News

SpaceX’s Starlink satellites “happy and healthy” as Elon Musk fires managers and VP

Reuters is reporting that SpaceX’s Starlink internet satellite constellation project experienced significant organizational upheaval earlier this year, triggered by fundamental disagreements between CEO Elon Musk and executives overseeing Starlink as to how exactly SpaceX should approach the complex system’s development.

Despite the report’s primary focus on reorganization and Musk’s decision to simply fire 5+ key executives, SpaceX employees that spoke with Reuters were of the opinion that the two demo satellites – named Tintin A and B – are operating nominally in orbit more than half a year after launch.

The 2 test sats launched in Feb, Tintin A and B, seem to be healthy. "We’re talking with them every time they pass a ground station, dozens of times a day," one employee said. In the first week they streamed "4k YouTube and played ‘Counter-Strike: GO’ from Hawthorne to Redmond."

— Joey Roulette (@joroulette) October 31, 2018

Musk apparently believed that Starlink’s development timeline ought to be far shorter than certain senior executives overseeing the program were planning for. As a result of continuing success with the first two prototype satellites that launched in March 2018, a SpaceX engineer paraphrased Musk as being of the opinion that Starlink “can do the job with cheaper and simpler satellites, sooner.”

Rajeev Badyal, Vice President of SpaceX’s satellite program before being fired by Musk in June 2018, apparently wanted another three full iterations of prototype satellites to be launched and tested prior to beginning serious mass-production and launching the first real batch of Starlink satellites. While his extremely cautious approach may have had undeniable long-term benefits, it would also be a major hindrance in a field now rife with competitors like Telesat, OneWeb, LeoSat, and more, all eager to be first to offer internet services from low Earth orbit (LEO).

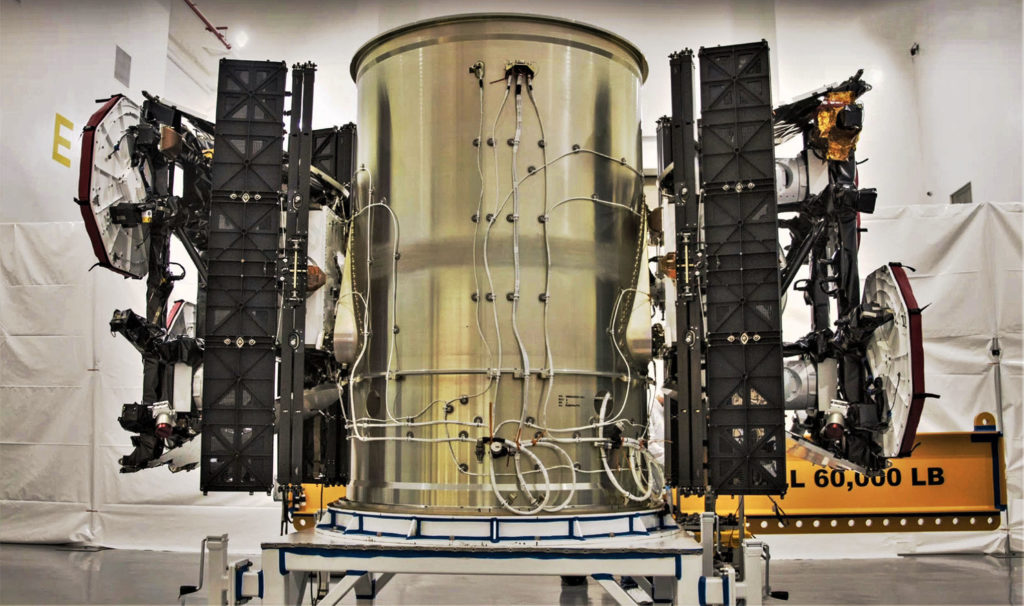

- SpaceX’s first two Starlink prototype satellites are pictured here before their inaugural launch, showing off a thoroughly utilitarian bus and several advanced components. (SpaceX)

- One of the first two prototype Starlink satellites separates from Falcon 9’s upper stage, February 2018. (SpaceX)

Prior to joining SpaceX in 2014, Badyal – like dozens of others now working on SpaceX’s Starlink constellation – worked at Microsoft for almost two decades, developing the consumer electronics and software company’s hardware programs (Zune, Xbox, Surface, etc.). In retrospect, it may not come as a huge surprise that a senior hardware development manager at Microsoft might be moderately risk-averse or at least methodical – while Surface and other more modern hardware programs have more functional iterative life cycles (usually annual), Xbox infamously spent nearly seven years between the launch of the Xbox 360 and Xbox One.

