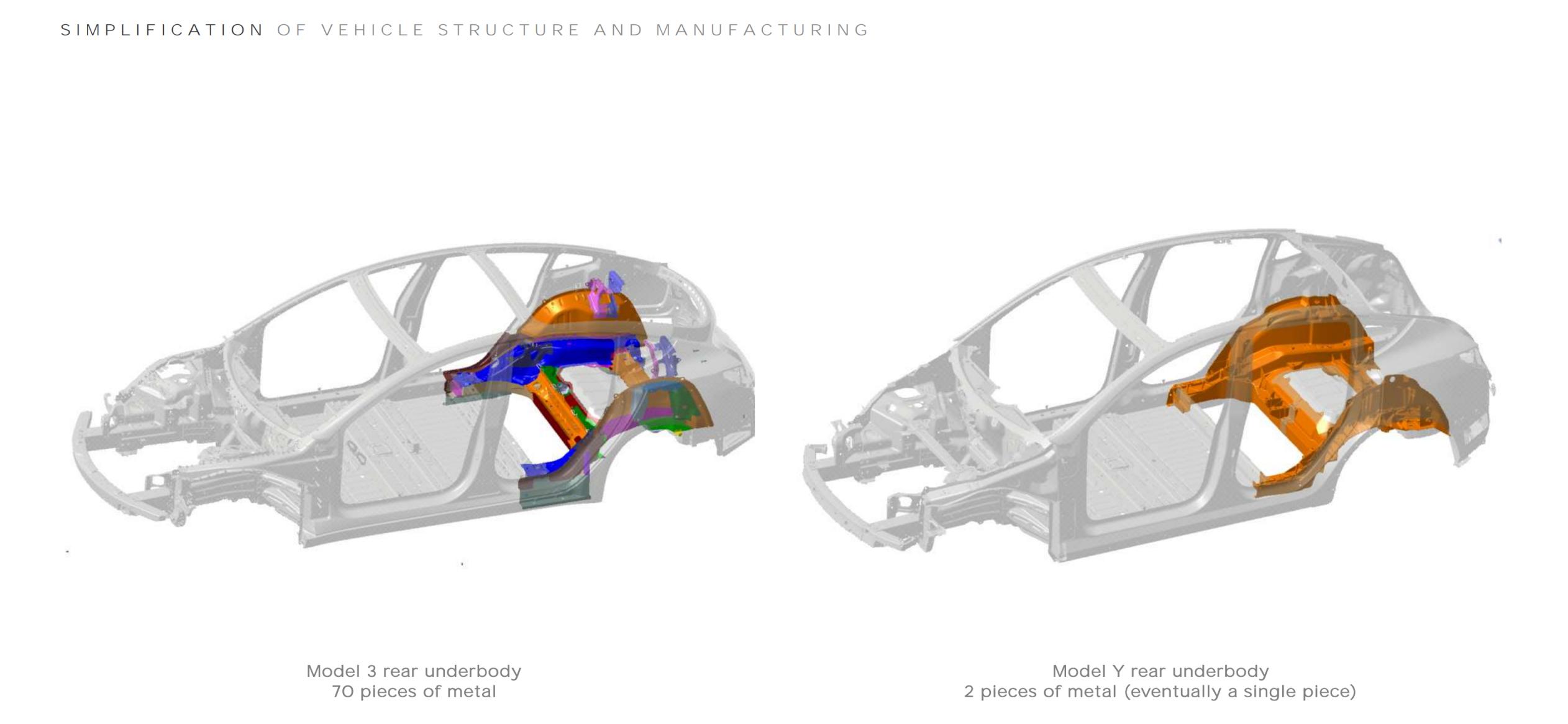

Elon Musk is one of many people who predicted that the Model Y would be Tesla’s most successful vehicle to date. The vehicle not only has mass-appeal due to its crossover body style and environmental advantages, but it also is Tesla’s most structurally innovative vehicle yet. The Model Y’s underbody rear casting is one of the reasons the car has become recognized as a marvel of automotive engineering, and Musk delved into the details of the project, along with advancements the company intends to make to it by the end of 2020.

During Tesla’s Q1 2020 Earnings Call, Musk discussed the strides the electric automaker had made in the first three months of the year. After outlining Tesla’s somewhat surprisingly successful Q1 despite the coronavirus pandemic, Musk dove into the Model Y and its superior casting design compared to past Tesla vehicles.

