News

Elon Musk and SpaceX won’t be stopped along the road to Mars

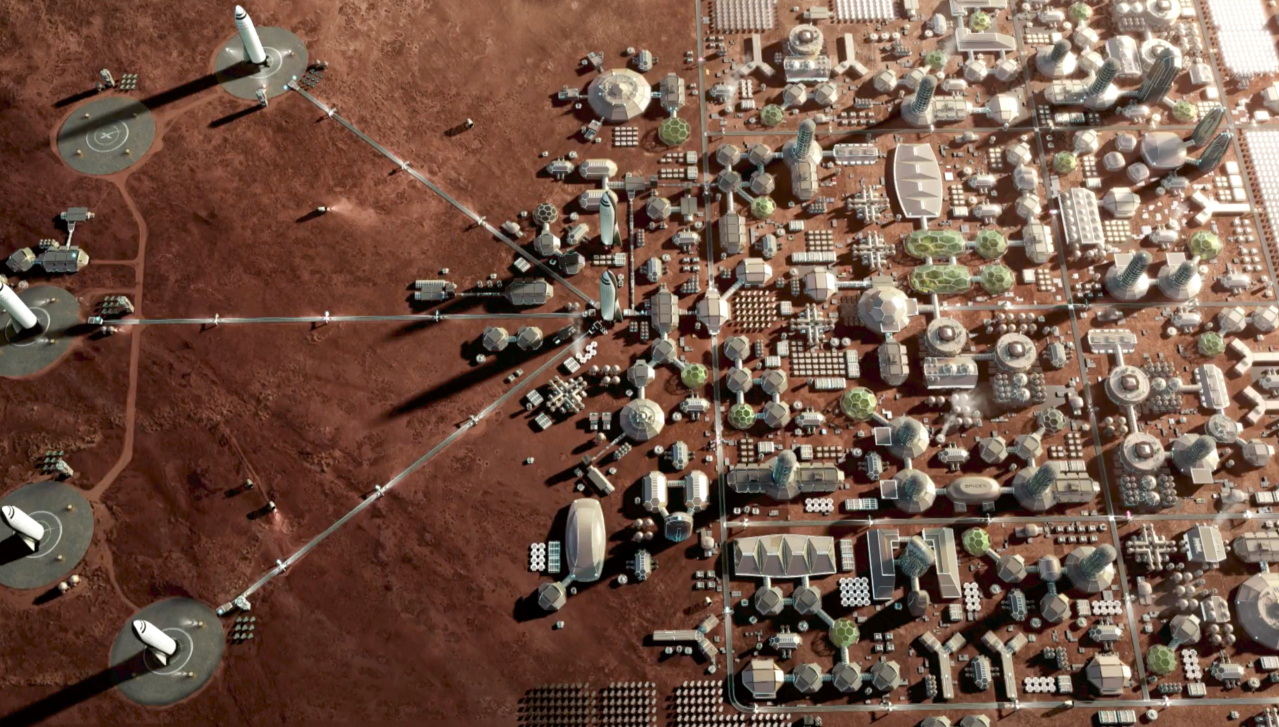

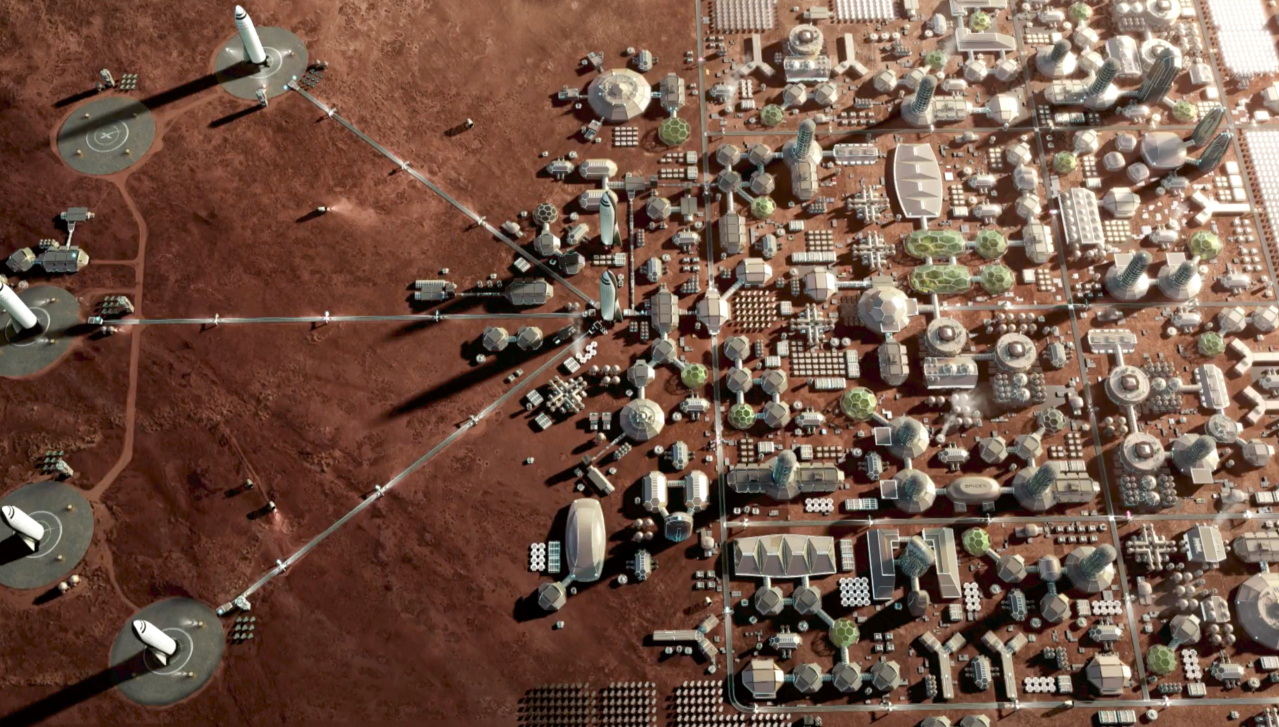

If one is to take anything at all away from Elon Musk’s update to SpaceX’s planetary colonization strategy on September 29, it ought to be the tangible and undeniable progress the company has made with real, Mars-focused hardware development.

To take Musk at his word, the general atmosphere pervading the two relevant programs is one of extreme success and confidence. Raptor, the powerful methane-oxygen rocket engine intended to be the workhorse for any larger launch vehicle, has conducted dozens (42, to be specific) of successful hot fires at SpaceX’s McGregor, Texas testing facilities. These ranged from a handful of seconds all the way to 100 seconds in duration, and Musk made it explicitly clear that the only limiting factor to test duration was the size of the tanks of propellant available to fuel the engine. Of crucial importance is the fact that the engine being tested in Texas is a subscale prototype, and is not representative of the final engine. However, SpaceX has since shrunk the final target for operational Raptors, and this means that the current scale is not far off from the final thrust figure. The prototype Raptor is believed to have a thrust of approximately 1,000 kN (Kilonewtons), with slides from Musk’s 2017 presentation pointing to a full scale thrust of 1700 kN, far closer to becoming real than the 3,000 kN figure given at the 2016 IAC.

