News

Tesla Semi competitor Nikola opens new headquarters, public tours to follow

Tesla Semi competitor Nikola Motors has opened its new headquarters in Phoenix, Arizona, according to CEO Trevor Milton. The facility will house the company’s design, research and development teams.

“Nikola HQ is awesome. Just opened last week,” Milton announced via Twitter alongside a photo of what appears to be a lobby inside the building. Most of the company’s product line was pictured, to include the Nikola One and Nikola Tre hydrogen-electric semi trucks, the all-electric Nikola NZT off-road vehicle, and the Nikola WAV sit-down electric watercraft. Only the Nikola Two, the day cab variant of their hydrogen-electric semi truck unveiled in April with the WAV and NZT, was missing from the image. Milton also suggested that tours of the headquarters may be open to the public as soon as August.

Earlier this year, Nikola released details surrounding a deal made with Saint Holdings, LLC for 400 acres in Pinal County, Arizona where the company will build its manufacturing facility. The location is inside Heritage, an 11,438-acre prime development area, within the Inland Port Arizona portion of the site, itself comprising 3,000 acres and dubbed a “manufacturing mega site.” Nikola’s presence in the area is expected to bring an estimated $1 billion in economic stimulus to the region by 2024.

https://twitter.com/nikolatrevor/status/1140751941846237184

Nikola’s latest product unveilings took place in Scottsdale at Nikola World 2019, a two-day event featuring a presentation, breakout sessions, track demos, and vehicle tours. In the weeks since, Milton and his team have continued to promote their products and mission via trade show appearances and interviews. One of the notable topics discussed during that time was Nikola’s commitment to hydrogen as a fuel source while acknowledging the advantages of fully-electric trucking systems for short-haul tasks.

“Around long-haul, you have more advantage on the hydrogen side because it’s lighter. It’s all about freight weight, or how much it costs to move a freight-ton per mile. There’s advantages to both infrastructures, but we’re mainly focused on the hydrogen side. We just offer battery-electric so we can tell people we’ll shoot you straight. There are areas where hydrogen does not make sense,” Milton said during an interview with Trucks.com. “The battery alone in an electric truck is going to cost $200,000. We’re shooting for an internal cost of $150,000 for our entire Nikola truck. Our truck also weighs less than the batteries in an electric truck. Now, electric is going to kick our butt in short-haul because it’s a really good solution, but electric trucks are not one size fits all.”

https://twitter.com/nikolatrevor/status/1140754280116183041

As part of Nikola’s commitment to hydrogen power, the trucking startup also announced a $14 million dollar fuel cell lab investment at the end of March this year, with several hundred dollars planned overall. The laboratory represents a critical component in the company’s plan to provide high-quality, high-efficiency fuel cell technology at a pace quick enough to meet the needs of the trucking industry as it drives towards an alternative-power future. Nikola plans to centralize the development, validation, and testing of its entire fuel cell system in one place, reducing the time required to meet its mission milestones.

Nikola will break ground on its main manufacturing facility later this year in Coolidge. Initial production is estimated to be 35,000 semi trucks annually and grow to an eventual 50,000 built per year. In the interim, Fitzgerald Glider Kits is producing the Class 8 long haulers with full production planned for 2022-2023.

Elon Musk

Tesla AI5 chip nears completion, Elon Musk teases 9-month development cadence

The Tesla CEO shared his recent insights in a post on social media platform X.

Tesla’s next-generation AI5 chip is nearly complete, and work on its successor is already underway, as per a recent update from Elon Musk.

The Tesla CEO shared his recent insights in a post on social media platform X.

