When they are too slow, most of us just shift up into a faster setting, but at times, even that’s not enough, see below:

What has happened to Mad Max?

At one point it was going 32 in a 35. Traffic ahead had pulled away considerably https://t.co/bjKvaMVTNX pic.twitter.com/aaZSWmLu5v

— TESLARATI (@Teslarati) January 24, 2026

There are times when it feels like it would be suitable for the car to just pull over and let the vehicle that is traveling behind pass. This, at least up until this point, it appears, was something that required human intervention.

Now, it looks like Tesla is trying to get FSD to a point where it just knows that it should probably get out of the way.

Elon Musk

Tesla Megapack powers $1.1B AI data center project in Brazil

By integrating Tesla’s Megapack systems, the facility will function not only as a major power consumer but also as a grid-supporting asset.

Tesla’s Megapack battery systems will be deployed as part of a 400MW AI data center campus in Uberlândia, Brazil. The initiative is described as one of Latin America’s largest AI infrastructure projects.

The project is being led by RT-One, which confirmed that the facility will integrate Tesla Megapack battery energy storage systems (BESS) as part of a broader industrial alliance that includes Hitachi Energy, Siemens, ABB, HIMOINSA, and Schneider Electric. The project is backed by more than R$6 billion (approximately $1.1 billion) in private capital.

According to RT-One, the data center is designed to operate on 100% renewable energy while also reinforcing regional grid stability.

“Brazil generates abundant energy, particularly from renewable sources such as solar and wind. However, high renewable penetration can create grid stability challenges,” RT-One President Fernando Palamone noted in a post on LinkedIn. “Managing this imbalance is one of the country’s growing infrastructure priorities.”

By integrating Tesla’s Megapack systems, the facility will function not only as a major power consumer but also as a grid-supporting asset.

“The facility will be capable of absorbing excess electricity when supply is high and providing stabilization services when the grid requires additional support. This approach enhances resilience, improves reliability, and contributes to a more efficient use of renewable generation,” Palamone added.

The model mirrors approaches used in energy-intensive regions such as California and Texas, where large battery systems help manage fluctuations tied to renewable energy generation.

The RT-One President recently visited Tesla’s Megafactory in Lathrop, California, where Megapacks are produced, as part of establishing the partnership. He thanked the Tesla team, including Marcel Dall Pai, Nicholas Reale, and Sean Jones, for supporting the collaboration in his LinkedIn post.