News

SpaceX’s odd Starbase propellant storage tank prototype passes first test

Likely to the relief of many, SpaceX appears to have successfully tested a prototype of the custom-built Starbase propellant storage tanks that will eventually hold thousands of tons of fuel and oxidizer.

For reasons unknown, SpaceX’s built its first ground support equipment (GSE) ‘test tank’ – a subscale prototype designed to quickly verify basic production quality and design goals – months after it began mass-producing operational storage tanks. In fact, of the seven total GSE tanks expected to be built, SpaceX has already completed seven, installed five, and scrapped one. Known as GSE4, SpaceX actually used modified parts of that scrapped tank to assemble the GSE test tank that first rolled to Starbase’s launch (and test) facilities on August 23rd.

Two days later, SpaceX subjected the small tank to its first test.

Given that SpaceX appears to have almost retroactively assembled the GSE4 test tank after building the final products, the results from its testing were always going to be significantly more anxiety-inducing than any of the more than half-dozen other tanks the company has tested in the last year and a half. Having already fabricated, assembled, or even installed six of seven planned GSE tanks, the discovery of major issues during testing could potentially cause months of delays by forcing SpaceX to perform lengthy repairs or even fully scrap all six existing tanks and start over.

Thankfully, at least for the time being, it appears that SpaceX can write off those potential worst-case scenarios. On August 25th, SpaceX took advantage of a test window initially believed to be for Starship S20 and put the cobbled-together GSE4 tank through its paces for the first time. As with previous test tanks, all SpaceX can really do is fill the prototype with liquid nitrogen (LN2), a non-flammable alternative to liquid oxygen or methane propellant that is approximately as cold and heavy. As a storage tank prototype, though, GSE4 has no need for hydraulic ram setups used to simulate the thrust of Raptor engines on several previous prototypes.

As such, one or several cryogenic proof tests were all that were ever really in GSE4’s future. On GSE4’s first test, SpaceX performed a more or less normal cryogenic proof, completely filling the tank with LN2, closing its vents, and then allowing the natural process of LN2 boiloff to raise the tank to the desired test pressure. However, unlike other test tanks, GSE4 never actually appeared to reopen its main vents. In fact, SpaceX may have never actually drained liquid nitrogen from the test tank, instead simply letting it slowly warm up and boil off into gas that was seemingly managed and vented by ground systems instead of the tank itself.

As a result, GSE4 stayed frosty (indicating a significant amount of remaining liquid nitrogen) for more than eight hours, strongly implying that it was either very slowly drained or simply allowed to warm up naturally. Given that large cryogenic storage tanks really don’t have to be significantly pressurized to complete their job, it’s possible that GSE4’s first test was primarily meant to verify the basic structural integrity of a tank that’s slightly different than those on Starship and, more importantly, test a different method of pressure and fluid management where most of that work is done by external, permanent systems on the ground.

That’s exactly what one might expect of rocket tankage slightly modified to serve as ground storage tanks. SpaceX’s GSE tanks never have to act as self-contained units and can instead rely almost entirely on separate systems.

Aside from verifying that that slightly different method of tank operations works as expected, GSE4’s first test likely also allowed SpaceX to better characterize the thermal properties of the thin steel skin and domes that are Starship and GSE tanks. Unlike GSE4, operational GSE tanks will be enclosed inside 12m (~40 ft) wide ‘cryo shells’ designed to insulate their cryogenic contents, but the insulative properties of the inner tanks (or the lack there of, rather) will still determine how well that insulation works and how much is actually needed to reach the desired boiloff rates. A contractor hired by SpaceX has already completed all seven cryo shells, so any results gathered from GSE4 will obviously be more of a check than a developmental test, but data is still data.

Elon Musk

Tesla engineers deflected calls from this tech giant’s now-defunct EV project

Tesla engineers deflected calls from Apple on a daily basis while the tech giant was developing its now-defunct electric vehicle program, which was known as “Project Titan.”

Back in 2022 and 2023, Apple was developing an EV in a top-secret internal fashion, hoping to launch it by 2028 with a fully autonomous driving suite.

However, Apple bailed on the project in early 2024, as Project Titan abandoned the project in an email to over 2,000 employees. The company had backtracked its expectations for the vehicle on several occasions, initially hoping to launch it with no human driving controls and only with an autonomous driving suite.

Apple canceling its EV has drawn a wide array of reactions across tech

It then planned for a 2028 launch with “limited autonomous driving.” But it seemed to be a bit of a concession at that point; Apple was not prepared to take on industry giants like Tesla.

Wedbush’s Dan Ives noted in a communication to investors that, “The writing was on the wall for Apple with a much different EV landscape forming that would have made this an uphill battle. Most of these Project Titan engineers are now all focused on AI at Apple, which is the right move.”

Apple did all it could to develop a competitive EV that would attract car buyers, including attempting to poach top talent from Tesla.

