Investor's Corner

Tesla streamlined Model 3 battery pack production time by 96%, says Elon Musk

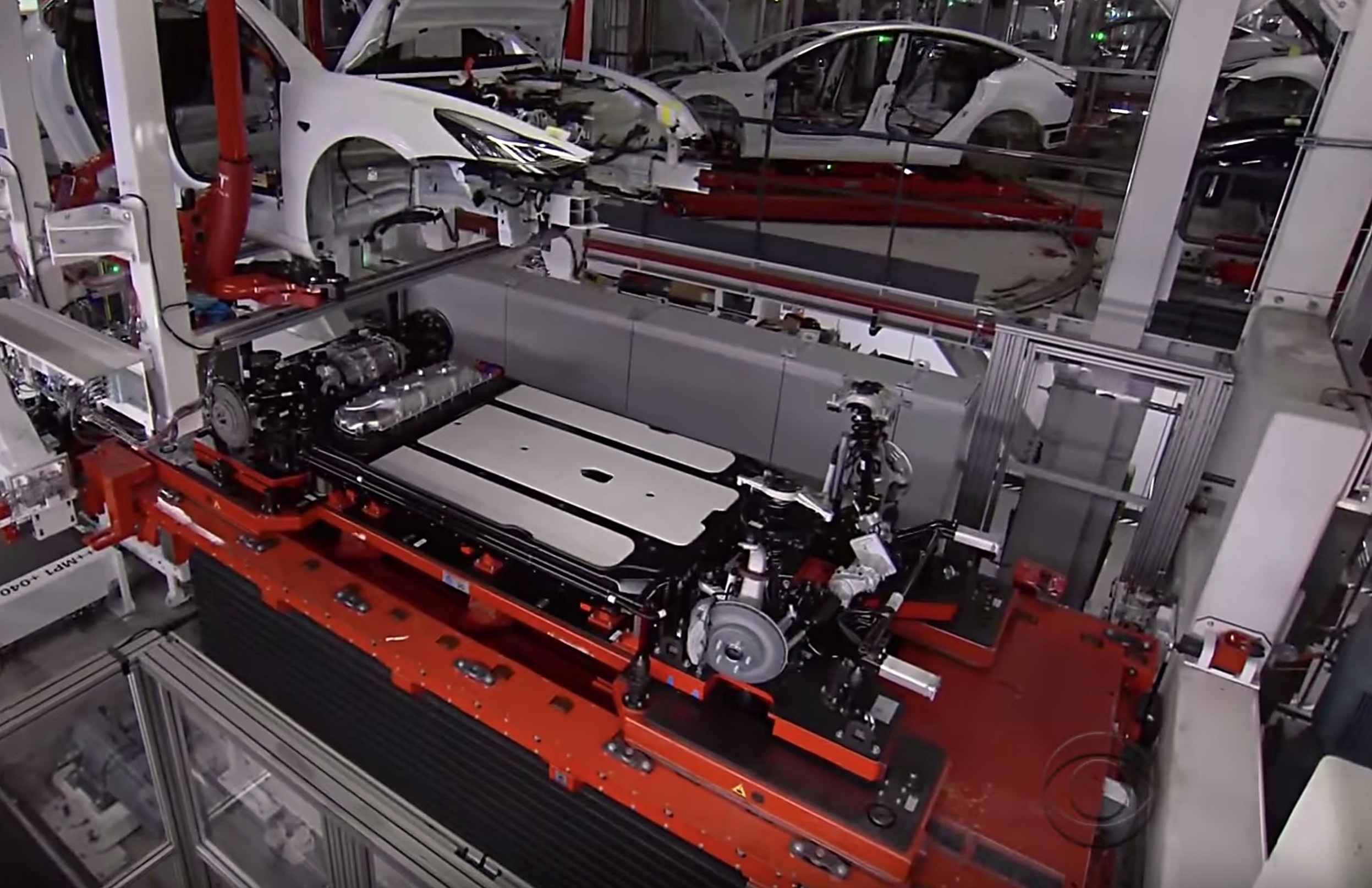

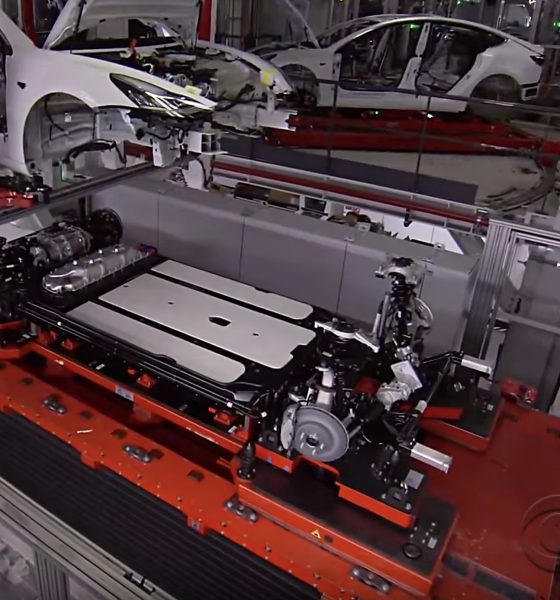

Tesla CEO Elon Musk stated during Wednesday’s Q1 2018 earnings call that the company has managed to reduce the time it takes to produce a Model 3 battery pack by 94%, from 7 hours to under 17 minutes. According to Musk, addressing the over-generalization of the Model 3’s design, as well as the excessive automation in Gigafactory, proved beneficial to the improvement in the manufacturing rate of the car’s battery packs.

“This still remains to be fixed, but in any case, overgeneralizing the design. For example, the current battery pack has a port for front drive units, which we then put a steel blanking plate on. So essentially, we punched a hole in it and put a blanking plate at the hole. And (we had to) do that for all rear drive unit cars, which is kinda crazy.

“It would have added cost, it would have added a manufacturing step, it would have added a failure mode; and four ports was unnecessary… That’s changed. So, the result was we had a rapid improvement in battery pack production, from taking 7 hrs to make a pack 3 weeks ago to under 17 minutes now. We’re able to also achieve a sustained rate of 3,000 vehicles a week, so we’re actually slightly ahead in battery module and pack production than expected.”

With the optimizations to the line in place, Musk revealed that Tesla is now producing 3,000 battery packs per week at the Nevada Gigafactory, with peak hours of production hitting a rate of 5,000 per week.

