News

SpaceX vs. Blue Origin: The bickering titans of new space

In the past three years, SpaceX has made incredible progress in their program of reusability. In the practice’s first year, the young space company led by serial tech entrepreneur Elon Musk has performed three successful commercial reuses of Falcon 9 boosters in approximately eight months, and has at least two more reused flights scheduled before 2017 is out. Blue Origin, headed and funded by Jeff Bezos of Amazon fame, is perhaps most famous for its supreme confidence, best illustrated by Bezos offhandedly welcoming SpaceX “to the club” after the company first recovered the booster stage of its Falcon 9 rocket in 2015.

Blue Origin began in the early 2000s as a pet project of Bezos, a long-time fan of spaceflight and proponent of developing economies in space. After more than a decade of persistent development and increasingly complex testbeds, Blue Origin began a multi-year program of test flights with its small New Shepard launch vehicle. Designed to eventually launch tourists to the veritable edge of Earth’s atmosphere in a capsule atop it, New Shepard began its test flights in 2015 and after one partial failure, has completed five successful flights in a row. The space tourism company has subtly and not-so-subtly belittled SpaceX’s accomplishments over the last several years, and has engendered a fair bit of hostility towards it as a result.

Admittedly, CEO Elon Musk nurtured high expectations for the consequences of reuse, and has frequently discussed SpaceX’s ambition to reduce the cost of access to orbit by a factor of 10 to 100. However, after several reuses, it is clear that costs have decreased no more than 10-20%. What gives?

Well, Musk’s many comments on magnitudes of cost reduction were clearly premised upon rapid and complete reuse of both stages of Falcon 9, best evidenced by a concept video the company released in 2011.

The reality was considerably harder and Musk clearly underestimated the difficulty of second stage reuse, something he himself has admitted. COO Gwynne Shotwell was interviewed earlier this summer and discussed SpaceX’s updated approach to complete reusability, and acknowledged that second stage reuse was no longer a real priority, although the company will likely attempt second stage recovery as a validation of future technologies. Instead of pursuing the development of a completely reusable Falcon 9, SpaceX is instead pushing ahead with the development of a much larger rocket, BFR. BFR being designed to enable the sustainable colonization of space by realizing Musk’s original ambition of magnitudes-cheaper orbital launch capabilities.

Competition on the horizon?

Meanwhile, SpaceX’s only near-term competitor interested in serious reuse has made gradual progress over the last several years, accelerating its pace of development more recently. Blue Origin’s second New Shepard vehicle, designed to serve the suborbital space tourism industry, conducted an impressive five successful launches and landings over the course of 2016 before being summarily retired. NS2’s antecedent suffered a failure while attempting its first landing and was destroyed in 2015, but Blue learned quickly from the issues of Shepard 1 and has already shipped New Shepard 3 to its suborbital launch facilities near Van Horn, Texas. While NS3 is aiming for an inaugural flight later this year, NS4 is under construction in Kent, Washington and could support Blue’s first crewed suborbital launches in 2018.

More significant waves were made with an announcement in 2016 that Blue was pursuing development of a partially reusable orbital-class launch vehicle, the massive New Glenn. On paper, New Glenn is quite a bit larger than even SpaceX’s Falcon 9, and appears to likely be more capable than the company’s “world’s most powerful rocket” while completely recovering its boost stage. In a completed, manufactured, and demonstrably reliable form, New Glenn would be an extraordinarily impressive and capable launch vehicle that could undoubtedly catapult Blue Origin into position of true competition with SpaceX’s reusability efforts.

- The New Shepard booster. (Blue Origin)

- Blue Origin’s New Shepard capsule could carry passengers as high as 100km in 2018. (Blue Origin)

- A render of Blue Origin’s larger New Glenn vehicle. (Blue Origin)

However, while Blue Origin executives brag about “operational reusability” and tastelessly lampoon efforts that “decided to slap some legs on [to] see if [they] could land it”, the unmentioned company implicated in those barbs has begun to routintely and commercially reuse orbital-class boosters five times the size of Blue’s suborbital testbed, New Shepard.

