Energy

Tesla completes 22 Powerpack installation for PG&E outside San Francisco

Tesla has completed the installation of a 2MWh Powerpack system for Pacific Gas & Electric in Browns Valley near San Francisco, making it the second utility-scale Powerpack project the company has completed in California.

The Browns Valley project, designed and installed by Cupertino Electric, is made up of 22 Tesla Powerpack systems which use battery cells manufactured at the company’s Gigafactory plant in Nevada. Total capacity of the system is half a megawatt — enough to power 380 homes for up to four hours. Demand can shift from moment to moment. Batteries can respond to such transitory needs instantaneously in a way that a peaker plant cannot.

The California legislature requires utility companies to use storage solutions for excess electricity produced by solar panels during the day so it can be used later when demand spikes — usually in the late afternoon and early evening hours when people are getting home from work. This approach, known as “time shifting” — reduces the need to build so-called peaker plants, generating facilities that sit idle most of the day but get fired up whenever extra electricity is needed.

Electrical storage is not a new idea. Since 1984, PG&E has relied on a pumped storage facility in the Helms Valley high up in the Sierra Nevada mountains east of San Francisco. That installation uses excess electricity to pump water uphill during the day so it can flow back downhill later, turning hydroelectric turbines as it falls. It has a total capacity of 1.2 megawatts.

But such projects require years of planning, permitting, and construction. So do natural gas fired facilities. The allure of battery storage is that it can be completed quickly and can be sited close to the grid structure it serves. “It’s pretty modular — you can scale up and down as you need,” said Mike Della Penna, PG&E’s project manager for the Browns Valley installation.

Battery storage is still relatively expensive (neither PG&E nor Tesla would reveal the cost of the Browns Valley installation reports the SF Gate), but the speed with which battery storage facility can be designed, built, and brought online helps to offset some of that additional cost. Taking a longer view, firing up a peaker plant is expensive. Eliminating that cost over a period of years will help balance out the initial investment.

And battery costs are dropping faster than most people anticipated. The second generation Tesla Powerwall home battery system came on the market barely one year after the original went on sale. It has double the capacity but actually costs less because the inverter is built in. Tesla does not reveal the cost of its grid scale Powerpack batteries, but it is a safe assumption that a similar drop in price applies to them as well.

Grid scale battery storage is still in its infancy and all stakeholders are exploring the least expensive and most efficient way to make use of it going forward. PG&E and Tesla are working together on a pilot project that uses Powerwall batteries in homes and businesses in the Bay Area. The total capacity of the distributed storage will be equal to that of the Browns Valley project. PG&E will be able to study the performance of both systems — one distributed and one centralized — to learn how each benefits the local grid. “They’re each with their own challenges and opportunities,” Della Penna says. “We’ve structured it so we’ll have a lot of really good learning here.”

Elon Musk has said he expects the storage battery business to be larger than Tesla’s automobile business one day. The lessons learned from projects like Mira Loma and Browns Valley will become the foundation for the Tesla’s grid storage business in the future.

Interested in solar? Get a solar cost estimate and find out how much a solar system would cost for your home or business.

Energy

Tesla launches Cybertruck vehicle-to-grid program in Texas

The initiative was announced by the official Tesla Energy account on social media platform X.