“In the last 24 hours at the Gigafactory, we managed to keep a sustained rate of over 3,000 packs per week. We actually reached a peak hour, extrapolated outward would be a rate of over 5,000 cars per week… Every hour is as good as its peak. If you can achieve it even once in an hour, then with continued refinement of the system, and improved operational time of the machinery, you can achieve that sustained rate with more refinement.”

Musk reiterated his previous statement about the company automating too much of its production line. According to Musk, Tesla “went too far and automated some pretty silly things,” including an incredibly complex “fluff machine” that ended up making production complicated.

“One of the things we’ve found is that there are some things that are very well suited to manual operations, and there are some things are very well suited to automated operations. The two should not be confused. We did go too far in the automation front, and automated some pretty silly things.

“One example would be, we have these fiberglass mats on top of the battery pack. They’re basically fluff. We tried to automate the placement and bonding of fluff to the top of the battery pack, which was ridiculous. ‘Flufferbot,’ which was really an incredibly difficult machine to make work. Machines are not good at picking up pieces of fluff. Hands are way better at doing that.

“So we had this super-complicated machine, using a vision system to try and put a piece of fluff on a battery pack. The line kept breaking down because Flufferbot would frequently fail to pick up the fluff, or put it in a random location. So, that was one of the silliest things we’ve found.”

The revelations about the improvements in the pace of Model 3 battery pack production are in line with Elon Musk’s recent statements about relying too much on automation. Musk mentioned this in an interview with Gayle King of CBS This Morning, and later in a tweet, where he coyly stated that humans are “underrated.”