“For Model Y, we introduced a revolutionary two-piece rear underbody casting that we are going to be making a single-piece casting later this year,” Musk said. “Meaning like essentially the rear third of the body is cast as a single piece, which is no casting of the size of complexity has never been done before.”

Automotive industry veteran Sandy Munro once said that if Tesla had contracted someone to help produce the early versions of the Model 3, the car would have immediately wiped the floor with everyone. After Munro tore down the Tesla sedan in 2018, Musk and the company realized that there were improvements needed in the build of the car. These started with later builds of the Model 3, but the more significant improvements would be passed on to the Model Y, a sibling of the Model 3 as the two vehicles share 75% of the same parts.

One of the biggest complaints Munro had about the Model 3 was the rear casting. He felt the car was “over-engineered” because it utilized around 100 parts for the rear trunk. However, the Model Y is an entirely different build, and it is something Munro has complimented during recent episodes of his teardown series.

Tesla’s idea for the Model Y was to simplify the build process and utilize fewer parts. But nobody has ever come close to using two parts for rear casting as Tesla did with the Model Y. The decrease in parts helps with the build quality, weight reduction, and production efficiency.

“So, we’re really pushing the envelope on vehicle structural, engineering, and manufacturing. I’m very excited about this approach as it allows us to reduce the weight of the cast and improve NVH. It’s better in every way essentially,” Musk said.

In the past, Munro said that the Model 3’s welding processes looked like “some kind of a science project.” This issue wasn’t present in only the rear casting on the Model 3 but also throughout the entire vehicle. However, Tesla improved on all of these issues with the Model Y, much to the approval of Munro, who has seemed very happy with the build quality of the electric crossover.

The Model Y’s improved build quality and use of revolutionary technology give all indications that the car will end up being what everyone predicted it to be: Tesla’s most successful car in its short but rich history.

News

Tesla announces massive investment into xAI

“On January 16, 2026, Tesla entered into an agreement to invest approximately $2 billion to acquire shares of Series E Preferred Stock of xAI as part of their recent publicly-disclosed financing round,” it said.

Tesla has announced a major development in its ventures outside of electric vehicles, as it confirmed today that it invested $2 billion into xAI on January 16.

The move is significant, as it marks the acquisition of shares of Series E Preferred Stock, executed on market terms alongside other investors. The company officially announced it in its Q4 2025 Shareholder Deck, which was released at market close on Wednesday.

The investment follows shareholder approval in 2025 for potential equity stakes in xAI and echoes SpaceX’s earlier $2 billion contribution to xAI’s $10 billion fundraising round.

Tesla said that, earlier this month, it entered an agreement to invest $2 billion to acquire shares of Series E Preferred Stock of xAI:

“Tesla’s investment was made on market terms consistent with those previously agreed to by other investors in the financing round. As set forth… pic.twitter.com/HgtrcHdB2U

— TESLARATI (@Teslarati) January 28, 2026

CEO Elon Musk, who is behind both companies, is now weaving what appears to be an even tighter ecosystem among his ventures, blending Tesla’s hardware prowess with xAI’s cutting-edge AI models, like Grok.

Tesla confirmed the investment in a statement in its Shareholder Deck:

“On January 16, 2026, Tesla entered into an agreement to invest approximately $2 billion to acquire shares of Series E Preferred Stock of xAI as part of their recent publicly-disclosed financing round. Tesla’s investment was made on market terms consistent with those previously agreed to by other investors in the financing round. As set forth in Master Plan Part IV, Tesla is building products and services that bring AI into the physical world. Meanwhile, xAI is developing leading digital AI products and services, such as its large language model (Grok).”

It continued:

“In that context, and as part of Tesla’s broader strategy under Master Plan Part IV, Tesla and xAI also entered into a framework agreement in connection with the investment. Among other things, the framework agreement builds upon the existing relationship between Tesla and xAI by providing a framework for evaluating potential AI collaborations between the companies. Together, the investment and the related framework agreement are intended to enhance Tesla’s ability to develop and deploy AI products and services into the physical world at scale. This investment is subject to customary regulatory conditions with the expectation to close in Q1’2026.”

The history of the partnership traces back to xAI’s founding in July 2023, as Musk launched the company as a counterweight to dominant AI players like OpenAI and Google.

xAI aimed to “understand the true nature of the universe” through unbiased, truth-seeking AI. Tesla, meanwhile, has long invested in AI for its Full Self-Driving (FSD) software and Optimus robots, training models on vast datasets from its vehicle fleet.

The investment holds profound significance for both companies.

