News

SpaceX Starship prototype speeding towards launch pad for first Raptor engine tests

SpaceX continues to build full-scale Starship hardware at a jaw-dropping pace, testing the limits of rocket production to complete the fifth full-scale prototype in three months and prepare the ship for its first Raptor engine ignition tests.

This time around, SpaceX CEO Elon Musk is fairly confident that the latest Starship prototype – known as serial number 3 (SN3) – has the best chance yet of becoming the first full-scale ship to pass acceptance tests and kick off a Raptor engine static fire campaign. A step further, if said static fires go according to plan, Starship SN3 could become the first full-scale vehicle of its kind to perform controlled flight tests.

Starship SN3 will thus attempt to follow in the footsteps of Starhopper and hopefully avoid an unintentional launch debut similar to the one that destroyed Starship SN1 earlier this month. A successful Starship flight test powered by three Raptor engines would be a major bode of confidence in the upgraded rocket factory SpaceX is building in South Texas. Musk recently made it clear that setting up the machine that builds the machine is currently just as important as individual Starship tests. Thankfully, given that SpaceX is already managing to build colossal rocket prototypes in a matter of weeks for what has to be pennies on the dollar, all with a team of just a few hundred people, the next Starship test campaign is likely just a week or two away.

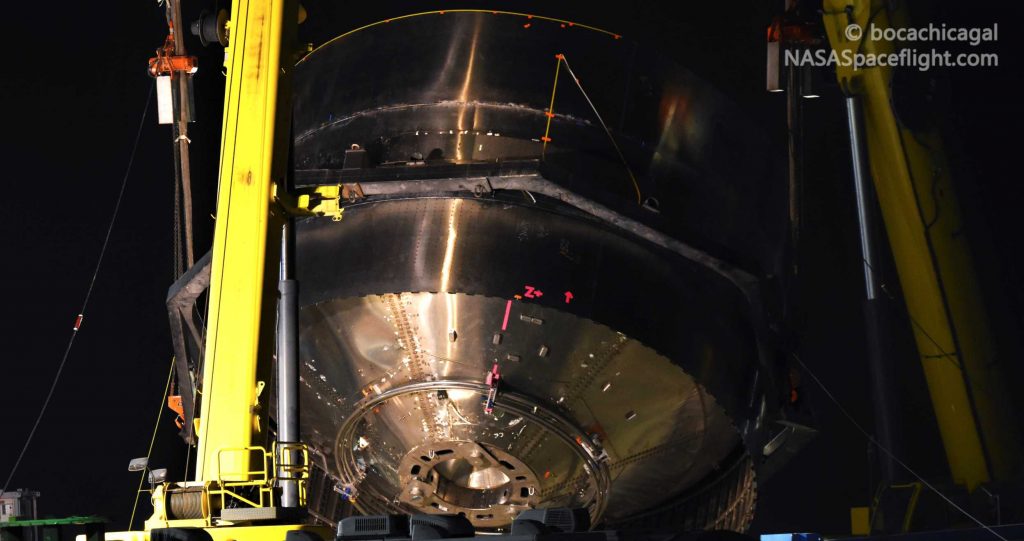

On March 9th, Musk revealed that the Starship SN2 prototype – an incomplete tank repurposed for specific testing – had passed a proof test with flying colors. SN2’s brief test campaign managed to prove that SpaceX had already fixed the weak point believed to have destroyed Starship SN1 less than two weeks prior. Featuring a redesigned engine section and thrust structure (or “thrust puck,” per Musk), the Starship SN2 test tank survived pressure testing and even made it through engine thrust simulations with the help of an industrial-scale hydraulic jack.

While the tank passed its tests looking no worse for wear, the last-second design changes SpaceX had to make to rapidly perform thrust structure verification testing made it impossible to repurpose for any alternative use. Starship SN2 has thus been relegated to the scrapyard, a technical necessity but also a sign of both the program’s high rate of progress and low prototype cost. SpaceX’s Boca Chica factory has already more or less completed a new engine section for Starship SN3 and is probably just a day or two away from integrating it with the rest of the steel vehicle.

