Energy

Tesla’s expansion of product offerings shows that a major expansion is in the making

Over the recent weeks, Tesla appears to be setting the stage for an intensive expansion of its product offerings. From the United States to China, the company seems to be intent on pursuing more and more avenues for its electric car and energy business. This hints at one thing: a major expansion is underway, and the all-too challenging battery supply code has been cracked.

Tesla CEO Elon Musk is known for his grand and ambitious dreams. If it were up to Musk, the world would completely abandon fossil fuels and dedicate a part of its resources to exploring interplanetary solutions. But Tesla, one of Musk’s two main businesses, is heavily reliant on batteries. No matter how much Tesla or Musk would want to accelerate the ramp towards sustainability, the proverbial battery supply problem has to be solved first.

This was highlighted by Musk in a previous earnings call last year. When asked about the Tesla Semi, a Class 8 truck that was initially set to begin deliveries in 2019 but was subsequently delayed, Musk explained that the vehicle could not be ramped fully unless the issue of battery cell supply is addressed. After all, the Semi is a massive vehicle, and it uses a lot of cells.

This sentiment is pretty much universal across Tesla’s lineup, including its Energy business and in products like the humble Powerwall and the grid-scale Megapack. Longtime followers of Tesla would remember that during the height of the Model 3’s production hell, Tesla ended up using lines that were allotted for the Powerwall’s cells to produce batteries for the electric sedan instead. This resulted in delays for the home battery storage unit.

But things today are much different than before. Amidst the impending announcements for Battery Day, reports are abounding that the company is poised to reveal the latest innovations in its battery tech. Among these is a million-mile battery, which would be resilient enough to outlast the internal combustion engine when used in electric cars and durable enough to last decades if deployed as battery storage.

These breakthroughs could change everything for Tesla, and it would allow the company to expand at a rate that exceeds its already rapid growth over the years. Tesla has been providing hints about the stages of this growth, from the rollout of China-made Model 3s that are equipped with batteries that have no cobalt content, the highly-anticipated production ramp of the Semi, the aggressive timeframe for the Cybertruck, renewed battery cell deals with Panasonic, to its recent permit to become a utility provider in the United Kingdom.

Each of these projects would not be possible unless the company has cracked the code on battery cell technology and production. Today, all signs are pointing to this very scenario. This should ultimately be validating for the company and its executives, considering that it has attracted a notable amount of criticism and mockery over the years due to its intense focus and pursuit of next-generation battery tech.

Back in 2014, after all, even the MIT Technology Review noted that there is little sense in an endeavor like Gigafactory Nevada, since Tesla’s car sales then did not warrant such a demand for batteries. Critics then also argued that it would be better for Tesla to just work with existing battery manufacturers. Interestingly, ARK Invest, one of Tesla’s most ardent bulls, was one of the few that actually believed in the value of Gigafactory Nevada in 2014, stating that it while ambitious, the company’s plans for the facility are actually feasible.

Energy

Tesla Megapack Megafactory in Texas advances with major property sale

Stream Realty Partners announced the sale of Buildings 9 and 10 at the Empire West industrial park, which total 1,655,523 square feet.

Tesla’s planned Megapack factory in Brookshire, Texas has taken a significant step forward, as two massive industrial buildings fully leased to the company were sold to an institutional investor.

In a press release, Stream Realty Partners announced the sale of Buildings 9 and 10 at the Empire West industrial park, which total 1,655,523 square feet. The properties are 100% leased to Tesla under a long-term agreement and were acquired by BGO on behalf of an institutional investor.

The two facilities, located at 100 Empire Boulevard in Brookshire, Texas, will serve as Tesla’s new Megafactory dedicated to manufacturing Megapack battery systems.

According to local filings previously reported, Tesla plans to invest nearly $200 million into the site. The investment includes approximately $44 million in facility upgrades such as electrical, utility, and HVAC improvements, along with roughly $150 million in manufacturing equipment.

Building 9, spanning roughly 1 million square feet, will function as the primary manufacturing floor where Megapacks are assembled. Building 10, covering approximately 600,000 square feet, will be dedicated to warehousing and logistics operations, supporting storage and distribution of completed battery systems.