Apples to oranges

The only point at which Blue Origin poses a risk to SpaceX’s business can be found in a comparison of funding sources. SpaceX first successes (and failures) were funded out of Elon Musk’s own pocket, but nearly all of the funding that followed was won through competitive government contracts and rounds of private investment. To put it more simply, SpaceX is a business that must balance costs and returns, while Blue Origin is funded exclusively out of billionaire CEO Jeff Bezos’ pocket.

As a result of being completely privately funded, Bezos’ deep pockets could render Blue more flexible than SpaceX when pricing launches. If Blue chooses to aggressively price New Glenn by accounting for booster reusability, it could pose a threat to SpaceX’s own business strategy. If SpaceX is unable to recoup its investment in reusability before New Glenn is regularly conducting multiple commercial missions per year, likely no earlier than 2021 or 2022, SpaceX’s Falcon 9 pricing could be rendered distinctly noncompetitive.

However, this concern seems almost entirely misplaced. SpaceX has half a decade of experience mass-producing orbital-class (reusable) rockets, (reusable) fairings, and propulsion systems, whereas Blue Origin at best has minimal experience manufacturing a handful of suborbital vehicles over a period of a few years. Blue has a respectable amount of experience with their BE-3 hydrolox propulsion system, and that will likely transfer over to the BE-3U vacuum variant to be used for New Glenn’s third stage. The large methalox rocket engine (BE-4) that will power New Glenn’s first stage also conducted its first-ever hot-fire just weeks ago, a major milestone in propulsion development but also a reminder that BE-4 has an exhaustive regime of engineering verification and flight qualification testing ahead of it.

First hotfire of our BE-4 engine is a success #GradatimFerociter pic.twitter.com/xuotdzfDjF

— Blue Origin (@blueorigin) October 19, 2017

Perhaps more importantly, the company’s relative success with New Shepard’s launch, recovery, and reuse has not and cannot move beyond small suborbital hops, and thus cannot provide the experience at the level of orbital rocketry. New Shepard is admittedly capable of reaching an altitude of 100km, but the suborbital vehicle’s flight regime does not require it to travel beyond Mach 4 (~1300 m/s). The first stage of Falcon 9, however, is approximately four times as tall and three times the mass of New Shepard, and boosters attempting recovery during geostationary missions routinely reach almost twice the velocity of New Shepard, entering the thicker atmosphere at more than 2300 m/s (1500-1800 m/s for LEO missions). Falcon 9’s larger mass and velocity translates into intense reentry heating and aerodynamic forces, best demonstrated by the glowing aluminum grid fins that can often be seen in SpaceX’s live coverage of booster recovery. Blue Origin’s New Glenn concept is extremely impressive on paper, but the company will have to pull off an extraordinary leap of technological maturation to move directly from suborbital single-stage hops to multi-stage orbital rocketry. Blue’s accomplishments with New Shepard are nothing to scoff at, but they are a far cry from routine orbital launch services.

SpaceX’s future fast approaches

Translating back to the new establishment, Falcon 9 will likely remain SpaceX’s workhorse rocket for some five or more years, at least until BFR can prove itself to be a reliable and affordable replacement. This change in focus, combined with the downsides of second stage recovery and reuse on a Falcon 9-sized vehicle, means that SpaceX will ‘only’ end up operationally reusing first stages and fairings from the vehicle. The second stage accounts for approximately 20-30% of Falcon 9’s total cost, suggesting that rapid and complete reuse of the fairing and first stage could more than halve its ~$62 million price. Yet this too ignores another mundane fact of corporate life SpaceX must face. Its executives, Musk included, have lately expressed a desire to at least partially recoup the ~$1 billion that was invested to develop reuse. Assuming a partial 10% reduction in cost to reuse customers and profit margins of 50% with rapid and total reuse of the first stage and fairing, 20 to 30 commercial reuses would recoup most or all of SpaceX’s reusability investment.

