News

SpaceX CEO Elon Musk explains Starship’s ‘transpiring’ steel heat shield in Q&A

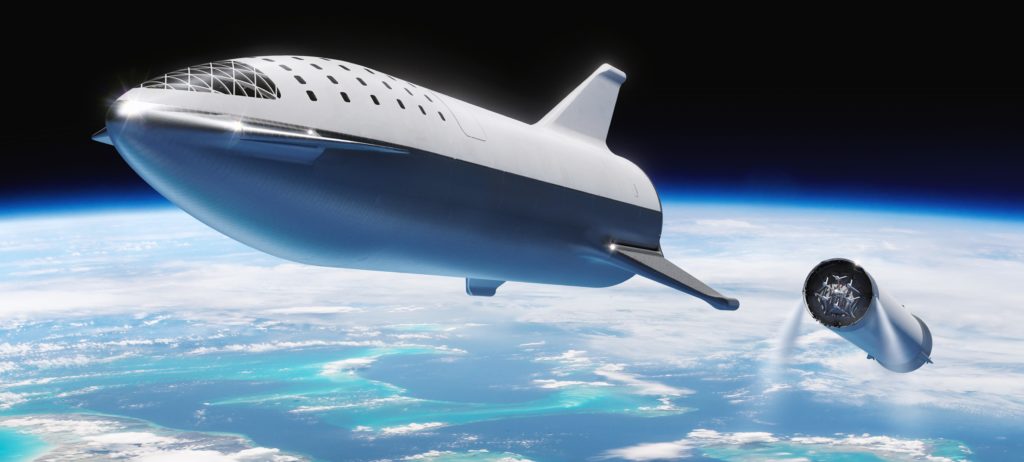

Speaking in a late-December 2018 interview with Popular Mechanics’ editor-in-chief, SpaceX CEO Elon Musk shared considerable insight into the thought processes that ultimately led him to – in his own words – “convince” his team that the company’s BFR rocket (now Starship and Super Heavy) should pivot from an advanced composite structure to a relatively common form of stainless steel.

Aside from steel’s relative ease of manipulation and affordability, Musk delved into the technical solution he arrived at for an advanced, ultra-reusable heat shield for Starship – build it out of steel and use water (or liquid methane) to wick reentry heat away.

When going to ~1750 Kelvin, specific heat is more important than latent heat of vaporization, which is why cryogenic fuel is a slightly better choice than water

— Elon Musk (@elonmusk) January 22, 2019

Although there has been some successful experimental research done on “transpirational” heat shields (relying on the heat capacity of vaporizing liquids or gases to soak up thermal energy during orbital rocket reentries), Musk is by no means wrong when he says that a stainless steel sandwich-hulled spaceship regeneratively cooled by microscopic holes and liquid water or propellant “has never been proposed before”. While the basic concept probably arose somewhere over the last 50-100 years, it does not appear that any serious theoretical or experimental research has been conducted to explore transpiration-cooled metallic heat shields, where metallic thermal protection systems (TPS) are already fairly exotic and unproven in the realm of modern aerospace.

“Very easy to work with steel. Oh, and I forgot to mention: [SpaceX’s high-quality] carbon fiber is $135 a kilogram, 35 percent scrap, so you’re starting to approach almost $200 a kilogram. [301] steel is $3 a kilogram.” – Elon Musk

While Musk’s solution could dramatically simplify what is needed for Starship’s high-performance heat shield, a stainless steel sandwich on half of Starship offers another huge benefit: the spacecraft can still gain many of the mass ratio benefits of stainless steel balloon tanks (metal tanks so thin that they collapse without positive pressure) while retaining structural rigidity even when depressurized. At the end of the day, Musk very well might be correct when he states that a stainless steel Starship can ultimately be more mass-efficient (“lighter”) than a Starship built out of advanced carbon composites, a characteristic he rightly describes as “counterintuitive”.

