Energy

Tesla’s success in Australia opens up opportunity for 2nd big battery project in country

Following Tesla’s successful deployment of the world’s largest battery in South Australia, carrying out CEO Elon Musk’s 100-day target to install a grid-scale Powerpack battery unit, or the system would be free, another state in the land down under has lined up as Tesla Energy’s next customer. As noted in a recent report from the Sydney Morning Herald, Victoria has joined South Australia in its push towards a large-scale renewable energy system.

Tesla’s South Australia Powerpack facility currently stands as the largest lithium-ion battery of its kind on the planet. Powered by clean energy from Neoen’s Hornsdale Wind Farm near Jamestown, the mammoth 100 MW/129 MWh battery is capable of powering up to 30,000 homes during blackout periods.

According to the Australian Energy Market Operator (AEMO), the Powerpack system in SA has already proven itself multiple times since it was completed, providing ample backup power and other grid services hundreds of times in December 2017 alone. More notably, Tesla’s energy system recently supplied emergency power to one of Australia’s biggest coal-fired power stations after it experienced an unexpected loss of power on December 14.

The notable success of Tesla’s South Australia facility seems to be a significant driving force for the state of Victoria, which ultimately decided to pursue a contract with the California-based electric carmaker and energy firm to install its very own Powerpack system. Victoria’s batteries would be installed in Bulgana, though at 20 MW, the system would only be 1/5th the size of South Australia’s facility.

Franck Woitiez, managing director of Neoen, a French energy firm and Tesla’s partner in the SA Powerpack system, is optimistic about the potential of Victoria’s batteries. According to the Neoen executive, the Bulgana Powerpack system might even be enough to provide adequate support for the area’s power grids in the near future.

“The performance of the South Australian battery is outstanding. The Bulgana battery is primarily going to provide energy to Nectar Farms and may support the grid in the future,” he said, according to a SMH report.

Tesla’s 100 MW/129 MWh Powerpack system dubbed as the ‘World’s largest battery’ in Jamestown, Australia

Energy officials in Victoria are also equally excited about Tesla’s upcoming Powerpack system. According to energy minister Lily D’Ambrosio, the Elon Musk-led energy company’s forthcoming project would play a vital role in Victoria’s pursuit of renewable energy.

“(The agreement is) a major step forward for communities, businesses and the renewable energy industry. This project will reduce greenhouse gas emissions while helping meet Victoria’s renewable energy generation targets,” the energy minister said.

John Grimes, head of the Smart Energy Council, further stated that the clean energy initiatives of South Australia, and now Victoria, are but the beginning. Grimes also said that 2018 might very well be a pivotal year for renewable energy.

“What we’re seeing with the South Australian battery, what we’re seeing in Victoria, is really the tip of the iceberg for a pipeline of projects that’s coming along. This is a breakout year for energy storage.”

Tesla’s South Australian Powerpack system initially captured the public’s eye after Elon Musk and fellow billionaire Mike Cannon-Brookes, who co-founded Atlassian, conducted a friendly wager on Twitter. During the two billionaires’ Twitter exchange, Musk raised the stakes of the bet by declaring that Tesla would build a working Powerpack system for SA in 100 days or it would be free. Not long after, South Australia became home to Tesla’s largest lithium-ion battery system in the world.

Energy

Tesla Megapack Megafactory in Texas advances with major property sale

Stream Realty Partners announced the sale of Buildings 9 and 10 at the Empire West industrial park, which total 1,655,523 square feet.

Tesla’s planned Megapack factory in Brookshire, Texas has taken a significant step forward, as two massive industrial buildings fully leased to the company were sold to an institutional investor.

In a press release, Stream Realty Partners announced the sale of Buildings 9 and 10 at the Empire West industrial park, which total 1,655,523 square feet. The properties are 100% leased to Tesla under a long-term agreement and were acquired by BGO on behalf of an institutional investor.

The two facilities, located at 100 Empire Boulevard in Brookshire, Texas, will serve as Tesla’s new Megafactory dedicated to manufacturing Megapack battery systems.

According to local filings previously reported, Tesla plans to invest nearly $200 million into the site. The investment includes approximately $44 million in facility upgrades such as electrical, utility, and HVAC improvements, along with roughly $150 million in manufacturing equipment.