Waller County Commissioners have approved a 10-year tax abatement agreement with Tesla, offering up to a 60% property-tax reduction if the company meets hiring and investment targets. Tesla has committed to employing at least 375 people by the end of 2026, increasing to 1,500 by the end of 2028, as noted in an Austin County News Online report.

The Brookshire Megafactory will complement Tesla’s Lathrop Megafactory in California and expand U.S. production capacity for the utility-scale energy storage unit. Megapacks are designed to support grid stabilization and renewable-energy integration, a segment that has become one of Tesla’s fastest-growing businesses.

Energy

Tesla meets Giga New York’s Buffalo job target amid political pressures

Giga New York reported more than 3,460 statewide jobs at the end of 2025, meeting the benchmark tied to its dollar-a-year lease.

Tesla has surpassed its job commitments at Giga New York in Buffalo, easing pressure from lawmakers who threatened the company with fines, subsidy clawbacks, and dealership license revocations last year.

The company reported more than 3,460 statewide jobs at the end of 2025, meeting the benchmark tied to its dollar-a-year lease at the state-built facility.

As per an employment report reviewed by local media, Tesla employed 2,399 full-time workers at Gigafactory New York and 1,060 additional employees across the state at the end of 2025. Part-time roles pushed the total headcount of Tesla’s New York staff above the 3,460-job target.

The gains stemmed in part from a new Long Island service center, a Buffalo warehouse, and additional showrooms in White Plains and Staten Island. Tesla also said it has invested $350 million in supercomputing infrastructure at the site and has begun manufacturing solar panels.

Empire State Development CEO Hope Knight said the agency was “very happy” with Giga New York’s progress, as noted in a WXXI report. The current lease runs through 2029, and negotiations over updated terms have included potential adjustments to job requirements and future rent payments.

Some lawmakers remain skeptical, however. Assemblymember Pat Burke questioned whether the reported job figures have been fully verified. State Sen. Patricia Fahy has also continued to sponsor legislation that would revoke Tesla’s company-owned dealership licenses in New York. John Kaehny of Reinvent Albany has argued that the project has not delivered the manufacturing impact originally promised as well.

Knight, for her part, maintained that Empire State Development has been making the best of a difficult situation.

“(Empire State Development) has tried to make the best of a very difficult situation. There hasn’t been another use that has come forward that would replace this one, and so to the extent that we’re in this place, the fact that 2,000 families at (Giga New York) are being supported through the activity of this employer. It’s the best that we can have happen,” the CEO noted.

Energy

Tesla launches Cybertruck vehicle-to-grid program in Texas

The initiative was announced by the official Tesla Energy account on social media platform X.

