News

An inside look at Tesla’s P100D battery pack: more cells, 102 kWh capacity, backwards compatibility in mind

New details of Tesla’s mysterious P100D battery pack, which Tesla CTO JB Straubel once described as having notable changes in battery module and pack technology, and a “complete redo on the cooling architecture”, have emerged thanks to Jason Hughes’s latest project.

Hughes posted photos of a dismantled 100 kWh battery pack, which he obtained through the purchase of a salvaged Tesla P100D, that reveal an increase in the number of 18650 lithium-ion cells being packed within each battery module. Hughes also discovered a surprising increase in battery capacity beyond 100 kWh, and what appears to be a replaceable connector that allows Tesla to retrofit older vehicles with the newer battery pack.

More 18650 Battery Cells

As outlined in Hughes’s blog post, Tesla was able to fit more of its cylindrical 18650 lithium-ion battery cells into each of the 16 modules making up the P100D battery pack. It’s worth noting that Tesla has maintained a relatively similar form factor on battery packs produced for Model S and Model X vehicles since their introduction. Regardless of the vehicle’s model version – be it a P85, a 60, 75D, or 90D – the uniform skateboard design of the battery pack allows for ease of production, as Tesla can manufacture a single-style pack that can be installed across its fleet of vehicles. Under that same notion, Tesla has also been able to create ‘unlockable features’ by software limiting vehicle range depending on the option purchased by the customer. In other words, Tesla installs the same battery pack into like-kind vehicles (e.g. Model S 60 uses the same pack as Model S 75).

Tesla P85 battery pack module vs. P100D module [Credit: Jason Hughes via @wk057]

Hughes’s dissection of the P100D battery shows that Tesla leveraged the same design concept by distributing a total of 8,256 battery cells across the 16 modules making up the battery pack, bringing total capacity up to the advertised 100 kWh number. However, and much to Hughes’s surprise – he had previously criticized Tesla for providing less battery capacity than what’s perceived by way of the vehicle’s nameplate – Tesla actually provided 102.4 kWh of capacity on the P100D pack, representing a 2.4% increase over what’s marketed.

Backwards Compatible Design

Tesla has also, seemingly, taken into account the ability to retrofit new battery packs onto older vehicles by using the same high and low-voltage connectors across packs. According to Hughes, “the pack itself has the same high-voltage connection, the same low voltages connectors, and the same cooling connector.” However, Hughes notes that there’s subtle changes on the P100D pack that would require a new part in order for it to be retrofittable onto non-P100D vehicles.

“The [P100D] pack has the newer ring around the high-voltage connector. So, it’s plug-and-play (for the most part, firmware and config changes needed) on the Model X and refreshed Model S, however it would require a different spacer ring on the high voltage connector. Tesla even has a part number for it, so it should be pretty simple to put into any Model S/X.” says Hughes.

What about that new P100D battery cooling architecture?

Well. It’s not magic. Tesla did improve battery cooling in the new P100D 100 kWh battery pack. And Tesla did provide a redone architecture, but it isn’t one of mythical proportions.

Hughes reveals Tesla’s approach to improve battery pack cooling was to use shorter and thinner cooling loops per battery module, thereby improving the rate of heat dissipation. Unlike most other electric car makers who do not “prime” their vehicle’s batteries through the use of a thermal management system, Tesla pumps fluid through the battery module to regulate the temperature of its battery pack in order to bring them to optimal operating temperatures. By ensuring the lithium-ion cells operate within ideal temperatures, Tesla is able to provide the best performance possible, while ensuring cell longevity.

Tesla P100D battery module cooling loops [Credit: Jason Hughes]

Elon Musk

Elon Musk fires back after Wikipedia co-founder claims neutrality and dubs Grokipedia “ridiculous”

Musk’s response to Wales’ comments, which were posted on social media platform X, was short and direct: “Famous last words.”

Elon Musk fired back at Wikipedia co-founder Jimmy Wales after the longtime online encyclopedia leader dismissed xAI’s new AI-powered alternative, Grokipedia, as a “ridiculous” idea that is bound to fail.

Musk’s response to Wales’ comments, which were posted on social media platform X, was short and direct: “Famous last words.”

Wales made the comments while answering questions about Wikipedia’s neutrality. According to Wales, Wikipedia prides itself on neutrality.

“One of our core values at Wikipedia is neutrality. A neutral point of view is non-negotiable. It’s in the community, unquestioned… The idea that we’ve become somehow ‘Wokepidea’ is just not true,” Wales said.

When asked about potential competition from Grokipedia, Wales downplayed the situation. “There is no competition. I don’t know if anyone uses Grokipedia. I think it is a ridiculous idea that will never work,” Wales wrote.