Less than three days after SpaceX’s brand new vehicle assembly building (VAB) had a single, small Starship section sat inside it, two additional sections of Starship SN3’s tank section departed their fabrication tents and were stacked on March 18th. Less than a day later, the third segment of the rocket’s tank section capped off the two that were stacked the day before. Once those three stacked sections are fully welded together to form a single, cohesive piece of steel, it will need to be stacked atop the aft tank dome and thrust structure to effectively complete Starship SN3’s tank section.

After all four sections are joined, technicians will need to install a few internal parts, but most remaining work mainly involves running wiring and plumbing for power, communications, propellant management, and pressurization. More likely than not, SpaceX replicate its Starship Mk1 and SN1 testing strategy and bring Starship SN3’s tank section to the launch pad for proof testing as soon as outfitting is complete. If the rocket passes proof testing, SpaceX can – for the first time – install functional Raptor engines on a full-scale Starship prototype and begin a crucial wet dress rehearsal (WDR) and static fire test campaign.

At the current rate of progress, SpaceX could easily be ready to transport Starship SN3 to the pad within the next week, give or take. Stay tuned for updates as the company works to quickly finish SN3 integration and move onto the testing phase.

Check out Teslarati’s Marketplace! We offer Tesla accessories, including for the Tesla Cybertruck and Tesla Model 3.

Cybertruck

Tesla confirms date when new Cybertruck trim will go up in price

Tesla has officially revealed that this price will only be available until February 28, as the company has placed a banner atop the Design Configurator on its website reflecting this.

Tesla has confirmed the date when its newest Cybertruck trim level will increase in price, after CEO Elon Musk noted that the All-Wheel-Drive configuration of the all-electric pickup would only be priced at its near-bargain level for ten days.

Last week, Tesla launched the All-Wheel-Drive configuration of the Cybertruck. Priced at $59,990, the Cybertruck featured many excellent features and has seemingly brought some demand to the pickup, which has been underwhelming in terms of sales figures over the past couple of years.

Tesla launches new Cybertruck trim with more features than ever for a low price

When Tesla launched it, many fans and current owners mulled the possibility of ordering it. However, Musk came out and said just hours after launching the pickup that Tesla would only keep it at the $59,990 price level for ten days.

What it would be priced at subsequently was totally dependent on how much demand Tesla felt for the new trim level, which is labeled as a “Dual Motor All-Wheel-Drive” configuration.

Tesla has officially revealed that this price will only be available until February 28, as the company has placed a banner atop the Design Configurator on its website reflecting this:

NEWS: Tesla has officially announced that the price of the new Cybertruck Dual-Motor AWD will be increasing after February 28th. pic.twitter.com/vZpA521ZwC

— Sawyer Merritt (@SawyerMerritt) February 24, 2026

Many fans and owners have criticized Tesla’s decision to unveil a trim this way, and then price it at something, only to change that price a few days later based on how well it sells.

Awful way to treat customers – particularly when they already sent out a marketing email announcing the $59,990 truck…with zero mention of it being a limited-time offer.

— Ryan McCaffrey (@DMC_Ryan) February 24, 2026

It seems the most ideal increase in price would be somewhere between $5,000 and $10,000, but it truly depends on how many orders Tesla sees for this new trim level. The next step up in configuration is the Premium All-Wheel-Drive, which is priced at $79,990.

The difference between the Dual Motor AWD Cybertruck and the Premium AWD configuration comes down to towing, interior quality, and general features. The base package is only capable of towing up to 7,500 pounds, while the Premium can handle 11,000 pounds. Additionally, the seats in the Premium build are Vegan Leather, while the base trim gets the textile seats.

It also has only 7 speakers compared to the 15 that the Premium trim has. Additionally, the base model does not have an adjustable ride height, although it does have a coil spring with an adaptive damping suspension package.

Cybertruck

Tesla set to activate long-awaited Cybertruck feature

Tesla will officially activate the Active Noise Cancellation (ANC) feature on Cybertruck soon, as the company has officially added the feature to its list of features by trim on its website.

