SpaceX

SpaceX CEO Elon Musk says that BFR could cost less to build than Falcon 9

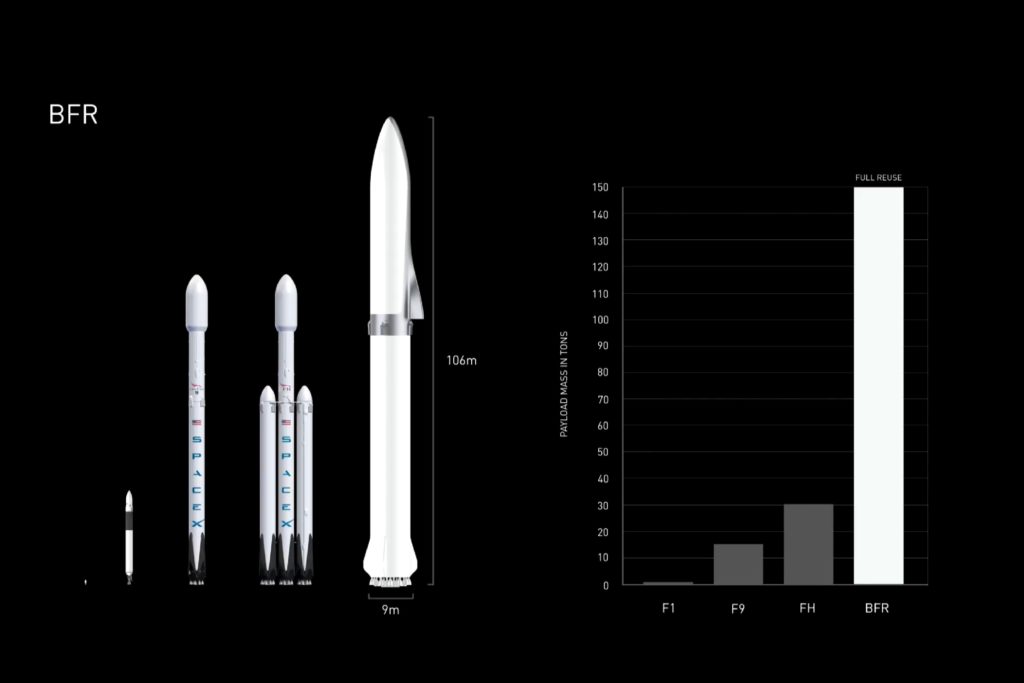

SpaceX CEO Elon Musk believes that there may be a path for the company to ultimately build the massive Starship spacecraft and Super Heavy booster (formerly BFR) for less than Falcon 9/Falcon Heavy, a rocket 3-9 times smaller than BFR.

While it certainly ranks high on the list of wild and wacky things the CEO has said over the years, there may be a few ways – albeit with healthy qualifications – that Starship/Super Heavy production costs could ultimately compare favorably with SpaceX’s Falcon family of launch vehicles. Nevertheless, there are at least as many ways in which the next-gen rocket can (or should) never be able to beat the production cost of what is effectively a far simpler rocket.

This will sound implausible, but I think there’s a path to build Starship / Super Heavy for less than Falcon 9

— Elon Musk (@elonmusk) February 11, 2019

Dirty boosters done dirt cheap

On the one hand, Musk might not necessarily be wrong, especially if one throws the CEO several bones in the interpretation of his brief tweet. BFR at its simplest is going to require a full 38 main rocket engines to achieve its nominal performance goals, 7 on Starship and 31 on Super Heavy. As a dramatically more advanced, larger, and far more complex engine, Raptor will (with very little doubt) cost far more per engine than the relatively simple Merlin 1D. BFR avionics (flight computers, electronics, wiring, harnesses) are likely to be more of a known quantity, meaning that costs will probably be comparable or even lower than Falcon 9’s when measured as a proportion of overall vehicle cost. Assuming that BFR can use the exact same cold gas thruster assemblies currently flying on Falcon 9, that cost should only grow proportionally with vehicle size. Finally, Starship will not require a deployable payload fairing (~10% of Falcon 9’s production cost).

All of those things mean that Starship/Super Heavy will probably be starting off with far better cost efficiency than Falcon 9 was able to, thanks to almost a decade of interim experience both building, flying, and refurbishing the rocket since its 2010 debut. Still, BFR will have to account for entirely new structures like six large tripod fins/wings and their actuators, wholly new thrust structures (akin to Falcon 9’s octaweb) for both stages, and more. Considering Starship on its own, the production of a human-rated spacecraft capable of safely housing dozens of people in space for weeks or months will almost without a doubt rival the cost of airliner production, where a 737 – with almost half a century of production and flight heritage – still holds a price tag of $100-130+ million.

