News

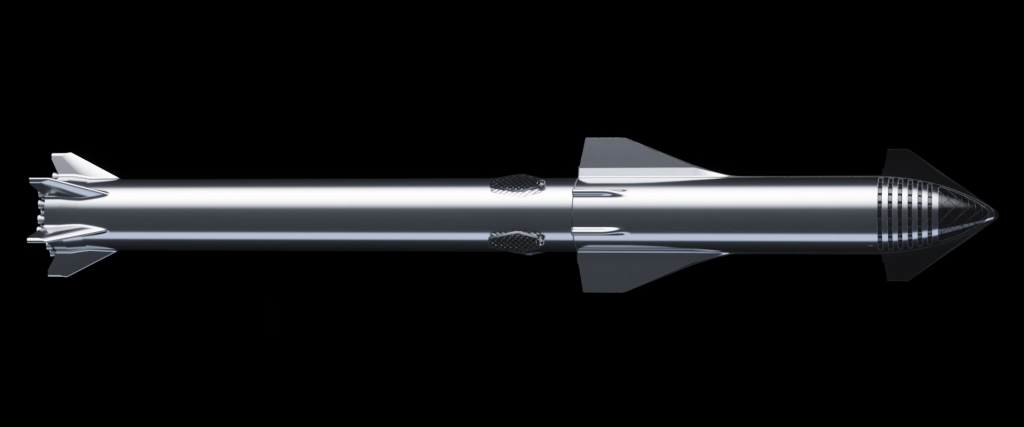

SpaceX to replace Falcon 9’s titanium grid fins with steel on Starship’s Super Heavy booster

Following a question on Twitter about how SpaceX intends to manufacture the truly massive grid fins shown in renders of Starship’s Super Heavy booster, CEO Elon Musk revealed that SpaceX will build them out of welded steel.

For the first several years of Falcon 9 and Falcon Heavy booster recovery operations, SpaceX built grid fins – used for maneuvering the rockets at high speeds – out of aluminum. With Falcon 9 Block 5, aluminum grid fins were phased out entirely in favor of larger titanium fins, necessitated by exceptionally high-speed reentries that nearly melted through the aluminum fins on several occasions. Now, SpaceX wants to move from titanium to steel fins for its next-generation Starship launch vehicle.

Welded steel— Elon Musk (@elonmusk) October 3, 2019

In response to the Twitter user’s question, Musk simply stated that Super Heavy’s grid fins would be manufactured out of “welded steel”, certainly keeping with the CEO’s now well-known love for the material. In October 2018, Musk finally managed to convince most of the senior engineers reporting to him that – despite years of work and full-scale testing – SpaceX needed to radically redesign Starship.

Prior to this radical change, SpaceX had spent at least 2-3 years on a Starship design (formerly Big F_____ Spaceship; BFS) made almost entirely out of carbon fiber composites, an extremely lightweight material that can be optimized for high strength. However, as Musk ultimately concluded in late 2018, although carbon composites are undeniably light and strong (optimal for spaceflight), they have extremely low heat tolerance and can react violently with supercooled liquid oxygen. Built almost entirely out of aluminum alloys with similarly low melting points, Falcon 9 has also struggled with the challenges posed by material choices, made far more difficult by the need to recover and reuse orbital-class rocket stages.

Musk ultimately decided that redesigning Starship with steel (alloys with particularly high melting points and good strength) was the right way to go. According to Musk, the high-quality carbon fiber composites SpaceX was originally pursuing cost something like $130,000 per metric ton, translating to a truly gobsmacking cost – accounting for unavoidable wastage – of $400M-$500M or more just to buy the materials needed to build a single Starship and Super Heavy booster. Steel, on the other hand, is quite literally 50 times cheaper, costing SpaceX around $2500 per ton, or as little as $10M in structural materials for each ship/booster pair.

