News

SpaceX’s Starship rocket program just had one of its best nights yet

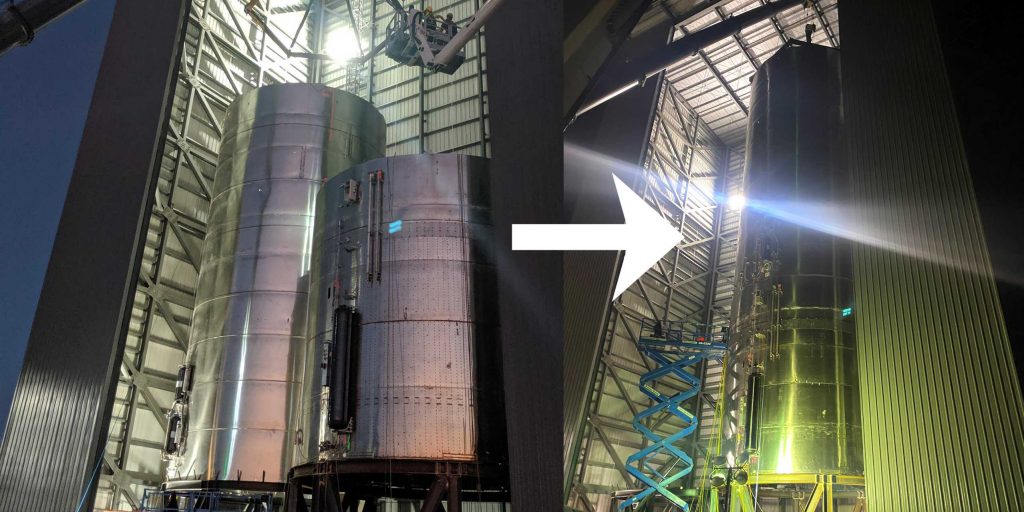

Before dawn on May 4th, SpaceX successfully fueled a full-scale Starship prototype and (partially) tested an installed Raptor engine for the first time ever – perhaps the Starship program’s best night yet.

While just a small test relative to what’s soon to come, the milestone is still an extremely significant one for SpaceX and its next-generation launch vehicle. Designed to launch atop the Super Heavy booster, both Starship and its booster are meant to be fully reusable, potentially making the launch system one of the cheapest in operation on Earth. Despite that unprecedented full reusability, they should still be able to place dozens (perhaps up to 100-150+) metric tons of payload into orbit in a single launch.

To get to that point, however, SpaceX must develop and demonstrate a cornucopia of technologies and approaches – most of which are unprecedented – at a scale unmatched by ever other launch vehicle in history, save two or three. It was perhaps the most fundamental of those steps that was on the table earlier this morning.

Perhaps the single most important and uncertain part of SpaceX’s ambitious Starship architecture, SpaceX’s May 4th wet dress rehearsal (WDR) was mainly a test of Starship’s overall structure and the manufacturing apparatus SpaceX has created to build it. Despite how exotic and challenging some of Starship’s goals may sound, SpaceX’s approach to production for its newest launch vehicle is arguably the single biggest risk for the program.

Notably, CEO Elon Musk says that the ultimate goal is to roll out a single finished Starship rocket every single week and at a cost of something like $5-10 million per vehicle. Including the Super Heavy booster, the production goals of which remain unknown, SpaceX effectively wants to mass-produce dozens of fully-reusable rockets – all larger (and potentially more capable) than NASA’s Saturn V Moon rocket – for anywhere from a tenth to a hundredth of the cost.

As if those goals weren’t ambitious enough, SpaceX intends to achieve them with perhaps the most spartan, minimalist factory ever attempted for orbital-class rockets. At the moment, all Starship hardware built by SpaceX to date has been manufactured in a series of tents, more recently graduating to a trio of warehouse-sized sprung structures. A large hangar – apparently dedicated to building pad infrastructure – is just shy of complete, while a separate windbreak structure and a vertical assembly building (VAB) are used to stack (assemble) full-scale Starship subsections built inside tents.

Unlike almost every other launch vehicle in history, Starship production – excluding its Raptor engines and certain other subassemblies and parts – is done in tents and is almost entirely divorced of the clean room operations rocket factories are famous for. Despite the extensive use of hand-welded seams and parts on SpaceX’s early Starship prototypes, the company has already proven that it’s well on its way to building Starships in just a week or two.

While it appears that SpaceX only performed a partial wet dress rehearsal with liquid methane and oxygen and completed a test of part of Starship SN4’s installed Raptor engine (known as the preburner), it means that a Starship has survived a truly launch vehicle-like procedure for the first time ever. In other words, Starship SN4’s May 4th success served as SpaceX’s most important verification yet that its exotic Starship manufacturing approach could be viable for building actual orbital-class rockets.

Up next, SpaceX will attempt to perform a full wet dress rehearsal (WDR) and a static fire test of Starship SN4 and its lone Raptor engine. That test attempt could come as soon as this evening.

News

Tesla executive moves on after 13 years: ‘It has been a privilege to serve’

“It is challenging to encapsulate 13 years in a single post. The journey at Tesla has been one of continuous evolution. From the technical intricacies of designing, building, and operating one of the world’s largest AI clusters to impactful contributions in IT, Security, Sales, and Service, it has been a privilege to serve,” Jegannathan said in the post.

Tesla executive Raj Jegannathan is moving on from the company after 13 years, he announced on LinkedIn on Monday.

“It is challenging to encapsulate 13 years in a single post. The journey at Tesla has been one of continuous evolution. From the technical intricacies of designing, building, and operating one of the world’s largest AI clusters to impactful contributions in IT, Security, Sales, and Service, it has been a privilege to serve,” Jegannathan said in the post.