- Starhopper and SpaceX’s spartan assembly facilities are pictured here, showing the inside of the aft section and a completed tank dome. (Austin Barnard)

- Starship has been shown with actuating fins and canard wings since SpaceX’s September 2018 update. (SpaceX)

What does Science™ have to say?

Based on research done in the 2010s by German space agency (DLR), a porous thermal protection material called Procelit 170 (P170) – 91% aluminum oxide and 9% silicon oxide – was cooled from a peak heat of ~1750 C (3200 F) to ~25 C (75 F) during wind tunnel testing, demonstrating that an average of 0.065 kg (~2.3 oz) of water per second would be needed to cool a square meter of P170 to the same degree, assuming a heating rate of around 200 kW/m^2. Given that 300-series stainless steels have a comparatively huge capacity for radiating heat at high temperatures, will be dramatically thinner than Procelit in any given Starship use-case, and will not need to be cooled all the way to 25C/75F during hot operations, the DLR-derived number is barely relevant without another round of wind tunnel tests focused on metallic thermal protection systems. Still, it allows for the creation of a sort of worst-case scenario for BFS/Starship’s water-cooled shield.

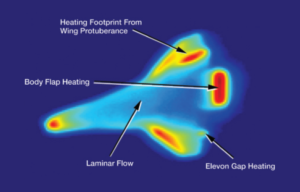

Assuming that the windward side of Starship’s regeneratively cooled heat shield has roughly the same surface area as half of a cylinder, 800 m^2 (8600 ft^2) will have to be actively cooled with water, translating to a water consumption rate of approximately 52 kg/s (115 lb/s) if the entire surface is being subjected to temperatures around ~1750 C. That is, of course, a grossly inaccurate generalization, as aerodynamic surfaces dramatically shape, dissipate, and concentrate airflows (and thus heat from friction) in complex and highly specific ways. Much like NASA’s Space Shuttle or DLR’s theoretical SpaceLiner, the reality of reentry heating is that that heat typically ends up being focused at leading edges and control surfaces, which thus require uniquely capable versions of thermal protection (TPS). Shuttle used fragile reinforced carbon-carbon tiles at those hotspots, while DLR was exploring water cooling as a viable and safer alternative for SpaceLiner.

- Starship’s first full-scale prototype is being rapidly assembled in South Texas. (NASASpaceflight – bocachicagal)

- Starship’s first full-scale prototype is being rapidly assembled in South Texas. (NASASpaceflight – bocachicagal)

- Meanwhile, giant 9m-diameter tank domes are being assembled and welded together a few hundred feet away from Starhopper. (NSF – bocachicagal)

- SpaceX’s Starhopper seen in a January render and a January photo. (SpaceX/Elon Musk)

- BFS seen standing vertically on the pads of its tripod fins. (SpaceX)

- A NASA team—via a US Navy aircraft—captured high-resolution, calibrated infrared imagery of Space Shuttle Discovery’s lower surface in addition to discrete instrumentation on the wing, downstream, and on the Boundary Layer Transition Flight Experiment protuberance. In the image, the red regions represent higher surface temperatures. (NASA)

Aside from heat flux, it’s also unclear when or how long the cooling system will need to be supplied with water during potential Starship reentries. At worst, the spacecraft would need to supply a constant 50+ kg/s throughout a 5+ minute (600+ second) regime of high-velocity, high-drag reentry conditions. Assuming that Starship will need to rely heavily on aerobraking to maintain efficient interplanetary operations, it might have to perform 2+ active-cooling cycles per reentry, potentially requiring a minimum of 15 tons of water per reentry. Given that SpaceX intends (at least as of September 2018) for Starship to be able to land more than 100 tons on the surface of Mars, 15t of water would cut drastically into payload margins and is thus likely an unfeasibly large mass reserve or any given interplanetary mission.

