News

SpaceX tests ceramic Starship heat shield tiles on Starhopper’s final flight test

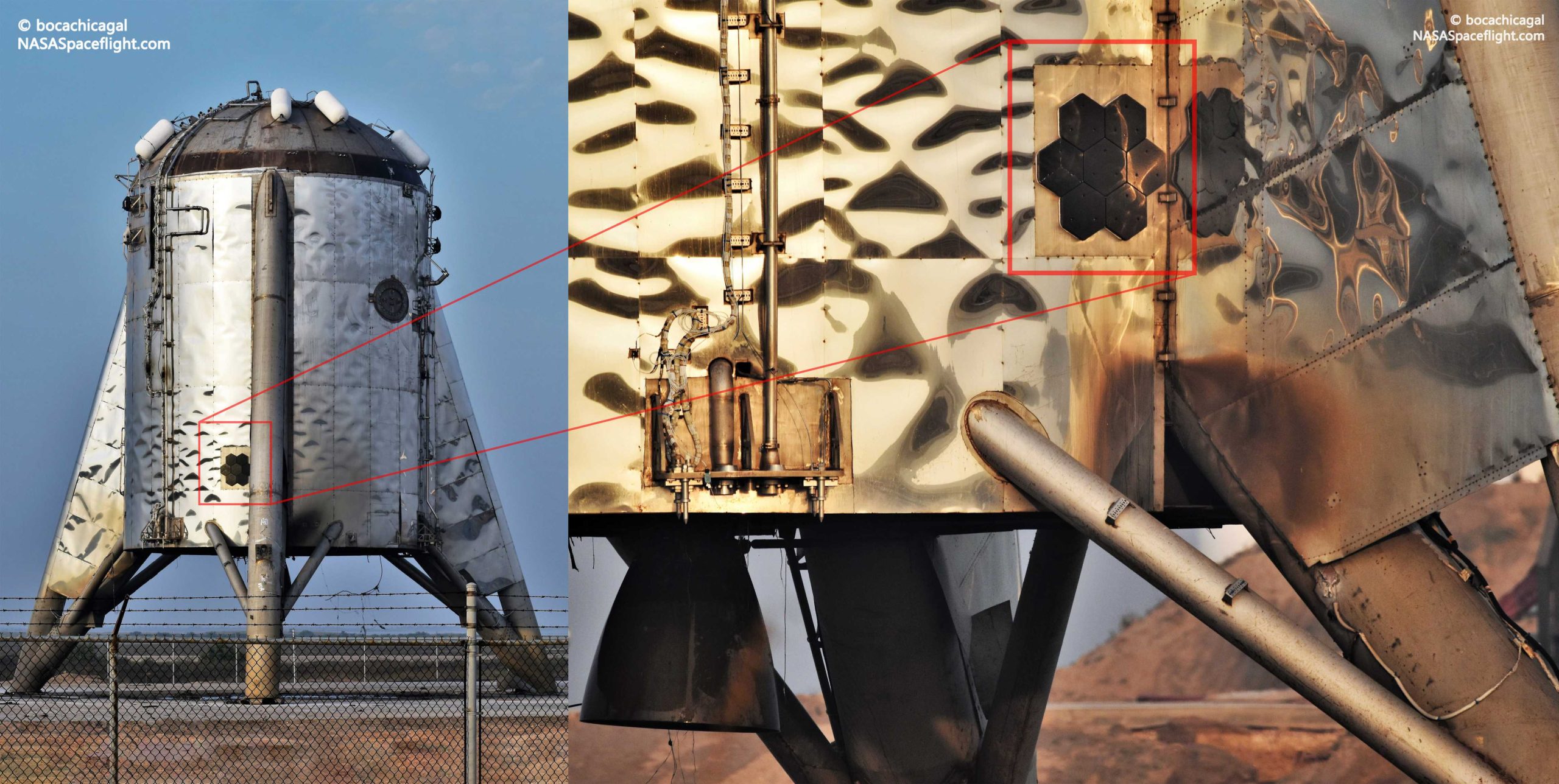

Although it flew under the radar in the heat of the moment, SpaceX’s final Starhopper test flight – completed on August 27th – happened to include an unusual bit of test hardware – eight (give or take) ceramic Starship heat shield tiles.