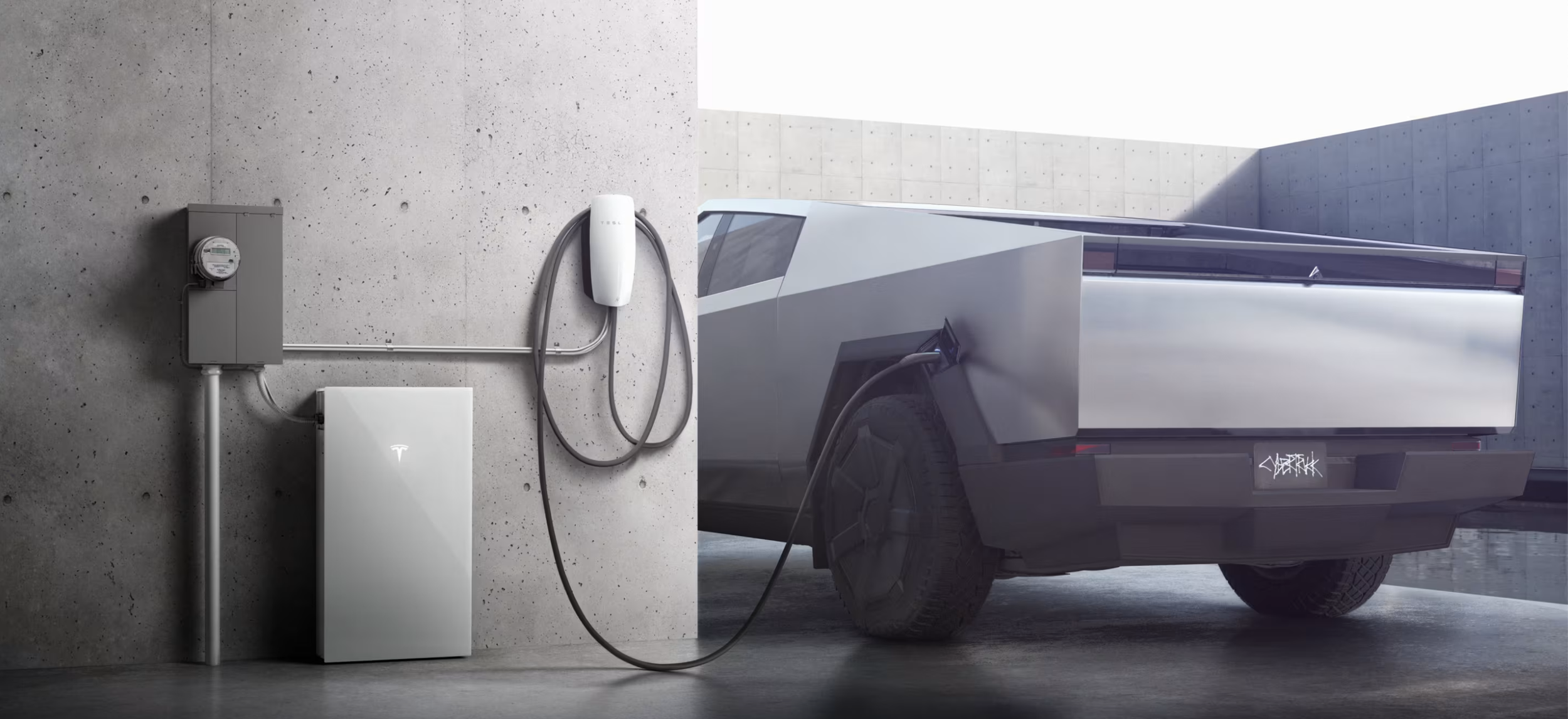

Tesla has launched a vehicle-to-grid (V2G) program in Texas, allowing eligible Cybertruck owners to send energy back to the grid during high-demand events and receive compensation on their utility bills.

The initiative, dubbed Powershare Grid Support, was announced by the official Tesla Energy account on social media platform X.

Texas’ Cybertruck V2G program

In its post on X, Tesla Energy confirmed that vehicle-to-grid functionality is “coming soon,” starting with select Texas markets. Under the new Powershare Grid Support program, owners of the Cybertruck equipped with Powershare home backup hardware can opt in through the Tesla app and participate in short-notice grid stress events.

During these events, the Cybertruck automatically discharges excess energy back to the grid, supporting local utilities such as CenterPoint Energy and Oncor. In return, participants receive compensation in the form of bill credits. Tesla noted that the program is currently invitation-only as part of an early adopter rollout.

The launch builds on the Cybertruck’s existing Powershare capability, which allows the vehicle to provide up to 11.5 kW of power for home backup. Tesla added that the program is expected to expand to California next, with eligibility tied to utilities such as PG&E, SCE, and SDG&E.

Powershare Grid Support

To participate in Texas, Cybertruck owners must live in areas served by CenterPoint Energy or Oncor, have Powershare equipment installed, enroll in the Tesla Electric Drive plan, and opt in through the Tesla app. Once enrolled, vehicles would be able to contribute power during high-demand events, helping stabilize the grid.

Tesla noted that events may occur with little notice, so participants are encouraged to keep their Cybertrucks plugged in when at home and to manage their discharge limits based on personal needs. Compensation varies depending on the electricity plan, similar to how Powerwall owners in some regions have earned substantial credits by participating in Virtual Power Plant (VPP) programs.