According to a Space Act Agreement signed by SpaceX and NASA’s Ames Research Center in June 2018, the private company has begun working with NASA to acquire some basic experience and lessons-learned with a thermal protection (heat shield) material that is largely new to SpaceX.

Known as TUFROC (short for Toughened Uni-piece Fibrous Reinforced Oxidation-Resistant Composite), the NASA Ames-developed material is capable of withstanding temperatures as high as 1700 C (~3100 F) and is apparently an item of interest to SpaceX’s next-gen BFR (Starship/Super Heavy) rocket program, particularly Starship’s heat shield.

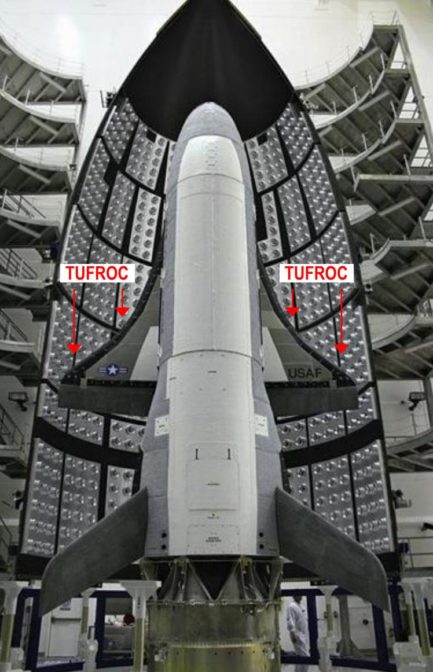

As far as the public is aware, SpaceX has never attempted to manufacture or utilize a heat shield technology like TUFROC. Falling under a domain of thermal protection materials known as ceramic matrix composites (CMCs), TUFROC is essentially an umbrella term that covers any thermal protection system that combines a carbon cap, silica base, and a cured glass coating to prevent oxidation. In recent years, Boeing’s secretive X-37B spaceplane has successfully demonstrated TUFROC reuse after orbital velocity reentries, confirming that the material is capable of surviving those conditions while experiencing minimal to no ablation.

Contour remains approx same, but fundamental materials change to airframe, tanks & heatshield

— Elon Musk (@elonmusk) November 25, 2018

Much like SpaceX borrowed the NASA-developed PICA (phenolic-impregnated carbon ablator) heat shield technology and dramatically improved it for cost-effective use on Cargo (and soon Crew) Dragon, the basic concept behind TUFROC’s heat shielding capabilities likely lends itself just as well to potential improvements in cost reduction, ease of manufacturing, mechanical strength, thermal protection characteristics, and more.

Unlike the fatally fragile carbon-carbon tiles used on the Space Shuttle, TUFROC’s namesake “Fibrous Reinforced” aspects also make it dramatically more resistant to impact related forces like those that led to the Columbia disaster, while still preserving the composite’s impressive heat resistance. NASA already categorizes TUFROC as a “low-cost” TPS, further indicating that SpaceX could quite easily cut the cost of production by a significant degree.

What is not clear about this budding relationship is how exactly SpaceX foresees TUFROC or a custom heat shield derivative fitting into its BFR program. Currently, the TPS has only been demonstrated on X-37B as a literal edge-case, standing in for a more traditional silica tile on the leading edges of the small spacecraft’s wings, where reentry heating is often the most extreme. It’s possible that SpaceX is interested in TUFROC for the same reasons – using it to cover BFS/Starship’s forward and rear fins and nothing more.

However, it could be the case that SpaceX hopes an improved TUFROC-X might be viable as a monolithic one-size-fits-all heat shield material throughout BFR’s Super Heavy booster and Starship upper stage. Being forced to deal with a variety of different TPS materials inevitably raises the complexity and cost of a given spacecraft, so being able to significantly reduce the number of materials needed could be a boon for Starship.

NASA and SpaceX’s Space Act Agreement can be found here [PDF].

For prompt updates, on-the-ground perspectives, and unique glimpses of SpaceX’s rocket recovery fleet check out our brand new LaunchPad and LandingZone newsletters!