“You just need, essentially, [a stainless-steel sandwich]. You flow either fuel or water in between the sandwich layer, and then you have [very tiny] perforations on the outside and you essentially bleed water [or fuel] through them … to cool the windward side of the rocket.” – SpaceX CEO Elon Musk (Popular Mechanics, December 2018)

The assumptions needed for the above calculations do mean that 30T is an absolute worst-case scenario for a regeneratively-cooled Starship reentry, given that SpaceX may only have to vigorously cool a small fraction of its windward surface and will likely be able to cut more than half of the water needed by allowing Starship’s steel skin to heat quite a lot while still staying well below its melting point (likely around 800C/1500F or higher). This also fails to account for the fact that a regeneratively-cooled stainless steel heat shield would effectively let SpaceX do away with what would otherwise be a massive and heavy ablative heat shield and mounting mechanism. Perhaps the benefits of stainless steel might ultimately mean that carrying around 10-30T of coolant is actually performance-neutral or a minimal burden when all costs and benefits are properly accounted for.

Probability at 60% & rising rapidly due to new architecture

— Elon Musk (@elonmusk) December 27, 2018

Musk clearly believes with almost zero doubt that a stainless steel Starship and booster (Super Heavy) is the way forward for the company’s BFR program, and he has now twice indicated that the switch away from advanced carbon composites will actually “accelerate” the rocket’s development schedule. For now, all we can do is watch as the first Starship prototype – meant to perform short hop tests ASAP – gradually comes into being in South Texas.

Cybertruck

Tesla confirms date when new Cybertruck trim will go up in price

Tesla has officially revealed that this price will only be available until February 28, as the company has placed a banner atop the Design Configurator on its website reflecting this.

Tesla has confirmed the date when its newest Cybertruck trim level will increase in price, after CEO Elon Musk noted that the All-Wheel-Drive configuration of the all-electric pickup would only be priced at its near-bargain level for ten days.

Last week, Tesla launched the All-Wheel-Drive configuration of the Cybertruck. Priced at $59,990, the Cybertruck featured many excellent features and has seemingly brought some demand to the pickup, which has been underwhelming in terms of sales figures over the past couple of years.

Tesla launches new Cybertruck trim with more features than ever for a low price

When Tesla launched it, many fans and current owners mulled the possibility of ordering it. However, Musk came out and said just hours after launching the pickup that Tesla would only keep it at the $59,990 price level for ten days.

What it would be priced at subsequently was totally dependent on how much demand Tesla felt for the new trim level, which is labeled as a “Dual Motor All-Wheel-Drive” configuration.

Tesla has officially revealed that this price will only be available until February 28, as the company has placed a banner atop the Design Configurator on its website reflecting this:

NEWS: Tesla has officially announced that the price of the new Cybertruck Dual-Motor AWD will be increasing after February 28th. pic.twitter.com/vZpA521ZwC

— Sawyer Merritt (@SawyerMerritt) February 24, 2026

Many fans and owners have criticized Tesla’s decision to unveil a trim this way, and then price it at something, only to change that price a few days later based on how well it sells.

Awful way to treat customers – particularly when they already sent out a marketing email announcing the $59,990 truck…with zero mention of it being a limited-time offer.

— Ryan McCaffrey (@DMC_Ryan) February 24, 2026

It seems the most ideal increase in price would be somewhere between $5,000 and $10,000, but it truly depends on how many orders Tesla sees for this new trim level. The next step up in configuration is the Premium All-Wheel-Drive, which is priced at $79,990.

The difference between the Dual Motor AWD Cybertruck and the Premium AWD configuration comes down to towing, interior quality, and general features. The base package is only capable of towing up to 7,500 pounds, while the Premium can handle 11,000 pounds. Additionally, the seats in the Premium build are Vegan Leather, while the base trim gets the textile seats.

It also has only 7 speakers compared to the 15 that the Premium trim has. Additionally, the base model does not have an adjustable ride height, although it does have a coil spring with an adaptive damping suspension package.

Cybertruck

Tesla set to activate long-awaited Cybertruck feature

Tesla will officially activate the Active Noise Cancellation (ANC) feature on Cybertruck soon, as the company has officially added the feature to its list of features by trim on its website.

