News

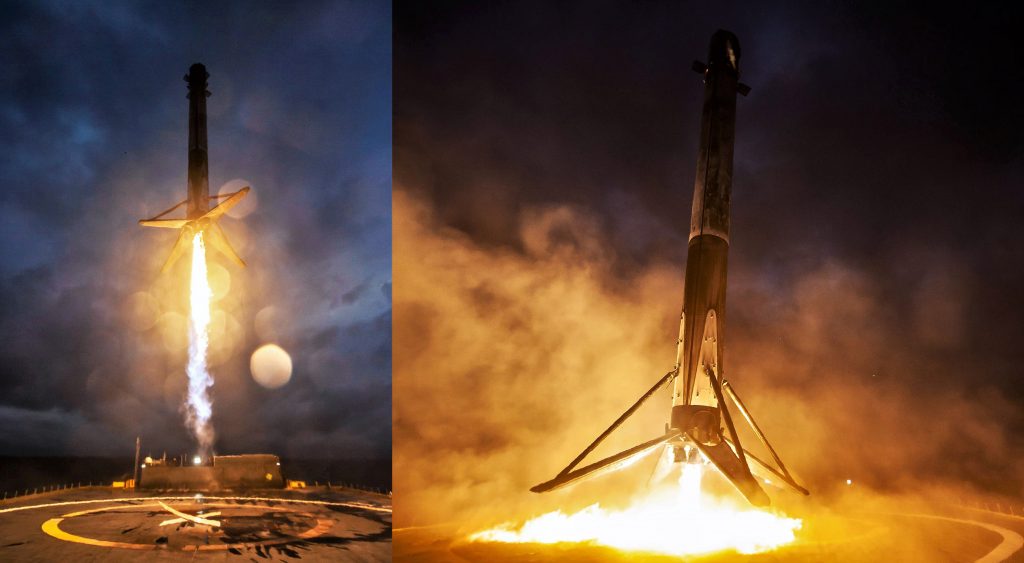

SpaceX eyes major drone ship fleet upgrades and a new rocket recovery robot

SpaceX has kicked off a series of major upgrades planned for its East Coast fleet of drone ships, centered around Just Read The Instructions (JRTI) and most recently culminating in the apparent fabrication of a second tank-like rocket recovery robot.

Back in Q4 2019, West Coast drone ship JRTI officially departed the Port of Los Angeles berth it operated out of for 3+ years — traversing the Panama Canal, making a weeks-long pit-stop in a Louisiana port, and ultimately arriving at Port Canaveral on December 11th. The modified barge spent more than a month relatively untouched – as was the somewhat mysterious cargo it had brought with it from the Gulf Coast – before SpaceX began JRTI’s long-awaited upgrades around a month ago.

For almost half a year, it’s looked like that SpaceX would move its West Coast drone ship to Florida after the company’s Vandenberg Air Force Base (VAFB) pad entered a major lull in launch activities in early 2019. Aside from one launch in June 2019, SpaceX’s West Coast pad has remained unused and that isn’t expected to change anytime soon. With Cape Canaveral potential reopening its dormant polar launch corridor just weeks from now, it’s entirely possible that SpaceX will be able to perform all of its planned launches from Florida alone for at least the next 6-12 months. Targeting more than 30 East Coast launches in 2020 alone, SpaceX could also benefit from at least one additional drone ship to continue high-volume Falcon booster recoveries without ship availability becoming a major launch constraint. Thankfully, JRTI may be the perfect solution.

Informally known as ‘Octagrabber’, a reference to the robot’s primary function, SpaceX has been using the only operational instance of the vehicle on drone ship Of Course I Still Love You (OCISLY) for more than two years, beginning in 2017. While far from autonomous, Octagrabber helps SpaceX’s maritime rocket recovery team minimize the risks workers are subjected to and gives the company a bit more flexibility to attempt Falcon booster landings in less-than-pristine ocean weather.

While Falcon boosters are relatively stable once landed, thanks to the vast majority of their empty mass being concentrated around their nine Merlin 1D engines, even moderate waves can cause them to slip and slide around the drone ship deck.

In fact, the best operational demonstration of the value of Octagrabber-style recovery robots came after SpaceX’s historic Falcon Heavy triple-booster recovery in April 2019 – the first time all three of the rocket’s first stage boosters successfully landed after liftoff. As it turns out, thanks to moderate hardware differences between Falcon Heavy center core boosters and normal Falcon 9 boosters, OCISLY’s Octagrabber robot did not have the attachment mechanisms needed to ‘grab’ the center core (B1055, in this case). In theory, this could be a non-issue but the drone ship unfortunately ran into high seas, making its deck to pitch and tilt and ultimately causing to B1055 to tip over, breaking in half and effectively destroyed the booster.

