News

Tesla’s near-obsessive efforts to improve efficiency shown in new ventilated seat patent

It is no secret that Tesla’s electric vehicles are among the most efficient in the auto industry. This is shown in the gap between Tesla and its competitors when it comes to battery tech and just how far the company’s vehicles can last between charges.

The Model X, for example, is Tesla’s largest vehicle available today, yet it is far more efficient than competitors from veteran automakers such as the Audi e-tron and the Jaguar I-PACE, both of which are smaller and newer than the Silicon Valley-based company’s flagship crossover. Part of this is likely due to Tesla’s proprietary battery chemistry, as well as the design and components of its vehicles themselves.

Tesla optimizes its vehicles’ efficiency in several ways, from equipping its cars with software that optimizes the battery pack to using materials that simply consume less power. The less power is consumed by the car’s systems, after all, the more power there is that could be used to turn the wheels of the vehicle.

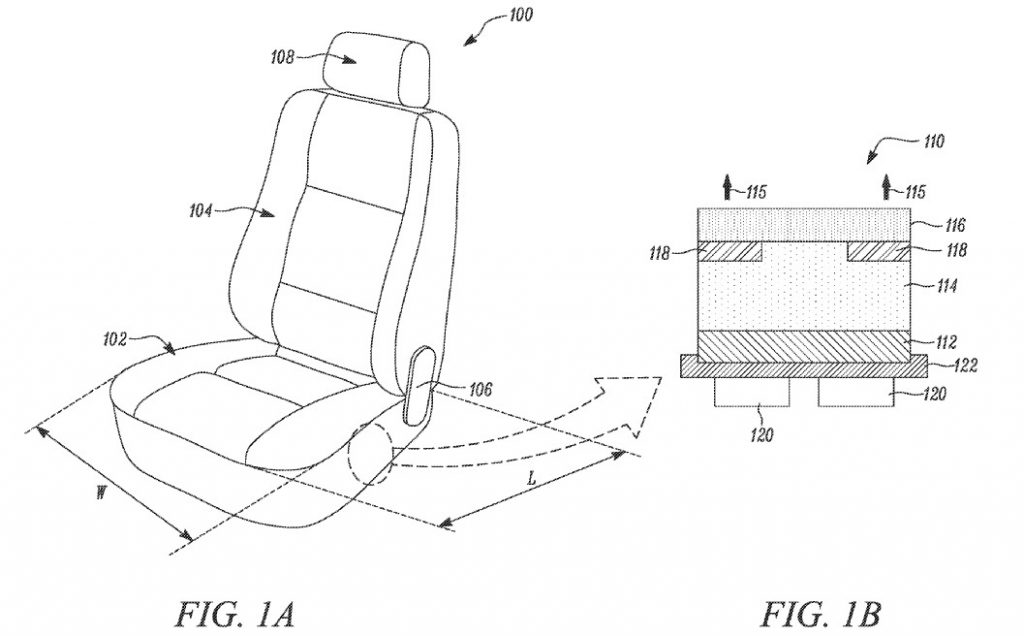

An example of this is described in a recently-published patent titled “Vehicle Seat with Integrated Temperature-Control System.” Tesla notes in its patent that heated seats could easily be very inefficient, as they require heat to travel through multiple layers of material.

“Attempts to provide air ventilation through the seat foam are typically insufficient to remove excess heat and provide a comfortable environment for the occupant. Further, conventional heating systems are bulky, occupy space in the seat which typically requires the seat to be thicker, and are inefficient in heating the seat as the heat typically must travel through multiple layers and heats regions of the seat that the occupant does not contact. Hence, there is a need for an improved temperature-control system for vehicle seats,” Tesla noted.

The electric car maker describes how its ventilated seat patent works as follows.

“The temperature-control system is associated with at least one of a seating portion and a backrest portion of the seat. The temperature control system includes a base layer. The temperature-control system includes an intermediate layer disposed adjacent to the base layer. The intermediate layer allows fluid to flow through it. The temperature-control system includes a cover layer disposed adjacent to the intermediate layer. The temperature-control system also includes at least one heating element disposed between the intermediate layer and the cover layer. The temperature-control system further includes a fluid pump to provide the flow of fluid through the intermediate layer,” the company wrote.

