News

Rocket Lab to resume launches following in-flight anomaly investigation

Less than a month after the complete loss of customer payload due to an in-flight anomaly, Rocket Lab has announced that it is ready to return its small-class Electron rocket to flight. Company CEO, Peter Beck, during a media briefing Friday (July 31) said that the Electron second-stage “re-entered the atmosphere and burned up” resulting in a failed July 4 launch of the Electron and complete loss the customer payload of seven small satellites. Beck went on to state that through a collaborative investigation with the Federal Aviation Administration Rocket Lab was “able to quickly reconstruct what happened and the AIB board (Accident Investigation Board) was able to confidently narrow down the issue to a single electrical connection.”

The thirteenth flight of the Electron carried seven small satellites, all Earth-imaging inspiring the “Pics Or It Didn’t Happen” mission name. The rocket initially experienced a flawless launch from the company’s Launch Complex-1A on New Zealand’s Mahia Penninsula and everything seemed like it was going to plan until the video feed cut out unexpectedly shortly after the nominal ignition of the second-stage which was intended to carry the payloads to orbit.

The launch was completely event free during the first-stage ascent, stage separation, second stage ignition, and payload fairing jettison, then trouble occurred. Beck stated that the electrical connection that went bad during the second-stage of the flight was “incredibly unusual because it was able to evade all of the pre-flight acceptance testing.” Beck went on to explain that “while all of the testing showed no issues, after a period of time one of the joints had high resistance and that high resistance led to heating. That heating then led to thermal expansion of one of the components. That thermal expansion and heating enabled some of the potting components – that are around that joint to keep it secure from vibration – to flow.”

Once the potting compound used to secure electrical connections was able to heat up and essentially melt – or began to flow – the electrical connection become unsecured and led to the interruption in electrical current throughout the second-stage. Beck stated that “when the video stops (in the webcast) is exactly the point (of failure).” Although the video cut out, Rocket Lab ground stations continued to receive telemetry data of the flight’s progress due to the amount of redundancy with the systems aboard Electron “telemetry is the only way you can reconstruct this stuff so we have a very high priority of those (data) channels” Beck said.

With the immense amount of data that was received during the flight and throughout the second-stage shutdown Rocket Lab was able to quickly determine the cause of the error and perform tests to determine exactly what occurred during the failed flight. “The vehicle as it flies every flight has just a huge amount of instrumentation. That coupled with a graceful shutdown coupled with full telemetry stream throughout the whole anomaly, we were really able to quickly reconstruct what happened” Beck said.

The vast amount of data and the ability to sufficiently replicate the incident now means that Rocket Lab has a plan of action in place to mitigate any failures – of this nature – on future missions. “We can actually mitigate (the anomaly) very easily through a slight change in production processes, but more importantly we can screen for it in our current vehicles and stock through more in-depth testing procedures.”

To that end, the Rocket Lab Electron is set to return to flight in August, an impeccable turn around time following an anomaly investigation.”I’m very proud of the way the team has been able to identify this issue and rectify it so quickly” Beck said. He gave high praise to the entire Rocket Lab team for relentlessly working toward determining, not only the cause of the anomaly but working toward a solution for a quick return to flight. “Literally ten minutes after we saw some anomalous behavior during the flight, the team already started to work it and they haven’t stopped. They’ve been relentless” Beck said.

The customer payload that will fly aboard the return to flight and fourteenth mission of Electron launch is expected to be announced very soon. Rocket Lab did state that following a successful launch from the LC-1A complex in New Zealand, the following mission would be the first to take place from the brand new Launch Complex 2 located at the Mid-Atlantic Regional Spaceport at NASA Wallops in Virginia. Although an American private company, Rocket Lab predominately launches from New Zealand. The upcoming mission will be the first Electron flight to occur from American soil.

Beck closed the media briefing by stating that Rocket Lab looks forward to returning to operational status and launching Electrons every month, if not bi-weekly. He expressed that Rocket Lab is looking to the future and hopes to achieve a full recovery effort of the first stage booster via a helicopter and a specially designed grappling hook with the seventeenth flight of Electron. He also hinted that “there’ll be a couple of other little surprises as well, as we execute some other programs that have been cooking up in the background.”