With Octagrabber robots, drone ships should almost never lose recovered boosters because of high seas (within reason). As such, it should come as no surprise at all that SpaceX is building a new recovery robot for drone ship JRTI – the newest addition to its Florida fleet.

Aside from the discovery of a second Octagrabber being built at SpaceX’s former East Coast Starship factory, the nature of other upgrades planned for drone ship JRTI are more mysterious. For several months, the rocket landing platform has had almost a dozen massive generators and new thruster pods stored on its deck, seemingly waiting on an unknown impetus for their installation. In recent weeks, visible work to prepare the new hardware for installation has begun.

Notably, the thrusters and power supplies that seem destined for installation on JRTI would make for a dramatic upgrade, potentially giving the drone ship more power than the tug boats that must currently tender and tow them to landing zones. In other words, that’s a complicated way of saying that SpaceX may be trying to make drone ship JRTI almost entirely independent of contracted tugboats, potentially simplifying and lowering the cost of booster recoveries.

While less likely, it’s also possible that SpaceX is finally in a position to fully realize the “autonomous” namesake of its autonomous spaceport drone ships (ASDS), with high-powered thrusters potentially giving JRTI the ability to leave port, cruise to Atlantic Ocean landing zones, deploy an Octagrabber, and return to port with a booster – all without humans in the loop. That capability is likely still on the horizon but powerful thrusters and generators would bring port-to-port drone ship autonomy within SpaceX’s grasp in the near future.

Check out Teslarati’s Marketplace! We offer Tesla accessories, including for the Tesla Cybertruck and Tesla Model 3.

News

Tesla Full Self-Driving likely to expand to yet another Asian country

“We are aiming for implementation in 2026. [We are] doing everything in our power [to achieve this],” Richi Hashimoto, president of Tesla’s Japanese subsidiary, said.

Tesla Full Self-Driving is likely to expand to yet another Asian country, as one country seems primed for the suite to head to it for the first time.

The launch of Full Self-Driving in yet another country this year would be a major breakthrough for Tesla as it continues to expand the driver-assistance program across the world. Bureaucratic red tape has held up a lot of its efforts, but things are looking up in some regions.

Tesla is poised to transform Japan’s roads with Full Self-Driving (FSD) technology by 2026.

Richi Hashimoto, president of Tesla’s Japanese subsidiary, announced the ambitious timeline, building on successful employee test drives that began in 2025 and earned positive media reviews. Test drives, initially limited to the Model 3 since August 2025, expanded to the Model Y on March 5.

Once regulators approve, Over-the-Air (OTA) software updates could activate FSD across roughly 40,000 Teslas already on Japanese roads. Japan’s orderly traffic and strict safety culture make it an ideal testing ground for autonomous driving.

Hashimoto said:

“We are aiming for implementation in 2026. [We are] doing everything in our power [to achieve this].”

The push aligns with Hashimoto’s leadership, which has been credited for Tesla’s sales turnaround.

In 2025, Tesla delivered a record 10,600 vehicles in Japan — a nearly 90% jump from the prior year and the first time exceeding 10,000 units annually.

BREAKING 🇯🇵 FSD IS LIKELY LAUNCHING IN JAPAN IN 2026 🚨

Richi Hashimoto, President of Tesla’s Japanese subsidiary, stated: “We are aiming for implementation in 2026” and added that they are “doing everything in our power” to achieve this 🔥

Test drives in Japan began in August… pic.twitter.com/jkkrJLszXN

— Ming (@tslaming) March 5, 2026

The strategy shifted from online-only sales to adding 29 physical showrooms in high-traffic malls, plus staff training and attractive financing offers launched in January 2026. Tesla also plans to expand its Supercharger network to over 1,000 points by 2027, boosting accessibility.

This Japanese momentum reflects Tesla’s broader international expansion. In Europe, Giga Berlin produced more than 200,000 vehicles in 2025 despite a temporary halt, supplying over 30 markets with plans for sequential production growth in 2026 and battery cell manufacturing by 2027.

While regional EV sales faced headwinds, the factory remains a cornerstone for Model Y deliveries across the continent.

In Asia, Giga Shanghai continues to be recognized as Tesla’s powerhouse. China, the company’s largest market, saw January 2026 deliveries from the plant rise 9 percent year-over-year to 69,129 units, with affordable new models expected later this year.

FSD advancements, already progressing in the U.S. and South Korea, are slated for Europe and further Asian rollout, complementing plans to expand Cybercab and Optimus to new markets as well.

With OTA-enabled autonomy on the horizon and retail strategies paying dividends, Tesla is strengthening its footprint from Tokyo showrooms to Berlin assembly lines and Shanghai exports. As Hashimoto continues to push Tesla forward in Japan, the company’s global vision for sustainable, self-driving mobility gains traction across Europe and Asia.

