SpaceX

SpaceX hangar packed with Falcon Heavy Block 5 boosters for early April debut

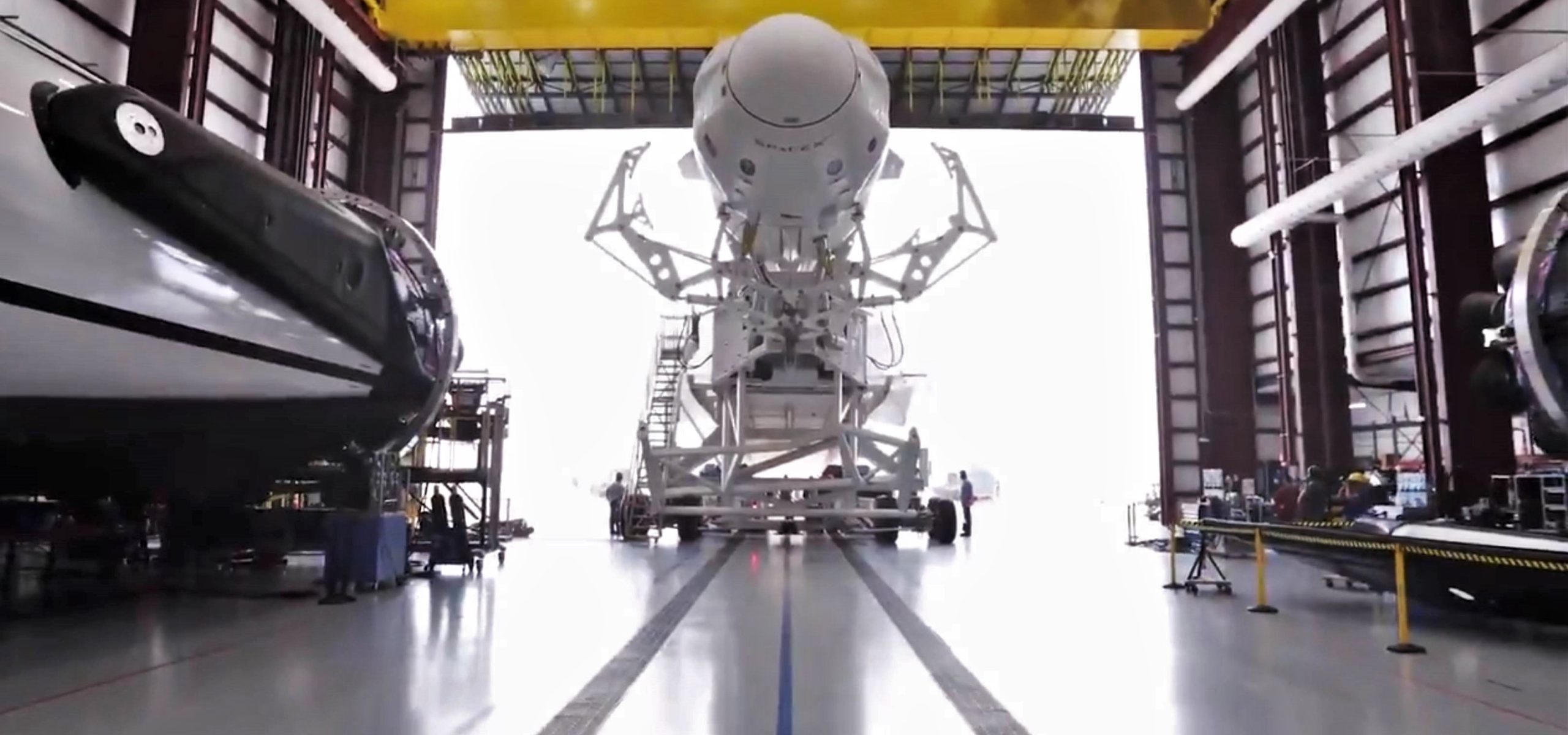

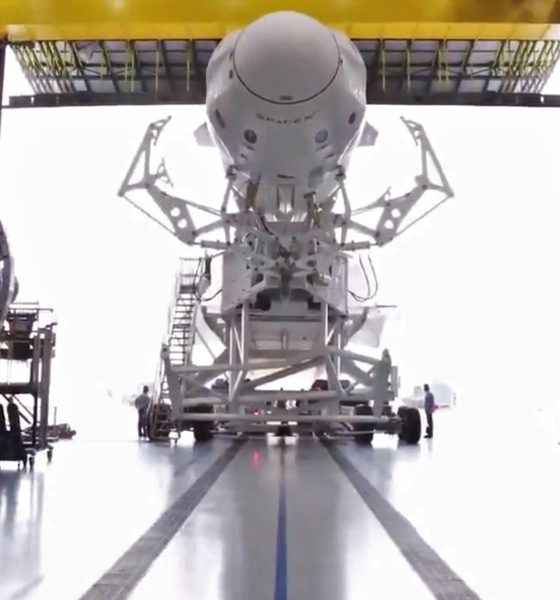

For a company that rarely reveals anything without explicit intent, a February 28th video posted by SpaceX during the lead-up to Crew Dragon’s launch debut featured a surprise cameo: two Block 5 side boosters meant to support Falcon Heavy’s commercial debut and second launch ever.

Likely a subtle nod to close observers and fans, the inclusion of Falcon Heavy is a perfect bit of foreshadowing for the next launch set to occur from Pad 39A after Crew Dragon’s flawless orbital debut. As of now, Falcon Heavy Flight 2 is settling in on a potential launch as early as the first week of April, although delays during the rocket’s critical preflight processing and static fire test are about as likely as they were during the vehicle’s inaugural mission. If the rocket’s first launch and booster recoveries are fully successful, both side boosters (and perhaps the center core) could fly for a second time as few as two months later in June 2019.

A number of photos taken by Instagram users visiting Kennedy Space Center appear to indicate that SpaceX has more or less completed the reconfiguration of Pad 39A’s transporter/erector (T/E), modifying the base with additional hold-down clamps to account for three Falcon boosters instead of the usual one. Ten days after the successful launch of Falcon 9 B1051 in support of Crew Dragon’s first mission to orbit, it’s likely that additional work remains to ensure that 39A is fully refurbished and reconfigured for Falcon Heavy.

