Rivian’s R1T electric pickup truck took to off-road and speed test proving grounds in Arizona to assess the vehicle’s suspension and performance capabilities ahead of next year’s planned production.

Rivian’s Director of Vehicle Dynamics, Max Koff, put R1T’s quad-motor system, with independent air suspension and hydraulic roll control functionality, to the test through a series of challenging and exhilarating off-road trails. The company’s all-electric pickup boasts a versatile air suspension that can adjust in height and provide clearance between eight inches and high as fourteen inches to optimize for range efficiency and off-road performance.

- Credit: Rivian

- (Credit: Rivian)

- Credit: Rivian

The Arizona testing ground was the ultimate test for Rivian’s claims of an off-road adventure. With plenty of challenges, Rivian shared a video of the R1T being able to make its way up a steep grade of a rock-covered hill and maneuver through an equally challenging descent.

“What you might consider punishing it off-road, but we’re learning. We’re taking all that data in, and we’re constantly developing, making it better on-road and off-road,” Koff explained.

The R1T is more than a durable and robust truck that can handle harsh terrain. It is a high-performance automobile that is capable of 0-60 in just three seconds—powered by the four electric motors that offer 200 horsepower at each wheel and a 180 kWh battery pack that has been developed by Rivian’s team of battery engineers.

- Credit: Rivian

- Credit: Rivian

One of the biggest challenges for Rivian was to come up with a design that would incorporate a concentrated and potent battery pack into Rivian’s small, flexible, and compact skateboard chassis. Engineers indicated that the storage of the cells also brought upon other issues that included cooling the pack assembly in an efficient manner that allows for extended high-performance driving.

Rivian’s development of in-house battery packs allowed the company to “open up possibilities,” one engineer said. This idea enabled the possibility of the battery packs to learn the specific driving styles and charging patterns of its owner to increase the lifespan of the pack, CEO RJ Scaringe said.

It was essential to manufacture a battery pack that could last through the hottest, most-intense driving sessions, but could also maintain its integrity and range capabilities within cold winters. This idea became the main focus of Rivian’s battery team, which ultimately drove Koff’s off and on-road testing session to display impressive results.

The electric automotive market continues to grow, and pickup trucks are becoming a focus of many battery-electric manufacturers whose idea is to create a powerful, high-performance machine that is capable of handling the most strenuous tasks thrown at it. Tesla’s Cybertruck, Ford’s electric F-150, Rivian’s R1T, Lordstown’s Endurance, and other battery-powered pickups will attempt to push their way into a market that is concentrated with petrol-powered machines.

Rivian’s R1T is expected to begin production in 2021.

Watch the Rivian R1T undergo off-road a speed performance testing below.

Elon Musk

Elon Musk shares incredible detail about Tesla Cybercab efficiency

Elon Musk shared an incredible detail about Tesla Cybercab’s potential efficiency, as the company has hinted in the past that it could be one of the most affordable vehicles to operate from a per-mile basis.

