Energy

Tesla Solar Roof tile design and installation showcased in first responders video

With Tesla ramping the production of its residential battery and solar products, Solar Roof installations are bound to become more commonplace. Being a new type of PV system, Tesla’s solar shingles could provide challenges to emergency personnel and first responders who are not trained to handle the glass tiles. The California Department of Forestry and Fire Protection, better known as CAL Fire, recently released a video demonstrating techniques on how to best respond to a home fitted with a Tesla Solar Roof installation.

CAL Fire veteran Brock Archer noted that the construction of the Tesla Solar Roof is actually pretty simple, with the photovoltaic cells being mounted on top of a firestone clad guard, which is a thin moisture barrier. The wiring for the tiles themselves is hidden underneath the shingles. Archer further stated that each Solar Roof tile represents itself as three shingles on the roof. As per Tesla’s design, one to four of these tiles can be wired together to create branches, which are then wired to a diode trunk harness. The diode trunk harness carries the electricity from all the panels through the roof itself.

Archer further noted that while the diode trunk harness operates at a high voltage, testing on the Solar Roof system indicates that there is almost zero risk of shock or electrocution when cutting or crushing the tiles. There is also almost no risk of electric shock when cutting through the diode trunk harness. A rapid shutdown device that’s installed close to the solar arrays, terminates DC power in the roof when AC power is interrupted.

- A Tesla Solar Roof installation. [Credit: E for Electric/YouTube]

- A Solar Roof tile installation on a residential unit. [Credit: Amanda Tobler]

While Tesla’s glass solar roof tiles are designed to be nearly indestructible, conducting emergency extrication maneuvers through the photovoltaic system could prove tricky. Fellow CAL Fire veteran Nick Papa noted that the Solar Roofs are very slippery, and are best treated like metal and slate roofs. Thus, for firefighters and other emergency personnel, using a ladder to gain access to a Solar Roof-equipped house is necessary. The fire veteran also noted that the tools such as fire axes and chainsaws work well with the Solar Roofs, as the shingles could be removed quickly without any problems.

The recently released emergency response training video for Solar Roof installations ultimately showcases the clever design of Tesla’s next-generation PV system. When Elon Musk unveiled the Solar Roof tiles back in 2016, Musk highlighted the shingles’ aesthetics and durability. If this recent video is any indication, it seems like the Solar Roof tiles are also designed with safety in mind.

In a recent statement, Tesla CTO JB Straubel noted that the company is aggressively ramping the production of its residential solar and battery products. Despite increasing competition from other residential solar companies in the United States, Straubel stated that Tesla is in no way stepping back from the residential solar industry. The Tesla CTO also noted that production of Powerwall 2 home batteries is set to ramp later this year. Solar Roof tile production is also expected to hit its full stride in 2019.

Watch emergency response techniques for the Tesla Solar Roof in the video below.

To learn more about how you can eliminate your energy bill through solar, we’ve partnered with the team at UnderstandSolar, an affiliate of ours that aims to customize the perfect solar system for you based on your location and property size.

Energy

Tesla launches Cybertruck vehicle-to-grid program in Texas

The initiative was announced by the official Tesla Energy account on social media platform X.

