Energy

Here’s what it takes to work at Tesla

The following post was originally published on EVANNEX

On March 28th, Andrew Stevenson of Tesla’s Special Projects delivered a keynote speech titled, “Opportunities for Students in Building a Sustainable Energy Future,” during the Carnegie Mellon University’s Scott Institute for Energy Innovation* 2017 Energy Week. Stevenson works closely with Tesla co-founder and chief technical officer, J.B. Straubel, tackling projects that don’t always fit neatly into existing programs within the company. That said, Stevenson was certainly qualified to discuss what he described as Tesla’s “scalable approach to problem solving.”

The presentation appeared to be part of Stevenson’s efforts to actively recruit some of the best and brightest students from Carnegie Mellon University. He noted that most of Tesla’s hiring is currently focused on engineering students with an emphasis on mechanical engineering. Stevenson’s presentation revolved around what he referred to as the “six core building blocks” needed while working at Tesla: 1. Mission; 2. Teams; 3. First Principles; 4. Autonomy and self-motivation; 5. Critical thinking and root cause analysis; and 6. Continuous improvement.

Stevenson reiterated that Tesla’s mission continues to be “to accelerate the world’s transition to sustainable energy.” He noted that Tesla started small with just 5 people on staff. Yet it’s grown to over 30,000 employees worldwide. Regardless of how big Tesla grows, the emphasis remains on small, entrepreneurial teams to handle the company’s challenges.

Stevenson described Tesla’s “first principles” approach as using “fundamental reasoning” — not deferring to “the way others have done it.” He pointed out the fact that the Model S was “designed from the ground up” to be an all-electric vehicle. And, he also described Tesla’s solar roof as another strong application of the first principles approach.

Another core building block Stevenson described was “autonomy and self-motivation” being a means for employees to be proactive instead of waiting for management to dictate deliverables. He described how the company (itself) used this approach. When rumors started about various government entities setting up charging networks, Tesla still went ahead and established their own Supercharger Network in advance of those efforts. This definitely paid off for Tesla and it’s customers later on.

With “critical thinking and root cause analysis,” Stevenson explained that, as part of Tesla’s mission, the company sought out renewable energy sources in hopes that they would become more prevalent on the grid. In turn, Tesla recognized that energy storage was “the missing piece.” Therefore, Tesla pushed forward and built their own Powerpack stationary storage product line in order to help implement grid-based solutions for renewables. One slide (see below) also highlighted Tesla’s recent acquisition of SolarCity as part of this 360-degree sustainable energy solution.

With “continuous improvement” Stevenson reminded us that software companies have been using this approach for some time. In Tesla’s case, the Gigafactory itself is a key example — as Tesla decided to build one section at a time in order to quickly start work within the building, it proceeded to continue construction — building additional sections and applying key learnings along the way. In addition, Stevenson also cited Tesla Autopilot as a prime example of continuous improvement.

Highlighting three of Tesla’s current special projects, Stevenson discussed: the solar roof, autopilot, and factory automation (the machine that builds the machine). Most fascinating was when Stevenson reviewed Tesla’s factory automation (referred to internally as MTBTM) as a mission-critical internal initiative. A slide (see above) also pointed out Germany’s Grohmann Engineering which the company recently acquired. He noted that Tesla didn’t want to rely so strongly on suppliers as it felt like “shopping from a catalog” and, instead, wanted more control via vertical integration.

Stevenson emphasized the Model 3 as the core focus right now companywide. But he also laid out five future challenges (see above) Tesla is currently facing: 1. Selling sustainable energy; 2. Scaling service and support; 3. Building a global company; 4. Re-thinking the materials supply chain; and 5. Recruiting and education. And he acknowledged plans for the Tesla truck (in the Q&A) and mentioned “developing a Tesla product to address all the vehicle segments” as part of Tesla’s future plans. For Stevenson’s full presentation, check out the video below.

