News

SpaceX to move Starship and Super Heavy production to Texas as hop tests near [updated]

SpaceX announced today that plans to ultimately build BFR (now known as Starship/Super Heavy) in the Port of Los Angeles have at least initially been replaced with a decision to move that development to South Texas, although details about the new facilities and their timelines remain have yet to be shared.

Drawn to one possible conclusion, this could mean that SpaceX no longer intends to build a BFR factory in the Port of Los Angeles, while all Falcon 9/Heavy, Merlin, and Raptor manufacturing will remain in the company’s Hawthorne, CA headquarters for the foreseeable future. However, the statements do not preclude the possibility that SpaceX still plans to develop an oceanside factory in the near future for Super Heavy, Starship, or both.

SpaceX will not longer be manufacturing its Mars spaceship and rocket booster at the Port of Los Angeles. Instead, the work will be done in South Texas. https://t.co/LqBfPawiZf

— Los Angeles Times (@latimes) January 16, 2019

Update: CEO Elon Musk stated on Twitter that the Los Angeles Times’ original report and a partial miscommunication on behalf of SpaceX misconstrued an official statement that early-stage Starship and Super Heavy prototype construction and development would stay in South Texas for the time being. It appears that SpaceX’s Port of LA plans remain largely unchanged.

The source info is incorrect. Starship & Raptor development is being done out of our HQ in Hawthorne, CA. We are building the Starship prototypes locally at our launch site in Texas, as their size makes them very difficult to transport.

— Elon Musk (@elonmusk) January 16, 2019

“To streamline operations, SpaceX is developing and will test the Starship test vehicle at our site in South Texas. This decision does not impact our current manufacture, design, and launch operations in Hawthorne and Vandenberg Air Force Base in California. Additionally, SpaceX will continue recovery operations of our reusable Falcon rockets and Dragon spacecraft at the Port of Los Angeles.” – SpaceX, January 16th, 2019

In early 2018, SpaceX announced that it had required a new berth in Port of San Pedro with the specific intention of building a brand-new BFR factory. By keeping BFR production in Los Angeles and locating it directly adjacent to its transportation mode of choice (a barge from California to Texas), the official hope was to retain the best aerospace talent in the US (generally centered around central California) and ensure that its main Hawthorne factory was just a short drive away while still being able to relatively affordably transport massive 9m/30 foot-diameter BFR spaceships and boosters between California and Texas.

Also speaking in 2018, COO and President Gwynne Shotwell noted that the estimated cost of moving a BFR-sized object from its main Hawthorne factory to Port of LA would average $5M for a one-way trip. For context, that is almost 10% of the list price of an entirely new Falcon 9 rocket ($62M) just to perform basic, necessary logistics. As a result, SpaceX decided to build a permanent factory at a Port of LA dock, where the company had already sprung a giant tent to begin prototype fabrication. Known as Berth 240, it’s now unclear whether SpaceX will retain and still develop the Port of San Pedro plot into a permanent facility, estimated to cost a few tens of millions of dollars to complete.

- SpaceX currently uses Berth 240 as fairing recovery vessel Mr. Steven’s base of operations. (Pauline Acalin)

- Most of the Berth 240 plot features decrepit but historic buildings from the early 20th century – SpaceX is required by its EIS to help preserve them and can only demolish one small hangar. (Pauline Acalin)

- Over the last six months, SpaceX has VERY gradually prepared the foundation of its prospective Berth 240 factory, although barely any visible progress has been made. (Pauline Acalin, 11/30/18)

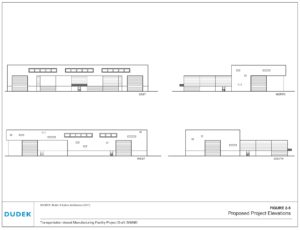

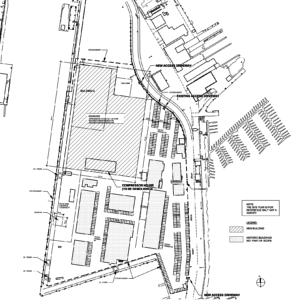

- Blueprints of the proposed BFR factory at Berth 240. (SpaceX)

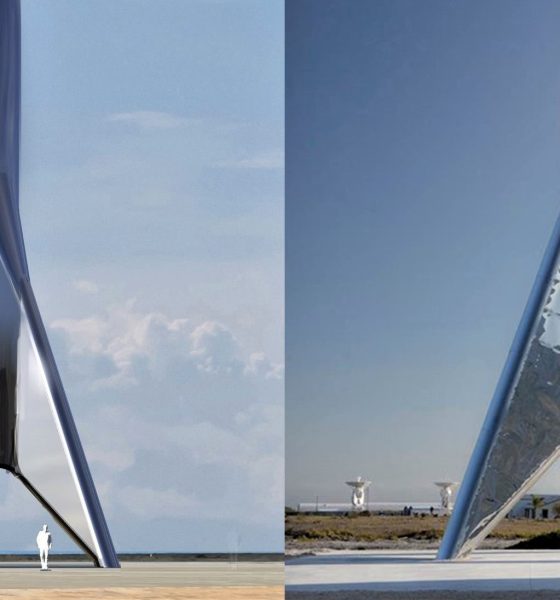

- Renders of the proposed BFR factory at Berth 240. (SpaceX)