On the ground hardware side of Starlink development, user terminals, ground terminals, and other high-volume networking equipment could certainly benefit from someone like Badyal’s extensive experience developing high-volume consumer electronics like Xbox, but the Starlink satellites themselves are a different story. As a technology essentially without precedent, it could ultimately be almost anachronistically expensive to ‘refine’ the design of constellations of hundreds or thousands of high-bandwidth internet satellites before ever actually building and operating such a system.

A clash of approaches – Musk vs. Silicon Valley

What Musk instead seems to prefer – as demonstrated through his strategic direction of Tesla and SpaceX – is an approach where hardware development projects explicitly avoid striving for perfection with the first general iteration of a new system. Tesla did not spend years prototyping and performing limited tests in secret before building Model 3 as their first car ever – high-volume desirable electric vehicles simply did not exist. With SpaceX, Musk chose to explicitly develop a very small operational rocket – Falcon 1 – rather than very tediously attempting to go from scratch to Falcon 9 or BFR.

For Starlink, a Musk-style development program would fast-track a bare-minimum baseline for the satellite constellation and its ground systems, mass-producing and launching hardware that would inevitably be lacking in many ways but would still be able to act as a proving ground for the broader concepts at stake. One step further, the FCC’s Starlink constellation grant depends on an odd but unwavering requirement that SpaceX (or any other prospective LEO constellation-operator) launch at least 50% of all of any planned constellation within six years of receiving a license.

- SpaceX’s first Starlink prototypes launched in late February aboard a flight-proven Falcon 9 booster. (Pauline Acalin)

- Falcon 9 Block 5 will be absolutely critical to the success (and even the basic completion) of Starlink. (Tom Cross)

- B1048 returns to port on drone ship JRTI after its successful July 2019 launch debut. (Pauline Acalin)

For SpaceX, that means that the basic ability to commercially operate Starlink is fundamentally at risk unless the company can somehow launch a minimum of 2213 (and up to ~5950) Starlink satellites between 2018 and 2024, an almost unfathomable challenge. Assuming ~500kg per satellite and perhaps 20 satellites per Falcon 9 launch, completing 50% of Starlink by 2024 would demand – without interruption – a minimum of one launch every two weeks for five years, mid-2019 to mid-2024. As such, every month spent prototyping and refining can essentially be viewed as a month where SpaceX didn’t launch dozens of Starlink satellites in pursuit of initial operational capabilities.

The news coming from Reuters’ reporting is ultimately a very positive look at Starlink, aside from Musk’s characteristically brusque and uncompromising approach to program management and leadership. Employees spoke proudly of the operational health and overall success of the two Tintin satellites already on orbit, noting that “they’re happy and healthy [and functioning as intended], and we’re talking with them [dozens of times a day] every time they pass a ground station”. Contrary to tenuous evidence to that suggested one of the two satellites had suffered an anomaly, preventing it from operating its electric thrusters, it appears that both satellites are doing just fine.

- SpaceX is already fairly experienced with launching multi-satellite missions and building custom payload adapters. (NASA)

- During a normal Iridium NEXT launch, two groups of five satellites are stacked on top of each other. Here, the top stack was replaced by NASA/DLR’s GRACE-FO spacecraft. (NASA)

- A spectacular view of Iridium NEXT satellites during orbital deployment. Starlink deployment will be even more of a spectacle. (SpaceX)

Up next for Starlink is the launch of a second batch of demonstration satellites, expected to occur “in short order” according to an official SpaceX comment on the matter.

“Given the success of our recent Starlink demonstration satellites, we have incorporated lessons learned and re-organized to allow for the next design iteration to be flown in short order.” – SpaceX spokesperson Eva Behrend

Musk’s ultimate hope with this reorganization is to push Starlink to begin operational satellite launches as early as mid-2019, an ambitious goal to say the least. Understandably, the intent with such an expedited schedule would be to continuously modify, update, and improve Starlink satellite, terminal, and network designs at the same time as they are being built and operated. Much like SpaceX and Tesla, this helps to ensure that the ultimate result of development is a rapid initial product offering eventually followed by a highly-optimized ‘finished’ product.

For prompt updates, on-the-ground perspectives, and unique glimpses of SpaceX’s rocket recovery fleet check out our brand new LaunchPad and LandingZone newsletters!

