News

SpaceX’s first redesigned Raptor static fire paves the way for Starship’s hop test debut

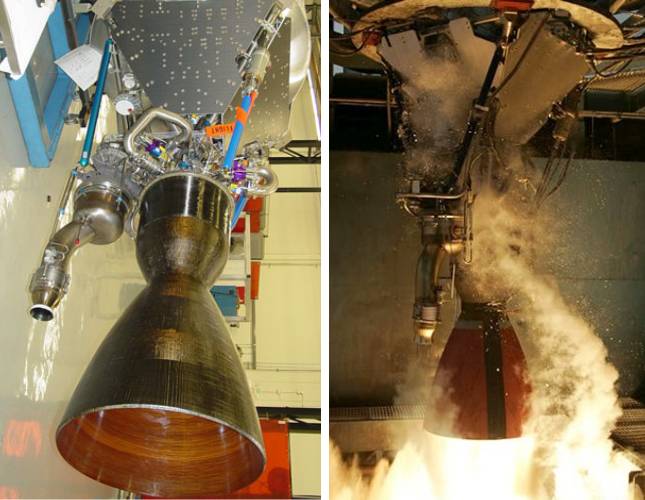

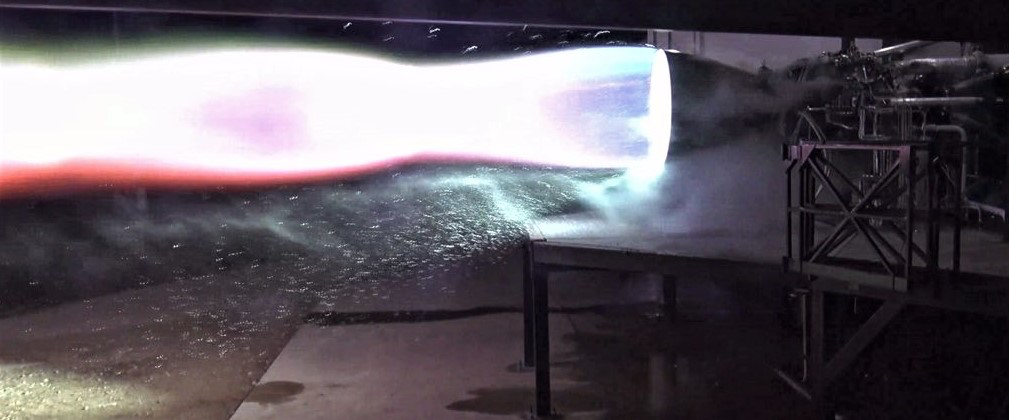

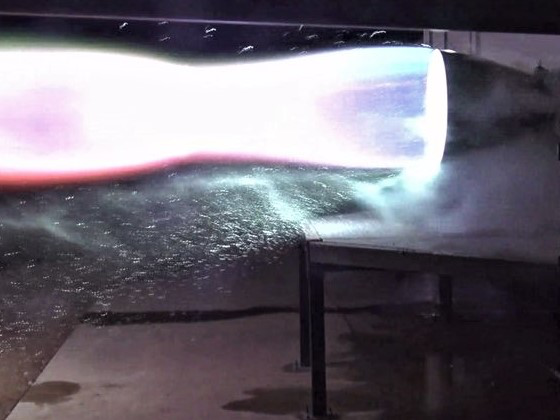

After years of development, multiple prototypes constructed, and more than 1200 seconds of cumulative static fire testing at durations longer than what is needed to land on Mars, SpaceX propulsion engineers and technicians have successfully built and static-fired the first flight-worthy Raptor for the first time ever.

This is an incredibly important step towards BFR (Starship/Super Heavy) launch operations and is even more directly encouraging for the first integrated hop tests of SpaceX’s Starship prototype (unofficially deemed Starhopper), which could very well be the next host of the pathfinder Raptor engine pictured below.

— Elon Musk (@elonmusk) February 4, 2019

In the scope of SpaceX’s history designing, building, and optimizing large-scale rocket engines, Raptor’s development likely followed a similar path. While Merlin 1 operates on a dramatically simpler combustion cycle (gas-generator), uses different fuel (kerolox vs. methalox), and is significantly less powerful and efficient than Raptor (as proposed), the workhorse engine went through a range of dramatically different iterations (Merlin 1A, 1B, 1C, and 1D) and is scarcely recognizable when its earliest block is compared to its most recent version. Merlin 1A began as an ablatively cooled 340 kN (76,000 lbf) engine, while the current workhorse (generally known as Merlin 1D Full Thrust, M1D FT) features a regeneratively-cooled nozzle and produces more than 840 kN (190,000 lbf), nearly a threefold improvement in thrust.

