News

SpaceX photos reveal Falcon 9 fairings parasailing to Pacific splashdown

SpaceX has released the first high-quality photos of Falcon 9’s payload fairing recovery hardware in action, showing the massive carbon fiber-aluminum halves gliding by parafoil less than a rocket-length away from recovery vessel Mr. Steven’s massive net.

If anything, these photos demonstrate just how close SpaceX is – both literally and figuratively – to successfully catching payload fairings out of the air, the final keystone of fairing reuse. Per the extraordinarily minimalist appearance of each half’s parafoil recovery hardware and the lack of any clear control mechanism, it’s very likely that SpaceX has sided with an in-canopy system of actuators tasked with subtly warping the parafoil, comparable in functionality to a crude replica of a bird’s wing.

Falcon 9 fairing halves deployed their parafoils and splashed down in the Pacific Ocean last week after the launch of Iridium-6/GRACE-FO. Closest half was ~50m from SpaceX’s recovery ship, Mr. Steven. https://t.co/JS7d5zTdIg pic.twitter.com/LjiTwnB4wd

— SpaceX (@SpaceX) May 31, 2018

In-wing actuation and control is an elegant – if complex – solution to the problem of parafoil guidance. In this case, SpaceX’s contractor (MMIST) likely deserves at least some of the credit for several nearly successful recoveries, delivering each unpowered fairing half from an altitude of 110+ kilometers, speeds of more than 2 kilometers per second, and parabolic trajectories stretching over 800 kilometers to a square roughly 100m by 100m. If each halve’s accuracy can be cut by 75% of that to an area of 50m by 50m, SpaceX and Mr Steven should have no trouble in reliably and routinely catching Falcon 9 payload fairings for rapid reuse, perhaps one day translating into a similar approach for the recovery of Falcon 9’s orbital upper stages.

- The payload fairing for NASA’s Transiting Exoplanet Survey Satellite (TESS) is moved inside the Payload Hazardous Servicing Facility at the agency’s Kennedy Space Center in Florida. (NASA)

- By all appearances, both Iridium-6/GRACE-FO fairing halves were retrieved intact from the ocean surface. Note the tiny technician installing a tarp inside one half. (Chuck Bennett, Instagram @chuckbennett)

- Both fairing halves from SpaceX’s Iridiium-6/GRACE-FO spied aboard Mr Steven after docking. (Pauline Acalin)

It’s unclear if SpaceX has designed and built its fairing recovery parafoils largely on its own or if it has instead sided with established subcontractors like MMIST and consumer-off-the-shelf (COTS) solutions. Regardless, after approximately a year of trying, SpaceX appears to be rounding the very last corner to fairing recovery and reuse, perhaps avoiding the need for a series of drop-and-catch tests hinted at recently by CEO Elon Musk.

Once the massive 800-kilogram components can be captured in flight by Mr. Steven, it should be a fairly prospect for SpaceX to move from recovery to reuse, potentially saving as much as 10% ($6m) of the cost of each Falcon 9 and Falcon Heavy launch. Perhaps even more importantly, fairing reuse would remove some of the pressure placed on SpaceX’s composite production floor, which currently must support the fabrication of dozens of fairing halves, booster interstages, payload adapters, Falcon Heavy nose cones, and much more, including smaller subassemblies required for both Crew and Cargo Dragons.

SpaceX’s composite production floor shown in mid-2016. Note the Falcon Heavy nose cone, two interstages, and two fairing halves. (SpaceX)

As a result of their carbon fiber-aluminum honeycomb construction, each half inherently takes a disproportionate amount of time to manufacture, exaggerated by the need for massive and expensive curing autoclaves (a mix of an oven and a pressure chamber), of which only a handful can fit inside SpaceX’s Hawthorne factory. For a manifest of roughly 30 launches per year, as is the goal for 2018, this would require the production of an entire fairing half every six days, an extraordinary feat of heroics when building massive monolithic composite parts in a space-constrained factory.

With reuse, those heroics could be relaxed or at least focused elsewhere on Falcon 9, Heavy, Crew Dragon, and BFR production. With any luck, SpaceX’s next West coast launch, currently NET early July, may see Mr. Steven’s first-ever successful fairing catch, thanks in part to a brand new net.

News

Tesla Robotaxi ride-hailing without a Safety Monitor proves to be difficult

Tesla Robotaxi ride-hailing without a Safety Monitor is proving to be a difficult task, according to some riders who made the journey to Austin to attempt to ride in one of its vehicles that has zero supervision.