- BFR shown to scale with Falcon 1, 9, and Heavy. (SpaceX)

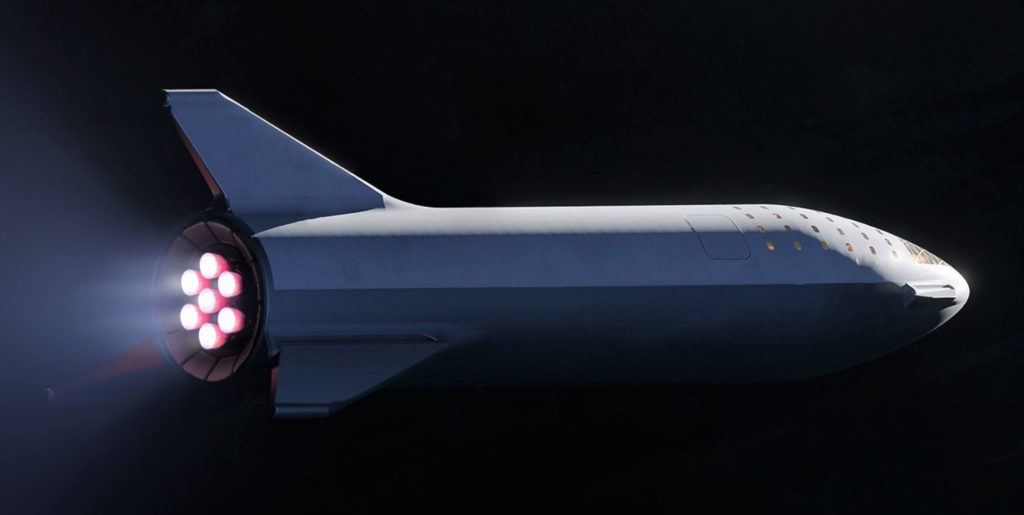

- A September 2018 render of Starship (then BFS) shows one of the vehicle’s two hinged wings/fins/legs. (SpaceX)

- BFR’s booster, now known as Super Heavy. (SpaceX)

- Sadly, this is a not a sight that will greet Falcon 9 booster B1046’s fourth launch – Crew Dragon’s critical In-Flight Abort test. (SpaceX)

Adding one more assumption, the most lenient interpretation of Musk’s tweet assumes that he is really only subjecting the overall structure (sans engines and any crew-relevant hardware) of BFR relative to Falcon 9. In other words, could a ~300-ton stainless steel rocket structure (BFR) cost the same amount or less to fabricate than a ~30-ton aluminum-lithium alloy rocket structure (Falcon 9/Heavy)? From the very roughest of numerical comparisons, Musk estimated the cost of the stainless steel alloys (300-series) to be used for BFR at around $3 per pound ($6.60/kg), while aluminum-lithium alloys used in aerospace (and on Falcon 9) are sold for around $20/lb ($44/kg)*. As such, simply buying the materials to build the basic structures of BFR and Falcon 9 would cost around and $7.5M and $5M, respectively.

Assuming that the process of assembling, welding, and integrating Starship and Super Heavy structures is somehow 5-10 times cheaper, easier, and less labor-intensive, it’s actually not inconceivable that the cost of building BFR’s structure could ultimately compete with Falcon 9 after production has stabilized after the new rocket’s prototyping phase is over and manufacturing processes are mature.

*Very rough estimate, difficult to find a public cost per unit mass from modern Al-Li suppliers

Costs vs. benefits

On the opposite hand, stainless steel rockets do not have a history of being uniquely cost-effective relative to vehicles using alternative materials. The only orbital-class launch vehicles to use stainless steel (and balloon) tanks are the Atlas booster and the Centaur upper stage, with Atlas dating back to the late 1950s and Centaur beginning launches in the early ’60s. Stainless steel Atlas launches ended in 2005 with the final Atlas III mission, while multiple forms of Centaur continue to fly regularly on ULA’s Atlas V and Delta IV.

