SpaceX

SpaceX fully installs Super Heavy booster’s ‘aerocovers’

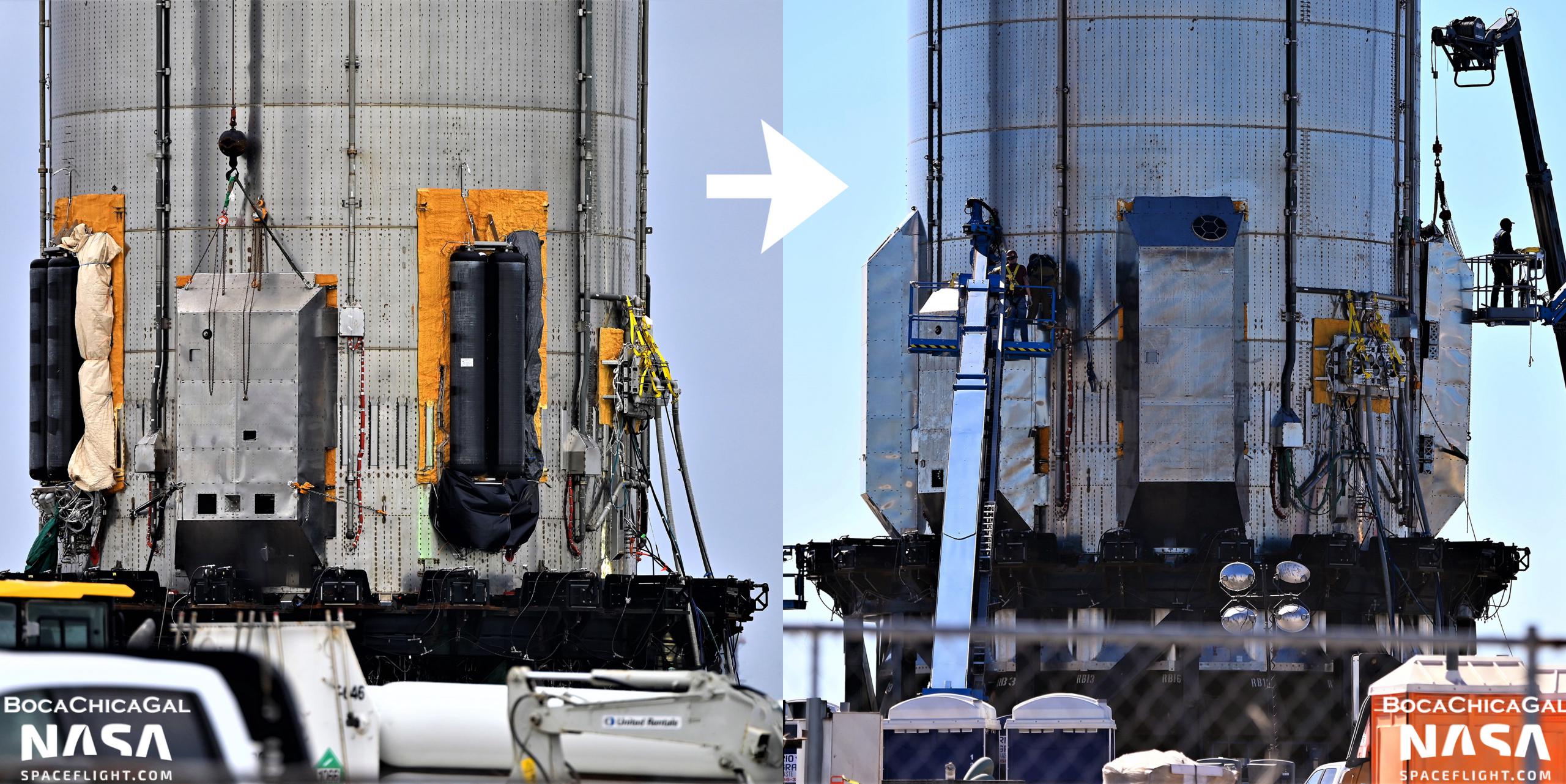

For the first time, SpaceX has more or less installed a full set of ‘aerocovers’ on a Super Heavy booster prototype.