News

Tesla Cybercab spotted with interesting charging solution, stimulating discussion

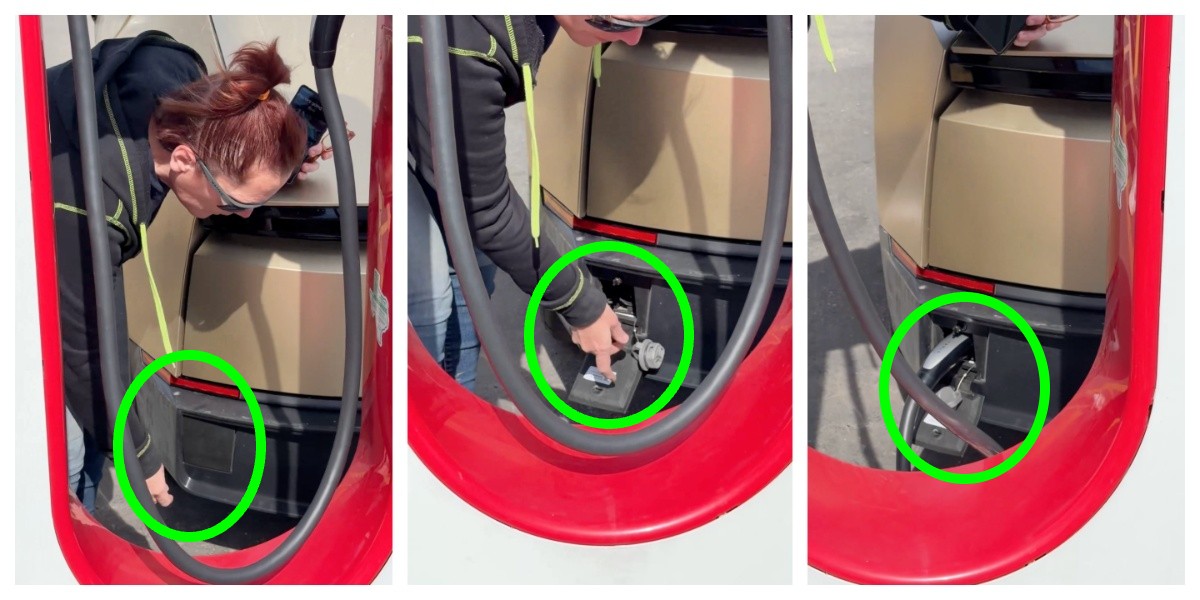

The port is located in the rear of the vehicle and features a manual door and latch for plug-in, and the video shows an employee connecting to a Tesla Supercharger.

Tesla Cybercab units are being tested publicly on roads throughout various areas of the United States, and a recent sighting of the vehicle’s charging port has certainly stimulated some discussions throughout the community.

The Cybercab is geared toward being a fully-autonomous vehicle, void of a steering wheel or pedals, only operating with the use of the Full Self-Driving suite. Everything from the driving itself to the charging to the cleaning is intended to be operated autonomously.

But a recent sighting of the vehicle has incited some speculation as to whether the vehicle might have some manual features, which would make sense, but let’s take a look:

🚨 Tesla Cybercab charging port is in the rear of the vehicle!

Here’s a great look at plugging it in!!

— TESLARATI (@Teslarati) January 29, 2026

The port is located in the rear of the vehicle and features a manual door and latch for plug-in, and the video shows an employee connecting to a Tesla Supercharger.

Now, it is important to remember these are prototype vehicles, and not the final product. Additionally, Tesla has said it plans to introduce wireless induction charging in the future, but it is not currently available, so these units need to have some ability to charge.

However, there are some arguments for a charging system like this, especially as the operation of the Cybercab begins after production starts, which is scheduled for April.

Wireless for Operation, Wired for Downtime

It seems ideal to use induction charging when the Cybercab is in operation. As it is for most Tesla owners taking roadtrips, Supercharging stops are only a few minutes long for the most part.

The Cybercab would benefit from more frequent Supercharging stops in between rides while it is operating a ride-sharing program.

Tesla wireless charging patent revealed ahead of Robotaxi unveiling event

However, when the vehicle rolls back to its hub for cleaning and maintenance, standard charging, where it is plugged into a charger of some kind, seems more ideal.

In the 45-minutes that the car is being cleaned and is having maintenance, it could be fully charged and ready for another full shift of rides, grabbing a few miles of range with induction charging when it’s out and about.

Induction Charging Challenges

Induction charging is still something that presents many challenges for companies that use it for anything, including things as trivial as charging cell phones.

While it is convenient, a lot of the charge is lost during heat transfer, which is something that is common with wireless charging solutions. Even in Teslas, the wireless charging mat present in its vehicles has been a common complaint among owners, so much so that the company recently included a feature to turn them off.

