News

SpaceX will host Hyperloop Pod Competition next week, Jan 27-29, 2017

Get ready to see Hyperloop concept pods fire through the 1-mile test track located outside of SpaceX and Tesla’s Design Studio in Hawthorne, California, next week between January 27-29. Elon Musk and SpaceX first unveiled the idea for a new high-speed ground transport system called the Hyperloop on August 12, 2013 with the publication of a white paper, the Hyperloop Alpha Preliminary Design Study. SpaceX’s sponsored Hyperloop Pod Competition is an incentive prize competition created to inspire university students and independent engineering teams to design and build a subscale prototype transport vehicle (a “Hyperloop pod”) that will demonstrate technical feasibility of various aspects of the high speed transportation concept. To support this competition, SpaceX has constructed a test track outside of its headquarters which we had the opportunity to see during early construction last year.

There are three judging phases in the Hyperloop Pod competition: a design competition that was held in January 2016 and an on-track competition to be held January 27–29, 2017 (Competition Weekend I), followed by a Summer 2017 (Competition Weekend II). The original specification for the Competition Basic for the Design Weekend and the competition Weekend I, though no longer available at SpaceX, can still be found online.

DESIGN WEEKEND

The Design weekend was held in January 2016 at Texas A&M University. Awards were given in three categories:

SUBSYSTEM

Best Overall Subsystem Award: Auburn University | Auburn University Hyperloop Team.

DESIGN ONLY

Top Design Concept Award: Universitat Politècnica de Valencia | Makers UPV Team

DESIGN AND BUILD CATEGORY OVERALL

Massachusetts Institute of Technology | MIT Hyperloop Team

MIT Hyperloop Team’s design was awarded the “Best Overall Design Award”, among the 23 designs selected to move to the prototype stage. The design proposes a 250 kg (551 lb) pod with a carbon fiber and polycarbonate sheet exterior. It is elevated by a passive magnetic levitation system comprising 20 neodymium magnets that will maintain a 15 mm (0.6 in) distance above the track. The team says with air pressure at 140 Pascals, the pod could accelerate at 2.4 G and have 2 Newton aerodynamic drag when traveling at 110 m/s. The design includes a fail-safe braking system that automatically halts the pod should the actuators or computers fail, and low speed emergency drive wheels that can move the pod 1 m/s. Delft Hyperloop received a “Pod Innovation Award”, while Badgerloop at University of Wisconsin, Madison, Hyperloop at Virginia Tech, and HyperXite at UC Irvine each received a “Pod Technical Excellence Award.” The full list of Awards and news clips from the Design Weekend can be found at the Texas A&M University Engineering web site. Besides the winning teams, several other teams were invited to compete in the upcoming Competition Weekend I from the Design and Build category:

- rLoop (Non-student team)

- University of Waterloo | uWaterloo Hyperloop

- University of Washington | UWashington Hyperloop

- University of Toronto | University of Toronto

- University of Maryland and Rutgers University | RUMD Loop

- University of Florida | GatorLoop

- University of of Colorado, Denver | Team HyperLynx

- University of Cincinnati | Hyperloop UC

- University of California, Santa Barbara | UCSB Hyperloop

- University of California, Berkeley | bLoop

- Texas A&M University | TAMU Aerospace Hyperloop

- Technical University of Munich | WARR Hyperloop

- Purdue University | Purdue Hyperloop Design Team

- Oral Roberts University | Codex

- Lehigh University | Lehigh Hyperloop

- Keio University | Keio Alpha

- Drexel University | Drexel Hyperloop

- Carnegie Mellon University | Carnegie Mellon Hyperloop

In February 3, 2016 eight more teams advanced to Competition Weekend I.

- Cornell University + Harvey Mudd College + University of Michigan + Northeastern University + Memorial University of Newfoundland(Canada) + Princeton University | OpenLoop

- Louisiana State University | Bayou Bengals

- New York University | NYU Hyperloop

- RMIT University | VicHyper

- John’s High School | HyperLift

- University of Illinois at Urbana-Champaign | Illini Hyperloop

- University of Southern California | USC Hyperloop

- University of Wisconsin, Milwaukee | Mercury Three

In the end, 30 of the 115 teams that submitted designs in January 2016 were selected to build hardware to compete in Competition Weekend I. There were more than 1,000 applicants at earlier stages of the competition.