Designed to protect the booster from both itself and Earth’s atmosphere during ground testing, liftoff, ascent, and reentry, Super Heavy’s the structures amount to thin, steel shells mounted on metal box frames. The most obvious aerocovers slot over the top of six racks of equipment installed on the outside of Super Heavy’s aft end, giving the booster a sort of utility belt of hydraulic systems, pressure vessels, avionics, and heat exchangers. Unsurprisingly, those racks are festooned with electronics, composites, and thousands of feet of wiring and thin plumbing – none of which are particularly suited to sit a few dozen feet from the fury of 29-33 Raptor engines or near the leading edge of a hypersonic reentry vehicle.

Aside from the steel they’re mounted on, it’s likely that every system located on Super Heavy’s ‘utility built’ would begin malfunctioning or be destroyed outright if directly exposed to just a few seconds of the hypersonic buffeting and heating Starship boosters will experience during reentry. Unlike Falcon boosters, which almost always use reentry burns to slow down and create a sort of heat shield with their own exhaust, SpaceX is theoretically designing Super Heavy to survive the full force of reentry without an extra burn to cushion the blow.

To survive reentry and still land in good enough condition to enable anything close to same-day reusability, which is SpaceX’s goal, every ounce of at-risk equipment installed on Super Heavy’s exterior will likely need to be carefully shielded. In theory, that’s the purpose of the aerocovers SpaceX has only just begun to fully install – let alone test – on Super Heavy B4.

Before Booster 4’s most recent installation on the orbital launch mount, SpaceX did install covers over a pair of hydraulic and heat exchanger racks but left all four composite overwrapped pressure vessel (COPV) racks and an umbilical port uncovered. After B4 was removed from the launch mount for the third time on December 30th, both covers were uninstalled. On January 14th, 2022, though, SpaceX rapidly installed all six covers for the first time and began sealing each cover’s exposed corners. On January 17th, SpaceX even installed aerodynamic surfaces around Booster 4’s protruding umbilical port, smoothing out any hypothetical airflow around the device.

Prior to main aerocover installation, SpaceX also added at least half a dozen small boxes seemingly designed to protect a number of thin metal probes that pierce through Super Heavy’s tanks and skin and are connected to avionics boxes. Additionally, while less visible, teams also worked to finish Super Heavy B4’s Raptor heat shielding with a large number of similar sheet steel covers and panels. Without official photos from SpaceX or another lift onto the launch mount, it’s impossible to know if Booster 4’s Raptor heat shield is fully closed out, but the shielding that runs around its circumference appears to be finished.