News

Tesla ships out update that brings massive change to two big features

“This change only updates the name of certain features and text in your vehicle,” the company wrote in Release Notes for the update, “and does not change the way your features behave.”

Tesla has shipped out an update for its vehicles that was caused specifically by a California lawsuit that threatened the company’s ability to sell cars because of how it named its driver assistance suite.

Tesla shipped out Software Update 2026.2.9 starting last week; we received it already, and it only brings a few minor changes, mostly related to how things are referenced.

“This change only updates the name of certain features and text in your vehicle,” the company wrote in Release Notes for the update, “and does not change the way your features behave.”

The following changes came to Tesla vehicles in the update:

- Navigate on Autopilot has now been renamed to Navigate on Autosteer

- FSD Computer has been renamed to AI Computer

Tesla faced a 30-day sales suspension in California after the state’s Department of Motor Vehicles stated the company had to come into compliance regarding the marketing of its automated driving features.

The agency confirmed on February 18 that it had taken a “corrective action” to resolve the issue. That corrective action was renaming certain parts of its ADAS.

Tesla discontinued its standalone Autopilot offering in January and ramped up the marketing of Full Self-Driving Supervised. Tesla had said on X that the issue with naming “was a ‘consumer protection’ order about the use of the term ‘Autopilot’ in a case where not one single customer came forward to say there’s a problem.”

This was a “consumer protection” order about the use of the term “Autopilot” in a case where not one single customer came forward to say there’s a problem.

Sales in California will continue uninterrupted.

— Tesla North America (@tesla_na) December 17, 2025

It is now compliant with the wishes of the California DMV, and we’re all dealing with it now.

This was the first primary dispute over the terminology of Full Self-Driving, but it has undergone some scrutiny at the federal level, as some government officials have claimed the suite has “deceptive” names. Previous Transportation Secretary Pete Buttigieg was one of those federal-level employees who had an issue with the names “Autopilot” and “Full Self-Driving.”

Tesla sued the California DMV over the ruling last week.

News

Tesla workers push back against Giga Berlin unionization

“IG Metall did not succeed in Giga Berlin‘s works council election earlier today. The union share was reduced from nearly 40% in 2024 to 31% in 2026! This is a clear message by the Giga Berlin team towards an independent co-determination! The list called Giga United, led by the current chairwoman, Michaela Schmitz, received the most votes with more than 40%! Good news for Giga Berlin!”

Tesla workers pushed back against unionization efforts at Gigafactory Berlin, and over the past few years, there has been a dramatic decrease in interest to unionize at the German plant.

Gigafactory Berlin Plant Manager André Thierig announced on Wednesday that IG Metall, the European union group, saw its share reduce from 40 to 31 percent in 2026 as employees eligible to vote on the issue. Instead, the Giga Berlin team, known as Giga United, received the most votes with more than 40 percent.

BREAKING! 🚨

IG Metall did not succeed in Giga Berlin‘s works council election earlier today. The union share was reduced from nearly 40% in 2024 to 31% in 2026!

This is a clear message by theGiga Berlin team towards an independent co-determination!

The list called Giga…

— André Thierig (@AndrThie) March 4, 2026

Thierig gave specific details in a post on X:

“IG Metall did not succeed in Giga Berlin‘s works council election earlier today. The union share was reduced from nearly 40% in 2024 to 31% in 2026! This is a clear message by the Giga Berlin team towards an independent co-determination! The list called Giga United, led by the current chairwoman, Michaela Schmitz, received the most votes with more than 40%! Good news for Giga Berlin!”

There were over 10,700 total employees who were eligible to vote, with 87 percent of them turning out to cast what they wanted. There were three key outcomes: Giga United, IG Metall, and other notable groups, with the most popular being the Polish Initiative.

The 37-seat council remains dominated by non-unionized representatives, preserving Giga Berlin as Germany’s only major auto plant without a collective bargaining agreement.

Thierig and Tesla framed the outcome as employee support for an “independent, flexible, and unbureaucratic” future, enabling acceleration on projects like potential expansions or new models. IG Metall expressed disappointment, accusing management of intimidation tactics and an “unfair” campaign.

The first election of this nature happened back in 2022. In 2024, IG Metall emerged as the largest single faction with 39.4 percent, but non-union lists coalesced for a majority.

But this year was different. There was some extra tension at Giga Berlin this year, as just two weeks ago, an IG Metall rep was accused by Tesla of secretly recording a council meeting. The group countersued for defamation.

Tesla Giga Berlin plant manager faces defamation probe after IG Metall union complaint

This result from the 2026 vote reinforced Tesla’s model of direct employee-management alignment over traditional German union structures, amid ongoing debates about working conditions. IG Metall views it as a setback but continues advocacy. Tesla sees it as validation of its approach in a competitive EV market.

This outcome may influence future labor dynamics at Giga Berlin, including any revival of expansion plans or product lines, which Musk has talked about recently.