SpaceX

SpaceX goes all-in on steel Starship, scraps expensive carbon fiber BFR tooling

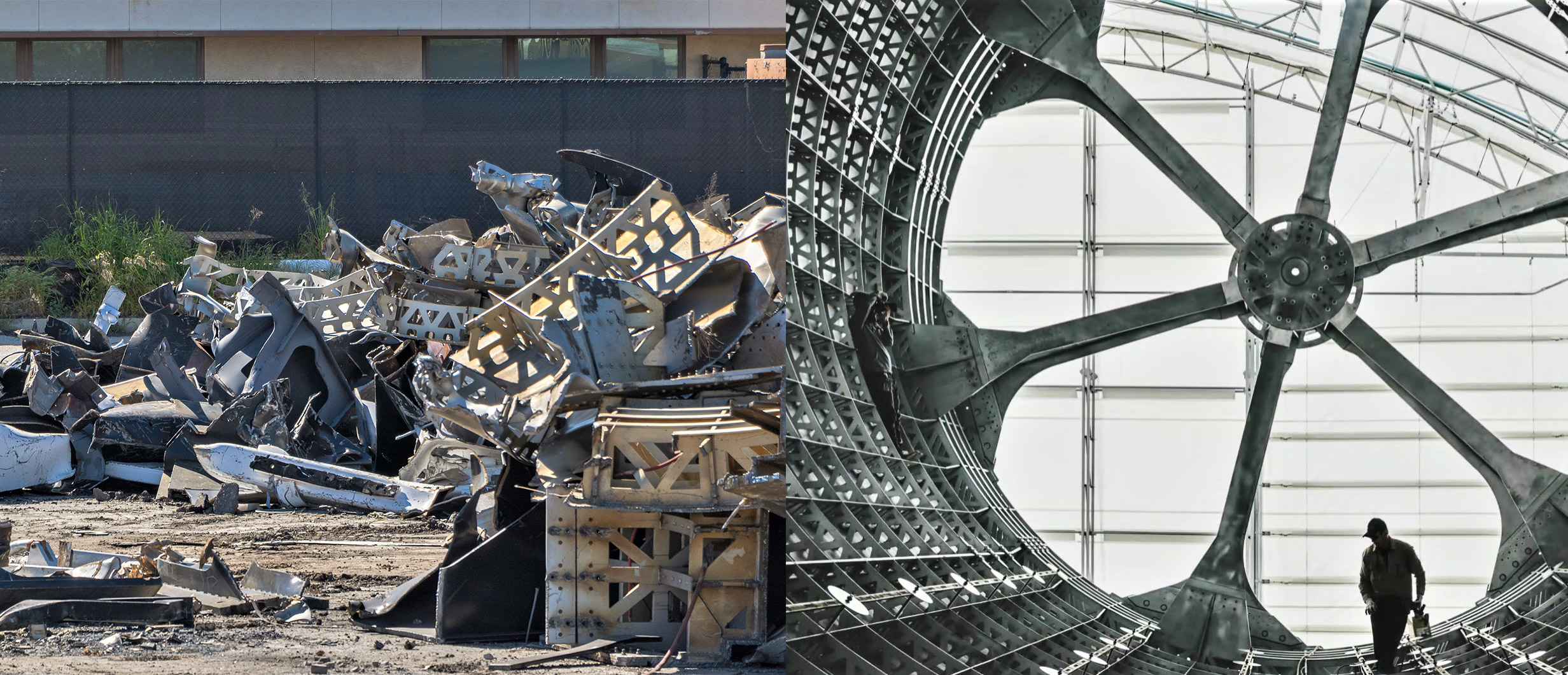

In a wholly unforeseen turn of events, SpaceX has taken the extraordinary step of permanently scrapping both its Port of Los Angeles-based BFR development tent and what seem to be the majority of what it contained, irreparably destroying custom-built tooling meant to support the fabrication of carbon composite BFR spaceships and boosters.