JUDGING CRITERIA

Originally, the second Phase of the competition was supposed to involve competitive runs in the Hyperloop test track to be awarded based on various classes (fully functional pod, susbsystem test pod, etc.) and pod mass. This phase of the competition was renamed“Competition Weekend I,” when SpaceX added a third phase of the competition, Competition Weekend II. The original SpaceX Hyperloop Pod Competition – Rules and Requirements for Weekend I can be seen at the end of this article. We’ve embedded a copy of the original document from SpaceX.

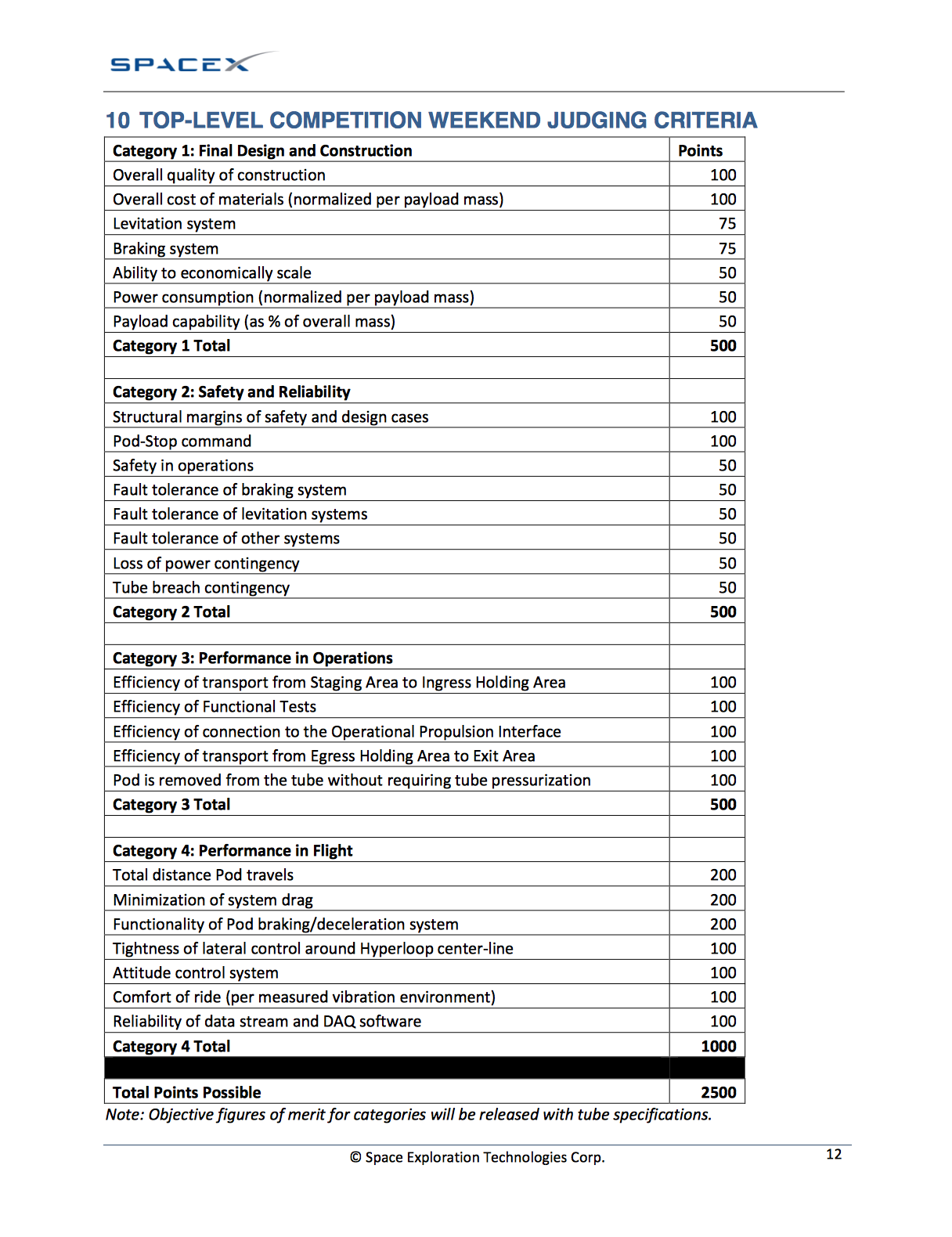

The Judging Criteria are listed in the document, and involve scoring in 4 different categories, for a maximum overall total of 2500 points.

