News

LG Energy Solutions & Toyota sign battery supply deal for EVs made in the United States

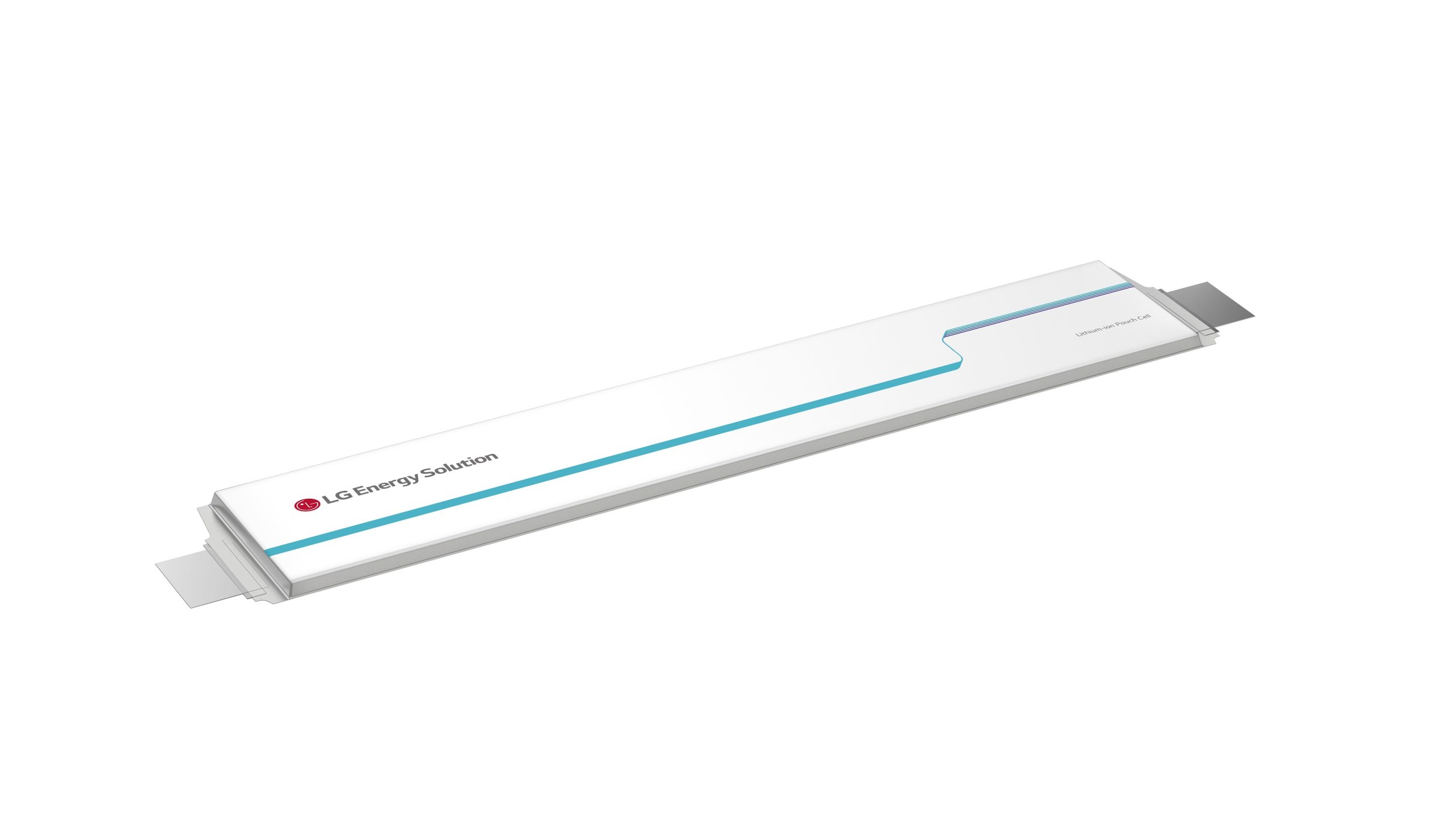

LG Energy Solution (LGES) and Toyota signed a battery supply deal for electric vehicles produced in the United States. LGES will supply Toyota with NCMA Long Cell pouch-type batteries.

The agreement stipulates that LGES will supply Toyota with 20 GWh of high-nickel NCMA battery modules annually beginning in 2025. The South Korean battery supplier will produce Toyota’s NCMA battery modules at its new Michigan facility. The Japanese automaker plans to equip the LGES battery modules in electric vehicles built at the Toyota manufacturing facility in Kentucky.

“At Toyota, our goal is to reduce carbon emissions as much as possible, as fast as possible,” said the President and CEO of Toyota Motor North America, Tetsuo “Ted” Ogawa.

“Having secure supplies of lithium-ion batteries at scale with a long-term relationship to support Toyota’s multi-pathway approach and growth plans for BEVs in North America is critical to achieving our manufacturing and carbon reduction plans. Working with LG Energy Solution, we are excited to be able to offer products that will provide the performance and quality our customers expect,” Ozawa added.

Last month, Toyota announced its aim to produce 600,000 battery electric vehicle units by 2025. The recent LGES supply deal is a step toward Toyota’s goal. As part of the agreement, LGES will invest $3 billion in its Michigan battery facility to establish cell and module production lines exclusively catering to Toyota’s needs. The new production lines are expected to be complete by 2025.

In May 2023, Toyota affirmed its commitment to electrification by unveiling a three-row battery electric SUV in Kentucky. The Japanese automaker announced that production of the new electric SUV would start by 2025 in Kentucky. It also shared that the batteries for the three-row all-electric SUV would come from Toyota’s battery manufacturing plant in North Carolina.