On the same day that Starhopper lifted off for the last time and completed a 150m (500 ft) hop test in South Texas, SpaceX Cargo Dragon capsule C108 wrapped up its third successful orbital mission, reentering Earth’s atmosphere with a complement of several ceramic Starship heat shield tiles. This marked the first known orbital test of Starship hardware on the same exact day that Starhopper was putting nearly identical tiles through an entirely different kind of flight test.

Tile #8

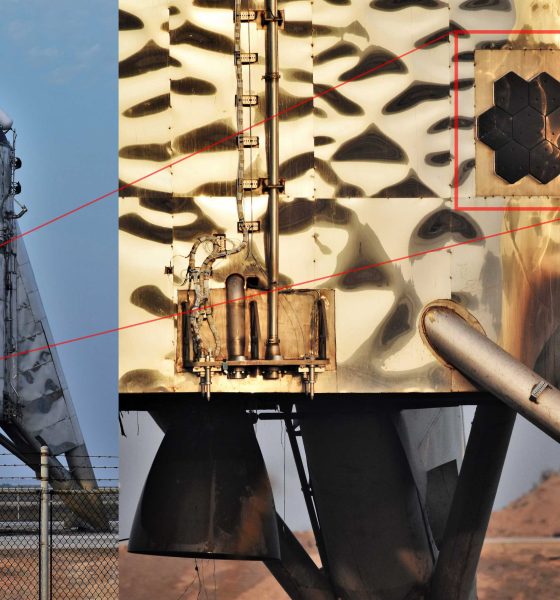

As pictured above, a group of seven hexagonal tiles appeared on Starhopper’s exterior around August 14th. Those tiles were black (somewhere between matte and glossy), featured indents likely related to manufacturing or mounting, and appeared to be attached to Starhopper by way of a white, marshmallow-esque adhesive. Altogether, each tile bears a striking resemblance to two-thirds of a hexagonal Oreo cookie, arranged in a grid and sort of squished onto Starhopper.

Aside from the seven tiles attached directly to the exterior Starhopper’s liquid methane tank, at least one additional tile was spotted on a small mount structure welded to the bottom of one of the vehicle’s tripod legs. Likely just five or so meters (~15 feet) away from Starhopper’s Raptor engine, that particular tile would have been subjected to intense heating and sound (i.e. thermal and acoustic shock) during the Starship testbed’s final ~60-second flight.

It is a busy morning at the Starship Hopper launch site!

⚙️/⬇️/? : https://t.co/zWfJdm095L pic.twitter.com/KL6azUo4Rd— ?Trevor Mahlmann (@TrevorMahlmann) August 26, 2019

In fact, the Raptor-facing tile may have been put through an even more stressful test than intended, owing to the apparent difficulties Raptor SN06 had during its minute-long performance. Whether the result of shoddy installation and plumbing or an issue with Raptor itself, the engine demonstrated some unusual behavior as it throttled down for Starhopper’s landing, turning its largely transparent exhaust plume into a massive flamethrower.

Raptor or adjacent plumbing also appeared to suffer some kind of leak just before landing, producing significant flames that clearly scorched Starhopper’s rear and destroyed a huge amount of cabling in the area, visible just below the hexagonal tile group. Likely related, several views of the test showed a COPV flying off – clearing having suffered an anomaly that broke it free from Starhopper – around the same time as the vehicle ended its hop with a hard landing.

Tiles on Starhopper?

This does raise the question: why were prototype Starship heat shield tiles attached to Starhopper, a distinctly suborbital prototype that never reached a speed of ~20 m/s (40 mph), let alone orbital velocity? Without actually performing a reentry, what value could be derived? Taken alongside the almost-simultaneous orbital reentry test of four separate Cargo Dragon-shaped tile prototypes, the likely explanation is actually pretty simple and serves as an excellent example of SpaceX’s agile approach to aerospace development.

The three separate tile locations (Starhopper’s tank and leg and Cargo Dragon’s heat shield) all delivered extremely unique test conditions to their respective ceramic tile prototypes. Attached directly to a cryogenic fuel tank, Starhopper’s seven-tile set was almost certainly meant to test methods of mounting a heat shield on a stainless steel tank. Those tiles went through several thermal cycles from propellant loading, spent weeks unprotected in hellish South Texas heat and humidity, and suffered through the shock of flight and a hard landing.