Tesla explains that the design outlined in its patent provides a low-cost, low-noise, power-efficient, and effective way of cooling or heating a vehicle’s seats. The company also explained that its patent could be incorporated in any seat, regardless of size and shape.

Tesla’s patent for its “Vehicle Seat with Integrated Temperature-Control System” could be accessed in full here.

Being a patent application, it is unknown if Tesla has or will utilize the design it described in the recently published document. Yet, regardless of this, it is difficult to not acknowledge the electric car maker’s constant efforts to improve its vehicles’ efficiency. In a way, the publication of this patent comes at a rather appropriate time for Tesla too, as the company is preparing to unveil its next vehicle, a pickup truck, later this year.

Pickup trucks are by tradition not the most efficient cars on the road, and even the Rivian R1T, a vehicle designed from the ground up to be all-electric, requires a massive 180 kWh battery pack to hit 400 miles of range. That’s a range that the Raven Tesla Model S is already approaching with its 100 kWh battery pack.

At this point in the EV race, it’s evident that the efficiency of Tesla’s electric cars is top-notch, and it will likely take a while before competitors can come close. Rivals will come for the company from several fronts, including veteran automakers and young, upstart manufacturers. But by being a moving target, it will likely be a very challenging task to catch up to Tesla. Very few companies out there could be just as dedicated and near-obsessive with improvement and innovation, after all.

News

Tesla ships out an update for everyone that California caused

“This change only updates the name of certain features and text in your vehicle,” the company wrote in Release Notes for the update, “and does not change the way your features behave.”

Tesla has shipped out an update for its vehicles that was caused specifically by a California lawsuit that threatened the company’s ability to sell cars because of how it named its driver assistance suite.

Tesla shipped out Software Update 2026.2.9 starting last week; we received it already, and it only brings a few minor changes, mostly related to how things are referenced.

“This change only updates the name of certain features and text in your vehicle,” the company wrote in Release Notes for the update, “and does not change the way your features behave.”

The following changes came to Tesla vehicles in the update:

- Navigate on Autopilot has now been renamed to Navigate on Autosteer

- FSD Computer has been renamed to AI Computer

Tesla faced a 30-day sales suspension in California after the state’s Department of Motor Vehicles stated the company had to come into compliance regarding the marketing of its automated driving features.

The agency confirmed on February 18 that it had taken a “corrective action” to resolve the issue. That corrective action was renaming certain parts of its ADAS.

Tesla discontinued its standalone Autopilot offering in January and ramped up the marketing of Full Self-Driving Supervised. Tesla had said on X that the issue with naming “was a ‘consumer protection’ order about the use of the term ‘Autopilot’ in a case where not one single customer came forward to say there’s a problem.”

This was a “consumer protection” order about the use of the term “Autopilot” in a case where not one single customer came forward to say there’s a problem.

Sales in California will continue uninterrupted.

— Tesla North America (@tesla_na) December 17, 2025

It is now compliant with the wishes of the California DMV, and we’re all dealing with it now.

This was the first primary dispute over the terminology of Full Self-Driving, but it has undergone some scrutiny at the federal level, as some government officials have claimed the suite has “deceptive” names. Previous Transportation Secretary Pete Buttigieg was one of those federal-level employees who had an issue with the names “Autopilot” and “Full Self-Driving.”

Tesla sued the California DMV over the ruling last week.

News

Tesla workers push back against Giga Berlin unionization

“IG Metall did not succeed in Giga Berlin‘s works council election earlier today. The union share was reduced from nearly 40% in 2024 to 31% in 2026! This is a clear message by the Giga Berlin team towards an independent co-determination! The list called Giga United, led by the current chairwoman, Michaela Schmitz, received the most votes with more than 40%! Good news for Giga Berlin!”

Tesla workers pushed back against unionization efforts at Gigafactory Berlin, and over the past few years, there has been a dramatic decrease in interest to unionize at the German plant.