Likely worth anywhere from several to tens of millions of dollars (USD), SpaceX’s advanced BFR production tools were procured from industry-expert Ascent Aerospace sometime in 2017 before being officially delivered to the rocket company’s newly-erected Port of LA tent around April 2018. Situated at the port specifically due to logistical concerns about the high cost of transporting 9m/30ft-diameter objects from SpaceX’s main Hawthorne facilities to a barge for transport east, the company has decided to unequivocally destroy its aerospace-grade composite tooling less than 12 months after accepting delivery. Put simply, this is the best evidence yet that SpaceX – willing or not – has gone all-in on build Starship and Super Heavy out of stainless steel less than six months after CEO Elon Musk began to hint at the program’s utterly radical pivot.

From the very beginning of SpaceX and Elon Musk’s serious pursuit of an entirely reusable launch vehicle capable of transporting dozens of astronauts and passengers to and from Earth and Mars, the plan had been to build the vast majority of the rocket’s booster and spacecraft structures out of advanced carbon fiber composite materials. Above all else, this fundamental architecture was motivated largely by the significant performance gains a rocket could achieve by replacing traditional aluminum tanks and structures with carbon fiber.

For a rocket (and especially an orbital spaceship) meant to somehow make Earth-Mars transport both routine and at least minutely affordable, focusing primarily on the optimization of the mass of cargo delivered relative to the empty weight of the spaceship and booster made (and still does make) a great deal of sense. Assuming that the reusability of a system is roughly constant, the only conceivable way to further lower the cost of price per unit of cargo or passenger ticket would be to increase the usable cargo/passenger capacity for each individual launch, making an extremely light and high-performance rocket the low-hanging fruit target.

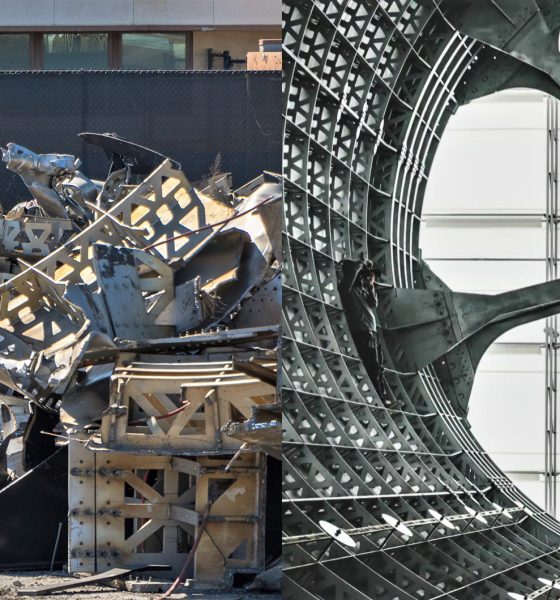

The centrality of carbon fiber composites remained with SpaceX’s Sept. 2017 iteration of BFR, downsized by 25% to a diameter of 9m (~30 ft). Around six months later, that commitment to composites was further solidified by the delivery of the first 9m-diameter carbon fiber tooling in March or April 2018. The tooling used to mold and

In the subsequent months of 2018, SpaceX’s BFR and composite R&D team spent tens of thousands of hours building out an ad-hoc advanced composites workshop inside a temporary tent in an industrial area, and ultimately managed to build a number of full-scale carbon fiber segments, including at least one large tank barrel section and the beginnings of a tank dome. In September 2018, that progress was partially revealed alongside the announcement that Japanese billionaire Yasuka Maezawa had purchased the first crewed lunar launch of BFR for several hundred million dollars, set to occur no earlier than 2023.

Two months after indicating that the first BFR “airframe/tank barrel section” would be built out of a “new carbon fiber material”, Musk provided the very first teaser for a “counterintuitive” development that would later be identified as the CEO’s decision to wholly replace BFR’s proposed used of composites with stainless steel and an advanced metallic heat shield. Still more than a little controversial and hard to follow almost half a year later, the feeling at the time was that SpaceX’s eccentric leader had decided to throw away more than 24 months of composite BFR design and development work for an almost entirely unproven alternative approach.