Man of Stainless Steel

Speaking at a September 28th presentation on the 2019 status of Starship’s design, CEO Elon Musk couldn’t praise his decision to move to stainless steel enough, describing it as likely being the single best design decision he has ever made. It remains to be seen if the eccentric self-taught engineer’s decision was the correct one, but the progress SpaceX has made in just 10-11 months is undeniable. SpaceX has gone from a nearly blank slate to Starhopper’s 150m (500ft) test flight in ~6 months and gone from nothing to Starship Mk1 in another 6 or so months.

According to Musk, the properties of stainless steel – mainly a high melting point/working temperature and a tendency to strengthen at cryogenic temperatures – mean that the relatively heavy material is able to produce a launch vehicle that could eventually be far lighter and higher-performance than one made with carbon composites (BFR) or aluminum alloys (Falcon 9). Thanks to those properties, Starship/Super Heavy will become much stronger when filled with cold propellant and will also require little to no external heat shielding on its leeward half, whereas a reusable Al/composite rocket would require major thermal protection on nearly all exposed surfaces.

As part of the move to remove any ultra-expensive nonessential materials from the designs of Starship and Super Heavy, Musk has apparently also turned his gaze on the booster’s grid fins. As described at the top of this article, SpaceX replaced Falcon 9’s aluminum grid fins with titanium fins, requiring the company to create the largest single-piece titanium casting in the world. Musk has repeatedly indicated that each grid fin is extremely expensive.

In light of their expense, Musk (or SpaceX) has seemingly decided that future (larger?) SpaceX rockets will try to avoid large, titanium castings. Super Heavy nevertheless still needs massive grid fins: official renders published by SpaceX last month revealed a new diamond shape for the booster’s fins, and Musk later took to Twitter to reveal that they would be made out of welded steel instead of titanium.

Based on SpaceX’s official 2019 Super Heavy renders, the booster’s grid fins measure approximately 7m by 3m (23 ft by 10 ft), dwarfing Falcon 9’s titanium fins (perhaps 2m by 1.2m) with something like 8-10 times the surface area. Although 301-series stainless steel has a melting point and heat capacity roughly 15% lower than Grade 5 titanium, its strength characteristics are otherwise similar, while also remaining mechanically functional at almost three times the working temperature of titanium (840C vs. 330C).

Most importantly, not only is 301 steel roughly 15-20 times cheaper than titanium, but the process of fabricating large steel components – particularly with welding instead of casting – is dramatically faster, easier, and cheaper than working with and forming titanium. With their reasonably similar properties and the increased size of Super Heavy, it’s likely that steel grid fins would exhibit little to no ablation during even the hottest atmospheric reentries, and it would nevertheless be extremely easy and cheap to either repair or replace fins in the unlikely event of damage.

Given just how quickly and relatively easily SpaceX has built full-scale flight hardware out of steel and assuming there are no technical showstoppers caused by changing scales, it wouldn’t be surprising in the slightest to see SpaceX fabricate and test welded steel grid fins on Falcon 9 boosters in the near future.

Check out Teslarati’s Marketplace! We offer Tesla accessories, including for the Tesla Cybertruck and Tesla Model 3.