- An overview of the two planned stages of BFR factory construction, March 2018. (SpaceX)

In the company’s approved environmental impact assessment, the implication was that the BFR factory could double as dedicated post-recovery processing and refurbishment facility for regular Falcon 9 missions and provide a far more spacious dock for drone ship Just Read The Instructions and support vessel NRC Quest. That sort of facility could easily still provide significant value to SpaceX, although it may be the case that it would not earn its keep nearly well enough to account for the redundancy of refurbishing at Port of LA instead of simply shipping recovered Falcon 9 boosters to the main Hawthorne factory, which can already host the refurbishment of at least two Falcon 9 boosters simultaneously.

Starship Hopper has been taken apart again (for the installation of the bulkhead etc.)

📸NSF's BocaChicaGalhttps://t.co/DlTj9Qiijz

NSF Overview News Article by Thomas Burghardt @TGMetsFan98 for those catching up:https://t.co/rgliFAkBMC pic.twitter.com/DzSJzjSvoI

— NSF – NASASpaceflight.com (@NASASpaceflight) January 15, 2019

SpaceX may also still want to have LA facilities capable of affordably supporting Starship and Super Heavy structures development and production in the event that some of its excellent staff of engineers and technicians are not interested in moving from Los Angeles to the sparsely-populated southeast tip of Texas. In the meantime, the company continues to work towards the completion of its first flightworthy(ish) Starship prototype at its rapidly expanding South Texas facilities, with CEO Elon Musk indicating that hop tests of the vehicle could begin as early as February or March 2019.

Expect a new article on the recent Starship hopper progress very soon!

News

Tesla confirms Robotaxi expansion plans with new cities and aggressive timeline

Tesla plans to launch in Dallas, Houston, Phoenix, Miami, Orlando, Tampa, and Las Vegas. It lists the Bay Area as “Safety Driver,” and Austin as “Ramping Unsupervised.”

Tesla confirmed its intentions to expand the Robotaxi program in the United States with an aggressive timeline that aims to send the ride-hailing service to several large cities very soon.

The Robotaxi program is currently active in Austin, Texas, and the California Bay Area, but Tesla has received some approvals for testing in other areas of the U.S., although it has not launched in those areas quite yet.

However, the time is coming.

During Tesla’s Q4 Earnings Call last night, the company confirmed that it plans to expand the Robotaxi program aggressively, hoping to launch in seven new cities in the first half of the year.

Tesla plans to launch in Dallas, Houston, Phoenix, Miami, Orlando, Tampa, and Las Vegas. It lists the Bay Area as “Safety Driver,” and Austin as “Ramping Unsupervised.”

These details were released in the Earnings Shareholder Deck, which is published shortly before the Earnings Call:

🚨 BREAKING: Tesla plans to launch its Robotaxi service in Dallas, Houston, Phoenix, Miami, Orlando, Tampa, and Las Vegas in the first half of this year pic.twitter.com/aTnruz818v

— TESLARATI (@Teslarati) January 28, 2026

Late last year, Tesla revealed it had planned to launch Robotaxi in Las Vegas, Phoenix, Dallas, and Houston, but Tampa and Orlando were just added to the plans, signaling an even more aggressive expansion than originally planned.

Tesla feels extremely confident in its Robotaxi program, and that has been reiterated many times.

Although skeptics still remain hesitant to believe the prowess Tesla has seemingly proven in its development of an autonomous driving suite, the company has been operating a successful program in Austin and the Bay Area for months.

In fact, it announced it achieved nearly 700,000 paid Robotaxi miles since launching Robotaxi last June.

🚨 Tesla has achieved nearly 700,000 paid Robotaxi miles since launching in June of last year pic.twitter.com/E8ldSW36La

— TESLARATI (@Teslarati) January 28, 2026

With the expansion, Tesla will be able to penetrate more of the ride-sharing market, disrupting the human-operated platforms like Uber and Lyft, which are usually more expensive and are dependent on availability.

Tesla launched driverless rides in Austin last week, but they’ve been few and far between, as the company is certainly easing into the program with a very cautiously optimistic attitude, aiming to prioritize safety.

Investor's Corner

Tesla (TSLA) Q4 and FY 2025 earnings call: The most important points

Executives, including CEO Elon Musk, discussed how the company is positioning itself for growth across vehicles, energy, AI, and robotics despite near-term pressures from tariffs, pricing, and macro conditions.