Tesla is set to activate a long-awaited Cybertruck feature, and no matter when you bought your all-electric pickup, it has the hardware capable of achieving what it is designed to do.

Tesla simply has to flip the switch, and it plans to do so in the near future.

Tesla will officially activate the Active Noise Cancellation (ANC) feature on Cybertruck soon, according to Not a Tesla App, as the company has officially added the feature to its list of features by trim on its website.

Tesla rolls out Active Road Noise Reduction for new Model S and Model X

The ANC feature suddenly appeared on the spec sheet for the Premium All-Wheel-Drive and Cyberbeast trims, which are the two configurations that have been delivered since November 2023.

However, those trims have both had the ANC disabled, and although they are found in the Model S and Model X, and are active in those vehicles, Tesla is planning to activate them.

In Tesla’s Service Toolbox, it wrote:

“ANC software is not enabled on Cybertruck even though the hardware is installed.”

Tesla has utilized an ANC system in the Model S and Model X since 2021. The system uses microphones embedded in the front seat headrests to detect low-frequency road noise entering the cabin. It then generates anti-noise through phase-inverted sound waves to cancel out or reduce that noise, creating quieter zones, particularly around the vehicle’s front occupants.

The Model S and Model X utilize six microphones to achieve this noise cancellation, while the Cybertruck has just four.

Tesla Cybertruck Dual Motor AWD estimated delivery slips to early fall 2026

As previously mentioned, this will be activated through a software update, as the hardware is already available within Cybertruck and can simply be activated at Tesla’s leisure.

The delays in activating the system are likely due to Tesla Cybertruck’s unique design, which is unlike anything before. In the Model S and Model X, Tesla did not have to do too much, but the Cybertruck has heavier all-terrain tires and potentially issues from the aluminum castings that make up the vehicle’s chassis, which are probably presenting some challenges.

Unfortunately, this feature will not be available on the new Dual Motor All-Wheel-Drive configuration, which was released last week.

News

Tesla Model S and X customization options begin to thin as their closure nears

Tesla’s Online Design Studio for both vehicles now shows the first color option to be listed as “Sold Out,” as Lunar Silver is officially no longer available for the Model S or Model X. This color is exclusive to these cars and not available on the Model S or Model X.

Tesla Model S and Model X customization options are beginning to thin for the first time as the closure of the two “sentimental” vehicles nears.

We are officially seeing the first options disappear as Tesla begins to work toward ending production of the two cars and the options that are available to those vehicles specifically.

Tesla’s Online Design Studio for both vehicles now shows the first color option to be listed as “Sold Out,” as Lunar Silver is officially no longer available for the Model S or Model X. This color is exclusive to these cars and not available on the Model S or Model X.

🚨 Tesla Model S and Model X availability is thinning, as Tesla has officially shown that the Lunar Silver color option on both vehicles is officially sold out

To be fair, Frost Blue is still available so no need to freak out pic.twitter.com/YnwsDbsFOv

— TESLARATI (@Teslarati) February 25, 2026

Tesla is making way for the Optimus humanoid robot project at the Fremont Factory, where the Model S and Model X are produced. The two cars are low-volume models and do not contribute more than a few percent to Tesla’s yearly delivery figures.

With CEO Elon Musk confirming that the Model S and Model X would officially be phased out at the end of the quarter, some of the options are being thinned out.

This is an expected move considering Tesla’s plans for the two vehicles, as it will make for an easier process of transitioning that portion of the Fremont plant to cater to Optimus manufacturing. Additionally, this is likely one of the least popular colors, and Tesla is choosing to only keep around what it is seeing routine demand for.

During the Q4 Earnings Call in January, Musk confirmed the end of the Model S and Model X:

“It is time to bring the Model S and Model X programs to an end with an honorable discharge. It is time to bring the S/X programs to an end. It’s part of our overall shift to an autonomous future.”

Fremont will now build one million Optimus units per year as production is ramped.