Energy

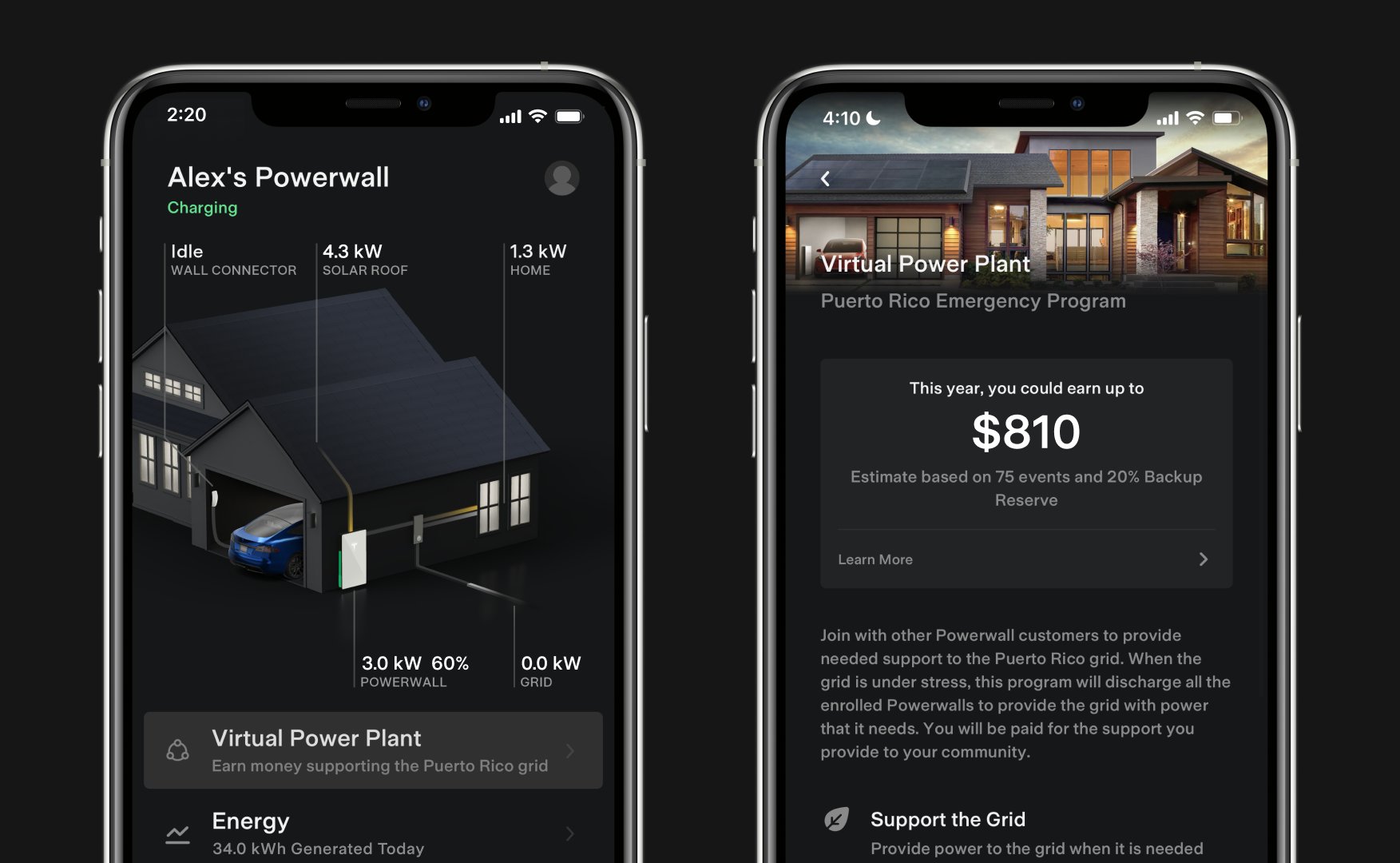

Tesla launches first Virtual Power Plant in UK – get paid to use solar

Tesla has launched its first-ever Virtual Power Plant program in the United Kingdom.

Tesla has launched its first-ever Virtual Power Plant program in the United Kingdom. This feature enables users of solar panels and energy storage systems to sell their excess energy back to the grid.

Tesla is utilizing Octopus Energy, a British renewable energy company that operates in multiple markets, including the UK, France, Germany, Italy, Spain, Australia, Japan, New Zealand, and the United States, as the provider for the VPP launch in the region.

The company states that those who enroll in the program can earn up to £300 per month.

Tesla has operated several VPP programs worldwide, most notably in California, Texas, Connecticut, and the U.S. territory of Puerto Rico. This is not the first time Tesla has operated a VPP outside the United States, as there are programs in Australia, Japan, and New Zealand.

This is its first in the UK:

Our first VPP in the UK

You can get paid to share your energy – store excess energy in your Powerwall & sell it back to the grid

You’re making £££ and the community is powered by clean energy

Win-win pic.twitter.com/evhMtJpgy1

— Tesla UK (@tesla_uk) July 17, 2025

Tesla is not the only company that is working with Octopus Energy in the UK for the VPP, as it joins SolarEdge, GivEnergy, and Enphase as other companies that utilize the Octopus platform for their project operations.

It has been six years since Tesla launched its first VPP, as it started its first in Australia back in 2019. In 2024, Tesla paid out over $10 million to those participating in the program.

Participating in the VPP program that Tesla offers not only provides enrolled individuals with the opportunity to earn money, but it also contributes to grid stabilization by supporting local energy grids.

Energy

Tesla Lathrop Megafactory celebrates massive Megapack battery milestone

The Tesla Megapack is the backbone of Tesla Energy’s battery deployments.

The Tesla Lathrop Megafactory recently achieved a new milestone. As per the official Tesla Megapack account on X, the Lathrop Megafactory has produced its 15,000th Megapack 2 XL battery.