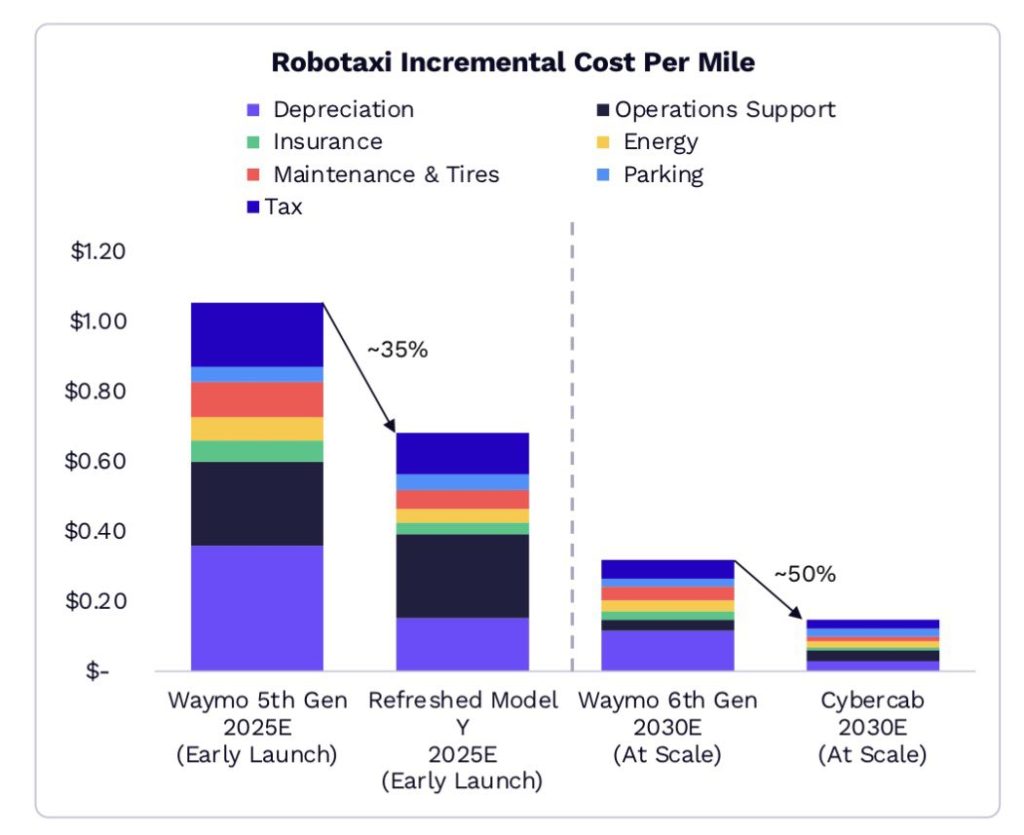

ARK Invest released a report recently that shed some light on the potential incremental cost per mile of various Robotaxis that will be available on the market in the coming years.

The Cybercab, which is detailed for the year 2030, has an exceptionally low cost of operation, which is something Tesla revealed when it unveiled the vehicle a year and a half ago at the “We, Robot” event in Los Angeles.

Musk said on numerous occasions that Tesla plans to hit the $0.20 cents per mile mark with the Cybercab, describing a “clear path” to achieving that figure and emphasizing it is the “full considered” cost, which would include energy, maintenance, cleaning, depreciation, and insurance.

Probably true

— Elon Musk (@elonmusk) January 22, 2026

ARK’s report showed that the Cybercab would be roughly half the cost of the Waymo 6th Gen Robotaxi in 2030, as that would come in at around $0.40 per mile all in. Cybercab, at scale, would be at $0.20.

Credit: ARK Invest

This would be a dramatic decrease in the cost of operation for Tesla, and the savings would then be passed on to customers who choose to utilize the ride-sharing service for their own transportation needs.

The U.S. average cost of new vehicle ownership is about $0.77 per mile, according to AAA. Meanwhile, Uber and Lyft rideshares often cost between $1 and $4 per mile, while Waymo can cost between $0.60 and $1 or more per mile, according to some estimates.

Tesla’s engineering has been the true driver of these cost efficiencies, and its focus on creating a vehicle that is as cost-effective to operate as possible is truly going to pay off as the vehicle begins to scale. Tesla wants to get the Cybercab to about 5.5-6 miles per kWh, which has been discussed with prototypes.

Additionally, fewer parts due to the umboxed manufacturing process, a lower initial cost, and eliminating the need to pay humans for their labor would also contribute to a cheaper operational cost overall. While aspirational, all of the ingredients for this to be a real goal are there.

It may take some time as Tesla needs to hammer the manufacturing processes, and Musk has said there will be growing pains early. This week, he said regarding the early production efforts:

“…initial production is always very slow and follows an S-curve. The speed of production ramp is inversely proportionate to how many new parts and steps there are. For Cybercab and Optimus, almost everything is new, so the early production rate will be agonizingly slow, but eventually end up being insanely fast.”