Building 9, spanning roughly 1 million square feet, will function as the primary manufacturing floor where Megapacks are assembled. Building 10, covering approximately 600,000 square feet, will be dedicated to warehousing and logistics operations, supporting storage and distribution of completed battery systems.

Waller County Commissioners have approved a 10-year tax abatement agreement with Tesla, offering up to a 60% property-tax reduction if the company meets hiring and investment targets. Tesla has committed to employing at least 375 people by the end of 2026, increasing to 1,500 by the end of 2028, as noted in an Austin County News Online report.

The Brookshire Megafactory will complement Tesla’s Lathrop Megafactory in California and expand U.S. production capacity for the utility-scale energy storage unit. Megapacks are designed to support grid stabilization and renewable-energy integration, a segment that has become one of Tesla’s fastest-growing businesses.

Energy

Tesla meets Giga New York’s Buffalo job target amid political pressures

Giga New York reported more than 3,460 statewide jobs at the end of 2025, meeting the benchmark tied to its dollar-a-year lease.

Tesla has surpassed its job commitments at Giga New York in Buffalo, easing pressure from lawmakers who threatened the company with fines, subsidy clawbacks, and dealership license revocations last year.

The company reported more than 3,460 statewide jobs at the end of 2025, meeting the benchmark tied to its dollar-a-year lease at the state-built facility.

As per an employment report reviewed by local media, Tesla employed 2,399 full-time workers at Gigafactory New York and 1,060 additional employees across the state at the end of 2025. Part-time roles pushed the total headcount of Tesla’s New York staff above the 3,460-job target.

The gains stemmed in part from a new Long Island service center, a Buffalo warehouse, and additional showrooms in White Plains and Staten Island. Tesla also said it has invested $350 million in supercomputing infrastructure at the site and has begun manufacturing solar panels.

Empire State Development CEO Hope Knight said the agency was “very happy” with Giga New York’s progress, as noted in a WXXI report. The current lease runs through 2029, and negotiations over updated terms have included potential adjustments to job requirements and future rent payments.

Some lawmakers remain skeptical, however. Assemblymember Pat Burke questioned whether the reported job figures have been fully verified. State Sen. Patricia Fahy has also continued to sponsor legislation that would revoke Tesla’s company-owned dealership licenses in New York. John Kaehny of Reinvent Albany has argued that the project has not delivered the manufacturing impact originally promised as well.

Knight, for her part, maintained that Empire State Development has been making the best of a difficult situation.

“(Empire State Development) has tried to make the best of a very difficult situation. There hasn’t been another use that has come forward that would replace this one, and so to the extent that we’re in this place, the fact that 2,000 families at (Giga New York) are being supported through the activity of this employer. It’s the best that we can have happen,” the CEO noted.

Energy

Tesla launches Cybertruck vehicle-to-grid program in Texas

The initiative was announced by the official Tesla Energy account on social media platform X.