Musk recently revealed that SpaceX is aiming to complete 30 launches in 2018, and that figure will likely continue to grow in 2019, assuming no major anomalies occur. Manufacturing will rapidly become the main choke point for increased launch cadence, suggesting that drastically higher cadences will largely depend upon first stage reuse with minimal refurbishment, which just so happens to be the goal of the Falcon 9’s upcoming Block 5 iteration. Even if the modifications only manage a handful of launches without refurbishment, rather than the ten flights being pursued, each additional flight without maintenance will effectively multiply SpaceX’s manufacturing capabilities. More bluntly: ten Falcon 9s capable of five reflights could do the same job of 50 brand new rockets with 1/5th of the manufacturing backend.

- BulgariaSat-1 was successfully launched 48 hours before Iridium-2, and marked the second or three successful, commercial reuses of an orbital rocket. (SpaceX)

- SpaceX’s Hawthorne factory routinely churns out one to two complete Falcon 9s every month. (SpaceX)

- Falcon 9 B1040 returns to LZ-1 after the launch of the USAF’s X-37B spaceplane. (SpaceX)

Assuming that upcoming reuses proceed without significant failures and Falcon 9 Block 5 subsumes all manufacturing sometime in 2018 or 2019, it is entirely possible that SpaceX will undergo an extraordinarily rapid phase change from expendability to reusability. Mirroring 2017, we can imagine that SpaceX’s Hawthorne factory will continue to churn out at least 10 to 20 Block 5 Falcon 9s over the course of 2018. Assuming 5 to 10 maintenance-free reuses and a lifespan of as many as 100 flights with intermittent refurb, a single year of manufacturing could provide SpaceX with enough first stages to launch anywhere from 50 to 2000 missions. The reality will inevitably find itself somewhere between those extremely pessimistic and optimistic bookends, and they of course do not account for fairings, second stages, or expendable flights.

If we assume that the proportional cost of Falcon 9’s many components very roughly approximates the amount of manufacturing backend needed to produce them, downsizing Falcon 9 booster production by a factor of two or more could free a huge fraction of SpaceX’s workforce and floor space to be repurposed for fairing and second stage production, as well as the company’s Mars efforts. Such a phase change would also free up a considerable fraction of the capital SpaceX continually invests in its manufacturing infrastructure and workforce, capital that could then be used to ready SpaceX’s facilities for production and testing of its Mars-focused BFR and BFS.

“Gradatim ferociter”

It cannot be overstated that the speculation in this article is speculation. Nevertheless, it is speculation built on real information provided over the years by SpaceX’s own executives. Rough estimates like this offer a glimpse into a new launch industry paradigm that could be only a year or two away and could allow SpaceX to begin aggressively pursuing its goal of enabling a sustainable human presence on Mars and throughout the Solar System.

Blue Origin’s future endeavors shine on paper and their goal of enabling millions to work and live space are admirable, but the years between the present and a future of routine orbital missions for the company may not be kind. The engineering hurdles that litter the path to orbital rocketry are unforgiving and can only be exacerbated by blind overconfidence, a lesson that is often only learned the hard way. Blue Origin’s proud motto “Gradatim ferociter” roughly translates to “Step by step, ferociously.” One can only hope that some level of humility and sobriety might temper that ferocity before customers entrust New Glenn with their infrastructural foundations and passengers entrust New Shepard with their lives.

News

Tesla Roadster patent hints at radical seat redesign ahead of reveal

A newly published Tesla patent could offer one of the clearest signals yet that the long-awaited next-generation Roadster is nearly ready for its public debut.