News

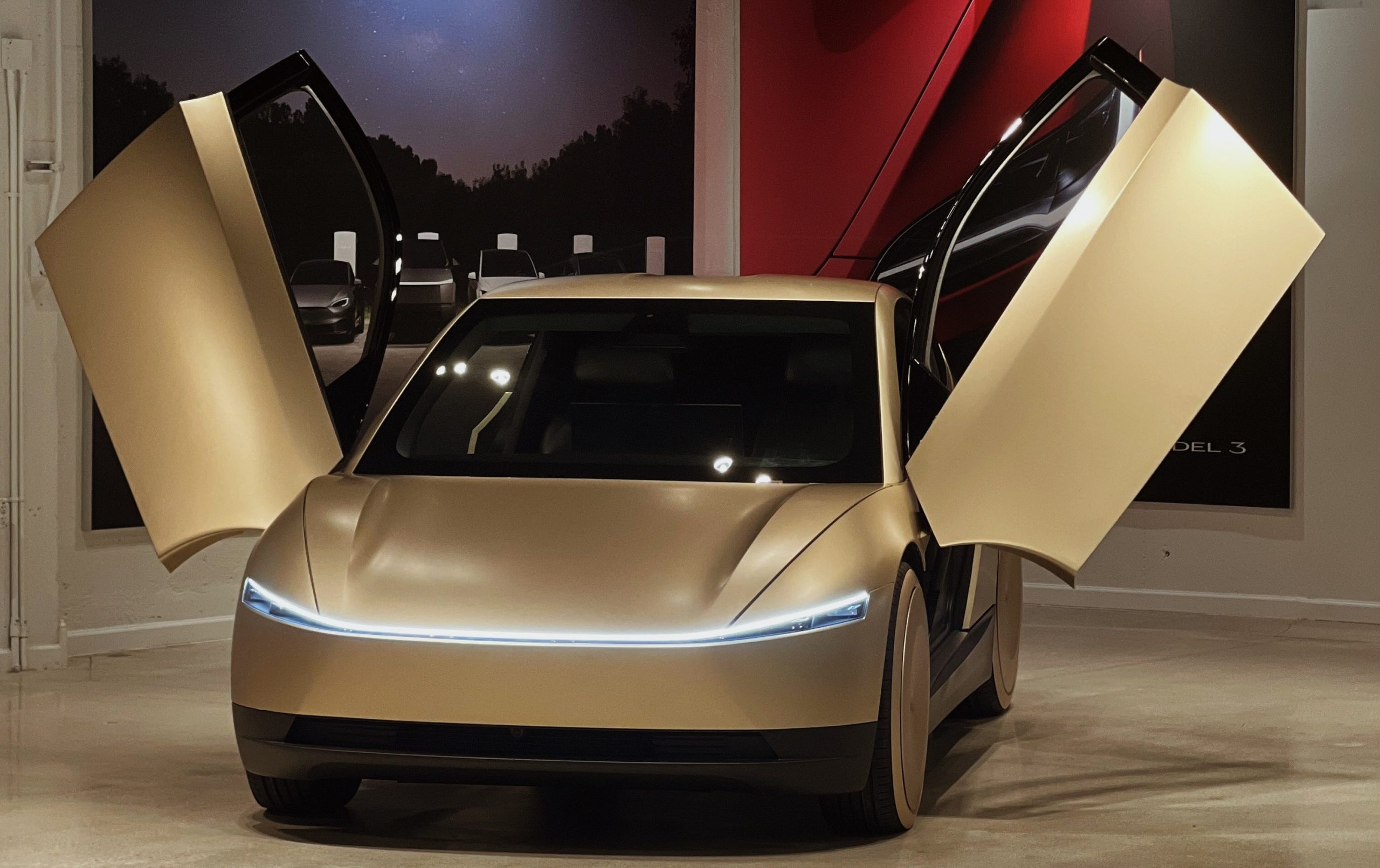

BREAKING: Tesla launches public Robotaxi rides in Austin with no Safety Monitor

Tesla has officially launched public Robotaxi rides in Austin, Texas, without a Safety Monitor in the vehicle, marking the first time the company has removed anyone from the vehicle other than the rider.

The Safety Monitor has been present in Tesla Robotaxis in Austin since its launch last June, maintaining safety for passengers and other vehicles, and was placed in the passenger’s seat.

Tesla planned to remove the Safety Monitor at the end of 2025, but it was not quite ready to do so. Now, in January, riders are officially reporting that they are able to hail a ride from a Model Y Robotaxi without anyone in the vehicle:

I am in a robotaxi without safety monitor pic.twitter.com/fzHu385oIb

— TSLA99T (@Tsla99T) January 22, 2026

Tesla started testing this internally late last year and had several employees show that they were riding in the vehicle without anyone else there to intervene in case of an emergency.

Tesla has now expanded that program to the public, but it is currently unclear if that is the case across its entire fleet of vehicles in Austin at this point.

Tesla Robotaxi goes driverless as Musk confirms Safety Monitor removal testing

The Robotaxi program also operates in the California Bay Area, where the fleet is much larger, but Safety Monitors are placed in the driver’s seat and utilize Full Self-Driving, so it is essentially the same as an Uber driver using a Tesla with FSD.