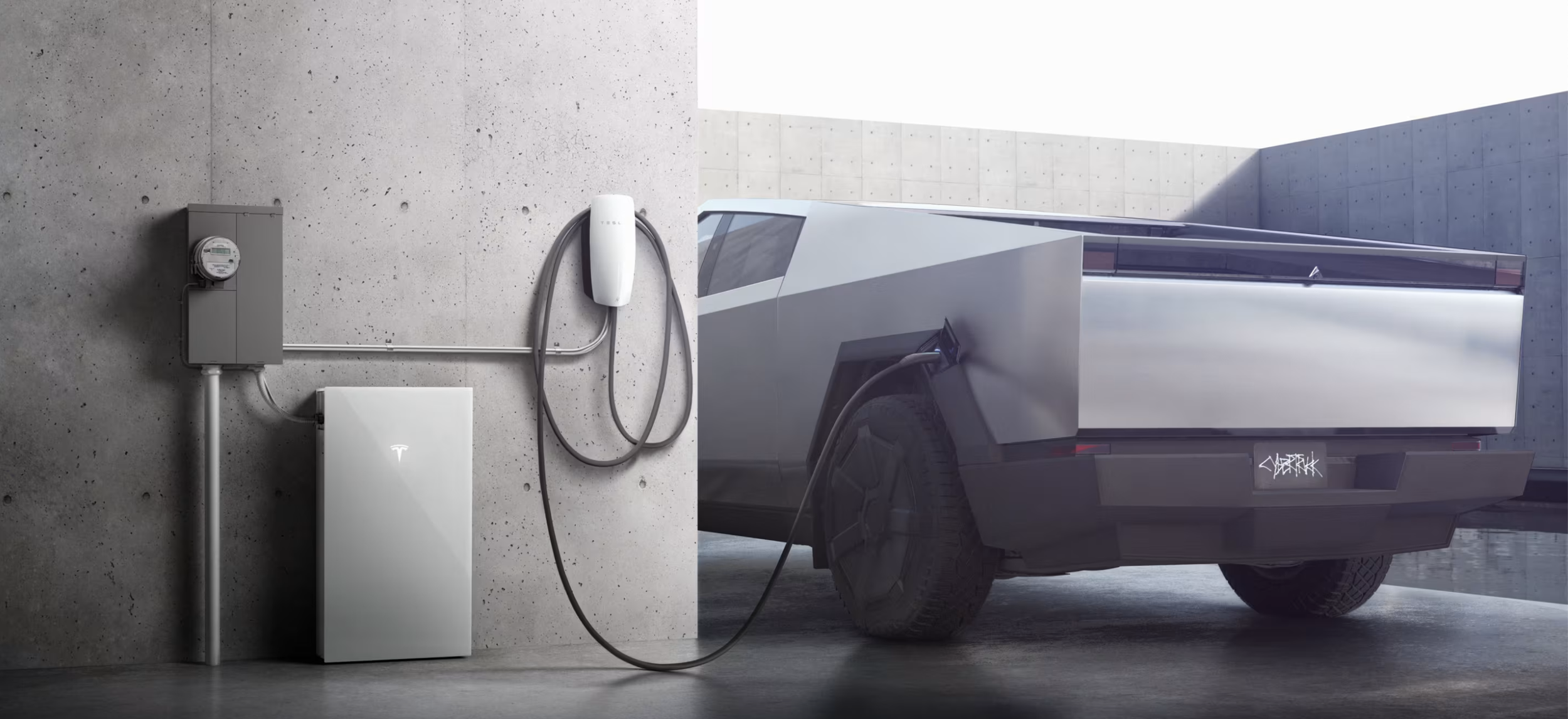

Tesla has launched a vehicle-to-grid (V2G) program in Texas, allowing eligible Cybertruck owners to send energy back to the grid during high-demand events and receive compensation on their utility bills.

The initiative, dubbed Powershare Grid Support, was announced by the official Tesla Energy account on social media platform X.

Texas’ Cybertruck V2G program

In its post on X, Tesla Energy confirmed that vehicle-to-grid functionality is “coming soon,” starting with select Texas markets. Under the new Powershare Grid Support program, owners of the Cybertruck equipped with Powershare home backup hardware can opt in through the Tesla app and participate in short-notice grid stress events.

During these events, the Cybertruck automatically discharges excess energy back to the grid, supporting local utilities such as CenterPoint Energy and Oncor. In return, participants receive compensation in the form of bill credits. Tesla noted that the program is currently invitation-only as part of an early adopter rollout.

The launch builds on the Cybertruck’s existing Powershare capability, which allows the vehicle to provide up to 11.5 kW of power for home backup. Tesla added that the program is expected to expand to California next, with eligibility tied to utilities such as PG&E, SCE, and SDG&E.

Powershare Grid Support

To participate in Texas, Cybertruck owners must live in areas served by CenterPoint Energy or Oncor, have Powershare equipment installed, enroll in the Tesla Electric Drive plan, and opt in through the Tesla app. Once enrolled, vehicles would be able to contribute power during high-demand events, helping stabilize the grid.

Tesla noted that events may occur with little notice, so participants are encouraged to keep their Cybertrucks plugged in when at home and to manage their discharge limits based on personal needs. Compensation varies depending on the electricity plan, similar to how Powerwall owners in some regions have earned substantial credits by participating in Virtual Power Plant (VPP) programs.

