News

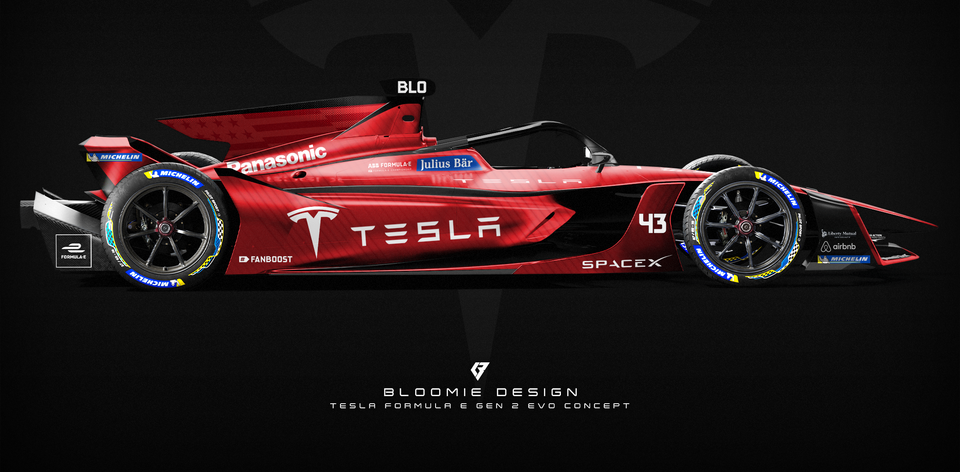

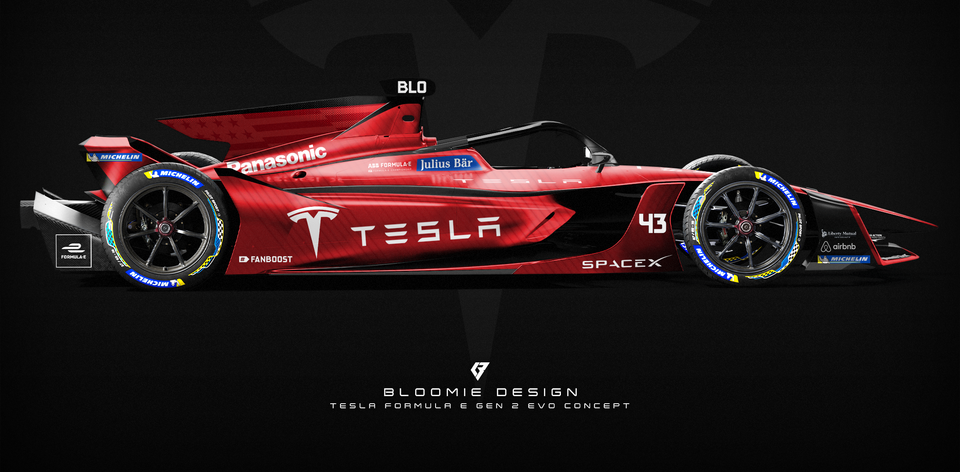

Tesla is primed for Formula E while its rivals are working in reverse

Tesla and Formula E: Will it ever happen? Probably not. At least, that’s what Elon Musk says, and he believes that production and scalability are more important. For the global EV scene, they certainly are, while professional motorsports are really just a trivial part of what Tesla does. While the company does build and create some of the fastest and highest-performing cars on Earth, it has no intentions of bringing them to a track or becoming a car company dedicated to winning shiny trophies. However, this didn’t stop other car companies from adopting different strategies.

Some companies, like BMW and Audi, for example, did their work in reverse. Years ago, when the Formula E Series became a real thing, these two companies were among the first to build a single-seat, all-electric powertrain that was extremely similar to the blazing fast F1 circuit. The only difference was that these new, sustainable racecars weren’t blaring loud motors for everyone to hear.

Instead of developing mass-market vehicles that would benefit the company in a multitude of ways, these automakers chose to work in reverse. Not focusing on building a reliable EV software infrastructure or production facilities to manufacture them in, German car companies went to their roots and focused o a few fast cars that would compete on the weekends at some of the toughest circuits in the world. But the problem is, they could have killed two birds with one stone by doing things in the correct order, which brings me to my next point: Tesla is already primed for Formula E, and it never had any intentions of competing.

A recent article from Bloomberg shows that BMW has decided to officially scrap its Formula E team at the end of this season, shifting its focus from racing and toward an intensifying EV market. The money it will save from not focusing on turning out fast laps at world-famous circuits will now be dedicated to developing EVs for consumers.

In the time that BMW has been racing in Formula E, it has only released one car: the i3, a boxy, widely unpopular car aesthetically. With plans to launch the iX, which it unveiled just last month, there are plenty of opportunities to establish a competitive lineup of all-electric cars in the future. But the focus has been all wrong from the start.