Nevertheless, Tesla pointed to strategic automation as key in its Q1 Update Letter. The company, for one, credits the quality improvements in the Model 3 line to the automation that is involved in manufacturing the vehicles. Tesla expects the Model 3 line to be optimized once more after a planned 10-day shutdown in production during the second quarter. With a hiring ramp underway, Tesla is aiming to adjust overtime hours and staffing levels to meet its production goals even further.

Tesla’s first-quarter earnings for 2018 saw the electric car maker posting $3.4 billion in revenue and beating earnings estimates with a loss of $568 million. Losses per share was listed at -$3.35 per share, lower than Wall Street estimates of -$3.58 per share.

Investor's Corner

Tesla gets tip of the hat from major Wall Street firm on self-driving prowess

“Tesla is at the forefront of autonomous driving, supported by a camera-only approach that is technically harder but much cheaper than the multi-sensor systems widely used in the industry. This strategy should allow Tesla to scale more profitably compared to Robotaxi competitors, helped by a growing data engine from its existing fleet,” BoA wrote.

Tesla received a tip of the hat from major Wall Street firm Bank of America on Wednesday, as it reinitiated coverage on Tesla shares with a bullish stance that comes with a ‘Buy’ rating and a $460 price target.

In a new note that marks a sharp reversal from its neutral position earlier in 2025, the bank declared Tesla’s Full Self-Driving (FSD) technology the “leading consumer autonomy solution.”

Analysts highlighted Tesla’s camera-only architecture, known as Tesla Vision, as a strategic masterstroke. While technically more challenging than the multi-sensor setups favored by rivals, the vision-based approach is dramatically cheaper to produce and maintain.

This cost edge, combined with Tesla’s rapidly expanding real-world data engine, positions the company to scale robotaxis far more profitably than competitors, BofA argues in the new note:

“Tesla is at the forefront of autonomous driving, supported by a camera-only approach that is technically harder but much cheaper than the multi-sensor systems widely used in the industry. This strategy should allow Tesla to scale more profitably compared to Robotaxi competitors, helped by a growing data engine from its existing fleet.”

The bank now attributes roughly 52% of Tesla’s total valuation to its Robotaxi ambitions. It also flagged meaningful upside from the Optimus humanoid robot program and the fast-growing energy storage business, suggesting the auto segment’s recent headwinds, including expired incentives, are being eclipsed by these higher-margin opportunities.

Tesla’s own data underscores exactly why Wall Street is waking up to FSD’s potential. According to Tesla’s official safety reporting page, the FSD Supervised fleet has now surpassed 8.4 billion cumulative miles driven.

Tesla FSD (Supervised) fleet passes 8.4 billion cumulative miles

That total ballooned from just 6 million miles in 2021 to 80 million in 2022, 670 million in 2023, 2.25 billion in 2024, and a staggering 4.25 billion in 2025 alone. In the first 50 days of 2026, owners added another 1 billion miles — averaging more than 20 million miles per day.

This avalanche of real-world, camera-captured footage, much of it on complex city streets, gives Tesla an unmatched training dataset. Every mile feeds its neural networks, accelerating improvement cycles that lidar-dependent rivals simply cannot match at scale.

Tesla owners themselves will tell you the suite gets better with every release, bringing new features and improvements to its self-driving project.

The $460 target implies roughly 15 percent upside from recent trading levels around $400. While regulatory and safety hurdles remain, BofA’s endorsement signals growing institutional conviction that Tesla’s data advantage is not hype; it’s a tangible moat already delivering billions of miles of proof.

Elon Musk

SpaceX IPO could push Elon Musk’s net worth past $1 trillion: Polymarket

The estimates were shared by the official Polymarket Money account on social media platform X.

Recent projections have outlined how a potential $1.75 trillion SpaceX IPO could generate historic returns for early investors. The projections suggest the offering would not only become the largest IPO in history but could also result in unprecedented windfalls for some of the company’s key investors.

The estimates were shared by the official Polymarket Money account on social media platform X.

As noted in a Polymarket Money analysis, Elon Musk invested $100 million into SpaceX in 2002 and currently owns approximately 42% of the company. At a $1.75 trillion valuation following SpaceX’s potential $1.75 trillion IPO, that stake would be worth roughly $735 billion.