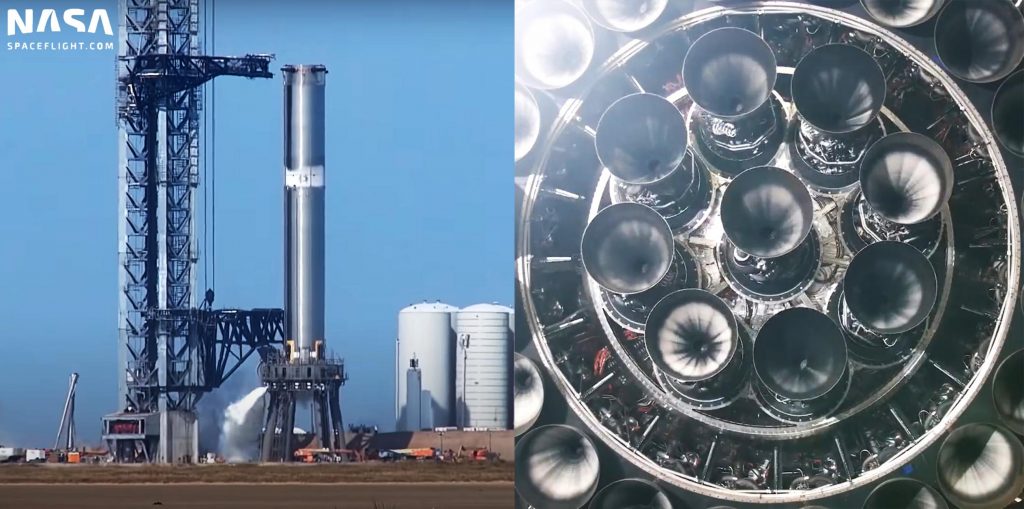

As it stands, Super Heavy B4 is likely just a few parts shy of true completion and is about as ready as it’ll ever be for static fire testing. More likely than not, those aerocovers and Raptor heat shields are essential for Super Heavy B4 to be able to perform more than one test at a time without immediately requiring major repairs. Unlike Starship, which has mostly tested three engines at once and only performed a few six-engine static fires, Super Heavy B4 may eventually test all 29 Raptor engines simultaneously.

When almost 30 engines are involved, even nominal preburner testing will likely produce a massive fireball that could engulf Super Heavy’s aft (if not the entire booster) with flames. For static fire testing, Raptors typically produce a smaller and briefer (but still substantial) fireball during shutdown, creating another potential source of damage to any sensitive hardware located anywhere on or in Booster 4’s thrust section. As such, Super Heavy aerocovers may be just as important for surviving static fires as they’ll be for surviving launches and landings.

It’s unclear if or when Super Heavy B4 will return to the orbital launch mount for wet dress rehearsal and static fire testing. SpaceX has ambiguous test windows scheduled from 10am to 10pm on January 18th, 19th, and 20th.

Elon Musk

SpaceX to launch Starlink V2 satellites on Starship starting 2027

The update was shared by SpaceX President Gwynne Shotwell and Starlink Vice President Mike Nicolls.

SpaceX is looking to start launching its next-generation Starlink V2 satellites in mid-2027 using Starship.

The update was shared by SpaceX President Gwynne Shotwell and Starlink Vice President Mike Nicolls during remarks at Mobile World Congress (MWC) in Barcelona, Spain.

“With Starship, we’ll be able to deploy the constellation very quickly,” Nicolls stated. “Our goal is to deploy a constellation capable of providing global and contiguous coverage within six months, and that’s roughly 1,200 satellites.”

Nicolls added that once Starship is operational, it will be capable of launching approximately 50 of the larger, more powerful Starlink satellites at a time, as noted in a Bloomberg News report.

The initial deployment of roughly 1,200 next-generation satellites is intended to establish global and contiguous coverage. After that phase, SpaceX plans to continue expanding the system to reach “truly global coverage, including the polar regions,” Nicolls said.

Currently, all Starlink satellites are launched on SpaceX’s Falcon 9 rocket. The next-generation fleet will rely on Starship, which remains in development following a series of test flights in 2025. SpaceX is targeting its next Starship test flight, featuring an upgraded version of the rocket, as soon as this month.

Starlink is currently the largest satellite network in orbit, with nearly 10,000 satellites deployed. Bloomberg Intelligence estimates the business could generate approximately $9 billion in revenue for SpaceX in 2026.

Nicolls also confirmed that SpaceX is rebranding its direct-to-cell service as Starlink Mobile.

The service currently operates with 650 satellites capable of connecting directly to smartphones and has approximately 10 million monthly active users. SpaceX expects that figure to exceed 25 million monthly active users by the end of 2026.

Elon Musk

Starlink V2 to bring satellite-to-phone service to Deutsche Telekom in Europe

Starlink stated that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Starlink is partnering with Deutsche Telekom to roll out satellite-to-mobile connectivity across Europe, extending coverage to more than 140 million subscribers across 10 countries.

The service, planned for launch in 2028 in several Telekom markets, including Germany, will use Starlink’s next-generation V2 satellites and Mobile Satellite Service (MSS) spectrum to enable direct-to-device connectivity.

