News

SpaceX fairing recovery ships return to port with Falcon 9 nosecone and battle scars

Four days after they headed out into the Atlantic Ocean, twin SpaceX fairing recovery ships Ms. Tree and Ms. Chief have returned to port with both halves of a Falcon 9 fairing, although they appear to have picked up some battle scars along the way.

Ms. Tree and its near-identical sibling Ms. Chief departed Port Canaveral on December 14th and arrived on station – 790 km (490 mi) off the coast of Florida – some 36 hours later. Each outfitted with a quartet of arms and pair of nets, it was the first time both ships successfully made it out into the Atlantic for a simultaneous fairing catch attempt, having been foiled by high seas during a prior November outing.

For unknown reasons, after the duo’s November false start, both ships stopped for almost two weeks at a South Carolina port, perhaps indicating that SpaceX was concerned about the structural integrity of the ships’ seemingly fragile net mechanism. In February 2019, Mr. Steven (now Ms. Tree) lost two of its four arms while heading downrange for an attempted catch, apparently broken off by pitching caused by high seas. Further strengthening the case that their net mechanisms are rather fragile, both Ms. Tree and Ms. Chief again suffered damage after their Kacific-1/JCSAT-18 Falcon 9 fairing recovery attempt.

Both ships arrived back at Port Canaveral on December 18th and were caught by Teslarati photographer Richard Angle while passing through the narrow mouth of the port. GO Ms. Chief took the lead, revealing a Falcon 9 fairing half snugly secured with a tarp on her deck – the ship’s very first launch vehicle hardware recovery.

First (partially) successful fairing recovery quite literally under wraps, Ms. Chief nevertheless did not make it through the rite of passage unscathed. Oddly, it appears that just one of the ship’s eight white arm supports is missing (the rear right or aft starboard arm), visibly resulting in the arm slouching a bit compared to its siblings. Intriguingly, it appears that the arm is partially stretching – and thus potentially resting on – Ms. Chief’s net and rigging.

The fact that only one of the arm’s two beams (of eight total) seems to have failed is more immediately indicative of possible human error during installation or a defective attachment mechanism, although it’s entirely possible that a fluke of weather could have damaged just the one beam.

Thankfully, Ms. Tree (formerly Mr. Steven) appears to have made it through the recovery mission with all four arms fully intact, although the ship clearly struggled with a separate mechanism. Notably, Ms. Tree seems to have struggled to use its secondary net to lift its fairing half out of the sea and onto her deck, with that smaller net clearly suffering a multitude of rips and tears at some point during the process. Her recovered fairing half is somewhat awkwardly strewn on the deck with no obvious attempt to rectify the issue, indicating that the net may have torn mid-lift, causing the fairing to fall maybe 5-10 feet.

If it did actually fall onto Ms. Tree’s deck, that will almost certainly be visible in the form of damage to its aluminum-composite honeycomb structure and white insulation coating.

Ultimately, fairing recovery continues to prove itself to be a major challenge, although SpaceX obviously has no intention of giving up. With two successful catches already in hand, it’s clear that fairing recovery is undeniably possible and is more a matter of tweaking existing systems than starting from scratch. Much like Falcon 9 booster recovery had and its fair share of failed landings even after the first success, it will likely take quite a while for SpaceX to optimize fairing recovery to the point that it can be considered reliable.

For now, routine fairing recovery and reuse will likely continue to be Falcon 9’s white whale, at worst adding to the excitement of every SpaceX satellite launch.

Check out Teslarati’s Marketplace! We offer Tesla accessories, including for the Tesla Cybertruck and Tesla Model 3.

Investor's Corner

Tesla delivers 384,000 vehicles in Q2 2025, deploys 9.6 GWh in energy storage

The quarter’s 9.6 GWh energy storage deployment marks one of Tesla’s highest to date.

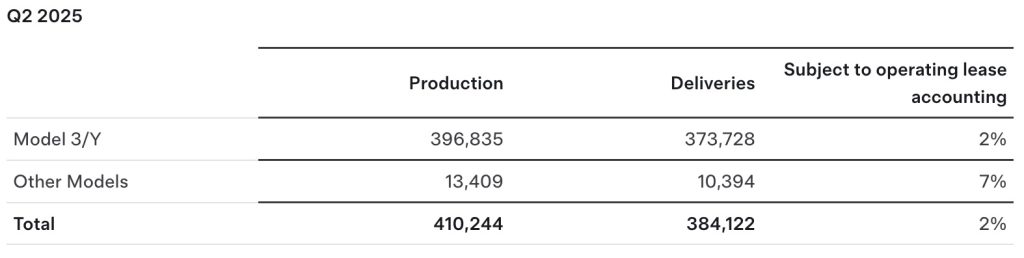

Tesla (NASDAQ: TSLA) has released its Q2 2025 vehicle delivery and production report. As per the report, the company delivered over 384,000 vehicles in the second quarter of 2025, while deploying 9.6 GWh in energy storage. Vehicle production also reached 410,244 units for the quarter.

Model 3/Y dominates output, ahead of earnings call

Of the 410,244 vehicles produced during the quarter, 396,835 were Model 3 and Model Y units, while 13,409 were attributed to Tesla’s other models, which includes the Cybertruck and Model S/X variants. Deliveries followed a similar pattern, with 373,728 Model 3/Ys delivered and 10,394 from other models, totaling 384,122.

The quarter’s 9.6 GWh energy storage deployment marks one of Tesla’s highest to date, signaling continued strength in the Megapack and Powerwall segments.