BMW didn’t have an overwhelmingly successful time in Formula E. Since it started racing in the series, which held its first race seasons ago, it has won only four races. But the company stated that it has “exhausted the opportunities to transfer Formula E’s pioneering racing technologies into passenger models.”

This is where the order of development may have been more advantageous for BMW. Now that their Formula E run is over, they have nothing to base passenger models off of, which pretty much puts them at square 1 if you take into account the i3 is not a widely popular or successful EV, to begin with.

This is where Tesla gains a real advantage in a hypothetical scenario where it would build cars for a racing series. Tesla has passenger vehicles now that could compete in several racing series, and other cars that actually have competed in racing forums like the Pikes Peak Hill Climb.

A big thanks to our long-time supporters and new subscribers! Thank you.

I use this newsletter to share my thoughts on what is going on in the Tesla world. If you want to talk to me directly, you can email me or reach me on Twitter. I don’t bite, be sure to reach out!

For example, the Roadster is 0-60 in 1.9 seconds, has a quarter-mile acceleration of 8.8 seconds, and seats four people. The powertrain is already powerful enough to compete in some racing circuits, but if Tesla were to refine it slightly and build a new, more reliable chassis that would benefit racing scenarios, there is no reason that the Next-Gen Roadster wouldn’t be extremely competitive in some racing series.

The Model S Plaid is another example. It has broken multiple records, including one at the Nürburgring in Germany (which is unconfirmed) and the Laguna Seca Raceway in California. It already has the handling, speed, and downforce to take on tough tracks that are windy and difficult to maneuver. It would just take some minor refinements to make it a “racecar.”

This is where Tesla gains a significant advantage in its structure. It is irrelevant whether the company will actually race some of its cars or not, but it would be ready today if it chose to. Meanwhile, other car companies decided to build racecars first, and after seven years of R&D, they have nothing that would contribute to a highly-effective passenger car. It is like baking a cake before putting any of the ingredients together.

It doesn’t bode well for these foreign automakers, either. Unfortunately for them, Tesla is pulling away. Every day, it seems like the company is improving in range or performance or battery tech that makes its lead in the EV sector a little bit bigger than before. Now, it has four passenger cars on the road: Two sedans, a crossover, and an SUV. It has a Supercar on the way, a truck coming in the next year, a Semi that will be launched shortly. The list goes on and on, it seems, and if Tesla wanted to race a car this weekend and be competitive, it could.

It almost sounds like the priorities of these highly-complex German car companies were simply out of line. They chose to do the fun stuff first instead of focusing on the real task at hand: Getting gas cars off the road and putting electric ones on it. Instead of worrying about the issues surrounding the manufacturing processes of EVs, which took Tesla several years to figure out (and it is still a work in progress), BMW will be forced to make a full-scale commitment if it wants to be competitive within the next ten years. The decision it made could be detrimental to the future development of the company’s EV fleet. It certainly has its work cut out for it.

And if you’re wondering, Musk said Tesla would not get into racing. The big picture deals with manufacturing and scalability, and racing is really the last of the CEO’s concerns.

On behalf of the entire Teslarati team, we’re working hard behind the scenes on bringing you more personalized members benefits, and can’t thank you enough for your continued support!

News

Tesla begins Robotaxi certification push in Arizona: report

Tesla seems serious about expanding its Robotaxi service to several states in the coming months.

Tesla has initiated discussions with Arizona transportation regulators to certify its driverless Robotaxi service in the state, as per a recent report from Bloomberg News. The move follows Tesla’s launch of its Robotaxi pilot program in Austin, Texas, as well as CEO Elon Musk’s recent comments about the service’s expansion in the Bay Area.

The Arizona Department of Transportation confirmed to Bloomberg that Tesla has reached out to begin the certification process for autonomous ride-sharing operations in the state. While details remain limited, the outreach suggests that Tesla is serious about expanding its driverless Robotaxi service to several territories in the coming months.

The Arizona development comes as Tesla prepares to expand its service area in Austin this weekend, as per CEO Elon Musk in a post on X. Musk also stated that Tesla is targeting the San Francisco Bay Area as its next major market, with a potential launch “in a month or two,” pending regulatory approvals.

Tesla first launched its autonomous ride-hailing program on June 22 in Austin with a small fleet of Model Y vehicles, accompanied by a Tesla employee in the passenger seat to monitor safety. While still classified as a test, Musk has said the program will expand to about 1,000 vehicles in the coming months. Tesla will later upgrade its Robotaxi fleet with the Cyercab, a two-seater that is designed without a steering wheel.

Sightings of Cybercab castings around the Giga Texas complex suggests that Tesla may be ramping the initial trial production of the self-driving two-seater. Tesla, for its part, has noted in the past that volume production of the Cybercab is expected to start sometime next year.

