News

SpaceX’s Starship rocket program just had one of its best nights yet

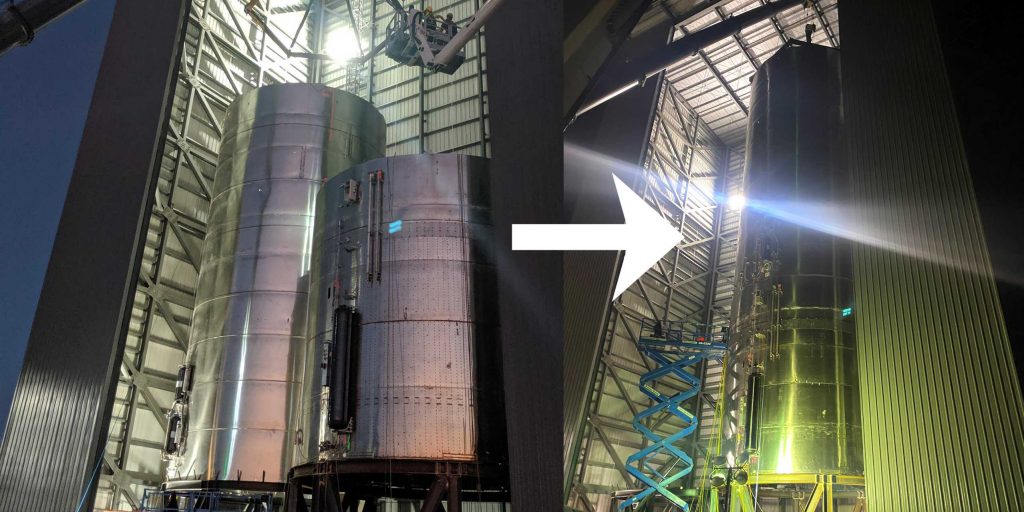

Before dawn on May 4th, SpaceX successfully fueled a full-scale Starship prototype and (partially) tested an installed Raptor engine for the first time ever – perhaps the Starship program’s best night yet.

While just a small test relative to what’s soon to come, the milestone is still an extremely significant one for SpaceX and its next-generation launch vehicle. Designed to launch atop the Super Heavy booster, both Starship and its booster are meant to be fully reusable, potentially making the launch system one of the cheapest in operation on Earth. Despite that unprecedented full reusability, they should still be able to place dozens (perhaps up to 100-150+) metric tons of payload into orbit in a single launch.

To get to that point, however, SpaceX must develop and demonstrate a cornucopia of technologies and approaches – most of which are unprecedented – at a scale unmatched by ever other launch vehicle in history, save two or three. It was perhaps the most fundamental of those steps that was on the table earlier this morning.

Perhaps the single most important and uncertain part of SpaceX’s ambitious Starship architecture, SpaceX’s May 4th wet dress rehearsal (WDR) was mainly a test of Starship’s overall structure and the manufacturing apparatus SpaceX has created to build it. Despite how exotic and challenging some of Starship’s goals may sound, SpaceX’s approach to production for its newest launch vehicle is arguably the single biggest risk for the program.

Notably, CEO Elon Musk says that the ultimate goal is to roll out a single finished Starship rocket every single week and at a cost of something like $5-10 million per vehicle. Including the Super Heavy booster, the production goals of which remain unknown, SpaceX effectively wants to mass-produce dozens of fully-reusable rockets – all larger (and potentially more capable) than NASA’s Saturn V Moon rocket – for anywhere from a tenth to a hundredth of the cost.

As if those goals weren’t ambitious enough, SpaceX intends to achieve them with perhaps the most spartan, minimalist factory ever attempted for orbital-class rockets. At the moment, all Starship hardware built by SpaceX to date has been manufactured in a series of tents, more recently graduating to a trio of warehouse-sized sprung structures. A large hangar – apparently dedicated to building pad infrastructure – is just shy of complete, while a separate windbreak structure and a vertical assembly building (VAB) are used to stack (assemble) full-scale Starship subsections built inside tents.

Unlike almost every other launch vehicle in history, Starship production – excluding its Raptor engines and certain other subassemblies and parts – is done in tents and is almost entirely divorced of the clean room operations rocket factories are famous for. Despite the extensive use of hand-welded seams and parts on SpaceX’s early Starship prototypes, the company has already proven that it’s well on its way to building Starships in just a week or two.

While it appears that SpaceX only performed a partial wet dress rehearsal with liquid methane and oxygen and completed a test of part of Starship SN4’s installed Raptor engine (known as the preburner), it means that a Starship has survived a truly launch vehicle-like procedure for the first time ever. In other words, Starship SN4’s May 4th success served as SpaceX’s most important verification yet that its exotic Starship manufacturing approach could be viable for building actual orbital-class rockets.

Up next, SpaceX will attempt to perform a full wet dress rehearsal (WDR) and a static fire test of Starship SN4 and its lone Raptor engine. That test attempt could come as soon as this evening.

Elon Musk

Elon Musk confirms Tesla Cybercab pricing and consumer release date

Elon Musk has confirmed that Tesla does intend to sell a version of the Cybercab for less than $30,000 by 2027.

Elon Musk has confirmed that Tesla does intend to sell a version of the Cybercab for less than $30,000 by 2027. He shared the update in a post on social media platform X.

Amidst Tesla’s announcement that the first Cybercab has been produced at Giga Texas’ production line, some members of the Tesla community immediately started joking about how the milestone will affect a wager shared by popular YouTube tech reviewer Marques Brownlee (MKBHD.)

Following Tesla’s We, Robot event in October 2024, MKBHD noted that while the Cybercab was impressive in a lot of ways, he is very skeptical about Elon Musk’s estimate that the autonomous two-seater could be sold to consumers for below $30,000 around 2027.