After Grokipedia went live, Larry Sanger, also a co-founder of Wikipedia, wrote on X that his initial impression of the AI-powered Wikipedia alternative was “very OK.”

“My initial impression, looking at my own article and poking around here and there, is that Grokipedia is very OK. The jury’s still out as to whether it’s actually better than Wikipedia. But at this point I would have to say ‘maybe!’” Sanger stated.

Musk responded to Sanger’s assessment by saying it was “accurate.” In a separate post, he added that even in its V0.1 form, Grokipedia was already better than Wikipedia.

During a past appearance on the Tucker Carlson Show, Sanger argued that Wikipedia has drifted from its original vision, citing concerns about how its “Reliable sources/Perennial sources” framework categorizes publications by perceived credibility. As per Sanger, Wikipedia’s “Reliable sources/Perennial sources” list leans heavily left, with conservative publications getting effectively blacklisted in favor of their more liberal counterparts.

As of writing, Grokipedia has reportedly surpassed 80% of English Wikipedia’s article count.

News

Tesla Sweden appeals after grid company refuses to restore existing Supercharger due to union strike

The charging site was previously functioning before it was temporarily disconnected in April last year for electrical safety reasons.

Tesla Sweden is seeking regulatory intervention after a Swedish power grid company refused to reconnect an already operational Supercharger station in Åre due to ongoing union sympathy actions.

The charging site was previously functioning before it was temporarily disconnected in April last year for electrical safety reasons. A temporary construction power cabinet supplying the station had fallen over, described by Tesla as occurring “under unclear circumstances.” The power was then cut at the request of Tesla’s installation contractor to allow safe repair work.

While the safety issue was resolved, the station has not been brought back online. Stefan Sedin, CEO of Jämtkraft elnät, told Dagens Arbete (DA) that power will not be restored to the existing Supercharger station as long as the electric vehicle maker’s union issues are ongoing.

“One of our installers noticed that the construction power had been backed up and was on the ground. We asked Tesla to fix the system, and their installation company in turn asked us to cut the power so that they could do the work safely.

“When everything was restored, the question arose: ‘Wait a minute, can we reconnect the station to the electricity grid? Or what does the notice actually say?’ We consulted with our employer organization, who were clear that as long as sympathy measures are in place, we cannot reconnect this facility,” Sedin said.

The union’s sympathy actions, which began in March 2024, apply to work involving “planning, preparation, new connections, grid expansion, service, maintenance and repairs” of Tesla’s charging infrastructure in Sweden.

Tesla Sweden has argued that reconnecting an existing facility is not equivalent to establishing a new grid connection. In a filing to the Swedish Energy Market Inspectorate, the company stated that reconnecting the installation “is therefore not covered by the sympathy measures and cannot therefore constitute a reason for not reconnecting the facility to the electricity grid.”

Sedin, for his part, noted that Tesla’s issue with the Supercharger is quite unique. And while Jämtkraft elnät itself has no issue with Tesla, its actions are based on the unions’ sympathy measures against the electric vehicle maker.

“This is absolutely the first time that I have been involved in matters relating to union conflicts or sympathy measures. That is why we have relied entirely on the assessment of our employer organization. This is not something that we have made any decisions about ourselves at all.

“It is not that Jämtkraft elnät has a conflict with Tesla, but our actions are based on these sympathy measures. Should it turn out that we have made an incorrect assessment, we will correct ourselves. It is no more difficult than that for us,” the executive said.

Elon Musk

Music City Loop could highlight The Boring Company’s real disruption

The real story behind the tunneling startup’s Nashville tunnel project is the company’s targeted $25 million per mile construction cost.

Recent commentary on social media has highlighted what could very well prove to be The Boring Company’s real disruption.

The analysis was shared by tech watcher Aakash Gupta on social media platform X, where he argued that the real story behind the tunneling startup’s Nashville tunnel project is the company’s targeted $25 million per mile construction cost.

According to Gupta’s breakdown, Nashville’s 2018 light rail proposal was priced at roughly $200 million per mile. New York’s East Side Access project reportedly cost about $3.5 billion per mile, while Los Angeles Metro expansion projects have approached $1 billion per mile.

By comparison, The Boring Company has stated it can construct 13 miles of twin tunnels in the Music City Loop for between $240 million and $300 million total. That implies a cost near $25 million per mile, or roughly a 95% reduction from industry averages cited in the post.

