News

SpaceX aims for a burst of December launches despite recent delays

Originally scheduled to launch on December 4, SpaceX’s thirteenth resupply mission to the International Space Station (ISS) has been pushed back to no earlier than Friday, December 15 after routine preflight checks identified potential contaminants in the Falcon 9 launch vehicle’s upper stage fuel lines.

The past six weeks have been something of an outlier in an otherwise relentless series of 2017 launches for SpaceX. In early November, defects in payload fairings were discovered at the company’s Hawthorne, CA factory and quickly traced to the Zuma mission’s fairing, at that point already vertical and prepared to launch from Kennedy Space Center. SpaceX chose to pause its launch indefinitely as it investigated the fairings already delivered to its several launch pads and began the process of either repairing or replacing those impacted. The CRS-13 Cargo Dragon mission soon took precedent as Zuma remained on hold.

A panorama of SpaceX’s newly-reactivated Launch Complex 40. Falcon 9 and Dragon can be seen in the center. (Tom Cross/Teslarati)

Although CRS-13 does not require a payload fairing and was thus unaffected by SpaceX’s ongoing investigation, the mission was scheduled to be launched from Launch Complex-40, essentially a new pad after ten months of extensive repairs and upgrades. This translated into a few days of additional delays as the SpaceX launch crew thoroughly tested the pad’s new systems and pushed towards static fire of the flight proven Falcon 9 booster, successfully completed on December 6 after an additional handful of days of pad-related delays. This pushed the launch date from the 4th to the 8th, then the 12th and the 13th to accommodate further limited testing in order to ensure pad readiness. However, routine tests revealed a possible fuel line contamination in Falcon 9’s second stage, and SpaceX delayed the mission an additional 48 hours to resolve the problem. CRS-13 is now aiming for launch no earlier than 7:35am/10:35am PST/EST on December 15, but the window is instantaneous and any additional delays would push the launch into late December, at which point Cape Canaveral Air Force Station returns to operational status with the conclusion of winter holidays.

Although LC-40 suffered through its own teething period of bugs and testing while returning to life, there is a certain irony in the fact that a bug in the only wholly new component of CRS-13’s Falcon 9 rocket has been the most recent cause of delay; both the Falcon 9 booster and Cargo Dragon capsule are refurbished, flight-proven hardware, although both the trunk and heat shield of the Dragon were likely replaced with new components. There is something to be said about the logical nature of truly “flight-proven” hardware being more trustworthy than completely new alternatives, but it is far more likely that the upper stage contamination can be largely traced back to the new pad hardware.

A refurbished Dragon perched upon its flight-proven Falcon 9 first stage, separated by the uncooperative second stage. (Tom Cross/Teslarati)

Although Teslarati’s launch photographer Tom Cross has been battered about by Zuma and CRS-13 delays, SpaceX has demonstrated an admirable level of patience and caution, risking significant delays to their launch manifest in order to best ensure the safety and reliability of their launch services. While delays are painful in the spaceflight fan business, they are impermanent and secondary to safety and success. SpaceX will undoubtedly return to their regular programming in no time at all, with the West-coast launch of Iridium-4 and first pad rollout of Falcon Heavy up next on the docket. Stay tuned!

News

Tesla Robotaxi ride-hailing without a Safety Monitor proves to be difficult

Tesla Robotaxi ride-hailing without a Safety Monitor is proving to be a difficult task, according to some riders who made the journey to Austin to attempt to ride in one of its vehicles that has zero supervision.

Last week, Tesla officially removed Safety Monitors from some — not all — of its Robotaxi vehicles in Austin, Texas, answering skeptics who said the vehicles still needed supervision to operate safely and efficiently.

BREAKING: Tesla launches public Robotaxi rides in Austin with no Safety Monitor

Tesla aimed to remove Safety Monitors before the end of 2025, and it did, but only to company employees. It made the move last week to open the rides to the public, just a couple of weeks late to its original goal, but the accomplishment was impressive, nonetheless.

However, the small number of Robotaxis that are operating without Safety Monitors has proven difficult to hail for a ride. David Moss, who has gained notoriety recently as the person who has traveled over 10,000 miles in his Tesla on Full Self-Driving v14 without any interventions, made it to Austin last week.