Musk details AI chip roadmap

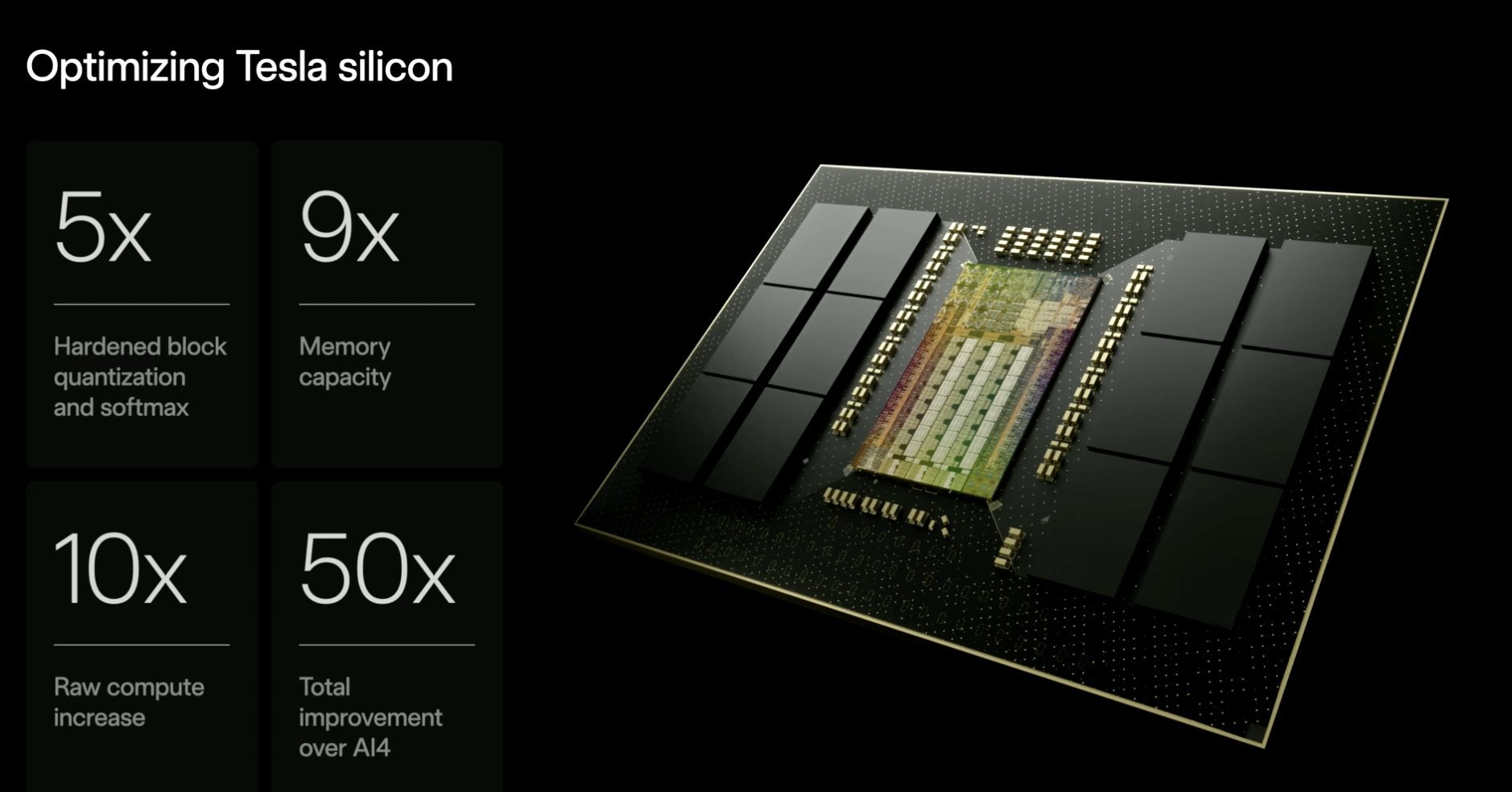

In his post, Elon Musk stated that Tesla’s AI5 chip design is “almost done,” while AI6 has already entered early development. Musk added that Tesla plans to continue iterating rapidly, with AI7, AI8, AI9, and future generations targeting a nine-month design cycle.

He also noted that Tesla’s in-house chips could become the highest-volume AI processors in the world. Musk framed his update as a recruiting message, encouraging engineers to join Tesla’s AI and chip development teams.

Tesla community member Herbert Ong highlighted the strategic importance of the timeline, noting that faster chip cycles enable quicker learning, faster iteration, and a compounding advantage in AI and autonomy that becomes increasingly difficult for competitors to close.

AI5 manufacturing takes shape

Musk’s comments align with earlier reporting on AI5’s production plans. In December, it was reported that Samsung is preparing to manufacture Tesla’s AI5 chip, accelerating hiring for experienced engineers to support U.S. production and address complex foundry challenges.

Samsung is one of two suppliers selected for AI5, alongside TSMC. The companies are expected to produce different versions of the AI5 chip, with TSMC reportedly using a 3nm process and Samsung using a 2nm process.

Musk has previously stated that while different foundries translate chip designs into physical silicon in different ways, the goal is for both versions of the Tesla AI5 chip to operate identically. AI5 will succeed Tesla’s current AI4 hardware, formerly known as Hardware 4, and is expected to support the company’s Full Self-Driving system as well as other AI-driven efforts, including Optimus.

News

Tesla Model Y and Model 3 named safest vehicles tested by ANCAP in 2025

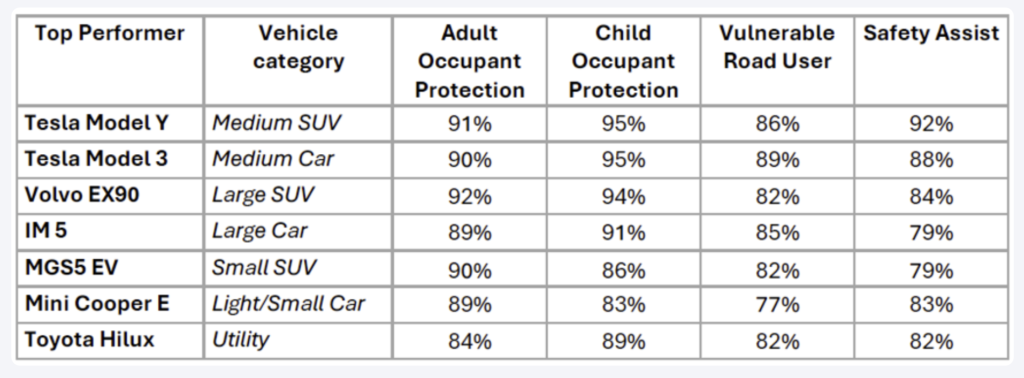

According to ANCAP in a press release, the Tesla Model Y achieved the highest overall weighted score of any vehicle assessed in 2025.