Elon Musk

Elon Musk to attend 2026 World Economic Forum at Davos

The Tesla CEO was confirmed as a last-minute speaker for a session with BlackRock CEO Larry Fink.

Elon Musk is poised to attend the 2026 World Economic Forum in Davos. The Tesla CEO was confirmed as a last-minute speaker for a session with BlackRock CEO Larry Fink, signaling a thaw in Musk’s long-strained relationship with the event.

A late addition

Organizers of the World Economic Forum confirmed that Elon Musk was added shortly before the event to a Thursday afternoon session, where he was scheduled to speak with Fink, as noted in a Bloomberg News report. Musk’s upcoming appearance marks Musk’s first participation in the forum, which annually draws political leaders, business executives, and global media to Davos, Switzerland.

Musk’s attendance represents a departure from his past stance toward the event. He had been invited in prior years but declined to attend, including in 2024. His upcoming appearance followed remarks from his political ally, Donald Trump, who addressed the forum earlier in the week with a wide-ranging speech.

A previously strained relationship

Musk had frequently criticized the World Economic Forum in the past, describing it as elitist and questioning its influence. In earlier posts, he characterized the gathering as “boring” and accused it of functioning like an unelected global authority. Those remarks contributed to a long-running distance between Musk and WEF organizers.

The forum previously said Musk had not been invited since 2015, though that position has since shifted. Organizers indicated last year that Musk was welcome amid heightened interest in his political and business activities, including his involvement in the Trump administration’s Department of Government Efficiency (DOGE). Musk later stepped away from that role.

Despite his friction with the World Economic Forum, Musk has remained central to several global events, from SpaceX’s provision of satellite internet services in geopolitically sensitive regions through Starlink to the growing use of xAI’s Grok in U.S. government applications.

News

Tesla states Giga Berlin workforce is stable, rejects media report

As per the electric vehicle maker, production and employment levels at the facility remain stable.

Tesla Germany has denied recent reports alleging that it has significantly reduced staffing at Gigafactory Berlin. As per the electric vehicle maker, production and employment levels at the facility remain stable.

Tesla denies Giga Berlin job cuts report

On Wednesday, German publication Handelsblatt reported that Tesla’s workforce in Gigafactory Berlin had been reduced by about 1,700 since 2024, a 14% drop. The publication cited internal documents as its source for its report.

In a statement to Reuters, Tesla Germany stated that there has been no significant reduction in permanent staff at its Gigafactory in Grünheide compared with 2024, and that there are no plans to curb production or cut jobs at the facility.

“Compared to 2024, there has been no significant reduction in the number of permanent staff. Nor are there any such plans. Compared to 2024, there has been no significant reduction in the number of permanent staff. Nor are there any such plans,” Tesla noted in an emailed statement.

Tesla Germany also noted that it’s “completely normal” for a facility like Giga Berlin to see fluctuations in its headcount.

A likely explanation

There might be a pretty good reason why Giga Berlin reduced its headcount in 2024. As highlighted by industry watcher Alex Voigt, in April of that year, Elon Musk reduced Tesla’s global workforce by more than 10% as part of an effort to lower costs and improve productivity. At the time, several notable executives departed the company, and the Supercharger team was culled.

As with Tesla’s other factories worldwide, Giga Berlin adjusted staffing during that period as well. This could suggest that a substantial number of the 1,700 employees reported by Handelsblatt were likely part of the workers who were let go by Elon Musk during Tesla’s last major workforce reduction.

In contrast to claims of contraction, Tesla has repeatedly signaled plans to expand production capacity in Germany. Giga Berlin factory manager André Thierig has stated on several occasions that the site is expected to increase output in 2026, reinforcing the idea that the facility’s long-term trajectory remains growth-oriented.