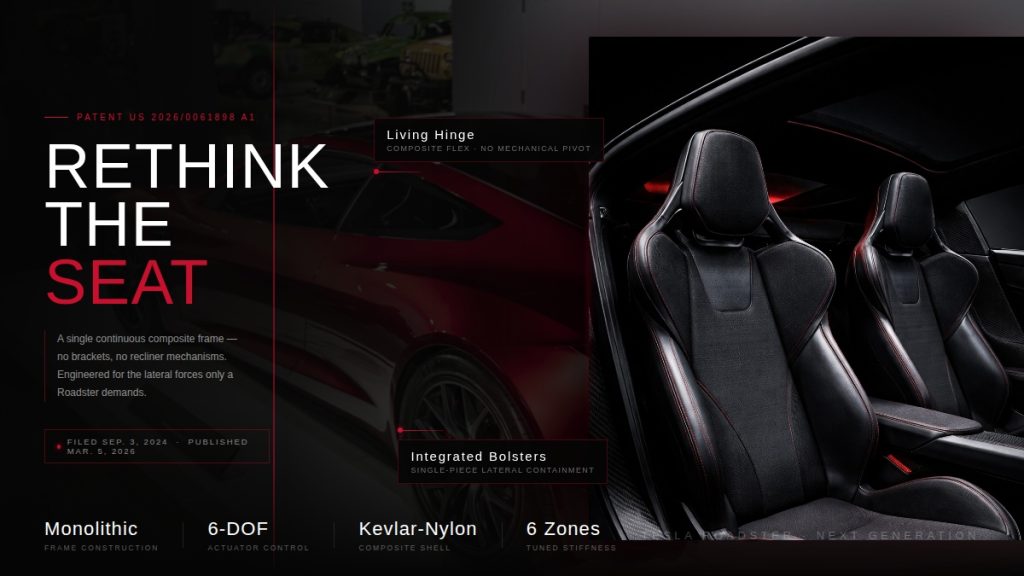

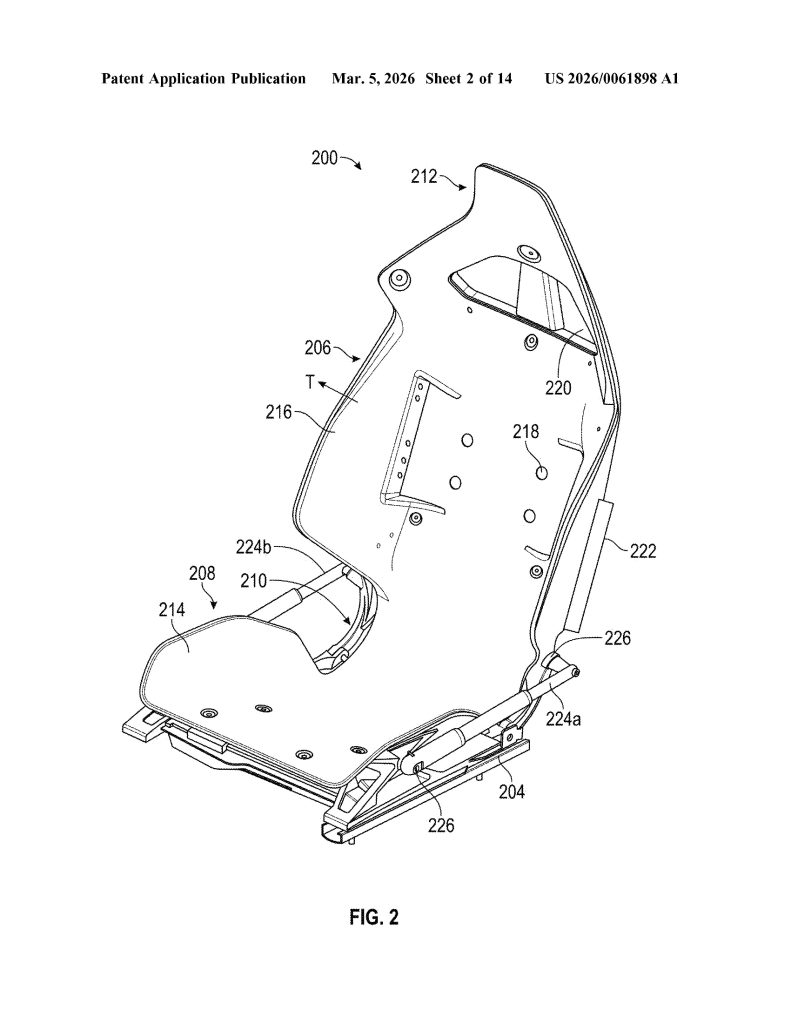

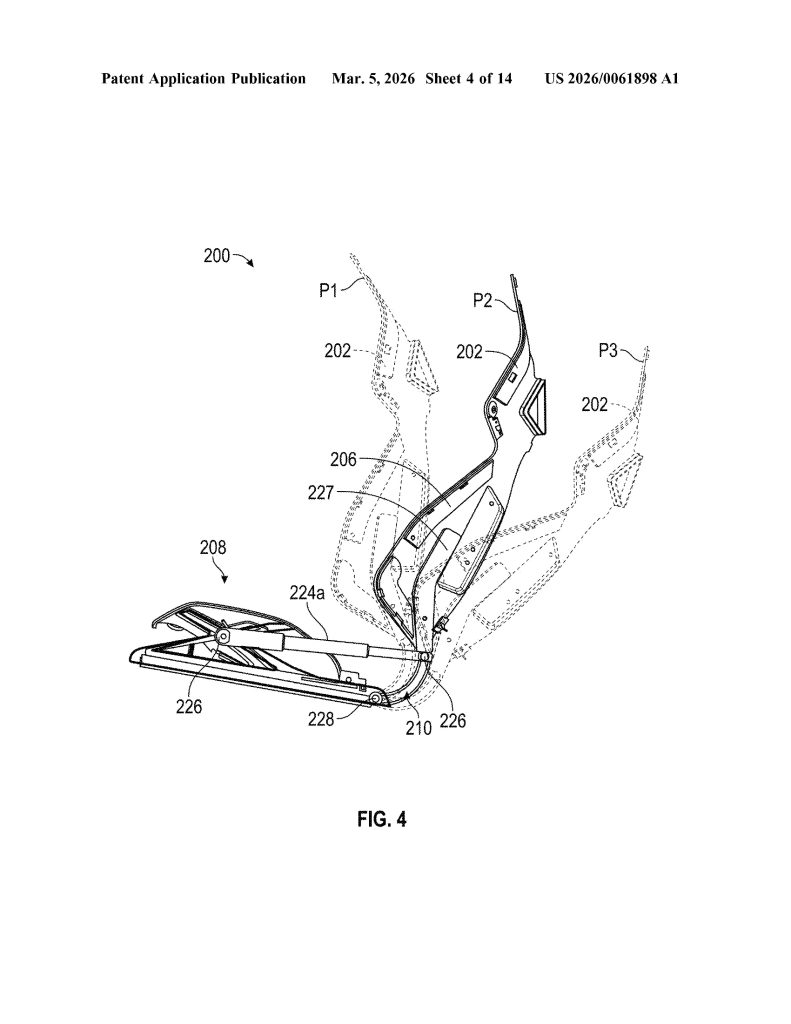

Patent No. US 20260061898 A1, published on March 5, 2026, describes a “vehicle seat system” built around a single continuous composite frame – a dramatic departure from the dozens of metal brackets, recliner mechanisms, and rivets that make up a traditional car seat. Tesla is calling it a monolithic structure, with the seat portion, backrest, headrest, and bolsters all thermoformed as one unified piece.

The approach mirrors Tesla’s broader manufacturing philosophy. The same company that pioneered massive aluminum castings to eliminate hundreds of body components is now applying that logic to the cabin. Fewer parts means fewer potential failure points, less weight, and a cleaner assembly process overall.