In a new podcast interview with Tesla CEO Elon Musk, it was revealed that Apple had been calling Tesla engineers nonstop during its development of the now-defunct project. Musk said the engineers “just unplugged their phones.”

Musk said in full:

“They were carpet bombing Tesla with recruiting calls. Engineers just unplugged their phones. Their opening offer without any interview would be double the compensation at Tesla.”

Interestingly, Apple had acquired some ex-Tesla employees for its project, like Senior Director of Engineering Dr. Michael Schwekutsch, who eventually left for Archer Aviation.

Tesla took no legal action against Apple for attempting to poach its employees, as it has with other companies. It came after EV rival Rivian in mid-2020, after stating an “alarming pattern” of poaching employees was noticed.

Elon Musk

Tesla to a $100T market cap? Elon Musk’s response may shock you

There are a lot of Tesla bulls out there who have astronomical expectations for the company, especially as its arm of reach has gone well past automotive and energy and entered artificial intelligence and robotics.

However, some of the most bullish Tesla investors believe the company could become worth $100 trillion, and CEO Elon Musk does not believe that number is completely out of the question, even if it sounds almost ridiculous.

To put that number into perspective, the top ten most valuable companies in the world — NVIDIA, Apple, Alphabet, Microsoft, Amazon, TSMC, Meta, Saudi Aramco, Broadcom, and Tesla — are worth roughly $26 trillion.

Will Tesla join the fold? Predicting a triple merger with SpaceX and xAI

Cathie Wood of ARK Invest believes the number is reasonable considering Tesla’s long-reaching industry ambitions:

“…in the world of AI, what do you have to have to win? You have to have proprietary data, and think about all the proprietary data he has, different kinds of proprietary data. Tesla, the language of the road; Neuralink, multiomics data; nobody else has that data. X, nobody else has that data either. I could see $100 trillion. I think it’s going to happen because of convergence. I think Tesla is the leading candidate [for $100 trillion] for the reason I just said.”

Musk said late last year that all of his companies seem to be “heading toward convergence,” and it’s started to come to fruition. Tesla invested in xAI, as revealed in its Q4 Earnings Shareholder Deck, and SpaceX recently acquired xAI, marking the first step in the potential for a massive umbrella of companies under Musk’s watch.

SpaceX officially acquires xAI, merging rockets with AI expertise

Now that it is happening, it seems Musk is even more enthusiastic about a massive valuation that would swell to nearly four-times the value of the top ten most valuable companies in the world currently, as he said on X, the idea of a $100 trillion valuation is “not impossible.”

It’s not impossible

— Elon Musk (@elonmusk) February 6, 2026

Tesla is not just a car company. With its many projects, including the launch of Robotaxi, the progress of the Optimus robot, and its AI ambitions, it has the potential to continue gaining value at an accelerating rate.

Musk’s comments show his confidence in Tesla’s numerous projects, especially as some begin to mature and some head toward their initial stages.