For Tesla, it accelerates its Master Plan Part IV, which envisions AI-driven autonomy in vehicles and humanoid robots. xAI’s Grok could enhance Tesla’s real-world AI applications, from optimizing battery management to predictive maintenance, potentially giving Tesla an edge over its biggest rivals, like Waymo.

Investors, on the other hand, stand to gain from this symbiosis. Tesla Shareholders may see boosted stock value through AI innovations, with analysts projecting enhanced margins and significant future growth in robotics. xAI’s valuation could soar, attracting more capital.

Investor's Corner

Tesla (TSLA) Q4 and FY 2025 earnings results

Tesla’s Q4 and FY 2025 earnings come on the heels of a quarter where the company produced over 434,000 vehicles, delivered over 418,000 vehicles, and deployed 14.2 GWh of energy storage products.

Tesla (NASDAQ:TSLA) has released its Q4 and FY 2025 earnings results in an update letter. The document was posted on the electric vehicle maker’s official Investor Relations website after markets closed today, January 28, 2025.

Tesla’s Q4 and FY 2025 earnings come on the heels of a quarter where the company produced over 434,000 vehicles, delivered over 418,000 vehicles, and deployed 14.2 GWh of energy storage products.

For the Full Year 2025, Tesla produced 1,654,667 and delivered 1,636,129 vehicles. The company also deployed a total of 46.7 GWh worth of energy storage products.

Tesla’s Q4 and FY 2025 results

As could be seen in Tesla’s Q4 and FY 2025 Update Letter, the company posted GAAP EPS of $0.24 and non-GAAP EPS of $0.50 per share in the fourth quarter. Tesla also posted total revenues of $24.901 billion. GAAP net income is also listed at $840 million in Q4.

Analyst consensus for Q4 has Tesla earnings per share falling 38% to $0.45 with revenue declining 4% to $24.74 billion, as per estimates from FactSet. In comparison, the consensus compiled by Tesla last week forecasted $0.44 per share on sales totaling $24.49 billion.

For FY 2025, Tesla posted GAAP EPS of $1.08 and non-GAAP EPS of $1.66 per share. Tesla also posted total revenues of $94.827 billion, which include $69.526 billion from automotive and $12.771 billion from the battery storage business. GAAP net income is also listed at $3.794 billion in FY 2025.

xAI Investment

Tesla entered an agreement to invest approximately $2 billion to acquire Series E preferred shares in Elon Musk’s artificial intelligence startup, xAI, as part of the company’s recently disclosed financing round. Tesla said the investment was made on market terms consistent with those agreed to by other participants in the round.

The investment aligns with Tesla’s strategy under Master Plan Part IV, which centers on bringing artificial intelligence into the physical world through products and services. While Tesla focuses on real-world AI applications, xAI is developing digital AI platforms, including its Grok large language model.

Below is Tesla’s Q4 and FY 2025 update letter.

TSLA-Q4-2025-Update by Simon Alvarez

News

Tesla rolls out new Supercharging safety feature in the U.S.

Tesla has rolled out a new Supercharging safety feature in the United States, one that will answer concerns that some owners may have if they need to leave in a pinch.

It is also a suitable alternative for non-Tesla chargers, like third-party options that feature J1772 or CCS to NACS adapters.

The feature has been available in Europe for some time, but it is now rolling out to Model 3 and Model Y owners in the U.S.

With Software Update 2026.2.3, Tesla is launching the Unlatching Charge Cable function, which will now utilize the left rear door handle to release the charging cable from the port. The release notes state:

“Charging can now be stopped and the charge cable released by pulling and holding the rear left door handle for three seconds, provided the vehicle is unlocked, and a recognized key is nearby. This is especially useful when the charge cable doesn’t have an unlatch button. You can still release the cable using the vehicle touchscreen or the Tesla app.”

The feature was first spotted by Not a Tesla App.

This is an especially nice feature for those who commonly charge at third-party locations that utilize plugs that are not NACS, which is the Tesla standard.

For example, after plugging into a J1772 charger, you will still be required to unlock the port through the touchscreen, which is a minor inconvenience, but an inconvenience nonetheless.

Additionally, it could be viewed as a safety feature, especially if you’re in need of unlocking the charger from your car in a pinch. Simply holding open the handle on the rear driver’s door will now unhatch the port from the car, allowing you to pull it out and place it back in its housing.

This feature is currently only available on the Model 3 and Model Y, so Model S, Model X, and Cybertruck owners will have to wait for a different solution to this particular feature.