Production Timing and Potential Challenges

With Tesla planning to begin Cybercab production in April, the real challenge with the induction charging is whether the company can develop an effective wireless apparatus in that short time frame.

It has been in development for several years, but solving the issue with heat and energy loss is something that is not an easy task.

In the short-term, Tesla could utilize this port for normal Supercharging operation on the Cybercab. Eventually, it could be phased out as induction charging proves to be a more effective and convenient option.

News

Tesla confirms that it finally solved its 4680 battery’s dry cathode process

The suggests the company has finally resolved one of the most challenging aspects of its next-generation battery cells.

Tesla has confirmed that it is now producing both the anode and cathode of its 4680 battery cells using a dry-electrode process, marking a key breakthrough in a technology the company has been working to industrialize for years.

The update, disclosed in Tesla’s Q4 and FY 2025 update letter, suggests the company has finally resolved one of the most challenging aspects of its next-generation battery cells.

Dry cathode 4680 cells

In its Q4 and FY 2025 update letter, Tesla stated that it is now producing 4680 cells whose anode and cathode were produced during the dry electrode process. The confirmation addresses long-standing questions around whether Tesla could bring its dry cathode process into sustained production.

The disclosure was highlighted on X by Bonne Eggleston, Tesla’s Vice President of 4680 batteries, who wrote that “both electrodes use our dry process.”

Tesla first introduced the dry-electrode concept during its Battery Day presentation in 2020, pitching it as a way to simplify production, reduce factory footprint, lower costs, and improve energy density. While Tesla has been producing 4680 cells for some time, the company had previously relied on more conventional approaches for parts of the process, leading to questions about whether a full dry-electrode process could even be achieved.

4680 packs for Model Y

Tesla also revealed in its Q4 and FY 2025 Update Letter that it has begun producing battery packs for certain Model Y vehicles using its in-house 4680 cells. As per Tesla:

“We have begun to produce battery packs for certain Model Ys with our 4680 cells, unlocking an additional vector of supply to help navigate increasingly complex supply chain challenges caused by trade barriers and tariff risks.”

The timing is notable. With Tesla preparing to wind down Model S and Model X production, the Model Y and Model 3 are expected to account for an even larger share of the company’s vehicle output. Ensuring that the Model Y can be equipped with domestically produced 4680 battery packs gives Tesla greater flexibility to maintain production volumes in the United States, even as global battery supply chains face increasing complexity.

Elon Musk

Tesla Giga Texas to feature massive Optimus V4 production line

This suggests that while the first Optimus line will be set up in the Fremont Factory, the real ramp of Optimus’ production will happen in Giga Texas.

Tesla will build Optimus 4 in Giga Texas, and its production line will be massive. This was, at least, as per recent comments by CEO Elon Musk on social media platform X.

Optimus 4 production

In response to a post on X which expressed surprise that Optimus will be produced in California, Musk stated that “Optimus 4 will be built in Texas at much higher volume.” This suggests that while the first Optimus line will be set up in the Fremont Factory, and while the line itself will be capable of producing 1 million humanoid robots per year, the real ramp of Optimus’ production will happen in Giga Texas.

This was not the first time that Elon Musk shared his plans for Optimus’ production at Gigafactory Texas. During the 2025 Annual Shareholder Meeting, he stated that Giga Texas’ Optimus line will produce 10 million units of the humanoid robot per year. He did not, however, state at the time that Giga Texas would produce Optimus V4.

“So we’re going to launch on the fastest production ramp of any product of any large complex manufactured product ever, starting with building a one-million-unit production line in Fremont. And that’s Line one. And then a ten million unit per year production line here,” Musk stated.

How big Optimus could become

During Tesla’s Q4 and FY 2025 earnings call, Musk offered additional context on the potential of Optimus. While he stated that the ramp of Optimus’ production will be deliberate at first, the humanoid robot itself will have the potential to change the world.

“Optimus really will be a general-purpose robot that can learn by observing human behavior. You can demonstrate a task or verbally describe a task or show it a task. Even show it a video, it will be able to do that task. It’s going to be a very capable robot. I think long-term Optimus will have a very significant impact on the US GDP.

“It will actually move the needle on US GDP significantly. In conclusion, there are still many who doubt our ambitions for creating amazing abundance. We are confident it can be done, and we are making the right moves technologically to ensure that it does. Tesla, Inc. has never been a company to shy away from solving the hardest problems,” Musk stated.