Based on a 1966 contract between NASA and General Dynamics placed shortly after Centaur’s tortured development had largely been completed, Centaur upper stages were priced around $25M apiece (2018 USD). In 1980, the hardware for a dedicated Atlas-Centaur launch of a ~1500 kg Comstar I satellite to GTO cost the US the 2018 equivalent of a bit less than $40M ($71M including miscellaneous administrative costs) – $22.4M for Centaur and $17.6M for Atlas. For Atlas, the rocket’s airframe (tanks and general structure) was purchased for around $8.5M. That version of Atlas-Centaur (Atlas-SLV3D Centaur-D1A) was capable of lifting around 5100 kg (11,250 lb) into Low Earth Orbit (LEO) and 1800 kg (~4000 lb) to geostationary transfer orbit (GTO), while it stood around 40m (130 ft) tall, had a tank diameter of 3.05m (10 ft), and weighed ~150t (330,000 lb) fully fueled.

- Atlas shows off its shiny steel balloon tanks. (SDASM)

- The original space-faring Atlas, known as SM-65, seen here with a Mercury space capsule. (NASA)

- A Centaur upper stage is pictured here in 1964. (NASA)

- Atlas SLV3D is pictured here launching a Comstar I satellite.

- A Falcon 9 booster is seen here near the end of its tank welding, just prior to painting. (SpaceX)

- An overview of SpaceX’s Hawthorne factory floor in early 2018. (SpaceX)

In a very loose sense, that particular stainless steel Atlas variant was about half as large and half as capable as the first flight-worthy version of Falcon 9 at roughly the same price at launch ($60-70M). What does this jaunt through the history books tell us about the prospects of a stainless steel Starship and Super Heavy? Well, not much. The problem with trying to understand and pick apart official claims about SpaceX’s next-generation launch architecture is quite simple: only one family of rockets in the history of the industry (Atlas) regularly flew with stainless steel propellant tanks, a half-century lineage that completed its final launch in 2005.

Generally speaking, an industrial sample size of more or less one makes it far from easy to come to any particular conclusions about a given technology or practice, and SpaceX – according to CEO Elon Musk – fully intends to push past the state of the art of stainless steel rocket tankage with BFR. Ultimately, American Marietta/Martin Marietta/Lockheed Martin was never able to produce launch vehicle variants of the stainless steel Atlas family at a cost more than marginally competitive with Falcon 9, despite the latter rocket’s use of a far more expensive metal alloy throughout its primary tanks and structure.

At least 10X cheaper

— Elon Musk (@elonmusk) February 11, 2019

At some point, it’s even worth asking whether the per-unit cost of Starship and Super Heavy should be relevant at all to their design and construction, at least within reason. If the goal of BFR is to drastically lower the cost of launch by radically improving the ease of reuse, it would be truly bizarre (and utterly unintuitive) if those goals could somehow be achieved without dramatically raising the cost of initial hardware procurement. Perhaps the best close comparison to BFR’s goals, modern airliners are eyewateringly expensive ($100-500M apiece) as a consequence of the extraordinary reliability, performance, efficiency, and longevity customers and regulatory agencies demand from them, although those costs are admittedly not the absolute lowest they could be in a perfect manufacturing scenario.

At the end of the day, it appears that Musk is increasingly of the opinion that the pivot to stainless steel could ultimately make BFR simultaneously “better, faster, [&] cheaper”. However improbable that may be, if it does turn out to be the case, Starship and Super Heavy could be an unfathomable leap ahead for reliable and affordable access to space. It could also be another case of Musk’s excitement and optimism getting the better of him and hyping a given product well beyond what it ultimately is able to achieve. Time will tell!

Check out Teslarati’s newsletters for prompt updates, on-the-ground perspectives, and unique glimpses of SpaceX’s rocket launch and recovery processes!

Elon Musk

SpaceX Starship V3 gets launch date update from Elon Musk

The first flight of Starship Version 3 and its new Raptor V3 engines could happen as early as March.

Elon Musk has announced that SpaceX’s next Starship launch, Flight 12, is expected in about six weeks. This suggests that the first flight of Starship Version 3 and its new Raptor V3 engines could happen as early as March.

In a post on X, Elon Musk stated that the next Starship launch is in six weeks. He accompanied his announcement with a photo that seemed to have been taken when Starship’s upper stage was just about to separate from the Super Heavy Booster. Musk did not state whether SpaceX will attempt to catch the Super Heavy Booster during the upcoming flight.

The upcoming flight will mark the debut of Starship V3. The upgraded design includes the new Raptor V3 engine, which is expected to have nearly twice the thrust of the original Raptor 1, at a fraction of the cost and with significantly reduced weight. The Starship V3 platform is also expected to be optimized for manufacturability.