Last week, Tesla officially removed Safety Monitors from some — not all — of its Robotaxi vehicles in Austin, Texas, answering skeptics who said the vehicles still needed supervision to operate safely and efficiently.

BREAKING: Tesla launches public Robotaxi rides in Austin with no Safety Monitor

Tesla aimed to remove Safety Monitors before the end of 2025, and it did, but only to company employees. It made the move last week to open the rides to the public, just a couple of weeks late to its original goal, but the accomplishment was impressive, nonetheless.

However, the small number of Robotaxis that are operating without Safety Monitors has proven difficult to hail for a ride. David Moss, who has gained notoriety recently as the person who has traveled over 10,000 miles in his Tesla on Full Self-Driving v14 without any interventions, made it to Austin last week.

He has tried to get a ride in a Safety Monitor-less Robotaxi for the better part of four days, and after 38 attempts, he still has yet to grab one:

Wow just wow!

It’s 8:30PM, 29° out ice storm hailing & Tesla Robotaxi service has turned back on!

Waymo is offline & vast majority of humans are home in the storm

Ride 38 was still supervised but by far most impressive yet pic.twitter.com/1aUnJkcYm8

— David Moss (@DavidMoss) January 25, 2026

Tesla said last week that it was rolling out a controlled test of the Safety Monitor-less Robotaxis. Ashok Elluswamy, who heads the AI program at Tesla, confirmed that the company was “starting with a few unsupervised vehicles mixed in with the broader Robotaxi fleet with Safety Monitors,” and that “the ratio will increase over time.”

This is a good strategy that prioritizes safety and keeps the company’s controlled rollout at the forefront of the Robotaxi rollout.

However, it will be interesting to see how quickly the company can scale these completely monitor-less rides. It has proven to be extremely difficult to get one, but that is understandable considering only a handful of the cars in the entire Austin fleet are operating with no supervision within the vehicle.