Tesla is set to activate a long-awaited Cybertruck feature, and no matter when you bought your all-electric pickup, it has the hardware capable of achieving what it is designed to do.

Tesla simply has to flip the switch, and it plans to do so in the near future.

Tesla will officially activate the Active Noise Cancellation (ANC) feature on Cybertruck soon, according to Not a Tesla App, as the company has officially added the feature to its list of features by trim on its website.

Tesla rolls out Active Road Noise Reduction for new Model S and Model X

The ANC feature suddenly appeared on the spec sheet for the Premium All-Wheel-Drive and Cyberbeast trims, which are the two configurations that have been delivered since November 2023.

However, those trims have both had the ANC disabled, and although they are found in the Model S and Model X, and are active in those vehicles, Tesla is planning to activate them.

In Tesla’s Service Toolbox, it wrote:

“ANC software is not enabled on Cybertruck even though the hardware is installed.”

Tesla has utilized an ANC system in the Model S and Model X since 2021. The system uses microphones embedded in the front seat headrests to detect low-frequency road noise entering the cabin. It then generates anti-noise through phase-inverted sound waves to cancel out or reduce that noise, creating quieter zones, particularly around the vehicle’s front occupants.

The Model S and Model X utilize six microphones to achieve this noise cancellation, while the Cybertruck has just four.

Tesla Cybertruck Dual Motor AWD estimated delivery slips to early fall 2026

As previously mentioned, this will be activated through a software update, as the hardware is already available within Cybertruck and can simply be activated at Tesla’s leisure.

The delays in activating the system are likely due to Tesla Cybertruck’s unique design, which is unlike anything before. In the Model S and Model X, Tesla did not have to do too much, but the Cybertruck has heavier all-terrain tires and potentially issues from the aluminum castings that make up the vehicle’s chassis, which are probably presenting some challenges.

Unfortunately, this feature will not be available on the new Dual Motor All-Wheel-Drive configuration, which was released last week.

News

Tesla Model S and X customization options begin to thin as their closure nears

Tesla’s Online Design Studio for both vehicles now shows the first color option to be listed as “Sold Out,” as Lunar Silver is officially no longer available for the Model S or Model X. This color is exclusive to these cars and not available on the Model S or Model X.

Tesla Model S and Model X customization options are beginning to thin for the first time as the closure of the two “sentimental” vehicles nears.

We are officially seeing the first options disappear as Tesla begins to work toward ending production of the two cars and the options that are available to those vehicles specifically.

Tesla’s Online Design Studio for both vehicles now shows the first color option to be listed as “Sold Out,” as Lunar Silver is officially no longer available for the Model S or Model X. This color is exclusive to these cars and not available on the Model S or Model X.

🚨 Tesla Model S and Model X availability is thinning, as Tesla has officially shown that the Lunar Silver color option on both vehicles is officially sold out

To be fair, Frost Blue is still available so no need to freak out pic.twitter.com/YnwsDbsFOv

— TESLARATI (@Teslarati) February 25, 2026

Tesla is making way for the Optimus humanoid robot project at the Fremont Factory, where the Model S and Model X are produced. The two cars are low-volume models and do not contribute more than a few percent to Tesla’s yearly delivery figures.

With CEO Elon Musk confirming that the Model S and Model X would officially be phased out at the end of the quarter, some of the options are being thinned out.

This is an expected move considering Tesla’s plans for the two vehicles, as it will make for an easier process of transitioning that portion of the Fremont plant to cater to Optimus manufacturing. Additionally, this is likely one of the least popular colors, and Tesla is choosing to only keep around what it is seeing routine demand for.

During the Q4 Earnings Call in January, Musk confirmed the end of the Model S and Model X:

“It is time to bring the Model S and Model X programs to an end with an honorable discharge. It is time to bring the S/X programs to an end. It’s part of our overall shift to an autonomous future.”

Fremont will now build one million Optimus units per year as production is ramped.