In California, Tesla has already applied for a transportation charter-party carrier permit from the state’s Public Utilities Commission. The company is reportedly taking a phased approach to operating in California, with the Robotaxi service starting with pre-arranged rides for employees in vehicles with safety drivers.

News

Tesla sets November 6 date for 2025 Annual Shareholder Meeting

The automaker announced the date on Thursday in a Form 8-K.

Tesla has scheduled its 2025 annual shareholder meeting for November 6, addressing investor concerns that the company was nearing a legal deadline to hold the event.

The automaker announced the date on Thursday in a Form 8-K submitted to the United States Securities and Exchange Commission (SEC). The company also listed a new proposal submission deadline of July 31 for items to be included in the proxy statement.

Tesla’s announcement followed calls from a group of 27 shareholders, including the leaders of large public pension funds, which urged Tesla’s board to formally set the meeting date, as noted in a report from The Wall Street Journal.

The group noted that under Texas law, where Tesla is now incorporated, companies must hold annual meetings within 13 months of the last one if requested by shareholders. Tesla’s previous annual shareholder meeting was held on June 13, 2024, which placed the July 13 deadline in focus.

Tesla originally stated in its 2024 annual report that it would file its proxy statement by the end of April. However, an amended filing on April 30 indicated that the Board of Directors had not yet finalized a meeting date, at least at the time.

The April filing also confirmed that Tesla’s board had formed a special committee to evaluate certain matters related to CEO Elon Musk’s compensation plan. Musk’s CEO performance award remains at the center of a lengthy legal dispute in Delaware, Tesla’s former state of incorporation.

Due to the aftermath of Musk’s legal dispute about his compensation plan in Delaware, he has not been paid for his work at Tesla for several years. Musk, for his part, has noted that he is more concerned about his voting stake in Tesla than his actual salary.

At last year’s annual meeting, TSLA shareholders voted to reapprove Elon Musk’s compensation plan and ratified Tesla’s decision to relocate its legal domicile from Delaware to Texas.

Elon Musk

Grok coming to Tesla vehicles next week “at the latest:” Elon Musk

Grok’s rollout to Tesla vehicles is expected to begin next week at the latest.

Elon Musk announced on Thursday that Grok, the large language model developed by his startup xAI, will soon be available in Tesla vehicles. Grok’s rollout to Tesla vehicles is expected to begin next week at the latest, further deepening the ties between the two Elon Musk-led companies.

Tesla–xAI synergy

Musk confirmed the news on X shortly after livestreaming the release of Grok 4, xAI’s latest large language model. “Grok is coming to Tesla vehicles very soon. Next week at the latest,” Musk wrote in a post on social media platform X.

During the livestream, Musk and several members of the xAI team highlighted several upgrades to Grok 4’s voice capabilities and performance metrics, positioning the LLM as competitive with top-tier models from OpenAI and Google.

The in-vehicle integration of Grok marks a new chapter in Tesla’s AI development. While Tesla has long relied on in-house systems for autonomous driving and energy optimization, Grok’s integration would introduce conversational AI directly into its vehicles’ user experience. This integration could potentially improve customer interaction inside Tesla vehicles.

xAI and Tesla’s collaborative footprint

Grok’s upcoming rollout to Tesla vehicles adds to a growing business relationship between Tesla and xAI. Earlier this year, Tesla disclosed that it generated $198.3 million in revenue from commercial, consulting, and support agreements with xAI, as noted in a report from Bloomberg News. A large portion of that amount, however, came from the sale of Megapack energy storage systems to the artificial intelligence startup.

In July 2023, Musk polled X users about whether Tesla should invest $5 billion in xAI. While no formal investment has been made so far, 68% of poll participants voted yes, and Musk has since stated that the idea would be discussed with Tesla’s board.

-

Elon Musk1 week ago

Elon Musk1 week agoTesla investors will be shocked by Jim Cramer’s latest assessment

-

Elon Musk3 days ago

Elon Musk3 days agoElon Musk confirms Grok 4 launch on July 9 with livestream event

-

Elon Musk17 hours ago

Elon Musk17 hours agoxAI launches Grok 4 with new $300/month SuperGrok Heavy subscription

-

News7 days ago

News7 days agoTesla Model 3 ranks as the safest new car in Europe for 2025, per Euro NCAP tests

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoA Tesla just delivered itself to a customer autonomously, Elon Musk confirms

-

Elon Musk1 week ago

Elon Musk1 week agoxAI’s Memphis data center receives air permit despite community criticism

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla’s Omead Afshar, known as Elon Musk’s right-hand man, leaves company: reports

-

News2 weeks ago

News2 weeks agoXiaomi CEO congratulates Tesla on first FSD delivery: “We have to continue learning!”