In Austin, the removal of Safety Monitors marks a substantial achievement for Tesla moving forward. Now that it has enough confidence to remove Safety Monitors from Robotaxis altogether, there are nearly unlimited options for the company in terms of expansion.

While it is hoping to launch the ride-hailing service in more cities across the U.S. this year, this is a much larger development than expansion, at least for now, as it is the first time it is performing driverless rides in Robotaxi anywhere in the world for the public to enjoy.

Investor's Corner

Tesla Earnings Call: Top 5 questions investors are asking

Tesla has scheduled its Earnings Call for Q4 and Full Year 2025 for next Wednesday, January 28, at 5:30 p.m. EST, and investors are already preparing to get some answers from executives regarding a wide variety of topics.

The company accepts several questions from retail investors through the platform Say, which then allows shareholders to vote on the best questions.

Tesla does not answer anything regarding future product releases, but they are willing to shed light on current timelines, progress of certain projects, and other plans.

There are five questions that range over a variety of topics, including SpaceX, Full Self-Driving, Robotaxi, and Optimus, which are currently in the lead to be asked and potentially answered by Elon Musk and other Tesla executives:

- You once said: Loyalty deserves loyalty. Will long-term Tesla shareholders still be prioritized if SpaceX does an IPO?

- Our Take – With a lot of speculation regarding an incoming SpaceX IPO, Tesla investors, especially long-term ones, should be able to benefit from an early opportunity to purchase shares. This has been discussed endlessly over the past year, and we must be getting close to it.

- When is FSD going to be 100% unsupervised?

- Our Take – Musk said today that this is essentially a solved problem, and it could be available in the U.S. by the end of this year.

- What is the current bottleneck to increase Robotaxi deployment & personal use unsupervised FSD? The safety/performance of the most recent models or people to monitor robots, robotaxis, in-car, or remotely? Or something else?

- Our Take – The bottleneck seems to be based on data, which Musk said Tesla needs 10 billion miles of data to achieve unsupervised FSD. Once that happens, regulatory issues will be what hold things up from moving forward.

- Regarding Optimus, could you share the current number of units deployed in Tesla factories and actively performing production tasks? What specific roles or operations are they handling, and how has their integration impacted factory efficiency or output?

- Our Take – Optimus is going to have a larger role in factories moving forward, and later this year, they will have larger responsibilities.

- Can you please tie purchased FSD to our owner accounts vs. locked to the car? This will help us enjoy it in any Tesla we drive/buy and reward us for hanging in so long, some of us since 2017.

- Our Take – This is a good one and should get us some additional information on the FSD transfer plans and Subscription-only model that Tesla will adopt soon.

Tesla will have its Earnings Call on Wednesday, January 28.

Elon Musk

Elon Musk shares incredible detail about Tesla Cybercab efficiency

Elon Musk shared an incredible detail about Tesla Cybercab’s potential efficiency, as the company has hinted in the past that it could be one of the most affordable vehicles to operate from a per-mile basis.

