News

SpaceX to launch asteroid mining spacecraft alongside private Moon lander

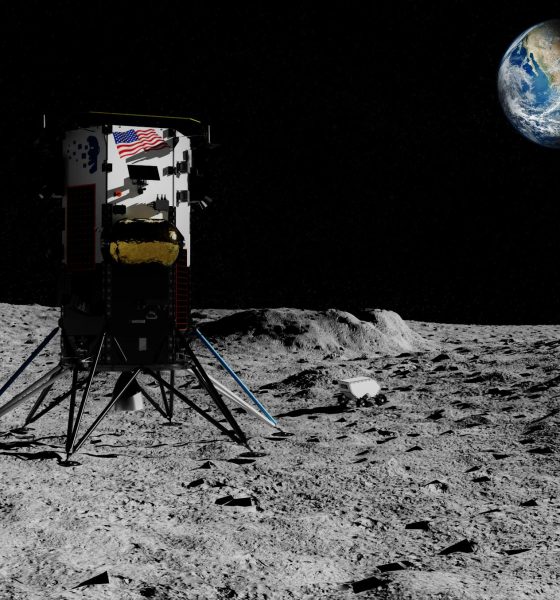

SpaceX customer Intuitive Machines says it will use spare capacity on one of its Moon lander launches to send startup AstroForge’s first asteroid prospector spacecraft into deep space.

Intuitive Machines’ second Nova-C Moon lander is scheduled to launch no earlier than (NET) Q4 2023 on a SpaceX Falcon 9 rocket. The IM-2 lander is the primary payload but is only expected to weigh about 1.9 tons (~4300 lb). To take advantage of the rocket performance left on the table by the relatively light payload, Intuitive Machines has opted to include a secondary payload adapter ring (ESPA) located below each lander. That gives companies like AstroForge an opportunity to hitch a ride to high Earth orbit, deep space, and the Moon for a likely unbeatable price.

Built by UK startup Orbital Astronautics, AstroForge’s Brokkr-2 spacecraft will attempt to become the first private vehicle to prospect for resources on an asteroid. It’s also the third rideshare payload announced for Intuitive Machines’ IM-2 mission.

We’re excited to launch these missions and many more to come. More information on this year’s launches: https://t.co/MSR61V8Lh7— AstroForge (@ForgeAstro) January 24, 2023

The update that's rolling out to the fleet makes full use of the front and rear steering travel to minimize turning circle. In this case a reduction of 1.6 feet just over the air— Wes (@wmorrill3) April 16, 2024

Lunar Trailblazer

Coincidentally, the main purpose of the second IM-2 rideshare payload to be announced is to search for resources in space. It isn’t concerned with asteroids, but NASA’s 200-kilogram (440 lb) Lunar Trailblazer spacecraft is designed to find, characterize, and map water ice resources on the Moon. That map could help future missions explore the possibility of turning lunar ice into commodities like breathable oxygen or rocket propellant.

The challenges facing such a concept are extreme, but a rocket propellant depot located on the lunar surface could significantly increase the performance of future Moon landers. Propellant depots in cislunar orbit could also help boost spacecraft further and faster to destinations elsewhere in the solar system.