SpaceX has completed over 1,200 seconds of firing across 42 main Raptor engine tests. pic.twitter.com/EhxbPjd8Cj

— SpaceX (@SpaceX) September 29, 2017

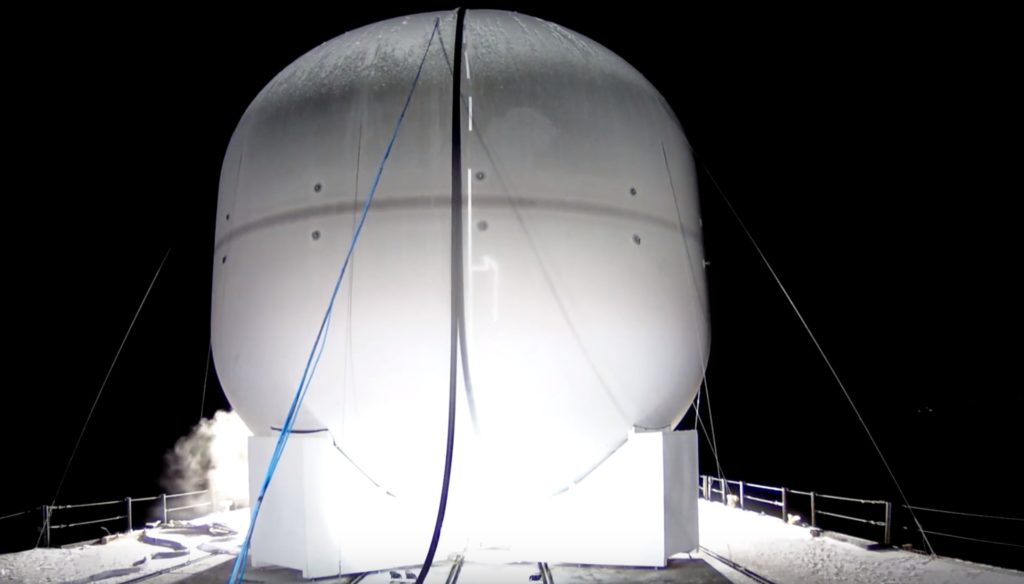

Possibly even more significant is the reported success SpaceX has had with the construction and stress testing of a full-scale carbon fiber liquid oxygen tank, which was tested to a very eventful destruction on Washington state’s Puget Sound. Fans closely followed this series of tests, but information was scarce and the general consensus was that the tank had failed unintentionally during those tests. The fact that Musk claimed that the 12 meter diameter tank was “successfully tested” at high pressures, as well as the confidence he expressed about a uniquely capable “carbon fiber matrix”, suggest that SpaceX have leaped over one of biggest potential hurdles of their larger vehicle plans. Carbon fiber propellant tanks have the potential to make rockets significantly lighter and thus more efficient, particularly if no internal liner of metal is needed to ensure the safety of those carbon fiber tanks. One might remember the difficulties SpaceX had with supercool liquid oxygen, culminating in the Amos-6 mishap that saw carbon fiber helium tanks clash with SpaceX’s then-new supercooled propellant procedures.

- SpaceX’s massive carbon fiber tank being tested on a barge. (SpaceX)

- The tank made a premature attempt to reach orbit as it exploded. (SpaceX)

- Musk said that it flew 300 feet in the air in the controlled failure. (SpaceX)

Through many challenging mistakes, SpaceX has learned the hard way that extra care must be taken when mixing carbon fiber and liquid oxygen. The telltale sign that SpaceX has, however, successfully learned from those mistakes can be found in the company’s aspiration to begin construction of the first BFR cargo ship as early as April of 2018, barely six months from today. Time will tell if they can maintain that aggressive schedule and launch two Mars-bound cargo ships in 2022. The company’s incontrovertible success with the development of Raptor engines and carbon fiber propellant tanks bode extremely well for the future of their planetary colonization efforts.

News

SpaceX’s Crew-11 mission targets July 31 launch amid tight ISS schedule

The flight will lift off from Launch Complex 39A at Kennedy Space Center in Florida.

NASA and SpaceX are targeting July 31 for the launch of Crew-11, the next crewed mission to the International Space Station (ISS). The flight will lift off from Launch Complex 39A at Kennedy Space Center in Florida, using the Crew Dragon Endeavour and a Falcon 9 booster.