News

Tesla gives its biggest hint that Full Self-Driving in Europe is imminent

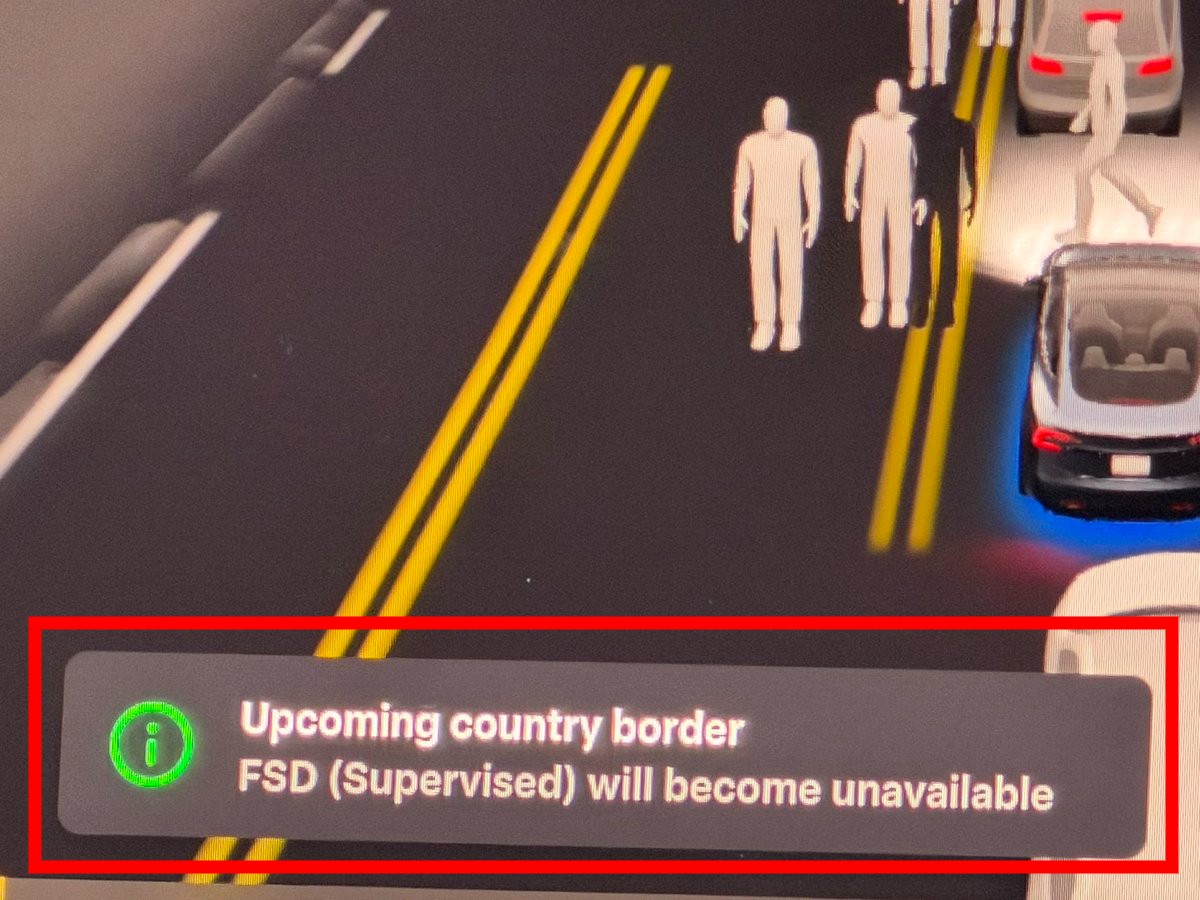

Tesla has given its biggest hint that Full Self-Driving in Europe is imminent, as a new feature seems to show that the company is preparing for frequent border crossings.

Tesla owner and influencer BLKMDL3, also known as Zack, recently took his Tesla to the border of California and Mexico at Tijuana, and at the international crossing, Full Self-Driving showed an interesting message: “Upcoming country border — FSD (Supervised) will become unavailable.”

FSD now shows a new message when approaching an international border crossing.

Stayed engaged the whole way as we crossed the border and worked great in Mexico! pic.twitter.com/bDzyLnyq0g

— Zack (@BLKMDL3) January 26, 2026

Due to regulatory approvals, once a Tesla operating on Full Self-Driving enters a new country, it is required to comply with the laws and regulations that are applicable to that territory. Even if legal, it seems Tesla will shut off FSD temporarily, confirming it is in a location where operation is approved.

This is something that will be extremely important in Europe, as crossing borders there is like crossing states in the U.S.; it’s pretty frequent compared to life in America, Canada, and Mexico.

Tesla has been working to get FSD approved in Europe for several years, and it has been getting close to being able to offer it to owners on the continent. However, it is still working through a lot of the red tape that is necessary for European regulators to approve use of the system on their continent.

This feature seems to be one that would be extremely useful in Europe, considering the fact that crossing borders into other countries is much more frequent than here in the U.S., and would cater to an area where approvals would differ.

Tesla has been testing FSD in Spain, France, England, and other European countries, and plans to continue expanding this effort. European owners have been fighting for a very long time to utilize the functionality, but the red tape has been the biggest bottleneck in the process.

Tesla Europe builds momentum with expanding FSD demos and regional launches

Tesla operates Full Self-Driving in the United States, China, Canada, Mexico, Puerto Rico, Australia, New Zealand, and South Korea.

Elon Musk

SpaceX Starship V3 gets launch date update from Elon Musk

The first flight of Starship Version 3 and its new Raptor V3 engines could happen as early as March.

Elon Musk has announced that SpaceX’s next Starship launch, Flight 12, is expected in about six weeks. This suggests that the first flight of Starship Version 3 and its new Raptor V3 engines could happen as early as March.

In a post on X, Elon Musk stated that the next Starship launch is in six weeks. He accompanied his announcement with a photo that seemed to have been taken when Starship’s upper stage was just about to separate from the Super Heavy Booster. Musk did not state whether SpaceX will attempt to catch the Super Heavy Booster during the upcoming flight.

The upcoming flight will mark the debut of Starship V3. The upgraded design includes the new Raptor V3 engine, which is expected to have nearly twice the thrust of the original Raptor 1, at a fraction of the cost and with significantly reduced weight. The Starship V3 platform is also expected to be optimized for manufacturability.

The Starship V3 Flight 12 launch timeline comes as SpaceX pursues an aggressive development cadence for the fully reusable launch system. Previous iterations of Starship have racked up a mixed but notable string of test flights, including multiple integrated flight tests in 2025.

Interestingly enough, SpaceX has teased an aggressive timeframe for Starship V3’s first flight. Way back in late November, SpaceX noted on X that it will be aiming to launch Starship V3’s maiden flight in the first quarter of 2026. This was despite setbacks like a structural anomaly on the first V3 booster during ground testing.

“Starship’s twelfth flight test remains targeted for the first quarter of 2026,” the company wrote in its post on X.