For better or for worse, it appears that SpaceX (or maybe just Musk) has quite literally trashed the most concrete demonstration of a prior commitment to advanced carbon fiber composites, scrapping the vast majority of its composite tooling and perhaps even the prototype BFR segments built in 2018.

It remains to be seen whether the now-permanent decision to pursue a stainless steel design in place of carbon fiber was a very expensive mistake, a stroke of genius, or something in between, However, the undeniably brisk progress made with the BFR’s steel variant in last four or so months bodes well – at a minimum – for Musk’s optimism that this radical change will ultimately result in an operational vehicle far sooner (and presumably cheaper) than the composites route.

Generally speaking, it seems safe to – on the face of it – agree with Musk’s argument that steel should ultimately lend itself far more easily to reusability thanks to its high tolerance for extreme temperatures. Unlike Falcon 9’s aluminum structures (and even the most exotic, advanced carbon fiber composites), certain varieties of stainless steel can weather heating approaching that experienced during orbital reentry with minimal erosion or damage to its mechanical properties. As Musk puts it, the Super Heavy booster’s suborbital trajectory could require almost no heat shielding – and perhaps even paint – at all.

Only time will tell whether the inevitably harsher realities of real-life engineering are so kind. In the meantime, SpaceX is perhaps just hours away from the first attempted static-fire test of a Raptor installed on something approaching flight-hardware, in this case a full-scale Starship hop test prototype.

Check out Teslarati’s Marketplace! We offer Tesla accessories, including for the Tesla Cybertruck and Tesla Model 3.

Elon Musk

Starlink V2 to bring satellite-to-phone service to Deutsche Telekom in Europe

Starlink stated that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Starlink is partnering with Deutsche Telekom to roll out satellite-to-mobile connectivity across Europe, extending coverage to more than 140 million subscribers across 10 countries.

The service, planned for launch in 2028 in several Telekom markets, including Germany, will use Starlink’s next-generation V2 satellites and Mobile Satellite Service (MSS) spectrum to enable direct-to-device connectivity.

In a post on X, the official Starlink account stated that the agreement will be the first in Europe to deploy its V2 next-generation satellite-to-mobile technology using new MSS spectrum. The company added that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Abdu Mudesir, Board Member for Product and Technology at Deutsche Telekom, shared his excitement for the partnership in a press release. “We provide our customers with the best mobile network. And we continue to invest heavily in expanding our infrastructure. At the same time, there are regions where expansion is especially complex due to topographical conditions or official constraints,” he said.

“We want to ensure reliable connectivity for our customers in those areas as well. That is why we are strategically complementing our network with satellite-to-mobile connectivity. For us, it is clear: connectivity creates security and trust. And we deliver. Everywhere.”

Under the partnership, compatible smartphones will automatically switch to Starlink’s satellite network when terrestrial coverage is unavailable, enabling access to data, voice, video, and messaging services.

Telekom reports 5G geographic coverage approaching 90% in Germany, with LTE exceeding 92% and voice coverage reaching up to 99%. Starlink’s satellite layer is intended to extend connectivity beyond those terrestrial limits, particularly in topographically challenging or infrastructure-constrained areas.

Stephanie Bednarek, VP of Starlink Sales, also shared her thoughts on the partnership. “We’re so pleased to bring reliable satellite-to-mobile connectivity to millions of people across 10 countries in partnership with Deutsche Telekom. This agreement will be the first-of-its-kind in Europe to launch Starlink’s V2 next-generation technology that will expand on data, voice and messaging by providing broadband directly to mobile phones,” she said.

Starlink’s V2 constellation is designed to expand bandwidth and capacity compared to its predecessor. If implemented as outlined, the 2028 launch would mark one of the first large-scale European deployments of integrated satellite-to-phone connectivity by a major telecom operator.

Elon Musk

SpaceX pursues 5G-level connectivity with Starlink Mobile V2 expansion

SpaceX noted that the upcoming Starlink V2 satellites will deliver up to 100 times the data density of the current first-generation system.