Gigafactory Berlin Plant Manager André Thierig announced on Wednesday that IG Metall, the European union group, saw its share reduce from 40 to 31 percent in 2026 as employees eligible to vote on the issue. Instead, the Giga Berlin team, known as Giga United, received the most votes with more than 40 percent.

BREAKING! 🚨

IG Metall did not succeed in Giga Berlin‘s works council election earlier today. The union share was reduced from nearly 40% in 2024 to 31% in 2026!

This is a clear message by theGiga Berlin team towards an independent co-determination!

The list called Giga…

— André Thierig (@AndrThie) March 4, 2026

Thierig gave specific details in a post on X:

“IG Metall did not succeed in Giga Berlin‘s works council election earlier today. The union share was reduced from nearly 40% in 2024 to 31% in 2026! This is a clear message by the Giga Berlin team towards an independent co-determination! The list called Giga United, led by the current chairwoman, Michaela Schmitz, received the most votes with more than 40%! Good news for Giga Berlin!”

There were over 10,700 total employees who were eligible to vote, with 87 percent of them turning out to cast what they wanted. There were three key outcomes: Giga United, IG Metall, and other notable groups, with the most popular being the Polish Initiative.

The 37-seat council remains dominated by non-unionized representatives, preserving Giga Berlin as Germany’s only major auto plant without a collective bargaining agreement.

Thierig and Tesla framed the outcome as employee support for an “independent, flexible, and unbureaucratic” future, enabling acceleration on projects like potential expansions or new models. IG Metall expressed disappointment, accusing management of intimidation tactics and an “unfair” campaign.

The first election of this nature happened back in 2022. In 2024, IG Metall emerged as the largest single faction with 39.4 percent, but non-union lists coalesced for a majority.

But this year was different. There was some extra tension at Giga Berlin this year, as just two weeks ago, an IG Metall rep was accused by Tesla of secretly recording a council meeting. The group countersued for defamation.

Tesla Giga Berlin plant manager faces defamation probe after IG Metall union complaint

This result from the 2026 vote reinforced Tesla’s model of direct employee-management alignment over traditional German union structures, amid ongoing debates about working conditions. IG Metall views it as a setback but continues advocacy. Tesla sees it as validation of its approach in a competitive EV market.

This outcome may influence future labor dynamics at Giga Berlin, including any revival of expansion plans or product lines, which Musk has talked about recently.

News

SpaceX President Gwynne Shotwell details xAI power pledge at White House event

The commitment was announced during an event with United States President Donald Trump.

SpaceX President Gwynne Shotwell stated that xAI will develop 1.2 gigawatts of power at its Memphis-area AI supercomputer site as part of the White House’s new “Ratepayer Protection Pledge.”

The commitment was announced during an event with United States President Donald Trump.

During the White House event, Shotwell stated that xAI’s AI data center near Memphis would include a major energy installation designed to support the facility’s power needs.

“As you know, xAI builds huge supercomputers and data centers and we build them fast. Currently, we’re building one on the Tennessee-Mississippi state line. As part of today’s commitment, we will take extensive additional steps to continue to reduce the costs of electricity for our neighbors…

“xAI will therefore commit to develop 1.2 GW of power as our supercomputer’s primary power source. That will be for every additional data center as well. We will expand what is already the largest global Megapack power installation in the world,” Shotwell said.

She added that the system would provide significant backup power capacity.

“The installation will provide enough backup power to power the city of Memphis, and more than sufficient energy to power the town of Southaven, Mississippi where the data center resides. We will build new substations and invest in electrical infrastructure to provide stability to the area’s grid.”

Shotwell also noted that xAI will be supporting the area’s water supply as well.

“We haven’t talked about it yet, but this is actually quite important. We will build state-of-the-art water recycling plants that will protect approximately 4.7 billion gallons of water from the Memphis aquifer each year. And we will employ thousands of American workers from around the city of Memphis on both sides of the TN-MS border,” she noted.

The Ratepayer Protection Pledge was introduced as part of the federal government’s effort to address concerns about rising electricity costs tied to large AI data centers, as noted in an Insider report. Under the agreement, companies developing major AI infrastructure projects committed to covering their own power generation needs and avoiding additional costs for local ratepayers.