News

Tesla China pushes back MIC Model 3 deliveries amid coronavirus outbreak

As the novel coronavirus outbreak continues in China, Tesla has opted to postpone MIC Model 3 deliveries scheduled for February, at least until the situation in the country improves. The update was related by Tesla China VP for External Affairs Grace Tao Lin, who noted on Weibo that MIC Model 3 deliveries will likely be pushed back, perhaps as far back as the third quarter of 2020.

Giga Shanghai currently has a run rate of 3,000 Model 3s per week and is poised to hit an annual production rate of 150,000 vehicles. The company has also launched the Model Y program in the country. With these in mind, the recently-announced delays will likely set back the ramp of the locally-made Model 3, while potentially pushing back the Model Y program in the country.

Interestingly enough, Tesla has noted that it does not expect a big financial hit in China due to the coronavirus outbreak. This is because the MIC Model 3 only represents a small fraction of the company’s quarterly profits, according to Tesla’s finance chief Zach Kirkhorn during the company’s Q4 2019 earnings call.

Analysts currently expect markets to underperform because of the ongoing coronavirus outbreak. However, Tesla seems to be defying the odds so far. This week, the Tesla stock continued to soar, with the Silicon Valley-based electric carmaker surpassing the current valuation of Volkswagen and BMW combined on Monday. Tesla’s price per share hit past $900 and settled at $887.06 when the market closed on Tuesday

The real impact of production delays and supply chain issues might be felt soon though if the closure of factories across China will be stretched to mid-March. Automotive research firm IHS Markit estimates that carmakers may lose about 1.7 million units during the first quarter of 2020. This corresponds to a 32.3% decline from the firm’s initial estimates.

“In this scenario, we might expect the potential of a China-wide supply chain disruption caused by parts shortages from Hubei, a major component hub — and adjacent province closures for the majority of the month of February as a result,” IHS Markit wrote in a press release.

The Shanghai government has ordered the shutdown of companies in the city, including Giga Shanghai, amid the coronavirus outbreak. Government and private companies are not allowed to resume operations before Feb. 9. Prior to the suspension of work, the government has also extended the Lunar New Year holidays to help control the spread of the 2019-nCOV that started in Wuhan, a city about 9 hours away by car from Shanghai.

Tesla is not the sole automaker that is being affected by the ongoing outbreak. Hyundai, Toyota, Ford, Nissan, Volkswagen, Daimler, and Continental have also shut down their respective factories in China due to the virus.

Based on the latest updates, there are more than 24,000 people infected by the coronavirus that causes fever, serious respiratory illness, impaired liver function, and kidney failure. As of Wednesday local time, there have been 490 deaths reported in connection to the virus. The World Health Organization has declared the outbreak, which has infected people in 25 countries, a public health emergency. The United States and several countries have also implemented travel bans to and from China.

In response to the coronavirus outbreak, Tesla China has offered local customers free Supercharging for an indefinite time to make traveling easier for drivers who reside in areas affected by the outbreak.

Amid the public health scare, Tesla has continued to provide customer support through Douyin, China’s version of TikTok. Tesla sales staff from certain experience centers live-streamed tours of the Made-in-China Model 3 and entertained questions from potential buyers. The company has also posted schedules of the live streams that interested consumers can join via Douyin.

Meanwhile, Tesla owners in China united to raise 123,000 yuan or about $17,500 to purchase N95 masks, surgical masks, and sets of protective clothing that they plan to donate to different hospitals treating patients infected by the coronavirus. Tesla has also donated 5 million yuan or more than $700,000 to assist the government and other institutions involved in disease control.

The recent news from China appears to have weighed down on Tesla stock. As of writing, TSLA stock is trading