Crew Dragon Endeavour returns

Crew-11 will be the sixth flight for Endeavour, making it SpaceX’s most experienced crew vehicle to date. According to SpaceX’s director of Dragon mission management, Sarah Walker, Endeavour has already carried 18 astronauts representing eight countries since its first mission with NASA’s Bob Behnken and Doug Hurley in 2020, as noted in an MSN report.

“This Dragon spacecraft has successfully flown 18 crew members representing eight countries to space already, starting with (NASA astronauts) Bob (Behnken) and Doug (Hurley) in 2020, when it returned human spaceflight capabilities to the United States for the first time since the shuttle retired in July of 2011,” Walker said.

For this mission, Endeavour will debut SpaceX’s upgraded drogue 3.1 parachutes, designed to further enhance reentry safety. The parachutes are part of SpaceX’s ongoing improvements to its human-rated spacecraft, and Crew-11 will serve as their first operational test.

The Falcon 9 booster supporting this launch is core B1094, which has launched in two previous Starlink missions, as well as the private Ax-4 mission on June 25, as noted in a Space.com report.

The four-members of Crew-11 are NASA astronauts Zena Cardman and Mike Fincke, as well as Japan’s Kimiya Yui and Russia’s Oleg Platonov.

Tight launch timing

Crew-11 is slated to arrive at the ISS just as NASA coordinates a sequence of missions, including the departure of Crew-10 and the arrival of SpaceX’s CRS-33 mission. NASA’s Bill Spetch emphasized the need for careful planning amid limited launch resources, noting the importance of maintaining station altitude and resupply cadence.

“Providing multiple methods for us to maintain the station altitude is critically important as we continue to operate and get the most use out of our limited launch resources that we do have. We’re really looking forward to demonstrating that capability with (CRS-33) showing up after we get through the Crew-11 and Crew-10 handover,” Spetch stated.

Lifestyle

EV fans urge Tesla to acquire Unplugged Performance for edge in fleet and security industry

Unplugged Performance has built a name for itself by producing performance upgrades for Tesla vehicles.

A growing number of Tesla enthusiasts and longtime community voices are calling on the electric vehicle maker to acquire Unplugged Performance, a California-based aftermarket company best known for tuning Tesla vehicles and developing specialized government fleet solutions under its UP.FIT division.

The idea was once considered a niche proposal among EV fans, but it is now gaining serious attention not just as a performance play but as a strategic move to deepen Tesla’s roots in the fleet and security industry.

A strategic fit

Unplugged Performance has built a name for itself by producing performance upgrades for Tesla vehicles, from track-optimized components to visual and aerodynamic upgrades. But in recent years, its UP.FIT division has pivoted toward a more functional future by outfitting Tesla vehicles like Model Ys for police, military, and government use.

That work has sparked growing calls for closer collaboration with Tesla, especially as the EV maker increasingly leans into autonomy, AI, and fleet services as core components of its next chapter.

“I posted this four years ago, but I think it’s more true now than ever,” wrote Whole Mars Catalog, a well-known Tesla investor and FSD Beta tester, on X. “Tesla should buy Unplugged. But not just as a Performance division. What they are doing with UP.FIT unlocks large government and commercial fleet purchases that can improve utilization.”

Tesla fans such as shareholder Sawyer Merritt echoed the sentiment, calling Unplugged a “great fit within Tesla.” adding, “They are literally located directly next to Tesla’s design studio in Hawthorne.”

Enabling the next wave

Supporters of the idea noted that integrating Unplugged into Tesla’s corporate structure could help accelerate the adoption of autonomous technologies in government sectors. With UP.FIT patrol cars already in use across some U.S. police departments, Tesla fans envisioned a future where self-driving Teslas could potentially revolutionize law enforcement, search-and-rescue, and public service logistics.

“Just imagine how autonomous patrol cars could transform policing and bring us into a safer future,” the veteran FSD tester wrote.

The benefits could also extend to Tesla’s existing consumer base. “They also have some incredible products in the works that I think will appeal to many ordinary Tesla drivers — not just those looking for performance or mods. Stuff that’s so good it should have come straight from the design studio next door,” Whole Mars Catalog noted.