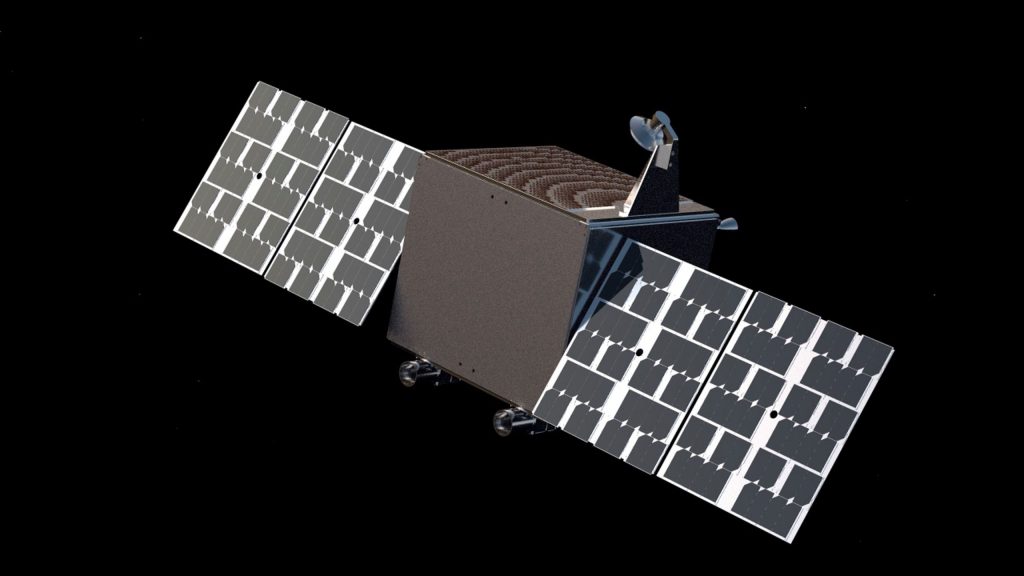

Tanker-002

The first IM-2 rideshare payload to be announced was OrbitFab’s Tanker-002 spacecraft. It’s unclear if OrbitFab is on track to fly Tanker-002 in late 2023, but the spacecraft is meant to be the first geostationary propellant depot ever launched. The Colorado startup has already won a $13.3 million contract from the US military to refuel satellites in geostationary orbit, 36,000 kilometers (~22,250 mi) above Earth’s surface. It’s possible that Tanker-002 is meant to support that refueling mission.

The spacecraft is designed to carry a few hundred pounds of hydrazine monopropellant, potentially enabling it to extend the useful lives of multiple multimillion-dollar satellites by several years. Alongside IM-2, Falcon 9 will launch Tanker-002 on a lunar flyby trajectory. But thanks to the cooperation of startup GeoJump, instead of entering orbit around the Moon, Tanker-002 will slingshot around the Moon to slow itself down. That lunar slingshot will allow the depot to efficiently enter geostationary orbit, where it can begin refueling spacecraft.

Brokkr-2

Brokkr-2 is the second of two AstroForge spacecraft scheduled to launch in 2023. The first, Brokkr-1, will head to low Earth orbit (LEO) as early as April 2023 on SpaceX’s seventh Falcon 9 rideshare launch. Once in orbit, it will attempt to demonstrate technology AstroForge has developed to refine platinum ore in microgravity conditions. Brokkr-2 will then visit an asteroid and search for platinum resources. If enough platinum is discovered, Bloomberg reports that AstroForge will send a third mission to demonstrate the ability to land on the asteroid. As early as 2025, AstroForge’s fourth mission would be the first to attempt to land, gather ore, turn that ore into platinum, and return the precious metal to Earth.

AstroForge has raised $13 million to date. Unlike failed asteroid mining startups Deep Space Industries and Planetary Resources, the new company intends to exploit increasingly capable off-the-shelf hardware and services to keep its costs as low as possible. In theory, that will allow it to focus most of its resources on developing the unproven technology required to gather and refine space-based resources.

IM-2

Finally, the IM-2 Nova-C Moon lander’s primary payload is a pair of NASA instruments designed to drill into the lunar surface and analyze the regolith for volatiles. Also known as PRIME-1, the mission will be NASA’s first serious exploration of in-situ resource utilization (ISRU) on the Moon.

The mission is a sort of microcosm of the future of space utilization, which may focus heavily on ISRU and refueling to extend the capabilities of chemically-powered rockets and spacecraft. Lunar Trailblazer will map lunar water resources. Brokkr-2 will attempt to prospect an asteroid for extractable metal. IM-2 will test technologies that could help extract resources from the Moon. And Tanker-002 will be a significant step forward for commercial propellant depots, which could eventually create markets for space resources.

Elon Musk

Elon Musk’s Boring Company opens Vegas Loop’s newest station

The Fontainebleau is the latest resort on the Las Vegas Strip to embrace the tunneling startup’s underground transportation system.

Elon Musk’s tunneling startup, The Boring Company, has welcomed its newest Vegas Loop station at the Fontainebleau Las Vegas.

The Fontainebleau is the latest resort on the Las Vegas Strip to embrace the tunneling startup’s underground transportation system.

Fontainebleau Loop station

The new Vegas Loop station is located on level V-1 of the Fontainebleau’s south valet area, as noted in a report from the Las Vegas Review-Journal. According to the resort, guests will be able to travel free of charge to the stations serving the Las Vegas Convention Center, as well as to Loop stations in Encore and Westgate.

The Fontainebleau station connects to the Riviera Station, which is located in the northwest parking lot of the convention center’s West Hall. From there, passengers will be able to access the greater Vegas Loop.

Vegas Loop expansion

In December, The Boring Company began offering Vegas Loop rides to and from Harry Reid International Airport. Those trips include a limited above-ground segment, following approval from the Nevada Transportation Authority to allow surface street travel tied to Loop operations.