Tesla ramps hiring for Roadster as latest unveiling approaches

The timing of the filing is difficult to ignore. Elon Musk has publicly targeted April 1, 2026 as the date for an “unforgettable” Roadster design reveal, and two new Roadster trademarks were filed just last month. A patent describing a seat architecture suited for a hypercar, and one that Tesla has promised will hit 60 mph in under two seconds.

The Roadster, originally unveiled in 2017, has been one of Tesla’s most anticipated yet most delayed products. With a target price around $200,000 and engineering ambitions to match, it is being positioned as the ultimate showcase for what Tesla’s technology can do.

The patent was first flagged by @seti_park on X.

Tesla Roadster Monolithic Seat: Feature Highlights via US Patent 20260061898 A1

- Single Continuous Frame (Monolithic Construction). The core invention is a seat assembly built from one continuous frame that integrates the seat portion, backrest portion, and hinge into a single component — eliminating the need for separate structural parts and mechanical joints typical in conventional seats.

- Integrated Flexible Hinge. Rather than a traditional mechanical recliner, the hinge is built directly into the continuous frame and is designed to flex, and allowing the backrest to move relative to the seat portion. The hinge can be implemented as a fiber composite leaf spring or an assembly of rigid linkages.

- Thermoformed Anisotropic Composite Material. The continuous frame is manufactured via thermoforming from anisotropic composite materials, including fiberglass-nylon, fiberglass-polymer, nylon carbon composite, Kevlar-nylon, or Kevlar-polymer composites, enabling a molded-to-shape monolithic structure.

- Regionally Tuned Stiffness Zones. The frame is engineered with up to six distinct stiffness regions (R1–R6) across the seat, backrest, hinge, headrest, and bolsters. Each zone can have a different stiffness, allowing precise ergonomic and structural tuning without adding separate components.