The Tesla Model Y recorded the highest overall safety score of any vehicle tested by ANCAP in 2025. The Tesla Model 3 also delivered strong results, reinforcing the automaker’s safety leadership in Australia and New Zealand.

According to ANCAP in a press release, the Tesla Model Y achieved the highest overall weighted score of any vehicle assessed in 2025. ANCAP’s 2025 tests evaluated vehicles across four key pillars: Adult Occupant Protection, Child Occupant Protection, Vulnerable Road User Protection, and Safety Assist technologies.

The Model Y posted consistently strong results in all four categories, distinguishing itself through a system-based safety approach that combines structural crash protection with advanced driver-assistance features such as autonomous emergency braking, lane support, and driver monitoring.

This marked the second time the Model Y has topped ANCAP’s annual safety rankings. The Model Y’s previous version was also ANCAP’s top performer in 2022.

The Tesla Model 3 also delivered a strong performance in ANCAP’s 2025 tests, contributing to Tesla’s broader safety presence across segments. Similar to the Model Y, the Model 3 also earned impressive scores across the ANCAP’s four pillars. This made the vehicle the top performer in the Medium Car category.

ANCAP Chief Executive Officer Carla Hoorweg stated that the results highlight a growing industry shift toward integrated safety design, with improvements in technologies such as autonomous emergency braking and lane support translating into meaningful real-world protection.

“ANCAP’s testing continues to reinforce a clear message: the safest vehicles are those designed with safety as a system, not a checklist. The top performers this year delivered consistent results across physical crash protection, crash avoidance and vulnerable road user safety, rather than relying on strength in a single area.

“We are also seeing increasing alignment between ANCAP’s test requirements and the safety technologies that genuinely matter on Australian and New Zealand roads. Improvements in autonomous emergency braking, lane support, and driver monitoring systems are translating into more robust protection,” Hoorweg said.

News

Tesla Sweden uses Megapack battery to bypass unions’ Supercharger blockade

Just before Christmas, Tesla went live with a new charging station in Arlandastad, outside Stockholm, by powering it with a Tesla Megapack battery.

Tesla Sweden has successfully launched a new Supercharger station despite an ongoing blockade by Swedish unions, using on-site Megapack batteries instead of traditional grid connections. The workaround has allowed the Supercharger to operate without direct access to Sweden’s electricity network, which has been effectively frozen by labor action.

Tesla has experienced notable challenges connecting its new charging stations to Sweden’s power grid due to industrial action led by Seko, a major Swedish trade union, which has blocked all new electrical connections for new Superchargers. On paper, this made the opening of new Supercharger sites almost impossible.

Despite the blockade, Tesla has continued to bring stations online. In Malmö and Södertälje, new Supercharger locations opened after grid operators E.ON and Telge Nät activated the sites. The operators later stated that the connections had been made in error.

More recently, however, Tesla adopted a different strategy altogether. Just before Christmas, Tesla went live with a new charging station in Arlandastad, outside Stockholm, by powering it with a Tesla Megapack battery, as noted in a Dagens Arbete (DA) report.

Because the Supercharger station does not rely on a permanent grid connection, Tesla was able to bypass the blocked application process, as noted by Swedish car journalist and YouTuber Peter Esse. He noted that the Arlandastad Supercharger is likely dependent on nearby companies to recharge the batteries, likely through private arrangements.

Eight new charging stalls have been launched in the Arlandastad site so far, which is a fraction of the originally planned 40 chargers for the location. Still, the fact that Tesla Sweden was able to work around the unions’ efforts once more is impressive, especially since Superchargers are used even by non-Tesla EVs.

Esse noted that Tesla’s Megapack workaround is not as easily replicated in other locations. Arlandastad is unique because neighboring operators already have access to grid power, making it possible for Tesla to source electricity indirectly. Still, Esse noted that the unions’ blockades have not affected sales as much.

“Many want Tesla to lose sales due to the union blockades. But you have to remember that sales are falling from 2024, when Tesla sold a record number of cars in Sweden. That year, the unions also had blockades against Tesla. So for Tesla as a charging operator, it is devastating. But for Tesla as a car company, it does not matter in terms of sales volumes. People charge their cars where there is an opportunity, usually at home,” Esse noted.