He has tried to get a ride in a Safety Monitor-less Robotaxi for the better part of four days, and after 38 attempts, he still has yet to grab one:

Wow just wow!

It’s 8:30PM, 29° out ice storm hailing & Tesla Robotaxi service has turned back on!

Waymo is offline & vast majority of humans are home in the storm

Ride 38 was still supervised but by far most impressive yet pic.twitter.com/1aUnJkcYm8

— David Moss (@DavidMoss) January 25, 2026

Tesla said last week that it was rolling out a controlled test of the Safety Monitor-less Robotaxis. Ashok Elluswamy, who heads the AI program at Tesla, confirmed that the company was “starting with a few unsupervised vehicles mixed in with the broader Robotaxi fleet with Safety Monitors,” and that “the ratio will increase over time.”

This is a good strategy that prioritizes safety and keeps the company’s controlled rollout at the forefront of the Robotaxi rollout.

However, it will be interesting to see how quickly the company can scale these completely monitor-less rides. It has proven to be extremely difficult to get one, but that is understandable considering only a handful of the cars in the entire Austin fleet are operating with no supervision within the vehicle.

News

Tesla gives its biggest hint that Full Self-Driving in Europe is imminent

Tesla has given its biggest hint that Full Self-Driving in Europe is imminent, as a new feature seems to show that the company is preparing for frequent border crossings.