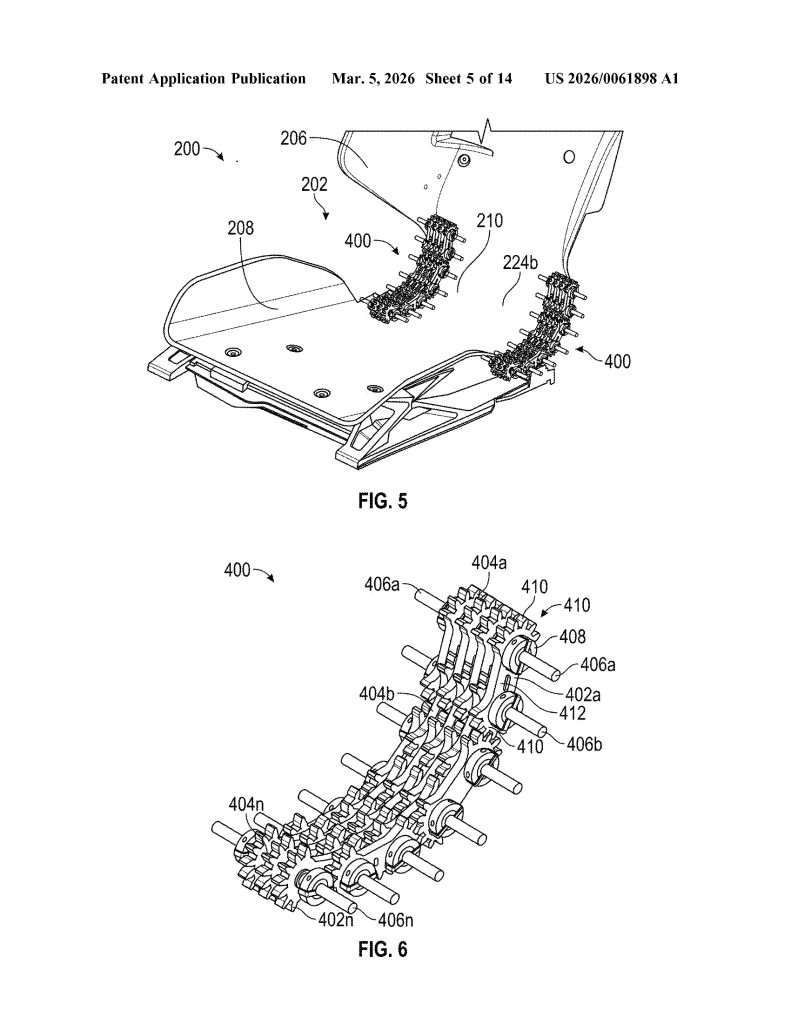

- Linkage Assembly Hinge Mechanism. The hinge incorporates one or more linkage assemblies consisting of multiple interlocking links with gears, connected by rods. When driven by motors or actuators, these linkages act as a flexible member to control backrest movement along a precise, ergonomically optimized trajectory.

- Multi-Actuator Six-Degree-of-Freedom Positioning System. The seat uses four distinct actuator pairs, all controlled by a central controller. These actuators work in coordinated combinations to achieve fore/aft, height, cushion tilt, and backrest rotation adjustments simultaneously.

- ECU-Based Controller Architecture. An Electronic Control Unit (ECU) and programmable controller manage all seat actuators, receive user input via a user interface (touchscreen, buttons, or switches), and incorporate sensor feedback to confirm and maintain desired seat positions, essentially making this a software-driven seat system.

- Airbag-Integrated Bolster Deployment System. The backrest bolsters (216) are geometrically shaped and sized to guide airbag deployment along a specific, pre-configured trajectory. Left and right bolsters can have different shapes so that each guides its respective airbag along a distinct trajectory, improving occupant protection.

- Ventilation Holes Formed into the Backrest. The continuous frame includes one or more ventilation holes formed directly into the backrest portion, configured to either receive airflow into or deliver airflow from the seat frame — enabling passive or active thermal comfort without requiring separate ventilation components.

- Soft Trim Recess for Tool-Free Integration. The headrest and backrest portions together define a molded recess, specifically designed to receive and secure a soft trim component (foam, fabric, or cushioning) directly into the continuous frame, eliminating the need for separate attachment hardware and simplifying final assembly.

Elon Musk

Elon Musk’s xAI plans $659M expansion at Memphis supercomputer site

The new building is planned for a 79-acre parcel located at 5414 Tulane Road, next to xAI’s Colossus 2 data center site.

Elon Musk’s artificial intelligence company xAI has filed a permit to construct a new building at its growing data center complex outside Memphis, Tennessee.

As per a report from Data Center Dynamics, xAI plans to spend about $659 million on a new facility adjacent to its Colossus 2 data center. Permit documents submitted to the Memphis and Shelby County Division of Planning and Development show the proposed structure would be a four-story building totaling about 312,000 square feet.

The new building is planned for a 79-acre parcel located at 5414 Tulane Road, next to xAI’s Colossus 2 data center site. Permit filings indicate the structure would reach roughly 75 feet high, though the specific function of the building has not been disclosed.

The filing was first reported by the Memphis Business Journal.

xAI uses its Memphis data centers to power Grok, the company’s flagship large language model. The company entered the Memphis area in 2024, launching its Colossus supercomputer in a repurposed Electrolux factory located in the Boxtown district.

The company later acquired land for the Colossus 2 data center in March last year. That facility came online in January.

A third data center is also planned for the cluster across the Tennessee–Mississippi border. Musk has stated that the broader campus could eventually provide access to about 2 gigawatts of compute power.

The Memphis cluster is also tied to new power infrastructure commitments announced by SpaceX President Gwynne Shotwell. During a White House event with United States President Donald Trump, Shotwell stated that xAI would develop 1.2 gigawatts of power for its supercomputer facility as part of the administration’s “Ratepayer Protection Pledge.”