News

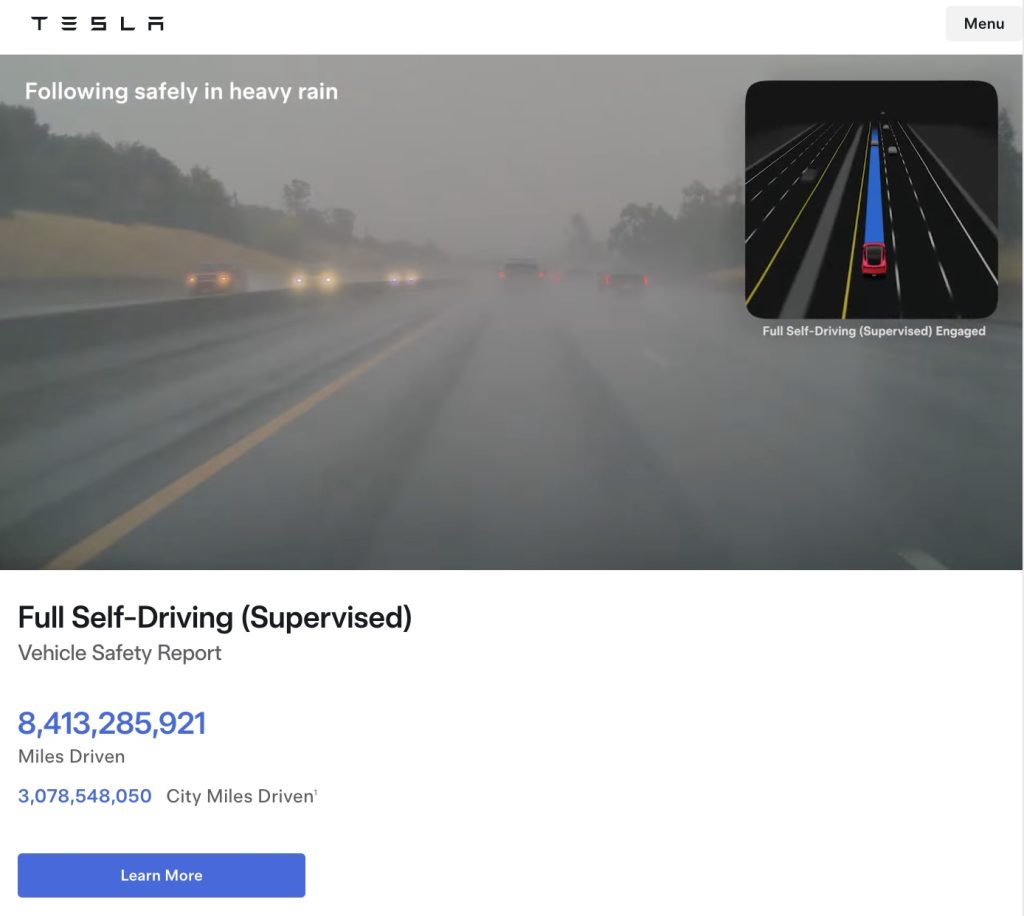

Tesla FSD (Supervised) fleet passes 8.4 billion cumulative miles

The figure appears on Tesla’s official safety page, which tracks performance data for FSD (Supervised) and other safety technologies.

Tesla’s Full Self-Driving (Supervised) system has now surpassed 8.4 billion cumulative miles.

The figure appears on Tesla’s official safety page, which tracks performance data for FSD (Supervised) and other safety technologies.

Tesla has long emphasized that large-scale real-world data is central to improving its neural network-based approach to autonomy. Each mile driven with FSD (Supervised) engaged contributes additional edge cases and scenario training for the system.

The milestone also brings Tesla closer to a benchmark previously outlined by CEO Elon Musk. Musk has stated that roughly 10 billion miles of training data may be needed to achieve safe unsupervised self-driving at scale, citing the “long tail” of rare but complex driving situations that must be learned through experience.

The growth curve of FSD Supervised’s cumulative miles over the past five years has been notable.

As noted in data shared by Tesla watcher Sawyer Merritt, annual FSD (Supervised) miles have increased from roughly 6 million in 2021 to 80 million in 2022, 670 million in 2023, 2.25 billion in 2024, and 4.25 billion in 2025. In just the first 50 days of 2026, Tesla owners logged another 1 billion miles.

At the current pace, the fleet is trending towards hitting about 10 billion FSD Supervised miles this year. The increase has been driven by Tesla’s growing vehicle fleet, periodic free trials, and expanding Robotaxi operations, among others.

With the fleet now past 8.4 billion cumulative miles, Tesla’s supervised system is approaching that threshold, even as regulatory approval for fully unsupervised deployment remains subject to further validation and oversight.

Elon Musk

Elon Musk fires back after Wikipedia co-founder claims neutrality and dubs Grokipedia “ridiculous”

Musk’s response to Wales’ comments, which were posted on social media platform X, was short and direct: “Famous last words.”