News

Tesla Cybercab spotted with interesting charging solution, stimulating discussion

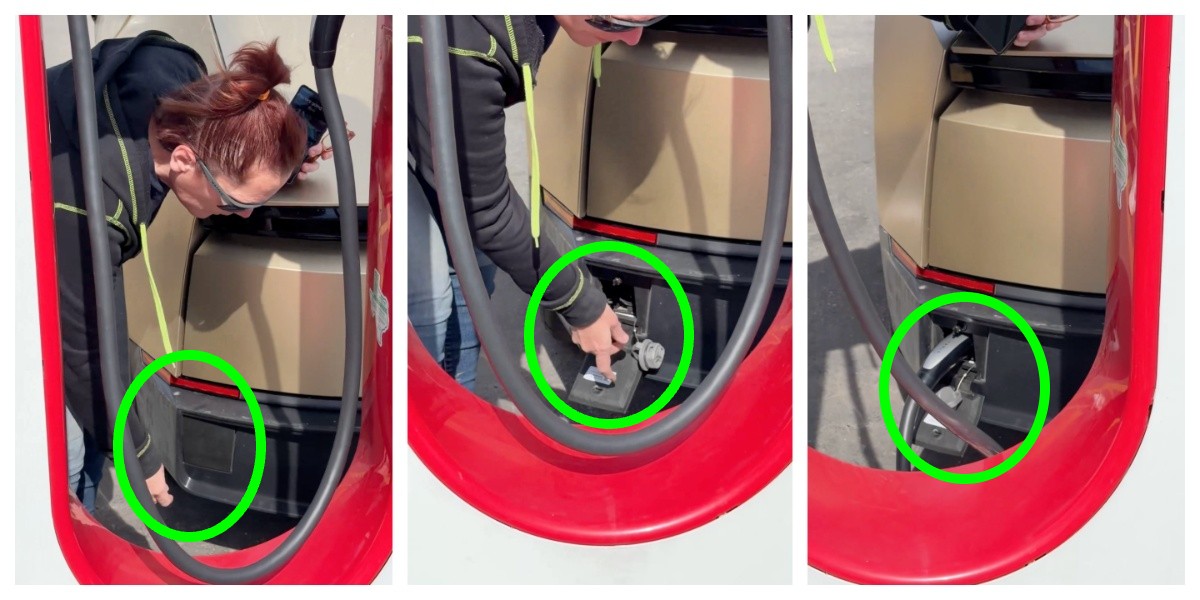

The port is located in the rear of the vehicle and features a manual door and latch for plug-in, and the video shows an employee connecting to a Tesla Supercharger.

Tesla Cybercab units are being tested publicly on roads throughout various areas of the United States, and a recent sighting of the vehicle’s charging port has certainly stimulated some discussions throughout the community.

The Cybercab is geared toward being a fully-autonomous vehicle, void of a steering wheel or pedals, only operating with the use of the Full Self-Driving suite. Everything from the driving itself to the charging to the cleaning is intended to be operated autonomously.

But a recent sighting of the vehicle has incited some speculation as to whether the vehicle might have some manual features, which would make sense, but let’s take a look:

🚨 Tesla Cybercab charging port is in the rear of the vehicle!

Here’s a great look at plugging it in!!

— TESLARATI (@Teslarati) January 29, 2026

The port is located in the rear of the vehicle and features a manual door and latch for plug-in, and the video shows an employee connecting to a Tesla Supercharger.

Now, it is important to remember these are prototype vehicles, and not the final product. Additionally, Tesla has said it plans to introduce wireless induction charging in the future, but it is not currently available, so these units need to have some ability to charge.

However, there are some arguments for a charging system like this, especially as the operation of the Cybercab begins after production starts, which is scheduled for April.

Wireless for Operation, Wired for Downtime

It seems ideal to use induction charging when the Cybercab is in operation. As it is for most Tesla owners taking roadtrips, Supercharging stops are only a few minutes long for the most part.

The Cybercab would benefit from more frequent Supercharging stops in between rides while it is operating a ride-sharing program.

Tesla wireless charging patent revealed ahead of Robotaxi unveiling event

However, when the vehicle rolls back to its hub for cleaning and maintenance, standard charging, where it is plugged into a charger of some kind, seems more ideal.

In the 45-minutes that the car is being cleaned and is having maintenance, it could be fully charged and ready for another full shift of rides, grabbing a few miles of range with induction charging when it’s out and about.

Induction Charging Challenges

Induction charging is still something that presents many challenges for companies that use it for anything, including things as trivial as charging cell phones.

While it is convenient, a lot of the charge is lost during heat transfer, which is something that is common with wireless charging solutions. Even in Teslas, the wireless charging mat present in its vehicles has been a common complaint among owners, so much so that the company recently included a feature to turn them off.