“As you know, xAI builds huge supercomputers and data centers and we build them fast. Currently, we’re building one on the Tennessee-Mississippi state line… xAI will therefore commit to develop 1.2 GW of power as our supercomputer’s primary power source. That will be for every additional data center as well…

“The installation will provide enough backup power to power the city of Memphis, and more than sufficient energy to power the town of Southaven, Mississippi where the data center resides. We will build new substations and invest in electrical infrastructure to provide stability to the area’s grid,” Shotwell said.

Shotwell also stated that xAI plans to support the region’s water supply through new infrastructure tied to the project. “We will build state-of-the-art water recycling plants that will protect approximately 4.7 billion gallons of water from the Memphis aquifer each year. And we will employ thousands of American workers from around the city of Memphis on both sides of the TN-MS border,” she said.

News

Tesla wins another award critics will absolutely despise

Tesla earned an overall score of 49 percent, up 6 percentage points from the previous year, widening its lead over second-place Ford (45 percent, up 2 points) to a commanding 4-percentage-point gap. The company also excelled in the Fossil Free & Environment category with a 50 percent score, reflecting strong progress in reducing emissions and decarbonizing operations.

Tesla just won another award that critics will absolutely despise, as it has been recognized once again as the company with the most sustainable supply chain.

Tesla has once again proven its critics wrong, securing the number one spot on the 2026 Lead the Charge Auto Supply Chain Leaderboard for the second consecutive year, Lead the Charge rankings show.

NEWS: Tesla ranked 1st on supply chain sustainability in the 2026 Lead the Charge auto/EV supply chain scorecard.

“@Tesla remains the top performing automaker of the Leaderboard for the second year running, and increased its overall score by 6 percentage points, while Ford only… pic.twitter.com/nAgGOIrGFS

— Sawyer Merritt (@SawyerMerritt) March 4, 2026

This independent ranking, produced by a coalition of environmental, human rights, and investor groups including the Sierra Club, Transport & Environment, and others, evaluates 18 major automakers on their efforts to build equitable, sustainable, and fossil-free supply chains for electric vehicles.

Tesla earned an overall score of 49 percent, up 6 percentage points from the previous year, widening its lead over second-place Ford (45 percent, up 2 points) to a commanding 4-percentage-point gap. The company also excelled in the Fossil Free & Environment category with a 50 percent score, reflecting strong progress in reducing emissions and decarbonizing operations.

Perhaps the most impressive achievement came in the batteries subsection, where Tesla posted a massive +20-point jump to reach 51 percent, becoming the first automaker ever to surpass 50 percent in this critical area.

Tesla achieved this milestone through transparency, fully disclosing Scope 3 emissions breakdowns for battery cell production and key materials like lithium, nickel, cobalt, and graphite.

The company also requires suppliers to conduct due diligence aligned with OECD guidelines on responsible sourcing, which it has mentioned in past Impact Reports.

While Tesla leads comfortably in climate and environmental performance, it scores 48 percent in human rights and responsible sourcing, slightly behind Ford’s 49 percent.

The company made notable gains in workers’ rights remedies, but has room to improve on issues like Indigenous Peoples’ rights.

Overall, the leaderboard highlights that a core group of leaders, Tesla, Ford, Volvo, Mercedes, and Volkswagen, are advancing twice as fast as their peers, proving that cleaner, more ethical EV supply chains are not just possible but already underway.

For Tesla detractors who claim EVs aren’t truly green or that the company cuts corners, this recognition from sustainability-focused NGOs delivers a powerful rebuttal.

Tesla’s vertical integration, direct supplier contracts, low-carbon material agreements (like its North American aluminum deal with emissions under 2kg CO₂e per kg), and raw materials reporting continue to set the industry standard.

As the world races toward electrification, Tesla isn’t just building cars; it’s building a more responsible future.