SpaceX has previewed a major upgrade to Starlink Mobile, outlining next-generation satellites that aim to deliver significantly higher capacity and full 5G-level connectivity directly to mobile phones.

The update comes as Starlink rebrands its Direct-to-Cell service to Starlink Mobile, positioning the platform as a scalable satellite-to-mobile solution that’s integrated with global telecom partners.

SpaceX noted that the upcoming Starlink V2 satellites will deliver up to 100 times the data density of the current first-generation system. The company also noted that the new V2 satellites are designed to provide significantly higher throughput capability compared to its current iteration.

“The next generation of Starlink Mobile satellites – V2 – will deliver full cellular coverage to places never thought possible via the highest performing satellite-to-mobile network ever built.

“Driven by custom SpaceX-designed silicon and phased array antennas, the satellites will support thousands of spatial beams and higher bandwidth capability, enabling around 20x the throughput capability as compared to a first-generation satellite,” SpaceX wrote in its official Starlink Mobile page.

Thanks to the higher bandwidth of Starlink Mobile, users should be able to stream, browse the internet, use high-speed apps, and enjoy voice services comparable to terrestrial cellular networks.

In most environments, Starlink says the upgraded system will enable full 5G cellular connectivity with a user experience similar to existing ground-based networks.

The satellites function as “cell towers in space,” using advanced phased-array antennas and laser interlinks to integrate with terrestrial infrastructure in a roaming-like architecture.

“Starlink Mobile works with existing LTE phones wherever you can see the sky. The satellites have an antenna that acts like a cellphone tower in space, the most advanced phased array antennas in the world that connect seamlessly over lasers to any point in the globe, allowing network integration similar to a standard roaming partner,” SpaceX wrote.

Starlink Mobile currently operates with approximately 650 satellites in low-Earth orbit and is active across more than 32 countries, representing over 1.7 billion people through partnerships with mobile network operators. Starlink Mobile’s current partnerships span North America, Europe, Asia, Africa, and Oceania, allowing reciprocal access across participating nations.

Elon Musk

SpaceX IPO could push Elon Musk’s net worth past $1 trillion: Polymarket

The estimates were shared by the official Polymarket Money account on social media platform X.

Recent projections have outlined how a potential $1.75 trillion SpaceX IPO could generate historic returns for early investors. The projections suggest the offering would not only become the largest IPO in history but could also result in unprecedented windfalls for some of the company’s key investors.

The estimates were shared by the official Polymarket Money account on social media platform X.

As noted in a Polymarket Money analysis, Elon Musk invested $100 million into SpaceX in 2002 and currently owns approximately 42% of the company. At a $1.75 trillion valuation following SpaceX’s potential $1.75 trillion IPO, that stake would be worth roughly $735 billion.

Such a figure would dramatically expand Musk’s net worth. When combined with his holdings in Tesla Inc. and other ventures, a public debut at that level could position him as the world’s first trillionaire, depending on market conditions at the time of listing.

The Bloomberg Billionaires Index currently lists Elon Musk with a net worth of $666 billion, though a notable portion of this is tied to his TSLA stock. Tesla currently holds a market cap of $1.51 trillion, and Elon Musk’s currently holds about 13% to 15% of the company’s outstanding common stock.

Founders Fund, co-founded by Peter Thiel, invested $20 million in SpaceX in 2008. Polymarket Money estimates the firm owns between 1.5% and 3% of the private space company. At a $1.75 trillion valuation, that range would translate to approximately $26.25 billion to $52.5 billion in value.

That return would represent one of the most significant venture capital outcomes in modern Silicon Valley history, with a growth of 131,150% to 262,400%.

Alphabet Inc., Google’s parent company, invested $900 million into SpaceX in 2015 and is estimated to hold between 6% and 7% of the private space firm. At the projected IPO valuation, that stake could be worth between $105 billion and $122.5 billion. That’s a growth of 11,566% to 14,455%.

Other major backers highlighted in the post include Fidelity Investments, Baillie Gifford, Valor Equity Partners, Bank of America, and Andreessen Horowitz, each potentially sitting on multibillion-dollar gains.