For the heavy-lift rocket’s commercial debut and second flight ever, SpaceX is likely to be exceptionally cautious and methodical in their preflight preparations. This is especially necessary due to the fact that Falcon Heavy Flight 2 differs dramatically from Falcon Heavy’s demo configuration, degrading the applicability of some aspects of the data gathered during the rocket’s largely successful test flight.

Most notably, all three first stage boosters will be Block 5 variants on their first flights, whereas Flight 1’s first stage featured two flight-proven Block 2 boosters (B1023 and B1025) and one new Block 3 booster (B1033). Additionally, the center core – B1033 – was lost during a landing anomaly that prevented the booster from reigniting its engine for a landing burn, cutting off another valuable source of data that would have served to better inform engineers on the performance of Falcon Heavy’s complex and previously unproven mechanical stage separation mechanisms.

Falcon 9 Block 5 is a fairly radical departure from the Block 2 and 3 variants SpaceX based Falcon Heavy’s initial design on. It’s possible that the rocket’s engineers were able to at least set up that design and manufacturing work on a safe path to forward compatibility, but it’s equally possible that so much work was focused on simply getting the vehicle past its launch debut that compatibility with Falcon 9 Block 4 and 5 was pushed well into the periphery. Considering the fact that it has now been more than a year since Falcon Heavy’s February 6th, 2018 debut, the latter eventuality offers a much better fit. Nevertheless, with a solid 13-14 additional months of redesign and testing complete, it seems that SpaceX is keen to get its super heavy-lift launch vehicle back on the horse, so to speak.