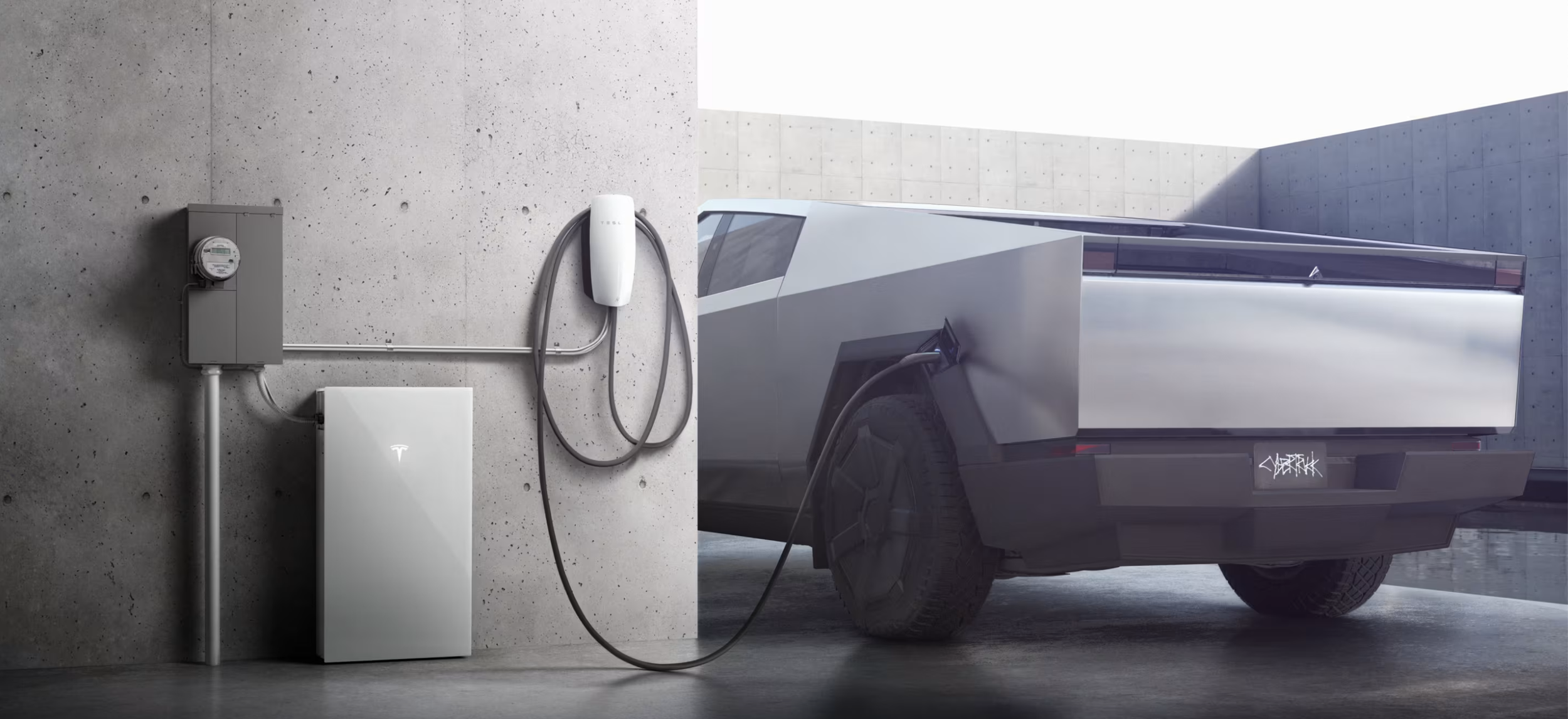

Tesla has launched a vehicle-to-grid (V2G) program in Texas, allowing eligible Cybertruck owners to send energy back to the grid during high-demand events and receive compensation on their utility bills.

The initiative, dubbed Powershare Grid Support, was announced by the official Tesla Energy account on social media platform X.

Texas’ Cybertruck V2G program

In its post on X, Tesla Energy confirmed that vehicle-to-grid functionality is “coming soon,” starting with select Texas markets. Under the new Powershare Grid Support program, owners of the Cybertruck equipped with Powershare home backup hardware can opt in through the Tesla app and participate in short-notice grid stress events.

During these events, the Cybertruck automatically discharges excess energy back to the grid, supporting local utilities such as CenterPoint Energy and Oncor. In return, participants receive compensation in the form of bill credits. Tesla noted that the program is currently invitation-only as part of an early adopter rollout.

The launch builds on the Cybertruck’s existing Powershare capability, which allows the vehicle to provide up to 11.5 kW of power for home backup. Tesla added that the program is expected to expand to California next, with eligibility tied to utilities such as PG&E, SCE, and SDG&E.

Powershare Grid Support

To participate in Texas, Cybertruck owners must live in areas served by CenterPoint Energy or Oncor, have Powershare equipment installed, enroll in the Tesla Electric Drive plan, and opt in through the Tesla app. Once enrolled, vehicles would be able to contribute power during high-demand events, helping stabilize the grid.

Tesla noted that events may occur with little notice, so participants are encouraged to keep their Cybertrucks plugged in when at home and to manage their discharge limits based on personal needs. Compensation varies depending on the electricity plan, similar to how Powerwall owners in some regions have earned substantial credits by participating in Virtual Power Plant (VPP) programs.