Elon Musk

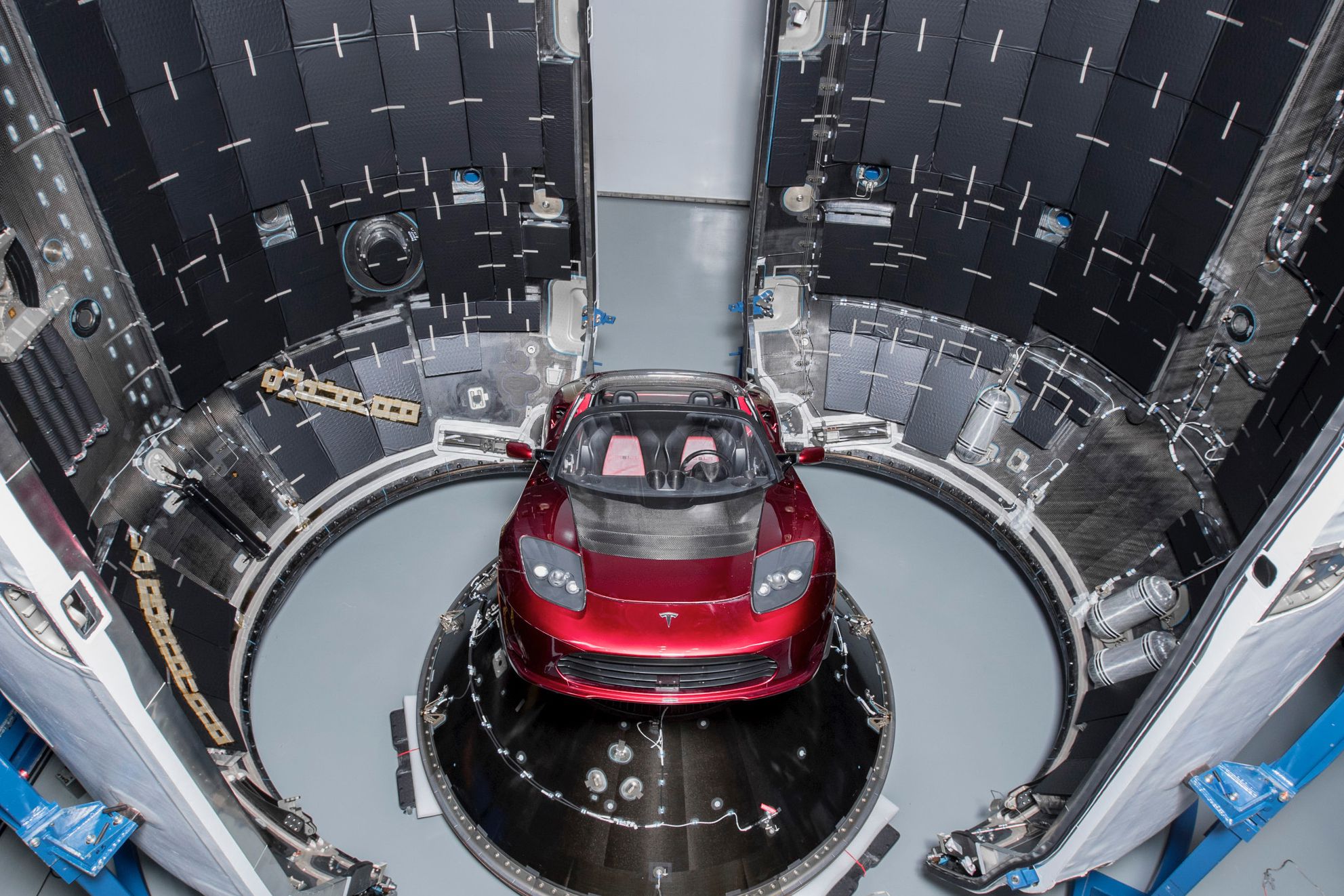

Celebrating SpaceX’s Falcon Heavy Tesla Roadster launch, seven years later (Op-Ed)

Seven years later, the question is no longer “What if this works?” It’s “How far does this go?”

When Falcon Heavy lifted off in February 2018 with Elon Musk’s personal Tesla Roadster as its payload, SpaceX was at a much different place. So was Tesla. It was unclear whether Falcon Heavy was feasible at all, and Tesla was in the depths of Model 3 production hell.

At the time, Tesla’s market capitalization hovered around $55–60 billion, an amount critics argued was already grossly overvalued. SpaceX, on the other hand, was an aggressive private launch provider known for taking risks that traditional aerospace companies avoided.

The Roadster launch was bold by design. Falcon Heavy’s maiden mission carried no paying payload, no government satellite, just a car drifting past Earth with David Bowie playing in the background. To many, it looked like a stunt. For Elon Musk and the SpaceX team, it was a bold statement: there should be some things in the world that simply inspire people.

Inspire it did, and seven years later, SpaceX and Tesla’s results speak for themselves.

Today, Tesla is the world’s most valuable automaker, with a market capitalization of roughly $1.54 trillion. The Model Y has become the best-selling car in the world by volume for three consecutive years, a scenario that would have sounded insane in 2018. Tesla has also pushed autonomy to a point where its vehicles can navigate complex real-world environments using vision alone.

And then there is Optimus. What began as a literal man in a suit has evolved into a humanoid robot program that Musk now describes as potential Von Neumann machines: systems capable of building civilizations beyond Earth. Whether that vision takes decades or less, one thing is evident: Tesla is no longer just a car company. It is positioning itself at the intersection of AI, robotics, and manufacturing.

SpaceX’s trajectory has been just as dramatic.

The Falcon 9 has become the undisputed workhorse of the global launch industry, having completed more than 600 missions to date. Of those, SpaceX has successfully landed a Falcon booster more than 560 times. The Falcon 9 flies more often than all other active launch vehicles combined, routinely lifting off multiple times per week.

Falcon 9 has ferried astronauts to and from the International Space Station via Crew Dragon, restored U.S. human spaceflight capability, and even stepped in to safely return NASA astronauts Butch Wilmore and Suni Williams when circumstances demanded it.

Starlink, once a controversial idea, now dominates the satellite communications industry, providing broadband connectivity across the globe and reshaping how space-based networks are deployed. SpaceX itself, following its merger with xAI, is now valued at roughly $1.25 trillion and is widely expected to pursue what could become the largest IPO in history.

And then there is Starship, Elon Musk’s fully reusable launch system designed not just to reach orbit, but to make humans multiplanetary. In 2018, the idea was still aspirational. Today, it is under active development, flight-tested in public view, and central to NASA’s future lunar plans.

In hindsight, Falcon Heavy’s maiden flight with Elon Musk’s personal Tesla Roadster was never really about a car in space. It was a signal that SpaceX and Tesla were willing to think bigger, move faster, and accept risks others wouldn’t.

The Roadster is still out there, orbiting the Sun. Seven years later, the question is no longer “What if this works?” It’s “How far does this go?”