Production Timing and Potential Challenges

With Tesla planning to begin Cybercab production in April, the real challenge with the induction charging is whether the company can develop an effective wireless apparatus in that short time frame.

It has been in development for several years, but solving the issue with heat and energy loss is something that is not an easy task.

In the short-term, Tesla could utilize this port for normal Supercharging operation on the Cybercab. Eventually, it could be phased out as induction charging proves to be a more effective and convenient option.

News

Tesla confirms that it finally solved its 4680 battery’s dry cathode process

The suggests the company has finally resolved one of the most challenging aspects of its next-generation battery cells.

Tesla has confirmed that it is now producing both the anode and cathode of its 4680 battery cells using a dry-electrode process, marking a key breakthrough in a technology the company has been working to industrialize for years.

The update, disclosed in Tesla’s Q4 and FY 2025 update letter, suggests the company has finally resolved one of the most challenging aspects of its next-generation battery cells.

Dry cathode 4680 cells

In its Q4 and FY 2025 update letter, Tesla stated that it is now producing 4680 cells whose anode and cathode were produced during the dry electrode process. The confirmation addresses long-standing questions around whether Tesla could bring its dry cathode process into sustained production.

The disclosure was highlighted on X by Bonne Eggleston, Tesla’s Vice President of 4680 batteries, who wrote that “both electrodes use our dry process.”

Tesla first introduced the dry-electrode concept during its Battery Day presentation in 2020, pitching it as a way to simplify production, reduce factory footprint, lower costs, and improve energy density. While Tesla has been producing 4680 cells for some time, the company had previously relied on more conventional approaches for parts of the process, leading to questions about whether a full dry-electrode process could even be achieved.

4680 packs for Model Y

Tesla also revealed in its Q4 and FY 2025 Update Letter that it has begun producing battery packs for certain Model Y vehicles using its in-house 4680 cells. As per Tesla:

“We have begun to produce battery packs for certain Model Ys with our 4680 cells, unlocking an additional vector of supply to help navigate increasingly complex supply chain challenges caused by trade barriers and tariff risks.”

The timing is notable. With Tesla preparing to wind down Model S and Model X production, the Model Y and Model 3 are expected to account for an even larger share of the company’s vehicle output. Ensuring that the Model Y can be equipped with domestically produced 4680 battery packs gives Tesla greater flexibility to maintain production volumes in the United States, even as global battery supply chains face increasing complexity.

Elon Musk

Tesla Giga Texas to feature massive Optimus V4 production line

This suggests that while the first Optimus line will be set up in the Fremont Factory, the real ramp of Optimus’ production will happen in Giga Texas.

Tesla will build Optimus 4 in Giga Texas, and its production line will be massive. This was, at least, as per recent comments by CEO Elon Musk on social media platform X.

Optimus 4 production

In response to a post on X which expressed surprise that Optimus will be produced in California, Musk stated that “Optimus 4 will be built in Texas at much higher volume.” This suggests that while the first Optimus line will be set up in the Fremont Factory, and while the line itself will be capable of producing 1 million humanoid robots per year, the real ramp of Optimus’ production will happen in Giga Texas.

This was not the first time that Elon Musk shared his plans for Optimus’ production at Gigafactory Texas. During the 2025 Annual Shareholder Meeting, he stated that Giga Texas’ Optimus line will produce 10 million units of the humanoid robot per year. He did not, however, state at the time that Giga Texas would produce Optimus V4.

“So we’re going to launch on the fastest production ramp of any product of any large complex manufactured product ever, starting with building a one-million-unit production line in Fremont. And that’s Line one. And then a ten million unit per year production line here,” Musk stated.

How big Optimus could become

During Tesla’s Q4 and FY 2025 earnings call, Musk offered additional context on the potential of Optimus. While he stated that the ramp of Optimus’ production will be deliberate at first, the humanoid robot itself will have the potential to change the world.

“Optimus really will be a general-purpose robot that can learn by observing human behavior. You can demonstrate a task or verbally describe a task or show it a task. Even show it a video, it will be able to do that task. It’s going to be a very capable robot. I think long-term Optimus will have a very significant impact on the US GDP.

“It will actually move the needle on US GDP significantly. In conclusion, there are still many who doubt our ambitions for creating amazing abundance. We are confident it can be done, and we are making the right moves technologically to ensure that it does. Tesla, Inc. has never been a company to shy away from solving the hardest problems,” Musk stated.