In a post on X, the official Starlink account stated that the agreement will be the first in Europe to deploy its V2 next-generation satellite-to-mobile technology using new MSS spectrum. The company added that the system is designed to deliver 5G speeds directly to compatible smartphones in remote areas.

Abdu Mudesir, Board Member for Product and Technology at Deutsche Telekom, shared his excitement for the partnership in a press release. “We provide our customers with the best mobile network. And we continue to invest heavily in expanding our infrastructure. At the same time, there are regions where expansion is especially complex due to topographical conditions or official constraints,” he said.

“We want to ensure reliable connectivity for our customers in those areas as well. That is why we are strategically complementing our network with satellite-to-mobile connectivity. For us, it is clear: connectivity creates security and trust. And we deliver. Everywhere.”

Under the partnership, compatible smartphones will automatically switch to Starlink’s satellite network when terrestrial coverage is unavailable, enabling access to data, voice, video, and messaging services.

Telekom reports 5G geographic coverage approaching 90% in Germany, with LTE exceeding 92% and voice coverage reaching up to 99%. Starlink’s satellite layer is intended to extend connectivity beyond those terrestrial limits, particularly in topographically challenging or infrastructure-constrained areas.

Stephanie Bednarek, VP of Starlink Sales, also shared her thoughts on the partnership. “We’re so pleased to bring reliable satellite-to-mobile connectivity to millions of people across 10 countries in partnership with Deutsche Telekom. This agreement will be the first-of-its-kind in Europe to launch Starlink’s V2 next-generation technology that will expand on data, voice and messaging by providing broadband directly to mobile phones,” she said.

Starlink’s V2 constellation is designed to expand bandwidth and capacity compared to its predecessor. If implemented as outlined, the 2028 launch would mark one of the first large-scale European deployments of integrated satellite-to-phone connectivity by a major telecom operator.

Elon Musk

SpaceX pursues 5G-level connectivity with Starlink Mobile V2 expansion

SpaceX noted that the upcoming Starlink V2 satellites will deliver up to 100 times the data density of the current first-generation system.

SpaceX has previewed a major upgrade to Starlink Mobile, outlining next-generation satellites that aim to deliver significantly higher capacity and full 5G-level connectivity directly to mobile phones.

The update comes as Starlink rebrands its Direct-to-Cell service to Starlink Mobile, positioning the platform as a scalable satellite-to-mobile solution that’s integrated with global telecom partners.

SpaceX noted that the upcoming Starlink V2 satellites will deliver up to 100 times the data density of the current first-generation system. The company also noted that the new V2 satellites are designed to provide significantly higher throughput capability compared to its current iteration.

“The next generation of Starlink Mobile satellites – V2 – will deliver full cellular coverage to places never thought possible via the highest performing satellite-to-mobile network ever built.

“Driven by custom SpaceX-designed silicon and phased array antennas, the satellites will support thousands of spatial beams and higher bandwidth capability, enabling around 20x the throughput capability as compared to a first-generation satellite,” SpaceX wrote in its official Starlink Mobile page.

Thanks to the higher bandwidth of Starlink Mobile, users should be able to stream, browse the internet, use high-speed apps, and enjoy voice services comparable to terrestrial cellular networks.

In most environments, Starlink says the upgraded system will enable full 5G cellular connectivity with a user experience similar to existing ground-based networks.

The satellites function as “cell towers in space,” using advanced phased-array antennas and laser interlinks to integrate with terrestrial infrastructure in a roaming-like architecture.

“Starlink Mobile works with existing LTE phones wherever you can see the sky. The satellites have an antenna that acts like a cellphone tower in space, the most advanced phased array antennas in the world that connect seamlessly over lasers to any point in the globe, allowing network integration similar to a standard roaming partner,” SpaceX wrote.

Starlink Mobile currently operates with approximately 650 satellites in low-Earth orbit and is active across more than 32 countries, representing over 1.7 billion people through partnerships with mobile network operators. Starlink Mobile’s current partnerships span North America, Europe, Asia, Africa, and Oceania, allowing reciprocal access across participating nations.