The specific changes made in Falcon 9 Block 4 is unclear aside from a general improvement in Merlin 1D and MVac performance, as well as significant upgrades to Falcon 9’s upper stage, likely focused on US military and NASA requirements for long-coast capabilities on unique mission profiles. Most significantly, Falcon 9 Block 5 transitioned the SpaceX rocket to a radically different primary thrust structure (also known as the octaweb), replacing welded assemblies with bolted assemblies wherever possible. This simultaneously allows for easier repairs and modifications, improves ease of manufacture, and increases the structure’s overall strength, a critical benefit for Falcon Heavy’s heavily-stressed center core. Meanwhile, Falcon 9 Block 5 moved from Full Thrust’s (Block 3/4) maximum 6800 kN (1,530,000 lbf) of thrust to more than 7600 kN (1,710,000 lbf), an increase of roughly 12%. Combined with Block 5’s focus on extreme reusability, SpaceX engineers and technicians likely had to do a huge amount of work to leap from Falcon Heavy Flight 1 to Flight 2.

Aside from the presence of both Falcon Heavy side boosters, both of which were spotted arriving in Florida by local observers, the first Block 5 Falcon Heavy center core also very likely arrived within the last few months, followed rapidly by can be assumed to be the mission’s fairing and Falcon upper stage. Falcon Heavy’s commercial debut will see the rocket attempt to place communications satellite Arabsat 6A – weighing around 6000 kg (13,200 lb) – into a high-energy geostationary orbit, either direct-to-GEO or a transfer (GTO) variety.

If all goes according to plan, SpaceX will attempt to turn around Falcon Heavy’s Block 5 side boosters (B1052 and B1053) for Falcon Heavy’s third launch – the USAF’s STP-2 mission – as few as 60-80 days later, June 2019. According to NASASpaceflight, STP-2 will fly with a new center core (presumed to be B1057) instead of reusing Arabsat 6A’s well-cooked B1055 booster.

Check out Teslarati’s Marketplace! We offer Tesla accessories, including for the Tesla Cybertruck and Tesla Model 3.

News

SpaceX President Gwynne Shotwell details xAI power pledge at White House event

The commitment was announced during an event with United States President Donald Trump.

SpaceX President Gwynne Shotwell stated that xAI will develop 1.2 gigawatts of power at its Memphis-area AI supercomputer site as part of the White House’s new “Ratepayer Protection Pledge.”

The commitment was announced during an event with United States President Donald Trump.

During the White House event, Shotwell stated that xAI’s AI data center near Memphis would include a major energy installation designed to support the facility’s power needs.

“As you know, xAI builds huge supercomputers and data centers and we build them fast. Currently, we’re building one on the Tennessee-Mississippi state line. As part of today’s commitment, we will take extensive additional steps to continue to reduce the costs of electricity for our neighbors…

“xAI will therefore commit to develop 1.2 GW of power as our supercomputer’s primary power source. That will be for every additional data center as well. We will expand what is already the largest global Megapack power installation in the world,” Shotwell said.

She added that the system would provide significant backup power capacity.

“The installation will provide enough backup power to power the city of Memphis, and more than sufficient energy to power the town of Southaven, Mississippi where the data center resides. We will build new substations and invest in electrical infrastructure to provide stability to the area’s grid.”

Shotwell also noted that xAI will be supporting the area’s water supply as well.

“We haven’t talked about it yet, but this is actually quite important. We will build state-of-the-art water recycling plants that will protect approximately 4.7 billion gallons of water from the Memphis aquifer each year. And we will employ thousands of American workers from around the city of Memphis on both sides of the TN-MS border,” she noted.

The Ratepayer Protection Pledge was introduced as part of the federal government’s effort to address concerns about rising electricity costs tied to large AI data centers, as noted in an Insider report. Under the agreement, companies developing major AI infrastructure projects committed to covering their own power generation needs and avoiding additional costs for local ratepayers.

Elon Musk

SpaceX to launch Starlink V2 satellites on Starship starting 2027

The update was shared by SpaceX President Gwynne Shotwell and Starlink Vice President Mike Nicolls.