Unplugged Performance, founded in 2013, shares not just a product vision with Tesla, but also geography. Its Hawthorne headquarters sits directly adjacent to Tesla’s design studio, and the two companies have maintained a close working relationship over the years. The aftermarket firm has long positioned itself as a “mission-aligned” partner to Tesla.

In response to the recent calls for acquisition, Unplugged Performance acknowledged the support from the community. “Our very existence is to support the Tesla mission with @UpfitTesla and @UnpluggedTesla,” Unplugged CEO Ben Schaffer posted on X. “We love working with Tesla and are grateful for the community’s support since 2013!”

News

Tesla debuts hands-free Grok AI with update 2025.26: What you need to know

All new Tesla vehicles delivered on or after July 12, 2025, will include Grok AI out of the box

Tesla has begun rolling out Grok, an in-car conversational AI assistant developed by xAI, to eligible vehicles starting July 12. The feature marks the most direct integration yet between Elon Musk’s artificial intelligence startup and Tesla’s consumer product lineup, offering drivers hands-free access to a chat-style companion while on the road.

Grok comes pre-installed on new vehicles

According to Tesla’s FAQ page for the feature, all new vehicles delivered on or after July 12, 2025, will include Grok AI out of the box. Owners of older vehicles may gain access through an over-the-air update, provided their vehicle meets a few hardware and software requirements.

Specifically, Grok is currently only supported on Tesla models equipped with an AMD infotainment processor and running vehicle software version 2025.26 and higher. Compatible models include the Model S, Model 3, Model X, Model Y, and Cybertruck. A Premium Connectivity subscription or active Wi-Fi connection is also required.

Tesla notes that additional vehicle compatibility may arrive in future software updates.

Grok’s features and limitations for now

Drivers can engage with Grok using the App Launcher or by pressing and holding the voice command button on the steering wheel. Grok is designed to answer questions and hold conversations using natural language, offering responses tailored to its chosen personality—ranging from “Storyteller” to the more eccentric “Unhinged.”

For fun, Tesla posted a demonstration of Grok likely running on “Unhinged” talking about what it would do to Optimus when they are on a date, much to the shock of the humanoid robot’s official social media account.

It should be noted, however, that Grok cannot currently issue commands to the vehicle itself, at least for now. Traditional voice commands for tasks like climate control, navigation, or media remain separate from Grok as of writing.

The feature is being released in Beta and does not require a Grok account or xAI subscription to activate, although that policy may change over time.

Grok privacy and in-car experience

Tesla emphasizes that interactions with Grok are securely processed by xAI and not linked to a user’s Tesla account or vehicle. Conversations remain anonymous unless a user signs into Grok separately to sync their history across devices.

Tesla has also begun promoting Grok directly on its official vehicle webpages, showcasing the feature as part of its in-car experience, further highlighting the company’s increasing focus on AI and infotainment features on its all-electric vehicles.

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla investors will be shocked by Jim Cramer’s latest assessment

-

Elon Musk3 days ago

Elon Musk3 days agoxAI launches Grok 4 with new $300/month SuperGrok Heavy subscription

-

Elon Musk5 days ago

Elon Musk5 days agoElon Musk confirms Grok 4 launch on July 9 with livestream event

-

News1 week ago

News1 week agoTesla Model 3 ranks as the safest new car in Europe for 2025, per Euro NCAP tests

-

Elon Musk1 week ago

Elon Musk1 week agoxAI’s Memphis data center receives air permit despite community criticism

-

News2 weeks ago

News2 weeks agoXiaomi CEO congratulates Tesla on first FSD delivery: “We have to continue learning!”

-

News2 weeks ago

News2 weeks agoTesla sees explosive sales growth in UK, Spain, and Netherlands in June

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla scrambles after Musk sidekick exit, CEO takes over sales