Elon Musk fired back at Wikipedia co-founder Jimmy Wales after the longtime online encyclopedia leader dismissed xAI’s new AI-powered alternative, Grokipedia, as a “ridiculous” idea that is bound to fail.

Musk’s response to Wales’ comments, which were posted on social media platform X, was short and direct: “Famous last words.”

Wales made the comments while answering questions about Wikipedia’s neutrality. According to Wales, Wikipedia prides itself on neutrality.

“One of our core values at Wikipedia is neutrality. A neutral point of view is non-negotiable. It’s in the community, unquestioned… The idea that we’ve become somehow ‘Wokepidea’ is just not true,” Wales said.

When asked about potential competition from Grokipedia, Wales downplayed the situation. “There is no competition. I don’t know if anyone uses Grokipedia. I think it is a ridiculous idea that will never work,” Wales wrote.

After Grokipedia went live, Larry Sanger, also a co-founder of Wikipedia, wrote on X that his initial impression of the AI-powered Wikipedia alternative was “very OK.”

“My initial impression, looking at my own article and poking around here and there, is that Grokipedia is very OK. The jury’s still out as to whether it’s actually better than Wikipedia. But at this point I would have to say ‘maybe!’” Sanger stated.

Musk responded to Sanger’s assessment by saying it was “accurate.” In a separate post, he added that even in its V0.1 form, Grokipedia was already better than Wikipedia.

During a past appearance on the Tucker Carlson Show, Sanger argued that Wikipedia has drifted from its original vision, citing concerns about how its “Reliable sources/Perennial sources” framework categorizes publications by perceived credibility. As per Sanger, Wikipedia’s “Reliable sources/Perennial sources” list leans heavily left, with conservative publications getting effectively blacklisted in favor of their more liberal counterparts.

As of writing, Grokipedia has reportedly surpassed 80% of English Wikipedia’s article count.

News

Tesla Sweden appeals after grid company refuses to restore existing Supercharger due to union strike

The charging site was previously functioning before it was temporarily disconnected in April last year for electrical safety reasons.

Tesla Sweden is seeking regulatory intervention after a Swedish power grid company refused to reconnect an already operational Supercharger station in Åre due to ongoing union sympathy actions.

The charging site was previously functioning before it was temporarily disconnected in April last year for electrical safety reasons. A temporary construction power cabinet supplying the station had fallen over, described by Tesla as occurring “under unclear circumstances.” The power was then cut at the request of Tesla’s installation contractor to allow safe repair work.

While the safety issue was resolved, the station has not been brought back online. Stefan Sedin, CEO of Jämtkraft elnät, told Dagens Arbete (DA) that power will not be restored to the existing Supercharger station as long as the electric vehicle maker’s union issues are ongoing.

“One of our installers noticed that the construction power had been backed up and was on the ground. We asked Tesla to fix the system, and their installation company in turn asked us to cut the power so that they could do the work safely.

“When everything was restored, the question arose: ‘Wait a minute, can we reconnect the station to the electricity grid? Or what does the notice actually say?’ We consulted with our employer organization, who were clear that as long as sympathy measures are in place, we cannot reconnect this facility,” Sedin said.

The union’s sympathy actions, which began in March 2024, apply to work involving “planning, preparation, new connections, grid expansion, service, maintenance and repairs” of Tesla’s charging infrastructure in Sweden.

Tesla Sweden has argued that reconnecting an existing facility is not equivalent to establishing a new grid connection. In a filing to the Swedish Energy Market Inspectorate, the company stated that reconnecting the installation “is therefore not covered by the sympathy measures and cannot therefore constitute a reason for not reconnecting the facility to the electricity grid.”

Sedin, for his part, noted that Tesla’s issue with the Supercharger is quite unique. And while Jämtkraft elnät itself has no issue with Tesla, its actions are based on the unions’ sympathy measures against the electric vehicle maker.

“This is absolutely the first time that I have been involved in matters relating to union conflicts or sympathy measures. That is why we have relied entirely on the assessment of our employer organization. This is not something that we have made any decisions about ourselves at all.

“It is not that Jämtkraft elnät has a conflict with Tesla, but our actions are based on these sympathy measures. Should it turn out that we have made an incorrect assessment, we will correct ourselves. It is no more difficult than that for us,” the executive said.