- Merlin 1A. (SpaceX)

- Merlin 1C – SpaceX considered but never actually built Merlin 1B. (Steve Jurvetson)

- Fresh Block 5 Merlin 1D engines are built and assembled in Hawthorne, CA before heading to Texas for testing. (SpaceX)

- An exceptional chart showing the extensive changes SpaceX’s Merlin family has undergone in more than a decade of development and operation. (www.B14643.de)

Raptor’s subscale prototype – featuring twice the chamber pressure of M1D (200 bar, ~3000 psi) and around the same maximum thrust as Merlin 1D (~1000 kN, 225,000 lbf) – can effectively be examined as the Merlin 1A to the Merlin 1C or 1D-class Raptor that SpaceX’s propulsion team settled on after learning from its smaller predecessors.

Performed on a Raptor-specific test cell at SpaceX’s McGregor, Texas “Rocket Ranch”, this milestone static fire was enabled by what one can safely assume were dozens or hundreds of lessons-learned over the course of two years of prototype engine testing and iterative improvement, working up to a quasi-final design that was shipped to Texas and installed just a few days ago. To kick off the first critical static fire of the pathfinder Raptor hardware, reports from ground observers indicate that SpaceX engineers began with a series of extremely short ‘blip’ tests that appeared perhaps 2-3 seconds from ignition to shutdown.

— Elon Musk (@elonmusk) February 4, 2019

Starhopper’s one-stop hop spot

The immensely encouraging news of Raptor Block 1’s first successful static fire comes as SpaceX engineers, technicians, and contractors work around the clock to build both the first full-scale Starship prototype (nicknamed Starhopper) and the spartan pad it will lift off from during hop tests. SpaceX’s Boca Chica facilities were marked by a burst of pad-related activity over the last week or two, including the early installation of a range of pipes (some of it insulated for supercool cryogenic methane and oxygen) and the creation of a berm pointing towards the probable location of Starhopper’s simple launch mount and pad. ‘

While the Starship prototype’s three Raptor engines will dramatically outclass Falcon 9’s Grasshopper and F9R development vehicles (also used for hop tests), it’s possible that the same setup – basically a flat (refractory?) concrete pad with GSE (ground support equipment) protected behind a berm and automated water jet turrets around the vicinity – could work for Starhopper, too. For now, the successful static fire of the first post-development Raptor engine marks a massive step towards those initial hop tests and towards the first orbital launches of Starship and Super Heavy a bit further down the road. Stay tuned as SpaceX continues to extensively test Raptor and build out its Boca Chica pad and Starship prototype.

1-31-19 #SpaceX pic.twitter.com/VUgbxApjEc

— Austin Barnard🚀 (@austinbarnard45) February 1, 2019

Check out Teslarati’s newsletters for prompt updates, on-the-ground perspectives, and unique glimpses of SpaceX’s rocket launch and recovery processes!

Elon Musk

Elon Musk hints Tesla investors will be rewarded heavily

“Hold onto your Tesla stock. It’s going to be worth a lot, I think. That’s my bet,” Musk said.

Elon Musk recently hinted that he believes Tesla investors will be rewarded heavily if they continue to hold onto their shares, and he reiterated that in a new interview that the company released on its social accounts this week.

Musk is one of the most successful CEOs in the modern era and has mammothed competitors on the Forbes Net Worth List over the past year as his holdings in his various companies have continued to swell.

Tesla investors, especially those who have been holding shares for several years, have also felt substantial gains in their portfolios. Over the past five years, the stock is up over 78 percent. Since February 2019, nearly seven years ago to the day, the stock is up over 1,800 percent.

Musk said in the interview:

“Hold onto your Tesla stock. It’s going to be worth a lot, I think. That’s my bet.”

Elon Musk in new interview: “Hold on to your $TSLA stock. It’s going to be worth a lot, I think. That’s my bet.” pic.twitter.com/cucirBuhq0

— Sawyer Merritt (@SawyerMerritt) February 26, 2026

It’s no secret Musk has been extremely bullish on his own companies, but Tesla in particular, because it is publicly traded.

However, the company has so many amazing projects that have an opportunity to revolutionize their respective industries. There is certainly a path to major growth on Wall Street for Tesla through its various future projects, including Optimus, Cybercab, Semi, and Unsupervised FSD.

- Optimus (Tesla’s humanoid robot): Musk has discussed its potential for tasks like childcare, walking dogs, or assisting elderly parents, positioning it as a massive long-term driver of company value.

- Cybercab (Tesla’s robotaxi/autonomous ride-hailing vehicle): a fully autonomous vehicle geared specifically for Tesla’s ride-sharing ambitions.

- Semi (Tesla’s electric truck, with mentions of expansion, like in Europe): brings Tesla into the commercial logistics sector.