SpaceX is looking to start launching its next-generation Starlink V2 satellites in mid-2027 using Starship.

The update was shared by SpaceX President Gwynne Shotwell and Starlink Vice President Mike Nicolls during remarks at Mobile World Congress (MWC) in Barcelona, Spain.

“With Starship, we’ll be able to deploy the constellation very quickly,” Nicolls stated. “Our goal is to deploy a constellation capable of providing global and contiguous coverage within six months, and that’s roughly 1,200 satellites.”

Nicolls added that once Starship is operational, it will be capable of launching approximately 50 of the larger, more powerful Starlink satellites at a time, as noted in a Bloomberg News report.

The initial deployment of roughly 1,200 next-generation satellites is intended to establish global and contiguous coverage. After that phase, SpaceX plans to continue expanding the system to reach “truly global coverage, including the polar regions,” Nicolls said.

Currently, all Starlink satellites are launched on SpaceX’s Falcon 9 rocket. The next-generation fleet will rely on Starship, which remains in development following a series of test flights in 2025. SpaceX is targeting its next Starship test flight, featuring an upgraded version of the rocket, as soon as this month.

Starlink is currently the largest satellite network in orbit, with nearly 10,000 satellites deployed. Bloomberg Intelligence estimates the business could generate approximately $9 billion in revenue for SpaceX in 2026.

Nicolls also confirmed that SpaceX is rebranding its direct-to-cell service as Starlink Mobile.

The service currently operates with 650 satellites capable of connecting directly to smartphones and has approximately 10 million monthly active users. SpaceX expects that figure to exceed 25 million monthly active users by the end of 2026.

Elon Musk

Starlink V2 to bring satellite-to-phone service to Deutsche Telekom in Europe

Starlink stated that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Starlink is partnering with Deutsche Telekom to roll out satellite-to-mobile connectivity across Europe, extending coverage to more than 140 million subscribers across 10 countries.

The service, planned for launch in 2028 in several Telekom markets, including Germany, will use Starlink’s next-generation V2 satellites and Mobile Satellite Service (MSS) spectrum to enable direct-to-device connectivity.

In a post on X, the official Starlink account stated that the agreement will be the first in Europe to deploy its V2 next-generation satellite-to-mobile technology using new MSS spectrum. The company added that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Abdu Mudesir, Board Member for Product and Technology at Deutsche Telekom, shared his excitement for the partnership in a press release. “We provide our customers with the best mobile network. And we continue to invest heavily in expanding our infrastructure. At the same time, there are regions where expansion is especially complex due to topographical conditions or official constraints,” he said.

“We want to ensure reliable connectivity for our customers in those areas as well. That is why we are strategically complementing our network with satellite-to-mobile connectivity. For us, it is clear: connectivity creates security and trust. And we deliver. Everywhere.”

Under the partnership, compatible smartphones will automatically switch to Starlink’s satellite network when terrestrial coverage is unavailable, enabling access to data, voice, video, and messaging services.

Telekom reports 5G geographic coverage approaching 90% in Germany, with LTE exceeding 92% and voice coverage reaching up to 99%. Starlink’s satellite layer is intended to extend connectivity beyond those terrestrial limits, particularly in topographically challenging or infrastructure-constrained areas.

Stephanie Bednarek, VP of Starlink Sales, also shared her thoughts on the partnership. “We’re so pleased to bring reliable satellite-to-mobile connectivity to millions of people across 10 countries in partnership with Deutsche Telekom. This agreement will be the first-of-its-kind in Europe to launch Starlink’s V2 next-generation technology that will expand on data, voice and messaging by providing broadband directly to mobile phones,” she said.

Starlink’s V2 constellation is designed to expand bandwidth and capacity compared to its predecessor. If implemented as outlined, the 2028 launch would mark one of the first large-scale European deployments of integrated satellite-to-phone connectivity by a major telecom operator.