Under the approval, airport rides are limited to no more than four miles of surface street travel, and each trip must include a tunnel segment. The Vegas Loop currently includes more than 10 miles of tunnels. From this number, about four miles of tunnels are operational.

The Boring Company President Steve Davis previously told the Review-Journal that the University Center Loop segment, which is currently under construction, is expected to open in the first quarter of 2026. That extension would allow Loop vehicles to travel beneath Paradise Road between the convention center and the airport, with a planned station located just north of Tropicana Avenue.

News

Tesla leases new 108k-sq ft R&D facility near Fremont Factory

The lease adds to Tesla’s presence near its primary California manufacturing hub as the company continues investing in autonomy and artificial intelligence.

Tesla has expanded its footprint near its Fremont Factory by leasing a 108,000-square-foot R&D facility in the East Bay.

The lease adds to Tesla’s presence near its primary California manufacturing hub as the company continues investing in autonomy and artificial intelligence.

A new Fremont lease

Tesla will occupy the entire building at 45401 Research Ave. in Fremont, as per real estate services firm Colliers. The transaction stands as the second-largest R&D lease of the fourth quarter, trailing only a roughly 115,000-square-foot transaction by Figure AI in San Jose.

As noted in a Silicon Valley Business Journal report, Tesla’s new Fremont lease was completed with landlord Lincoln Property Co., which owns the facility. Colliers stated that Tesla’s Fremont expansion reflects continued demand from established technology companies that are seeking space for engineering, testing, and specialized manufacturing.

Tesla has not disclosed which of its business units will be occupying the building, though Colliers has described the property as suitable for office and R&D functions. Tesla has not issued a comment about its new Fremont lease as of writing.

AI investments

Silicon Valley remains a key region for automakers as vehicles increasingly rely on software, artificial intelligence, and advanced electronics. Erin Keating, senior director of economics and industry insights at Cox Automotive, has stated that Tesla is among the most aggressive auto companies when it comes to software-driven vehicle development.

Other automakers have also expanded their presence in the area. Rivian operates an autonomy and core technology hub in Palo Alto, while GM maintains an AI center of excellence in Mountain View. Toyota is also relocating its software and autonomy unit to a newly upgraded property in Santa Clara.

Despite these expansions, Colliers has noted that Silicon Valley posted nearly 444,000 square feet of net occupancy losses in Q4 2025, pushing overall vacancy to 11.2%.

News

Tesla winter weather test: How long does it take to melt 8 inches of snow?

In Pennsylvania, we got between 10 and 12 inches of snow over the weekend as a nasty Winter storm ripped through a large portion of the country, bringing snow to some areas and nasty ice storms to others.

I have had a Model Y Performance for the week courtesy of Tesla, which got the car to me last Monday. Today was my last full day with it before I take it back to my local showroom, and with all the accumulation on it, I decided to run a cool little experiment: How long would it take for Tesla’s Defrost feature to melt 8 inches of snow?

Tesla’s Defrost feature is one of the best and most underrated that the car has in its arsenal. While every car out there has a defrost setting, Tesla’s can be activated through the Smartphone App and is one of the better-performing systems in my opinion.

It has come in handy a lot through the Fall and Winter, helping clear up my windshield more efficiently while also clearing up more of the front glass than other cars I’ve owned.

The test was simple: don’t touch any of the ice or snow with my ice scraper, and let the car do all the work, no matter how long it took. Of course, it would be quicker to just clear the ice off manually, but I really wanted to see how long it would take.

Tesla Model Y heat pump takes on Model S resistive heating in defrosting showdown

Observations

I started this test at around 10:30 a.m. It was still pretty cloudy and cold out, and I knew the latter portion of the test would get some help from the Sun as it was expected to come out around noon, maybe a little bit after.

I cranked it up and set my iPhone up on a tripod, and activated the Time Lapse feature in the Camera settings.

The rest of the test was sitting and waiting.

It didn’t take long to see some difference. In fact, by the 20-minute mark, there was some notable melting of snow and ice along the sides of the windshield near the A Pillar.

However, this test was not one that was “efficient” in any manner; it took about three hours and 40 minutes to get the snow to a point where I would feel comfortable driving out in public. In no way would I do this normally; I simply wanted to see how it would do with a massive accumulation of snow.

It did well, but in the future, I’ll stick to clearing it off manually and using the Defrost setting for clearing up some ice before the gym in the morning.

Check out the video of the test below:

❄️ How long will it take for the Tesla Model Y Performance to defrost and melt ONE FOOT of snow after a blizzard?

Let’s find out: pic.twitter.com/Zmfeveap1x

— TESLARATI (@Teslarati) January 26, 2026