Tesla’s (NASDAQ:TSLA) Q4 and FY 2025 earnings call highlighted improving margins, record energy performance, expanding autonomy efforts, and a sharp acceleration in AI and robotics investments.

Executives, including CEO Elon Musk, discussed how the company is positioning itself for growth across vehicles, energy, AI, and robotics despite near-term pressures from tariffs, pricing, and macro conditions.

Key takeaways

Tesla reported sequential improvement in automotive gross margins excluding regulatory credits, rising from 15.4% to 17.9%, supported by favorable regional mix effects despite a 16% decline in deliveries. Total gross margin exceeded 20.1%, the highest level in more than two years, even with lower fixed-cost absorption and tariff impacts.

The energy business delivered standout results, with revenue reaching nearly $12.8 billion, up 26.6% year over year. Energy gross profit hit a new quarterly record, driven by strong global demand and high deployments of MegaPack and Powerwall across all regions, as noted in a report from The Motley Fool.

Tesla also stated that paid Full Self-Driving customers have climbed to nearly 1.1 million worldwide, with about 70% having purchased FSD outright. The company has now fully transitioned FSD to a subscription-based sales model, which should create a short-term margin headwind for automotive results.

Free cash flow totaled $1.4 billion for the quarter. Operating expenses rose by $500 million sequentially as well.

Production shifts, robotics, and AI investment

Musk further confirmed that Model S and Model X production is expected to wind down next quarter, and plans are underway to convert Fremont’s S/X line into an Optimus robot factory with a capacity of one million units.

Tesla’s Robotaxi fleet has surpassed 500 vehicles, operating across the Bay Area and Austin, with Musk noting a rapid monthly expansion pace. He also reiterated that CyberCab production is expected to begin in April, following a slow initial S-curve ramp before scaling beyond other vehicle programs.

Looking ahead, Tesla expects its capital expenditures to exceed $20 billion next year, thanks to the company’s operations across its six factories, the expansion of its fleet expansion, and the ramp of its AI compute. Additional investments in AI chips, compute infrastructure, and future in-house semiconductor manufacturing were discussed but are not included in the company’s current CapEx guidance.

More importantly, Tesla ended the year with a larger backlog than in recent years. This is supported by record deliveries in smaller international markets and stronger demand across APAC and EMEA. Energy backlog remains strong globally as well, though Tesla cautioned that margin pressure could emerge from competition, policy uncertainty, and tariffs.

News

Tesla brings closure to flagship ‘sentimental’ models, Musk confirms

Tesla is bringing closure to its flagship Model S and Model X vehicles, which CEO Elon Musk said several years ago were only produced for “sentimental reasons.”

The Model S and Model X have been light contributors to Tesla’s delivery growth over the past few years, commonly contributing only a few percentage points toward the over 1.7 million cars the company has handed over to customers annually since 2022.

However, the Model S and Model X have remained in production because of their high-end performance and flagship status; they are truly two vehicles that are premium offerings and do not hold major weight toward Tesla’s future goals.

On Wednesday, during the Q4 2025 Earnings Call, Musk confirmed that Tesla would bring closure to the two models, ending their production and making way for the manufacturing efforts of the Optimus robot:

“It is time to bring the Model S and Model X programs to an end with an honorable discharge. It is time to bring the S/X programs to an end. It’s part of our overall shift to an autonomous future.”

Musk said the production lines that Tesla has for the Model S and Model X at the Fremont Factory in Northern California will be transitioned to Optimus production lines that will produce one million units per year.

Tesla Fremont Factory celebrates 15 years of electric vehicle production

Tesla will continue to service Model S and Model X vehicles, but it will officially stop deliveries of the cars in Q2, as inventory will be liquidated. When they’re gone, they’re gone.

BREAKING: Tesla will wind down Model S and Model X production next quarter, Elon Musk confirms.

“It is time to bring the Model S and Model X programs to an end with an honorable discharge.” pic.twitter.com/Czn7aQjJE1

— TESLARATI (@Teslarati) January 28, 2026

Tesla has been making moves to sunset the two vehicles for the better part of one year. Last July, it stopped taking any custom orders for vehicles in Europe, essentially pushing the idea that the program was coming to a close soon.

Musk said back in 2019:

“I mean, they’re very expensive, made in low volume. To be totally frank, we’re continuing to make them more for sentimental reasons than anything else. They’re really of minor importance to the future.”

That point is more relevant than ever as Tesla is ending the production of the cars to make way for Optimus, which will likely be Tesla’s biggest product in the coming years.

Musk added during the Earnings Call on Wednesday that he believes Optimus will be a major needle-mover of the United States’ GDP, as it will increase productivity and enable universal high income for humans.