“I think the obvious red flag, the biggest red flag to me is the timeline stuff. This is notorious Elon stuff. He gets on stage, he says we’re going to have this vehicle out for $30,000 before 2027,” he said, adding “No, they’re not. There’s just no way that they’re actually going to be able to do that. I mean, if they do, let’s say they do, I will shave my head on camera because I’m that confident.”

It was then no surprise that meme images of MKBHD with his head shaved immediately spread on X following Tesla’s announcement that the first Cybercab has been built at Giga Texas. One of these, which was posted by longtime FSD tester Whole Mars Catalog, received a response from Elon Musk. The CEO responded with the words “Gonna happen,” together with a laughing emoji.

Apart from riding jokes about MKBHD’s wager, Musk also confirmed that Tesla will be selling a Cybercab to regular consumers before 2027, and the vehicle will be priced for $30,000 or less. In response to an X user who asked if the exact scenario will be happening, Musk responded with a simple “Yes.”

While the first Cybercab has been produced at Giga Texas, it would not be surprising if the following months will only see low volumes of the autonomous two seater being produced. As per Elon Musk in previous comments, the Cybercab’s early production will likely be slow, but it will eventually be extremely fast. “For Cybercab and Optimus, almost everything is new, so the early production rate will be agonizingly slow, but eventually end up being insanely fast,” he said.

Elon Musk

First Tesla Cybercab rolls off Giga Texas production line

Tesla’s official account on X shared an image showing employees gathered around the first Cybercab built at Gigafactory Texas.

Tesla has produced the first Tesla Cybercab at Texas Gigafactory, marking a key milestone ahead of the planned autonomous two-seater’s production in April. The two-seat Robotaxi, which was unveiled in 2024, is designed without pedals or a steering wheel and represents Tesla’s most aggressive step yet toward fully autonomous mobility.

Tesla’s official account on X shared an image showing employees gathered around the first Cybercab built at Gigafactory Texas. Elon Musk echoed the milestone, writing, “Congratulations to the Tesla team on making the first production Cybercab!”

Previous comments from Musk on X reiterated the idea that production of the Cybercab “starts in April.” The vehicle will launch without traditional driver controls, and it will rely entirely on Tesla’s vision-based Full Self-Driving (FSD) system.

The Cybercab is positioned to compete with autonomous services such as Waymo. While Tesla has deployed Model Y vehicles in limited Robotaxi operations in Austin and the Bay Area, a serious ramp of the service to other cities across the United States is yet to be implemented. The production of the Cybercab could then be seen as a push towards the company’s autonomy plans.

Musk has linked the Cybercab to Tesla’s proposed “Unboxed” manufacturing process, which would assemble large vehicle modules separately before integrating them, rather than following a traditional production line. The approach is intended to cut costs, reduce factory footprint, and speed up output.

That being said, Elon Musk has set expectations for the Cybercab’s production ramp. As per Musk, it would likely take some time before meaningful volumes of the Cybercab are produced because it is such a new and different vehicle. But when the vehicle hits its pace, volumes will be notable.

“Initial production is always very slow and follows an S-curve. The speed of production ramp is inversely proportionate to how many new parts and steps there are. For Cybercab and Optimus, almost everything is new, so the early production rate will be agonizingly slow, but eventually end up being insanely fast,” Musk noted.

Elon Musk

California city weighs banning Elon Musk companies like Tesla and SpaceX

A resolution draft titled, “Resolution Ending Engagement With Elon Musk-Controlled Companies and To Encourage CalPERS To Divest Stock In These Companies,” alleges that Musk “has engaged in business practices that are alleged to include violations of labor laws, environmental regulations, workplace safety standards, and regulatory noncompliance.”

A California City Council is planning to weigh whether it would adopt a resolution that would place a ban on its engagement with Elon Musk companies, like Tesla and SpaceX.

The City of Davis, California, will have its City Council weigh a new proposal that would adopt a resolution “to divest from companies owned and/or controlled by Elon Musk.”

This would include a divestment proposal to encourage CalPERS, the California Public Employees Retirement System, to divest from stock in any Musk company.

A resolution draft titled, “Resolution Ending Engagement With Elon Musk-Controlled Companies and To Encourage CalPERS To Divest Stock In These Companies,” alleges that Musk “has engaged in business practices that are alleged to include violations of labor laws, environmental regulations, workplace safety standards, and regulatory noncompliance.”

It claims that Musk “has used his influence and corporate platforms to promote political ideologies and activities that threaten democratic norms and institutions, including campaign finance activities that raise ethical and legal concerns.”

If adopted, Davis would bar the city from entering into any new contracts or purchasing agreements with any company owned or controlled by Elon Musk. It also says it will not consider utilizing Tesla Robotaxis.

Hotel owner tears down Tesla chargers in frustration over Musk’s politics

A staff report on the proposal claims there is “no immediate budgetary impact.” However, a move like this would only impact its residents, especially with Tesla, as the Supercharger Network is open to all electric vehicle manufacturers. It is also extremely reliable and widespread.

Regarding the divestment request to CalPERS, it would not be surprising to see the firm make the move. Although it voted against Musk’s compensation package last year, the firm has no issue continuing to make money off of Tesla’s performance on Wall Street.

The decision to avoid Musk companies will be considered this evening at the City Council meeting.

The report comes from Davis Vanguard.

It is no secret that Musk’s political involvement, especially during the most recent Presidential Election, ruffled some feathers. Other cities considered similar options, like the City of Baltimore, which “decided to go in another direction” after awarding Tesla a $5 million contract for a fleet of EVs for city employees.