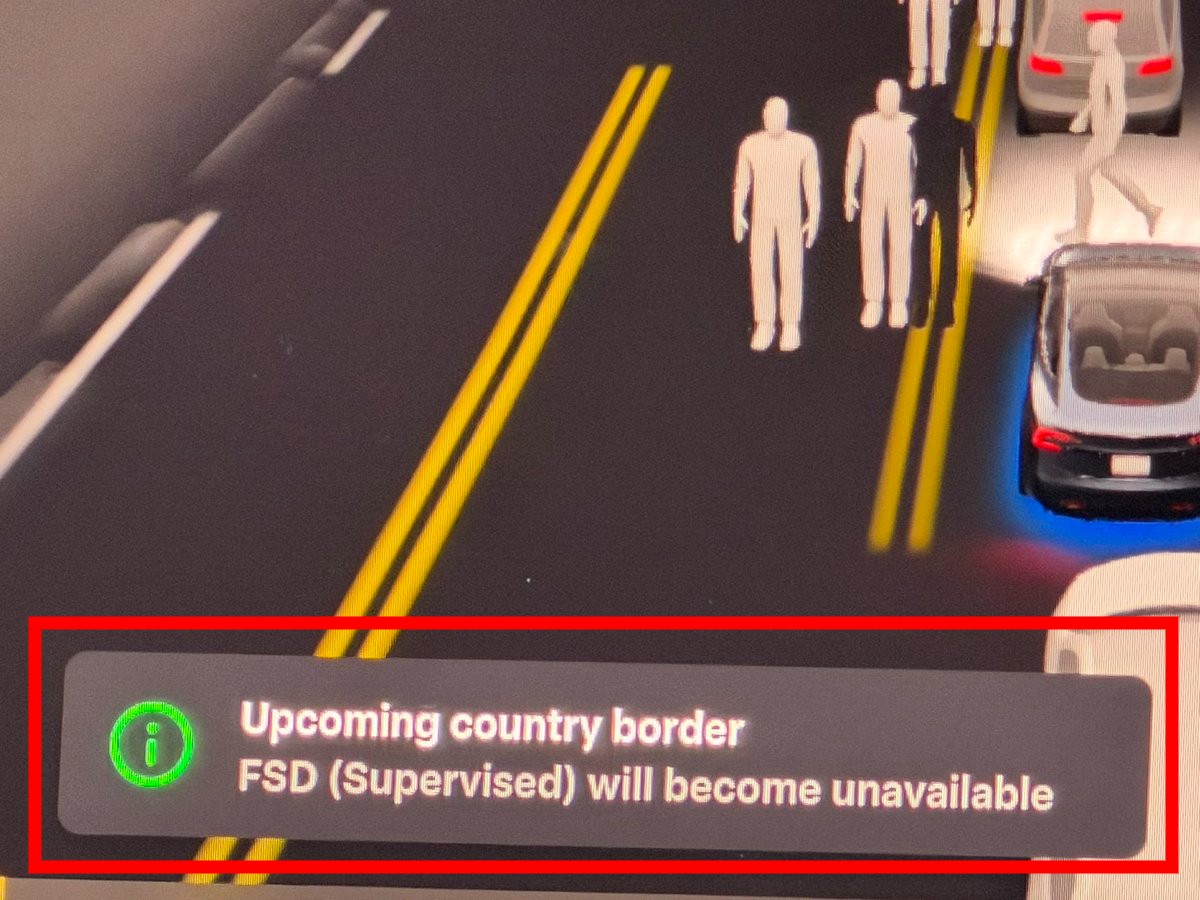

Tesla owner and influencer BLKMDL3, also known as Zack, recently took his Tesla to the border of California and Mexico at Tijuana, and at the international crossing, Full Self-Driving showed an interesting message: “Upcoming country border — FSD (Supervised) will become unavailable.”

FSD now shows a new message when approaching an international border crossing.

Stayed engaged the whole way as we crossed the border and worked great in Mexico! pic.twitter.com/bDzyLnyq0g

— Zack (@BLKMDL3) January 26, 2026

Due to regulatory approvals, once a Tesla operating on Full Self-Driving enters a new country, it is required to comply with the laws and regulations that are applicable to that territory. Even if legal, it seems Tesla will shut off FSD temporarily, confirming it is in a location where operation is approved.

This is something that will be extremely important in Europe, as crossing borders there is like crossing states in the U.S.; it’s pretty frequent compared to life in America, Canada, and Mexico.

Tesla has been working to get FSD approved in Europe for several years, and it has been getting close to being able to offer it to owners on the continent. However, it is still working through a lot of the red tape that is necessary for European regulators to approve use of the system on their continent.

This feature seems to be one that would be extremely useful in Europe, considering the fact that crossing borders into other countries is much more frequent than here in the U.S., and would cater to an area where approvals would differ.

Tesla has been testing FSD in Spain, France, England, and other European countries, and plans to continue expanding this effort. European owners have been fighting for a very long time to utilize the functionality, but the red tape has been the biggest bottleneck in the process.

Tesla Europe builds momentum with expanding FSD demos and regional launches

Tesla operates Full Self-Driving in the United States, China, Canada, Mexico, Puerto Rico, Australia, New Zealand, and South Korea.

Elon Musk

SpaceX Starship V3 gets launch date update from Elon Musk

The first flight of Starship Version 3 and its new Raptor V3 engines could happen as early as March.

Elon Musk has announced that SpaceX’s next Starship launch, Flight 12, is expected in about six weeks. This suggests that the first flight of Starship Version 3 and its new Raptor V3 engines could happen as early as March.

In a post on X, Elon Musk stated that the next Starship launch is in six weeks. He accompanied his announcement with a photo that seemed to have been taken when Starship’s upper stage was just about to separate from the Super Heavy Booster. Musk did not state whether SpaceX will attempt to catch the Super Heavy Booster during the upcoming flight.

The upcoming flight will mark the debut of Starship V3. The upgraded design includes the new Raptor V3 engine, which is expected to have nearly twice the thrust of the original Raptor 1, at a fraction of the cost and with significantly reduced weight. The Starship V3 platform is also expected to be optimized for manufacturability.

The Starship V3 Flight 12 launch timeline comes as SpaceX pursues an aggressive development cadence for the fully reusable launch system. Previous iterations of Starship have racked up a mixed but notable string of test flights, including multiple integrated flight tests in 2025.

Interestingly enough, SpaceX has teased an aggressive timeframe for Starship V3’s first flight. Way back in late November, SpaceX noted on X that it will be aiming to launch Starship V3’s maiden flight in the first quarter of 2026. This was despite setbacks like a structural anomaly on the first V3 booster during ground testing.

“Starship’s twelfth flight test remains targeted for the first quarter of 2026,” the company wrote in its post on X.