- Unsupervised FSD (Full Self-Driving software achieving full autonomy without human supervision): turns every Tesla owner’s vehicle into a fully-autonomous vehicle upon release

These projects specifically are some of the highest-growth pillars Tesla has ever attempted to develop, especially in Musk’s eyes, as he has said Optimus will be the best-selling product of all-time.

Many analysts agree, but the bullish ones, like Cathie Wood of ARK Invest, are perhaps the one who believes Tesla has incredible potential on Wall Street, predicting a $2,600 price target for 2030, but this is not even including Optimus.

She told Bloomberg last March that she believes that the project will present a potential additive if Tesla can scale faster than anticipated.

Cybertruck

Tesla drops latest hint that new Cybertruck trim is selling like hotcakes

According to Tesla’s Online Design Studio, the new All-Wheel-Drive Cybertruck will now be delivered in April 2027. Earlier orders are still slated for early this Summer, but orders from here on forward are now officially pushed into next year:

Tesla’s new Cybertruck offering has had its delivery date pushed back once again. This is now the second time, and deliveries for the newest orders are now pushed well into 2027.

According to Tesla’s Online Design Studio, the new All-Wheel-Drive Cybertruck will now be delivered in April 2027. Earlier orders are still slated for early this Summer, but orders from here on forward are now officially pushed into next year:

🚨 Tesla has updated the $59,990 Cybertruck Dual Motor AWD’s estimated delivery date to April 2027.

First deliveries are still slated for June, but if you order it now, you’ll be waiting over a year.

Demand appears to be off the charts for the new Cybertruck and consumers are… pic.twitter.com/raDCCeC0zP

— TESLARATI (@Teslarati) February 26, 2026

Just three days ago, the initial delivery date of June 2026 was pushed back to early Fall, and now, that date has officially moved to April 2027.

The fact that Tesla has had to push back deliveries once again proves one of two things: either Tesla has slow production plans for the new Cybertruck trim, or demand is off the charts.

Judging by how Tesla is already planning to raise the price based on demand in just a few days, it seems like the company knows it is giving a tremendous deal on this spec of Cybertruck, and units are moving quickly.

That points more toward demand and not necessarily to slower production plans, but it is not confirmed.

Tesla Cybertruck’s newest trim will undergo massive change in ten days, Musk says

Tesla is set to hike the price on March 1, so tomorrow will be the final day to grab the new Cybertruck trim for just $59,990.

It features:

- Dual Motor AWD w/ est. 325 mi of range

- Powered tonneau cover

- Bed outlets (2x 120V + 1x 240V) & Powershare capability

- Coil springs w/ adaptive damping

- Heated first-row seats w/ textile material that is easy to clean

- Steer-by-wire & Four Wheel Steering

- 6’ x 4’ composite bed

- Towing capacity of up to 7,500 lbs

- Powered frunk

Interestingly, the price offering is fairly close to what Tesla unveiled back in late 2019.

Elon Musk

Elon Musk outlines plan for first Starship tower catch attempt

Musk confirmed that Starship V3 Ship 1 (SN1) is headed for ground tests and expressed strong confidence in the updated vehicle design.

Elon Musk has clarified when SpaceX will first attempt to catch Starship’s upper stage with its launch tower. The CEO’s update provides the clearest teaser yet for the spacecraft’s recovery roadmap.

Musk shared the details in recent posts on X. In his initial post, Musk confirmed that Starship V3 Ship 1 (SN1) is headed for ground tests and expressed strong confidence in the updated vehicle design.

“Starship V3 SN1 headed for ground tests. I am highly confident that the V3 design will achieve full reusability,” Musk wrote.

In a follow-up post, Musk addressed when SpaceX would attempt to catch the upper stage using the launch tower’s robotic arms.

“Should note that SpaceX will only try to catch the ship with the tower after two perfect soft landings in the ocean. The risk of the ship breaking up over land needs to be very low,” Musk clarified.

His remarks suggest that SpaceX is deliberately reducing risk before attempting a tower catch of Starship’s upper stage. Such a milestone would mark a major step towards the full reuse of the Starship system.

SpaceX is currently targeting the first Starship V3 flight of 2026 this coming March. The spacecraft’s V3 iteration is widely viewed as a key milestone in SpaceX’s long-term strategy to make Starship fully reusable.

Starship V3 features a number of key upgrades over its previous iterations. The vehicle is equipped with SpaceX’s Raptor V3 engines, which are designed to deliver significantly higher thrust than earlier versions while reducing cost and weight.

The V3 design is also expected to be optimized for manufacturability, a critical step if SpaceX intends to scale the spacecraft’s production toward frequent launches for Starlink, lunar missions, and eventually Mars.