Year-on-year deliveries edge down, but energy shows resilience

Tesla will share its full Q2 2025 earnings results after the market closes on Wednesday, July 23, 2025, with a live earnings call scheduled for 4:30 p.m. CT / 5:30 p.m. ET. The company will publish its quarterly update at ir.tesla.com, followed by a Q&A webcast featuring company leadership. Executives such as CEO Elon Musk are expected to be in attendance.

Tesla investors are expected to inquire about several of the company’s ongoing projects in the upcoming Q2 2025 earnings call. Expected topics include the new Model Y ramp across the United States, China, and Germany, as well as the ramp of FSD in territories outside the US and China. Questions about the company’s Robotaxi business, as well as the long-referenced but yet to be announced affordable models are also expected.

News

Tesla China breaks 8-month slump by selling 71,599 vehicles wholesale in June

Tesla China’s June numbers were released by the China Passenger Car Association (CPCA) on Tuesday.

Tesla China was able to sell 71,599 vehicles wholesale in June 2025, reversing eight consecutive months of year-over-year declines. The figure marks a 0.83% increase from the 71,599 vehicles sold wholesale in June 2024 and a 16.1% jump compared to the 61,662 vehicles sold wholesale in May.

Tesla China’s June numbers were released by the China Passenger Car Association (CPCA) on Tuesday.

Tesla China’s June results in focus

Tesla produces both the Model 3 and Model Y at its Shanghai Gigafactory, which serves as the company’s primary vehicle export hub. Earlier this year, Tesla initiated a changeover for its best-selling vehicle, the Model Y, resulting in a drop in vehicle sales during the first and second quarters.

Tesla’s second-quarter China sales totaled 191,720 units including exports. While these numbers represent a 6.8% year-over-year decline for Tesla China, Q2 did show sequential improvement, rising about 11% from Q1 2025, as noted in a CNEV Post report.

For the first half of the year, Tesla sold 364,474 vehicles wholesale. This represents a 14.6% drop compared to the 426,623 units sold wholesale in the first half of 2024.

China’s competitive local EV market

Tesla’s position in China is notable, especially as the new Model Y is gaining ground in the country’s BEV segment. That being said, Tesla is also facing competition from impressive local brands such as Xiaomi, whose new YU7 electric SUV is larger and more affordable than the Model Y.

The momentum of the YU7 is impressive, as the vehicle was able to secure 200,000 firm orders within three minutes and over 240,000 locked-in orders within 18 hours. Xiaomi’s previous model, the SU7 electric sedan, which is aimed at the Tesla Model 3, also remains popular, with June deliveries surpassing 25,000 units for the ninth straight month.

While China’s EV market is getting more competitive, Tesla’s new Model Y is also ramping its production and deliveries. Needless to say, Tesla China’s results for the remaining two quarters of 2025 will be very interesting.

Elon Musk

Tesla reveals it is using AI to make factories more sustainable: here’s how

Tesla is using AI in its Gigafactory Nevada factory to improve HVAC efficiency.

Tesla has revealed in its Extended Impact Report for 2024 that it is using Artificial Intelligence (AI) to enable its factories to be more sustainable. One example it used was its achievement of managing “the majority of the HVAC infrastructure at Gigafactory Nevada is now AI-controlled” last year.

In a commitment to becoming more efficient and making its production as eco-friendly as possible, Tesla has been working for years to find solutions to reduce energy consumption in its factories.

For example, in 2023, Tesla implemented optimization controls in the plastics and paint shops located at Gigafactory Texas, which increased the efficiency of natural gas consumption. Tesla plans to phase out natural gas use across its factories eventually, but for now, it prioritizes work to reduce emissions from that energy source specifically.

It also uses Hygrometric Control Logic for Air Handling Units at Giafactory Berlin, resulting in 17,000 MWh in energy savings each year. At Gigafactory Nevada, Tesla saves 9.5 GWh of energy through the use of N-Methylpyrrolidone refineries when extracting critical raw material.

Perhaps the most interesting way Tesla is conserving energy is through the use of AI at Gigafactory Nevada, as it describes its use of AI to reduce energy demand:

“In 2023, AI Control for HVAC was expanded from Nevada and Texas to now include our Berlin-Brandenburg and Fremont factories. AI Control policy enables HVAC systems within each factory to work together to process sensor data, model factory dynamics, and apply control actions that safely minimize the energy required to support production. In 2024, this system achieved two milestones: the majority of HVAC infrastructure at Gigafactory Nevada is now AI-controlled, reducing fan and thermal energy demand; and the AI algorithm was extended to manage entire chiller plants, creating a closed-loop control system that optimizes both chilled water consumption and the energy required for its generation, all while maintaining factory conditions.”

Tesla utilizes AI Control “primarily on systems that heat or cool critical factory production spaces and equipment.” AI Control communicates with the preexisting standard control logic of each system, and any issues can be resolved by quickly reverting back to standard control. There were none in 2024.

Tesla says that it is utilizing AI to drive impact at its factories, and it has proven to be a valuable tool in reducing energy consumption at one of its facilities.

-

Elon Musk2 days ago

Elon Musk2 days agoTesla investors will be shocked by Jim Cramer’s latest assessment

-

News7 days ago

News7 days agoTesla Robotaxi’s biggest challenge seems to be this one thing

-

News2 weeks ago

News2 weeks agoTesla’s Grok integration will be more realistic with this cool feature

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoElon Musk slams Bloomberg’s shocking xAI cash burn claims

-

News2 weeks ago

News2 weeks agoTexas lawmakers urge Tesla to delay Austin robotaxi launch to September

-

News2 weeks ago

News2 weeks agoTesla dominates Cars.com’s Made in America Index with clean sweep

-

Elon Musk1 week ago

Elon Musk1 week agoFirst Look at Tesla’s Robotaxi App: features, design, and more

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla Robotaxis are becoming a common sight on Austin’s public roads