The lone Raptor-adjacent tile was subjected to heating from a live engine just a dozen or so feet away, along with all the brutal acoustic stresses associated with it, perhaps including an unintended fire during anomalous engine performance. Cargo Dragon C108’s four ceramic tiles were far closer to a full-fidelity test, although they were shaped for and attached to the spacecraft in a manner that minimized their one-to-one relevance to Starship’s likely shield design. Regardless of the level of the test’s fidelity, they still managed to survive a true-to-life orbital reentry with nothing more than some soot stains from Dragon’s normal PICA-X shield material.

In short, SpaceX (hopefully successfully) demonstrated a large number of Starship’s ceramic tile design requirements before an actual flight-capable Mk1 or Mk2 Starship is ready for comparable testing. Of course, the most important tests will involve a combination of all Starship-relevant conditions (Raptor engines, cryogenic tank-wall mounting, hexagonal tiles, weeks spent in space, orbital reentry, etc.) for a full-fidelity reentry campaign with an actual Starship prototype. SpaceX CEO Elon Musk says those tests could begin very soon – as early as October 2019 – and the suite of piecemeal Cargo Dragon and Starhopper tests that prototype tiles have already completed will undoubtedly grease the wheels towards that ambitious goal.

Check out Teslarati’s Marketplace! We offer Tesla accessories, including for the Tesla Cybertruck and Tesla Model 3.

News

Tesla ships out an update for everyone that California caused

“This change only updates the name of certain features and text in your vehicle,” the company wrote in Release Notes for the update, “and does not change the way your features behave.”

Tesla has shipped out an update for its vehicles that was caused specifically by a California lawsuit that threatened the company’s ability to sell cars because of how it named its driver assistance suite.

Tesla shipped out Software Update 2026.2.9 starting last week; we received it already, and it only brings a few minor changes, mostly related to how things are referenced.

“This change only updates the name of certain features and text in your vehicle,” the company wrote in Release Notes for the update, “and does not change the way your features behave.”

The following changes came to Tesla vehicles in the update:

- Navigate on Autopilot has now been renamed to Navigate on Autosteer

- FSD Computer has been renamed to AI Computer

Tesla faced a 30-day sales suspension in California after the state’s Department of Motor Vehicles stated the company had to come into compliance regarding the marketing of its automated driving features.

The agency confirmed on February 18 that it had taken a “corrective action” to resolve the issue. That corrective action was renaming certain parts of its ADAS.

Tesla discontinued its standalone Autopilot offering in January and ramped up the marketing of Full Self-Driving Supervised. Tesla had said on X that the issue with naming “was a ‘consumer protection’ order about the use of the term ‘Autopilot’ in a case where not one single customer came forward to say there’s a problem.”

This was a “consumer protection” order about the use of the term “Autopilot” in a case where not one single customer came forward to say there’s a problem.

Sales in California will continue uninterrupted.

— Tesla North America (@tesla_na) December 17, 2025

It is now compliant with the wishes of the California DMV, and we’re all dealing with it now.

This was the first primary dispute over the terminology of Full Self-Driving, but it has undergone some scrutiny at the federal level, as some government officials have claimed the suite has “deceptive” names. Previous Transportation Secretary Pete Buttigieg was one of those federal-level employees who had an issue with the names “Autopilot” and “Full Self-Driving.”

Tesla sued the California DMV over the ruling last week.

News

Tesla workers push back against Giga Berlin unionization

“IG Metall did not succeed in Giga Berlin‘s works council election earlier today. The union share was reduced from nearly 40% in 2024 to 31% in 2026! This is a clear message by the Giga Berlin team towards an independent co-determination! The list called Giga United, led by the current chairwoman, Michaela Schmitz, received the most votes with more than 40%! Good news for Giga Berlin!”

Tesla workers pushed back against unionization efforts at Gigafactory Berlin, and over the past few years, there has been a dramatic decrease in interest to unionize at the German plant.