- Category 1: Final Design and Construction (500 points)

- Category 2: Safety and Reliability (500 points)

- Category 3: Performance in Operations (500 points)

- Category 4: Performance in Flight (1000 points)

HYPERLOOP TEST TRACK

AECOM, a company that has designed and built some of the world’s most impressive transportation systems, was selected to design and build the world’s first Hyperloop test track as part of the pod competition hosted by SpaceX

The track is a straight one-mile run on Jack Northrop Avenue, between Crenshaw Blvd. and Prairie Ave. The SpaceX Hyperloop test track — or Hypertube — was designed in 2015 and was constructed in the fall 2016, reaching its full length of one mile by October 2016. The test track’s six-foot diameter steel tube includes a non-magnetic sub-track and said to be capable of achieving 99.8 percent vacuum. The test track itself is also a prototype, where SpaceX anticipates learning from the design, build process and evaluates how to apply automated construction techniques to future Hyperloop tracks.

The Hypertube test track is designed to enable competitors who implement a wide array of designs and build pods that will test a variety of subsystem technologies that are important to new vehicle transport systems. This will include Hyperloop-specific pods—with air-bearing suspension and low-pressure compressor designs—as well as wheeled vehicle and magnetic levitation rail designs that will support a wide array of vehicle technologies to be tested. While the Design Weekend held at Texas A&M University was open to the public, it is unclear if the Competition Weekend I will be as well, or if it will be an invitation only event like many of the SpaceX and Tesla events. Several inquiries for tickets posted to the Twitter account of the Hyperloop Pod Competition went unanswered. The Official SpaceX Hyperloop Pod Competition page does not shed any light on who will be able to attend either.

HYPERLOOP POD COMPETITION II

According to SpaceX, “based on the high-quality submissions and overwhelming enthusiasm surrounding the competition, SpaceX is moving forward with a second installment of the competition: Hyperloop Pod Competition II, which will culminate in a second competition in Summer 2017 at SpaceX’s Hyperloop test track. Hyperloop Competition II will be focused on a single criterion: maximum speed. The second competition is open to new student teams interested in competing on the test track, as well as to existing student teams who have already built and tested Pods to further refine their designs.” The Competition Weekend II event will be held in the Summer 2017 at the same SpaceX Hyperloop test track.

[pdf-embedder url=”http://www.teslarati.com/wp-content/uploads/2017/01/spacex-hyperloop-competition-rules.pdf”]

Cybertruck

Tesla drops latest hint that new Cybertruck trim is selling like hotcakes

According to Tesla’s Online Design Studio, the new All-Wheel-Drive Cybertruck will now be delivered in April 2027. Earlier orders are still slated for early this Summer, but orders from here on forward are now officially pushed into next year:

Tesla’s new Cybertruck offering has had its delivery date pushed back once again. This is now the second time, and deliveries for the newest orders are now pushed well into 2027.

According to Tesla’s Online Design Studio, the new All-Wheel-Drive Cybertruck will now be delivered in April 2027. Earlier orders are still slated for early this Summer, but orders from here on forward are now officially pushed into next year:

🚨 Tesla has updated the $59,990 Cybertruck Dual Motor AWD’s estimated delivery date to April 2027.

First deliveries are still slated for June, but if you order it now, you’ll be waiting over a year.

Demand appears to be off the charts for the new Cybertruck and consumers are… pic.twitter.com/raDCCeC0zP

— TESLARATI (@Teslarati) February 26, 2026

Just three days ago, the initial delivery date of June 2026 was pushed back to early Fall, and now, that date has officially moved to April 2027.

The fact that Tesla has had to push back deliveries once again proves one of two things: either Tesla has slow production plans for the new Cybertruck trim, or demand is off the charts.

Judging by how Tesla is already planning to raise the price based on demand in just a few days, it seems like the company knows it is giving a tremendous deal on this spec of Cybertruck, and units are moving quickly.

That points more toward demand and not necessarily to slower production plans, but it is not confirmed.