Such a figure would dramatically expand Musk’s net worth. When combined with his holdings in Tesla Inc. and other ventures, a public debut at that level could position him as the world’s first trillionaire, depending on market conditions at the time of listing.

The Bloomberg Billionaires Index currently lists Elon Musk with a net worth of $666 billion, though a notable portion of this is tied to his TSLA stock. Tesla currently holds a market cap of $1.51 trillion, and Elon Musk’s currently holds about 13% to 15% of the company’s outstanding common stock.

Founders Fund, co-founded by Peter Thiel, invested $20 million in SpaceX in 2008. Polymarket Money estimates the firm owns between 1.5% and 3% of the private space company. At a $1.75 trillion valuation, that range would translate to approximately $26.25 billion to $52.5 billion in value.

That return would represent one of the most significant venture capital outcomes in modern Silicon Valley history, with a growth of 131,150% to 262,400%.

Alphabet Inc., Google’s parent company, invested $900 million into SpaceX in 2015 and is estimated to hold between 6% and 7% of the private space firm. At the projected IPO valuation, that stake could be worth between $105 billion and $122.5 billion. That’s a growth of 11,566% to 14,455%.

Other major backers highlighted in the post include Fidelity Investments, Baillie Gifford, Valor Equity Partners, Bank of America, and Andreessen Horowitz, each potentially sitting on multibillion-dollar gains.

Elon Musk

Elon Musk hints Tesla investors will be rewarded heavily

“Hold onto your Tesla stock. It’s going to be worth a lot, I think. That’s my bet,” Musk said.

Elon Musk recently hinted that he believes Tesla investors will be rewarded heavily if they continue to hold onto their shares, and he reiterated that in a new interview that the company released on its social accounts this week.

Musk is one of the most successful CEOs in the modern era and has mammothed competitors on the Forbes Net Worth List over the past year as his holdings in his various companies have continued to swell.

Tesla investors, especially those who have been holding shares for several years, have also felt substantial gains in their portfolios. Over the past five years, the stock is up over 78 percent. Since February 2019, nearly seven years ago to the day, the stock is up over 1,800 percent.

Musk said in the interview:

“Hold onto your Tesla stock. It’s going to be worth a lot, I think. That’s my bet.”

Elon Musk in new interview: “Hold on to your $TSLA stock. It’s going to be worth a lot, I think. That’s my bet.” pic.twitter.com/cucirBuhq0

— Sawyer Merritt (@SawyerMerritt) February 26, 2026

It’s no secret Musk has been extremely bullish on his own companies, but Tesla in particular, because it is publicly traded.

However, the company has so many amazing projects that have an opportunity to revolutionize their respective industries. There is certainly a path to major growth on Wall Street for Tesla through its various future projects, including Optimus, Cybercab, Semi, and Unsupervised FSD.

- Optimus (Tesla’s humanoid robot): Musk has discussed its potential for tasks like childcare, walking dogs, or assisting elderly parents, positioning it as a massive long-term driver of company value.

- Cybercab (Tesla’s robotaxi/autonomous ride-hailing vehicle): a fully autonomous vehicle geared specifically for Tesla’s ride-sharing ambitions.

- Semi (Tesla’s electric truck, with mentions of expansion, like in Europe): brings Tesla into the commercial logistics sector.

- Unsupervised FSD (Full Self-Driving software achieving full autonomy without human supervision): turns every Tesla owner’s vehicle into a fully-autonomous vehicle upon release

These projects specifically are some of the highest-growth pillars Tesla has ever attempted to develop, especially in Musk’s eyes, as he has said Optimus will be the best-selling product of all-time.

Many analysts agree, but the bullish ones, like Cathie Wood of ARK Invest, are perhaps the one who believes Tesla has incredible potential on Wall Street, predicting a $2,600 price target for 2030, but this is not even including Optimus.

She told Bloomberg last March that she believes that the project will present a potential additive if Tesla can scale faster than anticipated.