The Starship V3 Flight 12 launch timeline comes as SpaceX pursues an aggressive development cadence for the fully reusable launch system. Previous iterations of Starship have racked up a mixed but notable string of test flights, including multiple integrated flight tests in 2025.

Interestingly enough, SpaceX has teased an aggressive timeframe for Starship V3’s first flight. Way back in late November, SpaceX noted on X that it will be aiming to launch Starship V3’s maiden flight in the first quarter of 2026. This was despite setbacks like a structural anomaly on the first V3 booster during ground testing.

“Starship’s twelfth flight test remains targeted for the first quarter of 2026,” the company wrote in its post on X.

Elon Musk

Elon Musk shares insights on SpaceX and Tesla’s potential scale

In a pair of recent posts on X, Musk argued that both companies operate in domains where growth is not linear, but exponential.

Elon Musk outlined why he believes Tesla and SpaceX ultimately dwarf their competitors, pointing to autonomy, robotics, and space-based energy as forces that fundamentally reshape economic scale.

In a pair of recent posts on X, Musk argued that both companies operate in domains where growth is not linear, but exponential.

Space-based energy

In a response to a user on X who observed that SpaceX has a larger valuation than all six US defense companies combined, Musk explained that space-based industries will eventually surpass the total economic value of Earth. He noted that space allows humanity to harness roughly 100,000 times more energy than Earth currently uses, while still consuming less than a millionth of the Sun’s total energy output.

That level of available energy should enable the emergence and development of industries that are simply not possible within Earth’s physical and environmental constraints. Continuous solar exposure in space, as per Musk’s comment, removes limitations imposed by atmosphere, weather, and land availability.

Autonomy and robots

In a follow-up post, Elon Musk explaned that “due to autonomy, Tesla is worth more than the rest of the auto industry.” Musk added that this assessment does not yet account for Optimus, Tesla’s humanoid robot. As per the CEO, once Optimus reaches scaled production, it could increase Earth’s gross domestic product by an order of magnitude, ultimately paving the way for sustainable abundance.

Even before the advent of Optimus, however, Tesla’s autonomous driving system already gives vehicles the option to become revenue-generating assets through services like the Tesla Robotaxi network. Tesla’s autonomous efforts seem to be on the verge of paying off, as services like the Robotaxi network have already been launched in its initial stages in Austin and the Bay Area.

Elon Musk

Tesla CEO Elon Musk trolls budget airline after it refuses Starlink on its planes

“I really want to put a Ryan in charge of Ryan Air. It is your destiny,” Musk said.

Tesla CEO Elon Musk trolled budget airline Ryanair on his social media platform X this week following the company’s refusal to adopt Starlink internet on its planes.

Earlier this week, it was reported that Ryanair did not plan to install Starlink internet services on its planes due to its budgetary nature and short flight spans, which are commonly only an hour or so in total duration.

Initially, Musk said installing Starlink on the company’s planes would not impact cost or aerodynamics, but Ryanair responded on its X account, which is comical in nature, by stating that a propaganda it would not fall for was “Wi-Fi on planes.”

Musk responded by asking, “How much would it cost to buy you?” Then followed up with the idea of buying the company and replacing the CEO with someone named Ryan:

I really want to put a Ryan in charge of Ryan Air. It is your destiny.

— Elon Musk (@elonmusk) January 19, 2026

Polymarket now states that there is an 8 percent chance that Musk will purchase Ryanair, which would cost Musk roughly $36 billion, based on recent financial data of the public company.

Although the banter has certainly crossed a line, it does not seem as if there is any true reason to believe Musk would purchase the airline. More than anything, it seems like an exercise of who will go further.

Starlink passes 9 million active customers just weeks after hitting 8 million

However, it is worth noting that if something is important enough, Musk will get involved. He bought Twitter a few years ago and then turned it into X, but that issue was much larger than simple banter with a company that does not want to utilize one of the CEO’s products.

The insufferable, special needs chimp currently running Ryan Air is an accountant. Has no idea how airplanes even fly.

— Elon Musk (@elonmusk) January 20, 2026

In a poll posted yesterday by Musk, asking whether he should buy Ryanair and “restore Ryan as their rightful ruler.” 76.5 percent of respondents said he should, but others believe that the whole idea is just playful dialogue for now.

But it is not ideal to count Musk out, especially if things continue to move in the direction they have been.