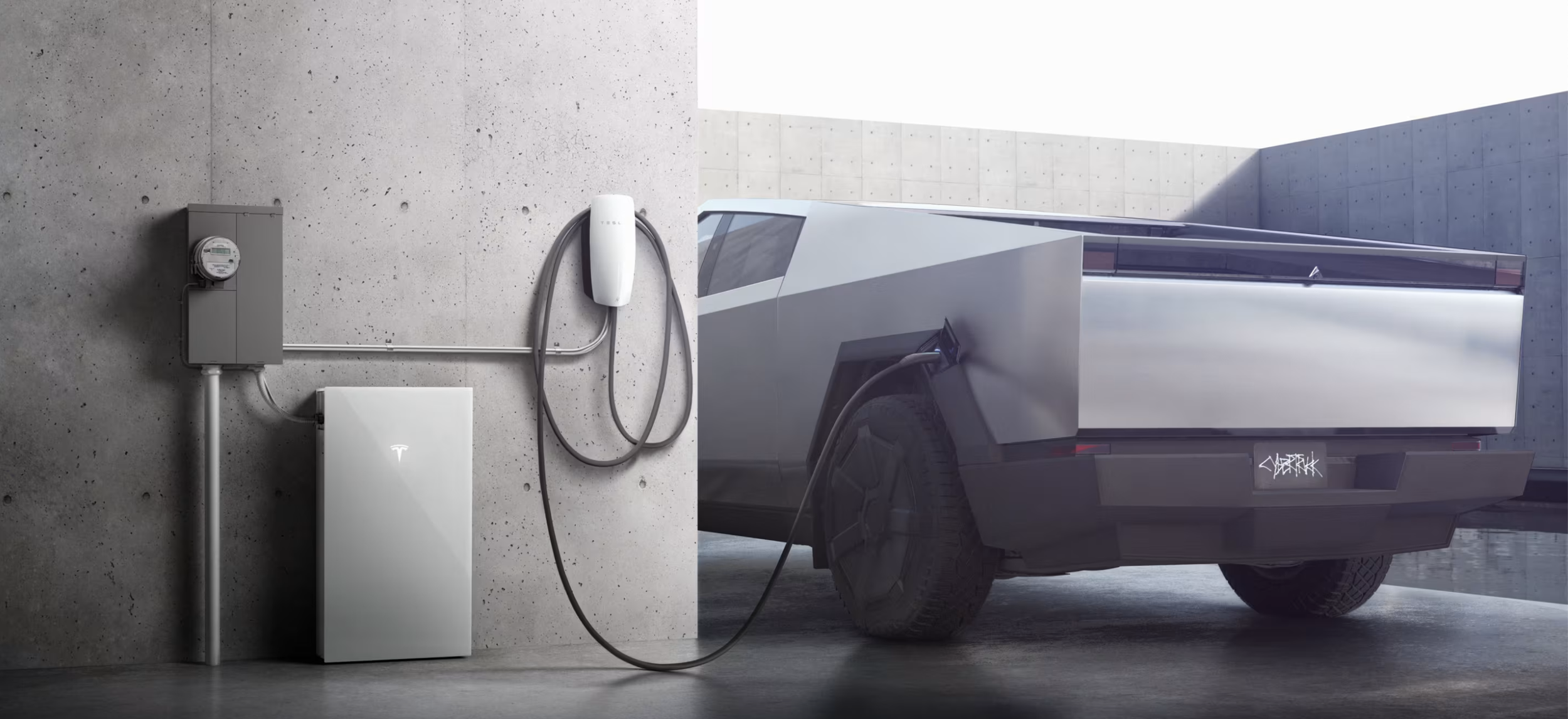

Tesla has launched a vehicle-to-grid (V2G) program in Texas, allowing eligible Cybertruck owners to send energy back to the grid during high-demand events and receive compensation on their utility bills.

The initiative, dubbed Powershare Grid Support, was announced by the official Tesla Energy account on social media platform X.

Texas’ Cybertruck V2G program

In its post on X, Tesla Energy confirmed that vehicle-to-grid functionality is “coming soon,” starting with select Texas markets. Under the new Powershare Grid Support program, owners of the Cybertruck equipped with Powershare home backup hardware can opt in through the Tesla app and participate in short-notice grid stress events.

During these events, the Cybertruck automatically discharges excess energy back to the grid, supporting local utilities such as CenterPoint Energy and Oncor. In return, participants receive compensation in the form of bill credits. Tesla noted that the program is currently invitation-only as part of an early adopter rollout.

The launch builds on the Cybertruck’s existing Powershare capability, which allows the vehicle to provide up to 11.5 kW of power for home backup. Tesla added that the program is expected to expand to California next, with eligibility tied to utilities such as PG&E, SCE, and SDG&E.

Powershare Grid Support

To participate in Texas, Cybertruck owners must live in areas served by CenterPoint Energy or Oncor, have Powershare equipment installed, enroll in the Tesla Electric Drive plan, and opt in through the Tesla app. Once enrolled, vehicles would be able to contribute power during high-demand events, helping stabilize the grid.

Tesla noted that events may occur with little notice, so participants are encouraged to keep their Cybertrucks plugged in when at home and to manage their discharge limits based on personal needs. Compensation varies depending on the electricity plan, similar to how Powerwall owners in some regions have earned substantial credits by participating in Virtual Power Plant (VPP) programs.