Cybertruck

Tesla updates Cybertruck owners about key Powershare feature

Tesla is updating Cybertruck owners on its timeline of a massive feature that has yet to ship: Powershare with Powerwall.

Powershare is a bidirectional charging feature exclusive to Cybertruck, which allows the vehicle’s battery to act as a portable power source for homes, appliances, tools, other EVs, and more. It was announced in late 2023 as part of Tesla’s push into vehicle-to-everything energy sharing, and acting as a giant portable charger is the main advantage, as it can provide backup power during outages.

Cybertruck’s Powershare system supports both vehicle-to-load (V2L) and vehicle-to-home (V2H), making it flexible and well-rounded for a variety of applications.

However, even though the feature was promised with Cybertruck, it has yet to be shipped to vehicles. Tesla communicated with owners through email recently regarding Powershare with Powerwall, which essentially has the pickup act as an extended battery.

Powerwall discharge would be prioritized before tapping into the truck’s larger pack.

However, Tesla is still working on getting the feature out to owners, an email said:

“We’re writing to let you know that the Powershare with Powerwall feature is still in development and is now scheduled for release in mid-2026.

This new release date gives us additional time to design and test this feature, ensuring its ability to communicate and optimize energy sharing between your vehicle and many configurations and generations of Powerwall. We are also using this time to develop additional Powershare features that will help us continue to accelerate the world’s transition to sustainable energy.”

Owners have expressed some real disappointment in Tesla’s continuous delays in releasing the feature, as it was expected to be released by late 2024, but now has been pushed back several times to mid-2026, according to the email.

Foundation Series Cybertruck buyers paid extra, expecting the feature to be rolled out with their vehicle upon pickup.

Cybertruck’s Lead Engineer, Wes Morrill, even commented on the holdup:

As a Cybertruck owner who also has Powerwall, I empathize with the disappointed comments.

To their credit, the team has delivered powershare functionality to Cybertruck customers who otherwise have no backup with development of the powershare gateway. As well as those with solar…

— Wes (@wmorrill3) December 12, 2025

He said that “it turned out to be much harder than anticipated to make powershare work seamlessly with existing Powerwalls through existing wall connectors. Two grid-forming devices need to negotiate who will form and who will follow, depending on the state of charge of each, and they need to do this without a network and through multiple generations of hardware, and test and validate this process through rigorous certifications to ensure grid safety.”

It’s nice to see the transparency, but it is justified for some Cybertruck owners to feel like they’ve been bait-and-switched.

Energy

Tesla starts hiring efforts for Texas Megafactory

Tesla’s Brookshire site is expected to produce 10,000 Megapacks annually, equal to 40 gigawatt hours of energy storage.

Tesla has officially begun hiring for its new $200 million Megafactory in Brookshire, Texas, a manufacturing hub expected to employ 1,500 people by 2028. The facility, which will build Tesla’s grid-scale Megapack batteries, is part of the company’s growing energy storage footprint.

Tesla’s hiring efforts for the Texas Megafactory are hinted at by the job openings currently active on the company’s Careers website.

Tesla’s Texas Megafactory

Tesla’s Brookshire site is expected to produce 10,000 Megapacks annually, equal to 40 gigawatt hours of energy storage, similar to the Lathrop Megafactory in California. Tesla’s Careers website currently lists over 30 job openings for the site, from engineers, welders, and project managers. Each of the openings is listed for Brookshire, Texas.

The company has leased two buildings in Empire West Business Park, with over $194 million in combined property and equipment investment. Tesla’s agreement with Waller County includes a 60% property tax abatement, contingent on meeting employment benchmarks: 375 jobs by 2026, 750 by 2027, and 1,500 by 2028, as noted in a report from the Houston Business Journal. Tesla is required to employ at least 1,500 workers in the facility through the rest of the 10-year abatement period.

Tesla’s clean energy boom

City officials have stated that Tesla’s arrival marks a turning point for the Texas city, as it highlights a shift from logistics to advanced clean energy manufacturing. Ramiro Bautista from Brookshire’s economic development office, highlighted this in a comment to the Journal.

“(Tesla) has great-paying jobs. Not just that, but the advanced manufacturing (and) clean energy is coming to the area,” he said. “So it’s not just your normal logistics manufacturing. This is advanced manufacturing coming to this area, and this brings a different type of job and investment into the local economy.”