Gigafactory Berlin Plant Manager André Thierig announced on Wednesday that IG Metall, the European union group, saw its share reduce from 40 to 31 percent in 2026 as employees eligible to vote on the issue. Instead, the Giga Berlin team, known as Giga United, received the most votes with more than 40 percent.

BREAKING! 🚨

IG Metall did not succeed in Giga Berlin‘s works council election earlier today. The union share was reduced from nearly 40% in 2024 to 31% in 2026!

This is a clear message by theGiga Berlin team towards an independent co-determination!

The list called Giga…

— André Thierig (@AndrThie) March 4, 2026

Thierig gave specific details in a post on X:

“IG Metall did not succeed in Giga Berlin‘s works council election earlier today. The union share was reduced from nearly 40% in 2024 to 31% in 2026! This is a clear message by the Giga Berlin team towards an independent co-determination! The list called Giga United, led by the current chairwoman, Michaela Schmitz, received the most votes with more than 40%! Good news for Giga Berlin!”

There were over 10,700 total employees who were eligible to vote, with 87 percent of them turning out to cast what they wanted. There were three key outcomes: Giga United, IG Metall, and other notable groups, with the most popular being the Polish Initiative.

The 37-seat council remains dominated by non-unionized representatives, preserving Giga Berlin as Germany’s only major auto plant without a collective bargaining agreement.

Thierig and Tesla framed the outcome as employee support for an “independent, flexible, and unbureaucratic” future, enabling acceleration on projects like potential expansions or new models. IG Metall expressed disappointment, accusing management of intimidation tactics and an “unfair” campaign.

The first election of this nature happened back in 2022. In 2024, IG Metall emerged as the largest single faction with 39.4 percent, but non-union lists coalesced for a majority.

But this year was different. There was some extra tension at Giga Berlin this year, as just two weeks ago, an IG Metall rep was accused by Tesla of secretly recording a council meeting. The group countersued for defamation.

Tesla Giga Berlin plant manager faces defamation probe after IG Metall union complaint

This result from the 2026 vote reinforced Tesla’s model of direct employee-management alignment over traditional German union structures, amid ongoing debates about working conditions. IG Metall views it as a setback but continues advocacy. Tesla sees it as validation of its approach in a competitive EV market.

This outcome may influence future labor dynamics at Giga Berlin, including any revival of expansion plans or product lines, which Musk has talked about recently.

News

SpaceX President Gwynne Shotwell details xAI power pledge at White House event

The commitment was announced during an event with United States President Donald Trump.

SpaceX President Gwynne Shotwell stated that xAI will develop 1.2 gigawatts of power at its Memphis-area AI supercomputer site as part of the White House’s new “Ratepayer Protection Pledge.”

The commitment was announced during an event with United States President Donald Trump.

During the White House event, Shotwell stated that xAI’s AI data center near Memphis would include a major energy installation designed to support the facility’s power needs.

“As you know, xAI builds huge supercomputers and data centers and we build them fast. Currently, we’re building one on the Tennessee-Mississippi state line. As part of today’s commitment, we will take extensive additional steps to continue to reduce the costs of electricity for our neighbors…

“xAI will therefore commit to develop 1.2 GW of power as our supercomputer’s primary power source. That will be for every additional data center as well. We will expand what is already the largest global Megapack power installation in the world,” Shotwell said.

She added that the system would provide significant backup power capacity.

“The installation will provide enough backup power to power the city of Memphis, and more than sufficient energy to power the town of Southaven, Mississippi where the data center resides. We will build new substations and invest in electrical infrastructure to provide stability to the area’s grid.”

Shotwell also noted that xAI will be supporting the area’s water supply as well.

“We haven’t talked about it yet, but this is actually quite important. We will build state-of-the-art water recycling plants that will protect approximately 4.7 billion gallons of water from the Memphis aquifer each year. And we will employ thousands of American workers from around the city of Memphis on both sides of the TN-MS border,” she noted.

The Ratepayer Protection Pledge was introduced as part of the federal government’s effort to address concerns about rising electricity costs tied to large AI data centers, as noted in an Insider report. Under the agreement, companies developing major AI infrastructure projects committed to covering their own power generation needs and avoiding additional costs for local ratepayers.