Cybertruck

Tesla updates Cybertruck owners about key Powershare feature

Tesla is updating Cybertruck owners on its timeline of a massive feature that has yet to ship: Powershare with Powerwall.

Powershare is a bidirectional charging feature exclusive to Cybertruck, which allows the vehicle’s battery to act as a portable power source for homes, appliances, tools, other EVs, and more. It was announced in late 2023 as part of Tesla’s push into vehicle-to-everything energy sharing, and acting as a giant portable charger is the main advantage, as it can provide backup power during outages.

Cybertruck’s Powershare system supports both vehicle-to-load (V2L) and vehicle-to-home (V2H), making it flexible and well-rounded for a variety of applications.

However, even though the feature was promised with Cybertruck, it has yet to be shipped to vehicles. Tesla communicated with owners through email recently regarding Powershare with Powerwall, which essentially has the pickup act as an extended battery.

Powerwall discharge would be prioritized before tapping into the truck’s larger pack.

However, Tesla is still working on getting the feature out to owners, an email said:

“We’re writing to let you know that the Powershare with Powerwall feature is still in development and is now scheduled for release in mid-2026.

This new release date gives us additional time to design and test this feature, ensuring its ability to communicate and optimize energy sharing between your vehicle and many configurations and generations of Powerwall. We are also using this time to develop additional Powershare features that will help us continue to accelerate the world’s transition to sustainable energy.”

Owners have expressed some real disappointment in Tesla’s continuous delays in releasing the feature, as it was expected to be released by late 2024, but now has been pushed back several times to mid-2026, according to the email.

Foundation Series Cybertruck buyers paid extra, expecting the feature to be rolled out with their vehicle upon pickup.

Cybertruck’s Lead Engineer, Wes Morrill, even commented on the holdup:

As a Cybertruck owner who also has Powerwall, I empathize with the disappointed comments.

To their credit, the team has delivered powershare functionality to Cybertruck customers who otherwise have no backup with development of the powershare gateway. As well as those with solar…

— Wes (@wmorrill3) December 12, 2025

He said that “it turned out to be much harder than anticipated to make powershare work seamlessly with existing Powerwalls through existing wall connectors. Two grid-forming devices need to negotiate who will form and who will follow, depending on the state of charge of each, and they need to do this without a network and through multiple generations of hardware, and test and validate this process through rigorous certifications to ensure grid safety.”

It’s nice to see the transparency, but it is justified for some Cybertruck owners to feel like they’ve been bait-and-switched.

Energy

Tesla starts hiring efforts for Texas Megafactory

Tesla’s Brookshire site is expected to produce 10,000 Megapacks annually, equal to 40 gigawatt hours of energy storage.

Tesla has officially begun hiring for its new $200 million Megafactory in Brookshire, Texas, a manufacturing hub expected to employ 1,500 people by 2028. The facility, which will build Tesla’s grid-scale Megapack batteries, is part of the company’s growing energy storage footprint.

Tesla’s hiring efforts for the Texas Megafactory are hinted at by the job openings currently active on the company’s Careers website.

Tesla’s Texas Megafactory

Tesla’s Brookshire site is expected to produce 10,000 Megapacks annually, equal to 40 gigawatt hours of energy storage, similar to the Lathrop Megafactory in California. Tesla’s Careers website currently lists over 30 job openings for the site, from engineers, welders, and project managers. Each of the openings is listed for Brookshire, Texas.

The company has leased two buildings in Empire West Business Park, with over $194 million in combined property and equipment investment. Tesla’s agreement with Waller County includes a 60% property tax abatement, contingent on meeting employment benchmarks: 375 jobs by 2026, 750 by 2027, and 1,500 by 2028, as noted in a report from the Houston Business Journal. Tesla is required to employ at least 1,500 workers in the facility through the rest of the 10-year abatement period.

Tesla’s clean energy boom

City officials have stated that Tesla’s arrival marks a turning point for the Texas city, as it highlights a shift from logistics to advanced clean energy manufacturing. Ramiro Bautista from Brookshire’s economic development office, highlighted this in a comment to the Journal.

“(Tesla) has great-paying jobs. Not just that, but the advanced manufacturing (and) clean energy is coming to the area,” he said. “So it’s not just your normal logistics manufacturing. This is advanced manufacturing coming to this area, and this brings a different type of job and investment into the local economy.”