After starting as a Senior Staff Engineer in Fremont back in November 2012, Jegannathan slowly worked his way through the ranks at Tesla. His most recent role was Vice President of IT/AI Infrastructure, Business Apps, and Infosec.

However, it was reported last year that Jegannathan had taken on a new role, which was running the North American sales team following the departure of Troy Jones, who had held the position previously.

While Jegannathan’s LinkedIn does not mention this position specifically, it seemed to be accurate, considering Tesla had not explicitly promoted any other person to the role.

It is a big loss for Tesla, but not a destructive departure. Jegannathan was one of the few company executives who answered customer and fan questions on X, a unique part of the Tesla ownership experience.

Tesla to offer Full Self-Driving gifting program: here’s how it will work

It currently remains unclear if Jegannathan was removed from the position or if he left under his own accord.

“As I move on, I do so with a full heart and excitement for what lies ahead. Thank you, Tesla, for this wonderful opportunity!” he concluded.

The departure marks a continuing trend of executives leaving the company, as the past 24 months have seen some significant turnover at the executive level.

Tesla has shown persistently elevated executive turnover over the past two years, as names like Drew Baglino, Rohan Patel, Rebecca Tinucci, Daniel Ho, Omead Afshar, Milan Kovac, and Siddhant Awasthi have all been notable names to exit the company in the past two years.

There are several things that could contribute to this. Many skeptics will point to Elon Musk’s politics, but that is not necessarily the case.

Tesla is a difficult, but rewarding place to work. It is a company that requires a lot of commitment, and those who are halfway in might not choose to stick around. Sacrificing things like time with family might not outweigh the demands of Tesla and Musk.

Additionally, many of these executives have made a considerable amount of money thanks to stock packages the company offers to employees. While many might be looking for new opportunities, some might be interested in an early retirement.

Tesla is also in the process of transitioning away from its most notable division, automotive. While it still plans to manufacture cars in the millions, it is turning more focus toward robotics and autonomy, and these plans might not align with what some executives might want for themselves. There are a wide variety of factors in the decision to leave a job, so it is important not to immediately jump to controversy.

News

Lemonade launches Tesla FSD insurance program in Oregon

The program was announced by Lemonade co-founder Shai Wininger on social media platform X.

Tesla drivers in Oregon can now receive significant insurance discounts when using FSD, following the launch of Lemonade’s new Autonomous Car insurance program.

The program was announced by Lemonade co-founder Shai Wininger on social media platform X.

Lemonade launches FSD-based insurance in Oregon

In a post on X, Wininger confirmed that Lemondade’s Autonomous Car insurance product for Tesla is now live in Oregon. The program allows eligible Tesla owners to receive roughly 50% off insurance costs for every mile driven using Tesla’s FSD system.

“And… we’re ON. @Lemonade_Inc’s Autonomous Car for @Tesla FSD is now live in Oregon. Tesla drivers in Oregon can now get ~50% off their Tesla FSD-driven miles + the best car insurance experience in the US, bar none,” Wininger wrote in his post.

As per Lemonade on its official website, the program is built on Tesla’s safety data, which indicates that miles driven using FSD are approximately twice as safe as those driven manually. As a result, Lemonade prices those miles at a lower rate. The insurer noted that as FSD continues to improve, associated discounts could increase over time.

How Lemonade tracks FSD miles

Lemonade’s FSD discount works through a direct integration with Tesla vehicles, enabled only with a driver’s explicit permission. Once connected, the system distinguishes between miles driven manually and those driven using FSD, applying the discount automatically to qualifying miles.

There is no minimum FSD usage requirement. Drivers who use FSD occasionally still receive discounted rates for those miles, while non-FSD miles are billed at competitive standard rates. Lemonade also emphasized that coverage and claims handling remain unchanged regardless of whether a vehicle is operating under manual control or FSD at the time of an incident.

The program is currently available only to Teslas equipped with Hardware 4 or newer, running firmware version 2025.44.25.5 or later. Lemonade also allows policyholders to bundle Tesla insurance with renters, homeowners, pet, or life insurance policies for additional savings.

News

Tesla exec: Preparations underway but no firm timeline yet for FSD rollout in China

The information was related by Tesla China Vice President Grace Tao in a comment to local media.

Tesla has not set a specific launch date for Full Self-Driving in China, despite the company’s ongoing preparations for a local FSD rollout.

The information was related by Tesla China Vice President Grace Tao in a comment to local media.

Tesla China prepares FSD infrastructure

Speaking in a recent media interview, the executive confirmed that Tesla has established a local training center in China to support the full adaptation of FSD to domestic driving conditions, as noted in a report from Sina News. However, she also noted that the company does not have a specific date when FSD will officially roll out in China.

“We have set up a local training center in China specifically to handle this adaptation,” Tao said. “Once officially released, it will demonstrate a level of performance that is no less than, and may even surpass, that of local drivers.”

Tao also emphasized the rapid accumulation of data by Tesla’s FSD system, with the executive highlighting that Full Self-Driving has now accumulated more than 7.5 billion miles of real-world driving data worldwide.

Possible 2026 rollout

The Tesla executive’s comments come amidst Elon Musk’s previous comments suggesting that regulatory approval in China could arrive sometime this 2026. During Tesla’s annual shareholder meeting in November 2025, Musk clarified that FSD had only received “partial approval” in China, though full authorization could potentially arrive around February or March 2026.

Musk reiterated that timeline at the World Economic Forum in Davos, when he stated that FSD approval in China could come as early as February.

Tesla’s latest FSD software, version 14, is already being tested in more advanced deployments in the United States. The company has also started the rollout of its fully unsupervised Robotaxis in Austin, Texas, which no longer feature safety monitors.