15,000 Megapack Batteries

Tesla celebrated the milestone with a photo of the Lathrop Megafactory team posing with a freshly produced Megapack battery. To commemorate the event, the team held balloons that spelled out “15,000” as they posed for the photo.

The Tesla Megapack is the backbone of Tesla Energy’s battery deployments. Designed for grid-scale applications, each Megapack offers 3.9 MWh of energy and 1.9 MW of power. The battery is extremely scalable, making it perfect for massive energy storage projects.

More Megafactories

The Lathrop Megafactory is Tesla’s first dedicated facility for its flagship battery storage system. It currently stands as the largest utility-scale battery factory in North America. The facility is capable of producing 10,000 Megapack batteries every year, equal to 40 GWh of clean energy storage.

Thanks to the success of the Megapack, Tesla has expanded its energy business by building and launching the Shanghai Megafactory, which is also expected to produce 40 GWh of energy storage per year. The ramp of the Shanghai Megafactory is quite impressive, with Tesla noting in its Q1 2025 Update Letter that the Shanghai Megafactory managed to produce over 100 Megapack batteries in the first quarter alone.

Tesla Energy’s Potential

During the first quarter earnings call, CEO Elon Musk stated that the Megapack is extremely valuable to the energy industry.

“The Megapack enables utility companies to output far more total energy than would otherwise be the case… This is a massive unlock on total energy output of any given grid over the course of a year. And utility companies are beginning to realize this and are buying in our Megapacks at scale,” Musk said.

Energy

Tesla Megapacks powers the xAI Colossus supercomputer

Tesla Megapacks step in to stabilize xAI’s Colossus supercomputer, replacing natural gas turbines. Musk’s ventures keep intertwining.

Tesla Megapack batteries will power the xAI Colossus supercomputer in Memphis to ensure power stability. The collaboration between Tesla and xAI highlights the synergy among Elon Musk’s ventures.

The artificial intelligence startup has integrated Tesla Megapacks to manage outages and demand surges, bolstering the facility’s reliability. The Greater Memphis Chamber announced that Colossus, recently connected to a new 150-megawatt electric substation, is completing its first construction phase. This transition addresses criticism from environmental justice groups over the initial use of natural gas turbines.

“The temporary natural gas turbines that were being used to power the Phase I GPUs prior to grid connection are now being demobilized and will be removed from the site over the next two months.

“About half of the operating turbines will remain operating to power Phase II GPUs of xAI until a second substation (#22) already in construction is completed and connected to the electric grid, which is planned for the Fall of 2025, at which time the remaining turbines will be relegated to a backup power role,” the Chamber stated.

xAI’s rapid development of Colossus reflects its ambition to advance AI capabilities, but the project has faced scrutiny for environmental impacts. The shift to Megapacks and grid power aims to mitigate these concerns while ensuring operational continuity.

The Megapack deployment underscores the collaboration among Musk’s companies, including Tesla, SpaceX, Neuralink, and The Boring Company. Tesla appears to be the common link between all of Musk’s companies. For example, The Boring Company built a tunnel in Giga, Texas. In addition, Musk has hinted at a potential collaboration between the Tesla Optimus Bot and Neuralink. And from January 2024 to February 2025, xAI invested $230 million in Megapacks, per a Tesla filing.

Tesla Energy reported a 156% year-over-year increase in Q1 2025, deploying 10.4 GWh of storage products, including Megapacks and Powerwalls. Tesla’s plans for a new Megapack factory in Waller County, Texas, which is expected to create 1,500 jobs in the area, further signal its commitment to scaling energy solutions.

As xAI leverages Tesla’s Megapacks to power Colossus, the integration showcases Musk’s interconnected business ecosystem. The supercomputer’s enhanced stability positions xAI to drive AI innovation, while Tesla’s energy solutions gain prominence, setting the stage for broader technological and economic impacts.

-

Elon Musk1 day ago

Elon Musk1 day agoWaymo responds to Tesla’s Robotaxi expansion in Austin with bold statement

-

News1 day ago

News1 day agoTesla exec hints at useful and potentially killer Model Y L feature

-

Elon Musk2 days ago

Elon Musk2 days agoElon Musk reveals SpaceX’s target for Starship’s 10th launch

-

Elon Musk3 days ago

Elon Musk3 days agoTesla ups Robotaxi fare price to another comical figure with service area expansion

-

News1 day ago

News1 day agoTesla’s longer Model Y did not scale back requests for this vehicle type from fans

-

News1 day ago

News1 day ago“Worthy of respect:” Six-seat Model Y L acknowledged by Tesla China’s biggest rivals

-

News2 days ago

News2 days agoFirst glimpse of Tesla Model Y with six seats and extended wheelbase

-

Elon Musk2 days ago

Elon Musk2 days agoElon Musk confirms Tesla is already rolling out a new feature for in-car Grok