Tesla Cybertruck’s newest trim will undergo massive change in ten days, Musk says

Tesla is set to hike the price on March 1, so tomorrow will be the final day to grab the new Cybertruck trim for just $59,990.

It features:

- Dual Motor AWD w/ est. 325 mi of range

- Powered tonneau cover

- Bed outlets (2x 120V + 1x 240V) & Powershare capability

- Coil springs w/ adaptive damping

- Heated first-row seats w/ textile material that is easy to clean

- Steer-by-wire & Four Wheel Steering

- 6’ x 4’ composite bed

- Towing capacity of up to 7,500 lbs

- Powered frunk

Interestingly, the price offering is fairly close to what Tesla unveiled back in late 2019.

Elon Musk

Elon Musk outlines plan for first Starship tower catch attempt

Musk confirmed that Starship V3 Ship 1 (SN1) is headed for ground tests and expressed strong confidence in the updated vehicle design.

Elon Musk has clarified when SpaceX will first attempt to catch Starship’s upper stage with its launch tower. The CEO’s update provides the clearest teaser yet for the spacecraft’s recovery roadmap.

Musk shared the details in recent posts on X. In his initial post, Musk confirmed that Starship V3 Ship 1 (SN1) is headed for ground tests and expressed strong confidence in the updated vehicle design.

“Starship V3 SN1 headed for ground tests. I am highly confident that the V3 design will achieve full reusability,” Musk wrote.

In a follow-up post, Musk addressed when SpaceX would attempt to catch the upper stage using the launch tower’s robotic arms.

“Should note that SpaceX will only try to catch the ship with the tower after two perfect soft landings in the ocean. The risk of the ship breaking up over land needs to be very low,” Musk clarified.

His remarks suggest that SpaceX is deliberately reducing risk before attempting a tower catch of Starship’s upper stage. Such a milestone would mark a major step towards the full reuse of the Starship system.

SpaceX is currently targeting the first Starship V3 flight of 2026 this coming March. The spacecraft’s V3 iteration is widely viewed as a key milestone in SpaceX’s long-term strategy to make Starship fully reusable.

Starship V3 features a number of key upgrades over its previous iterations. The vehicle is equipped with SpaceX’s Raptor V3 engines, which are designed to deliver significantly higher thrust than earlier versions while reducing cost and weight.

The V3 design is also expected to be optimized for manufacturability, a critical step if SpaceX intends to scale the spacecraft’s production toward frequent launches for Starlink, lunar missions, and eventually Mars.

News

Tesla FSD (Supervised) could be approved in the Netherlands next month: Musk

Musk shared the update during a recent interview at Giga Berlin.

Tesla CEO Elon Musk shared that Full Self-Driving (FSD) could receive regulatory approval in the Netherlands as soon as March 20, potentially marking a major step forward for Tesla’s advanced driver-assistance rollout in Europe.

Musk shared the update during a recent interview at Giga Berlin, noting that the date was provided by local authorities.

“Tesla has the most advanced real-world AI, and hopefully, it will be approved soon in Europe. We’re told by the authorities that March 20th, it’ll be approved in the Netherlands,’ what I was told,” Musk stated.

“Hopefully, that date remains the same. But I think people in Europe are going to be pretty blown away by how good the Tesla car AI is in being able to drive.”

Tesla’s FSD system relies on vision-based neural networks trained on real-world driving data, allowing vehicles to navigate using cameras and AI rather than traditional sensor-heavy solutions.

The performance of FSD Supervised has so far been impressive. As per Tesla’s safety report, Full Self-Driving Supervised has already traveled 8.3 billion miles. So far, vehicles operating with FSD Supervised engaged recorded one major collision every 5,300,676 miles.

In comparison, Teslas driven manually with Active Safety systems recorded one major collision every 2,175,763 miles, while Teslas driven manually without Active Safety recorded one major collision every 855,132 miles. The U.S. average during the same period was one major collision every 660,164 miles.

If approval is granted on March 20, the Netherlands could become the first European market to greenlight Tesla’s latest supervised FSD (Supervised) software under updated regulatory frameworks. Tesla has been working to secure expanded FSD access across Europe, where regulatory standards differ significantly from those in the United States. Approval in the Netherlands would likely serve as a foundation for broader EU adoption, though additional country-level clearances may still be required.