The legacy automaker planned to invest an additional $2.1 billion in the new battery facility in North Carolina called the Liberty plant—for the production of the three-row electric SUV. The Liberty plant is expected to start production by 2025 with six battery assembly lines, four dedicated to hybrid EVs and two focused on cells for battery electric vehicles (BEVs).

The Teslarati team would appreciate hearing from you. If you have any tips, contact me at maria@teslarati.com or via X @Writer_01001101.

Elon Musk

xAI’s Grok approved for Pentagon classified systems: report

Under the agreement, Grok can be deployed in systems handling classified intelligence analysis, weapons development, and battlefield operations.

Elon Musk’s xAI has signed an agreement with the United States Department of Defense (DoD) to allow Grok to be used in classified military systems.

Previously, Anthropic’s Claude had been the only AI system approved for the most sensitive military work, but a dispute over usage safeguards has reportedly prompted the Pentagon to broaden its options, as noted in a report from Axios.

Under the agreement, Grok can be deployed in systems handling classified intelligence analysis, weapons development, and battlefield operations.

The publication reported that xAI agreed to the Pentagon’s requirement that its technology be usable for “all lawful purposes,” a standard Anthropic has reportedly resisted due to alleged ethical restrictions tied to mass surveillance and autonomous weapons use.

Defense Secretary Pete Hegseth is scheduled to meet with Anthropic CEO Dario Amodei in what sources expect to be a tense meeting, with the publication hinting that the Pentagon could designate Anthropic a “supply chain risk” if the company does not lift its safeguards.

Axios stated that replacing Claude fully might be technically challenging even if xAI or other alternative AI systems take its place. That being said, other AI systems are already in use by the DoD.

Grok already operates in the Pentagon’s unclassified systems alongside Google’s Gemini and OpenAI’s ChatGPT. Google is reportedly close to an agreement that will result in Gemini being used for classified use, while OpenAI’s progress toward classified deployment is described as slower but still feasible.

The publication noted that the Pentagon continues talks with several AI companies as it prepares for potential changes in classified AI sourcing.

Elon Musk

Elon Musk denies Starlink’s price cuts are due to Amazon Kuiper

“This has nothing to do with Kuiper, we’re just trying to make Starlink more affordable to a broader audience,” Musk wrote in a post on X.

Elon Musk has pushed back on claims that Starlink’s recent price reductions are tied to Amazon’s Kuiper project.

In a post on X, Musk responded directly to a report suggesting that Starlink was cutting prices and offering free hardware to partners ahead of a planned IPO and increased competition from Kuiper.

“This has nothing to do with Kuiper, we’re just trying to make Starlink more affordable to a broader audience,” Musk wrote in a post on X. “The lower the cost, the more Starlink can be used by people who don’t have much money, especially in the developing world.”

The speculation originated from a post summarizing a report from The Information, which ran with the headline “SpaceX’s Starlink Makes Land Grab as Amazon Threat Looms.” The report stated that SpaceX is aggressively cutting prices and giving free hardware to distribution partners, which was interpreted as a reaction to Amazon’s Kuiper’s upcoming rollout and possible IPO.

In a way, Musk’s comments could be quite accurate considering Starlink’s current scale. The constellation currently has more than 9,700 satellites in operation today, making it by far the largest satellite broadband network in operation. It has also managed to grow its user base to 10 million active customers across more than 150 countries worldwide.

Amazon’s Kuiper, by comparison, has launched approximately 211 satellites to date, as per data from SatelliteMap.Space, some of which were launched by SpaceX’s Falcon 9 rocket. Starlink surpassed that number in early January 2020, during the early buildout of its first-generation network.

Lower pricing also aligns with Starlink’s broader expansion strategy. SpaceX continues to deploy satellites at a rapid pace using Falcon 9, and future launches aboard Starship are expected to significantly accelerate the constellation’s growth. A larger network improves capacity and global coverage, which can support a broader customer base.

In that context, price reductions can be viewed as a way to match expanding supply with growing demand. Musk’s companies have historically used aggressive pricing strategies to drive adoption at scale, particularly when vertical integration allows costs to decline over time.

News

Tesla Giga Berlin makes a statement of solidarity amid IG Metall conflict

The display comes as tensions between Tesla and IG Metall continue to escalate.

Tesla Giga Berlin is sending a strong message of solidarity amid its ongoing legal dispute with German union IG Metall.

In a post on social media platform X, Giga Berlin plant manager André Thierig shared an image of the facility’s lobby covered with a large banner that reads: “Progress. Innovation. Success.” He added that the slogan reflects what the facility has stood for since Day One.

“Our lobby at Giga Berlin covered in a huge banner these days. Progress. Innovation. Success – this is what we stand for since we started production in 2022 and how we will go into our future!” Thierig wrote in his post on X.

The display comes as tensions between Tesla and IG Metall continue to escalate.

The dispute began after Tesla accused a union representative of secretly recording a works council meeting at Giga Berlin. Tesla stated that it filed a criminal complaint after the alleged incident. Police later confirmed they had seized a computer belonging to an IG Metall member as part of their investigation.

“What has happened today at Giga Berlin is truly beyond words! An external union representative from IG Metall attended a works council meeting. For unknown reasons he recorded the internal meeting and was caught in action! We obviously called police and filed a criminal complaint!” Thierig wrote on X at the time.

IG Metall denied the accusation and characterized Tesla’s move as an election tactic ahead of upcoming works council elections. The union subsequently filed a defamation complaint against Thierig. Authorities later confirmed that an investigation had been opened in connection with the matter.

Giga Berlin began production in 2022 and has since become one of Tesla’s key European manufacturing hubs, producing the Model Y, the company’s best-selling vehicle. The facility has expanded capacity over the past years despite environmental protests, labor disputes, and regulatory scrutiny.