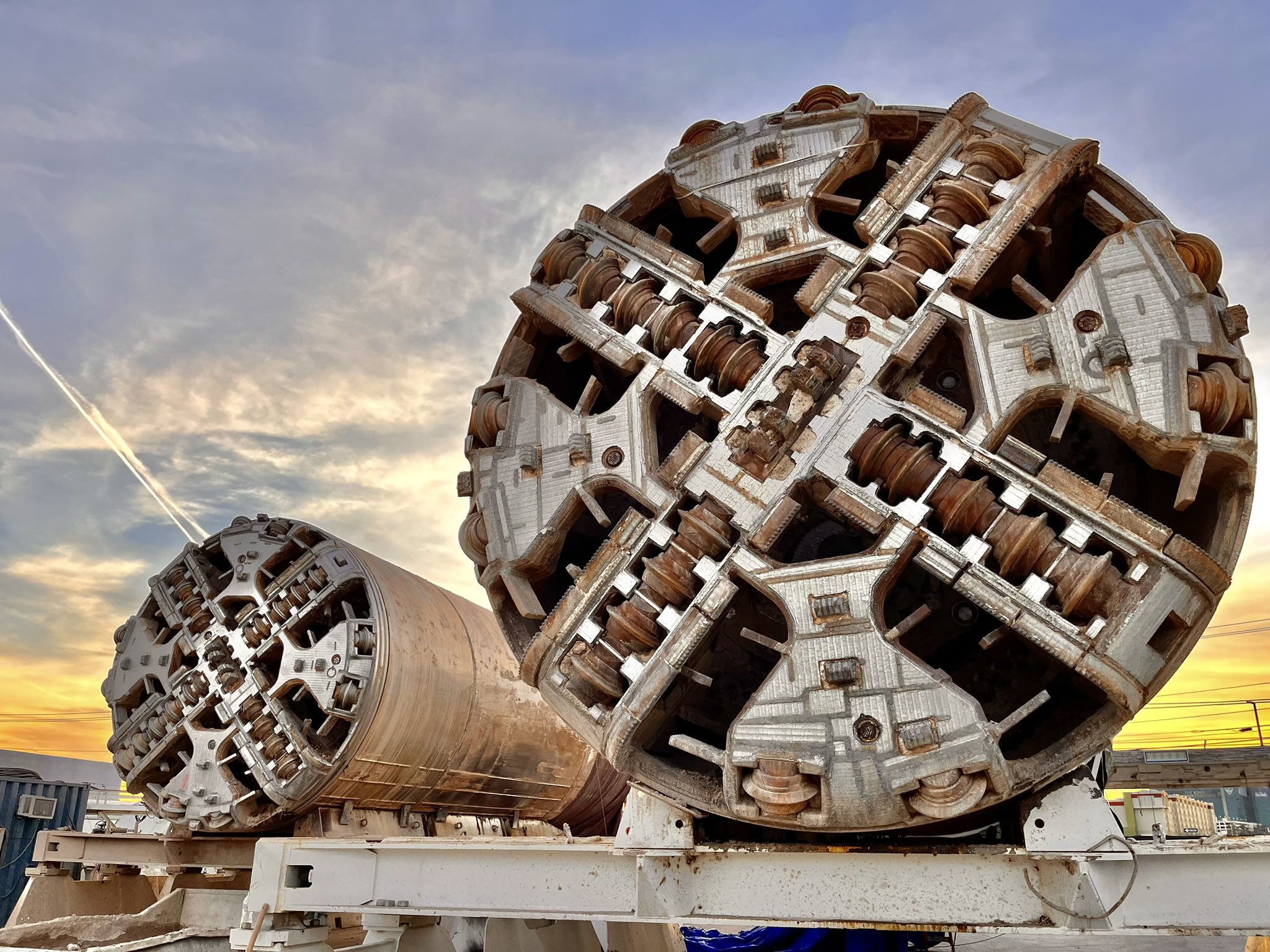

Several technical departures from conventional tunneling allow the Boring Company to lower its costs, from its smaller 12-foot diameter tunnels to its fully electric Prufrock machines that are designed to mine continuously with no personnel inside the tunnel and their capability to “porpoise” for easy launch and retrieval.

Tesla and Space CEO Elon Musk responded to the post on X, stating simply that “Tunnels are so underrated.”

The Boring Company has seen some momentum as of late, with the company recently signing a construction contract in Dubai and the Universal Orlando Loop progressing. Recent reports have also pointed to tunnels potentially being constructed to solve traffic congestion issues near the Giga Nevada area.

While The Boring Company’s tunnels have so far been used for Loop systems publicly for now, Elon Musk recently noted that the tunneling startup’s underground passages would not be limited only to ride-hailing vehicles.

In a reply to a post on X which discussed the specifications of the Music City Loop, Musk clarified that “any fully autonomous electric cars can use the tunnels.” This suggests that vehicles potentially running systems like FSD Supervised, even if they are not Teslas, could be used in systems like the Music City Loop in the future.