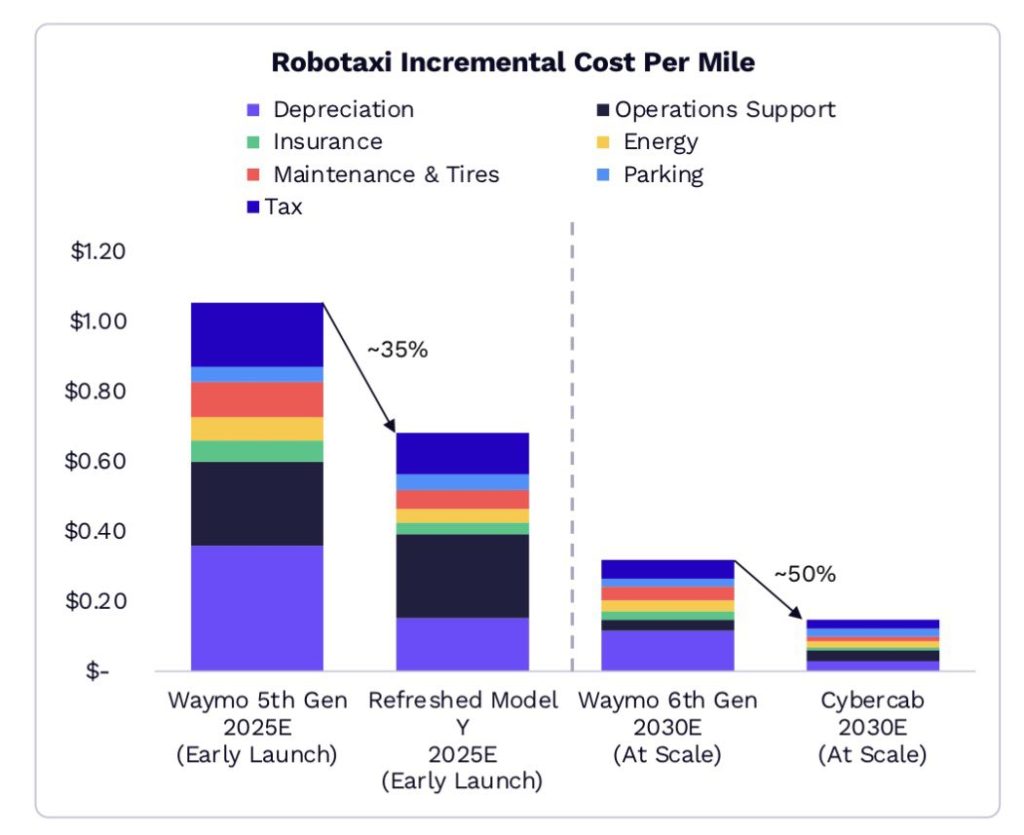

ARK Invest released a report recently that shed some light on the potential incremental cost per mile of various Robotaxis that will be available on the market in the coming years.

The Cybercab, which is detailed for the year 2030, has an exceptionally low cost of operation, which is something Tesla revealed when it unveiled the vehicle a year and a half ago at the “We, Robot” event in Los Angeles.

Musk said on numerous occasions that Tesla plans to hit the $0.20 cents per mile mark with the Cybercab, describing a “clear path” to achieving that figure and emphasizing it is the “full considered” cost, which would include energy, maintenance, cleaning, depreciation, and insurance.

Probably true

— Elon Musk (@elonmusk) January 22, 2026

ARK’s report showed that the Cybercab would be roughly half the cost of the Waymo 6th Gen Robotaxi in 2030, as that would come in at around $0.40 per mile all in. Cybercab, at scale, would be at $0.20.

Credit: ARK Invest

This would be a dramatic decrease in the cost of operation for Tesla, and the savings would then be passed on to customers who choose to utilize the ride-sharing service for their own transportation needs.

The U.S. average cost of new vehicle ownership is about $0.77 per mile, according to AAA. Meanwhile, Uber and Lyft rideshares often cost between $1 and $4 per mile, while Waymo can cost between $0.60 and $1 or more per mile, according to some estimates.

Tesla’s engineering has been the true driver of these cost efficiencies, and its focus on creating a vehicle that is as cost-effective to operate as possible is truly going to pay off as the vehicle begins to scale. Tesla wants to get the Cybercab to about 5.5-6 miles per kWh, which has been discussed with prototypes.

Additionally, fewer parts due to the umboxed manufacturing process, a lower initial cost, and eliminating the need to pay humans for their labor would also contribute to a cheaper operational cost overall. While aspirational, all of the ingredients for this to be a real goal are there.

It may take some time as Tesla needs to hammer the manufacturing processes, and Musk has said there will be growing pains early. This week, he said regarding the early production efforts:

“…initial production is always very slow and follows an S-curve. The speed of production ramp is inversely proportionate to how many new parts and steps there are. For Cybercab and Optimus, almost everything is new, so the early production rate will be agonizingly slow, but eventually end up being insanely fast.”