Video

A 90 Second Tour Inside The Tesla Factory (Video)

A 90 second video showing what goes on inside the Tesla factory has been uploaded to YouTube. It starts with coils of aluminum and ends with a test drive.

Tesla has posted a video on YouTube that opens the door to its Fremont, Calif factory floor and lets us take a peek at the magic inside.

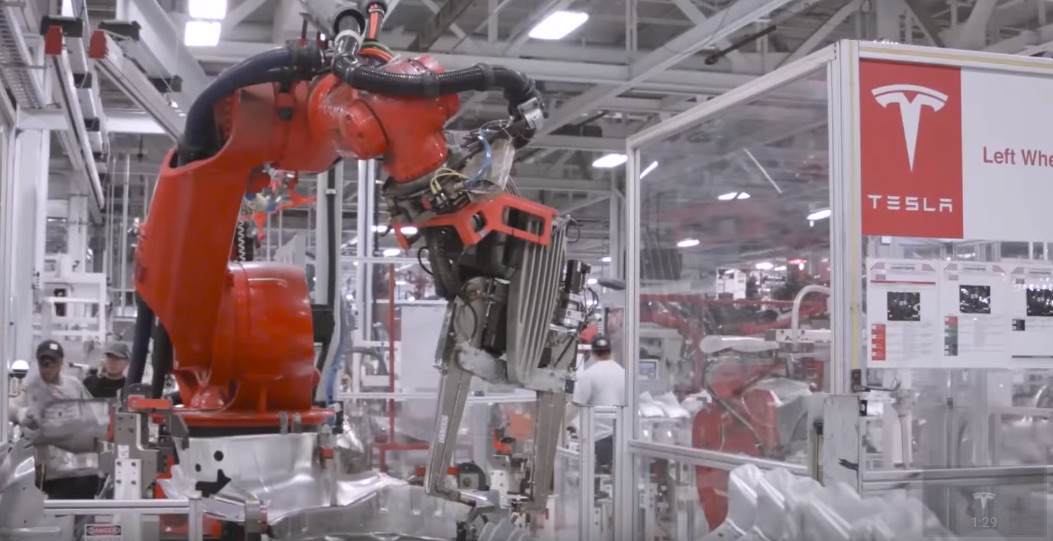

The tour begins with a view of the enormous coils of aluminum that will be formed into doors, roofs, trunk lids and structural components of the car during the stamping process. Then it proceeds to show how computer controlled robots stitch stamped parts together to form the actual structure of the car. The enormous machines make the cars look like Matchbox toys as they proceed along the assembly line.

Next, the cars are hand sanded and prepped for the paint shop, where Tesla’s superhero robots apply just the right thickness of paint to give the cars the showroom luster. After the finished is baked, the installation of glass begins, followed by interior finishing.

Once the drive units are installed, each Tesla is run on a dynamometer to make sure it performs as expected and that all systems are working perfectly. It then makes its way to to the test track outside the factory before being put into the proper queue for delivery to its new owner.

What is striking in the video is how all the workers are moving at a normal pace. No one is hurrying, no shop foreman are strutting around trying to speed up the process. Perfection does not come when there is intense time pressure and perfection is what Tesla is striving for in every car it builds.

Word of mouth is what sells Teslas. (That and Elon’s tweets!) The entire Tesla factory is constructed to insure all new owners are completely happy with their cars when they get delivered.

News

Watch the first true Tesla Robotaxi intervention by safety monitor

Watch the first Tesla Robotaxi intervention by a safety monitor.

Nearly 60 hours into the launch of the Tesla Robotaxi platform, it appears we have our first true intervention that required the in-car safety monitor to intervene.

We’ve seen and heard about a handful of minor issues with the Robotaxi fleet thus far, one of which included a risky, but very human-like behavior of navigating across yellow lines to a turn lane after missing a turn.

While that is not necessarily a legal maneuver, it is something that you’d see commonly from human drivers, and although aggressive, it is sometimes reasonable to perform depending on traffic conditions.

For what it’s worth, the car seemed very confused by the situation, and while the safety monitor did not get involved and the car handled the situation with no real issue, it is something as a rider you’d like to see less of.

First Look at Tesla’s Robotaxi App: features, design, and more

As previously stated, that specific example did not require any intervention by a safety monitor. On Tuesday, we saw a video of the first true intervention that required the safety monitor who sits in the passenger seat to intervene by pressing a button on the center touchscreen.

During a ride that Tesla investor and YouTuber Dave Lee was taking in Austin in a Robotaxi, the vehicle seemed to get a little confused by a UPS truck that was parallel parking in front of it. The monitor pressed the “Stop in Lane” button on the touchscreen:

This is the first intervention we’ve seen with Robotaxi (via @heydave7): https://t.co/5mp431Z5P8 pic.twitter.com/B9ji3iLa3a

— TESLARATI (@Teslarati) June 24, 2025

This appears to be one of the first errors shared by Tesla Robotaxi Early Access Program users that required the monitor to actually intervene. We have not seen any of it yet. You could also see the UPS truck is also a bit at fault here, as the space it pulled into did not seem even remotely large enough to fit the entire vehicle.

The car may not have anticipated that the truck would park there. You can see how the UPS truck was parked below, and it seems reasonable that the Tesla might not have thought it would attempt to fit there:

Credit: Dave Lee

The Model Y’s steering wheel was also turning sharply right into this spot, it appears. Dave ended his ride here, and stated that this was his dropoff spot. The UPS truck might have just cut off the Tesla, which led to the intervention.

It is a testament to Tesla’s strategy with this Robotaxi rollout. The company is obviously confident enough in the Full Self-Driving suite that it does not feel a human needs to be in the driver’s seat. However, it is still requiring someone, as of now, to sit in the passenger’s seat for instances just like this one.

Safety is the company’s priority with the launch of Robotaxi, and CEO Elon Musk has reiterated that. It is expected that we’d eventually see some kind of intervention that requires a monitor to step in. Everyone was safe.

Obviously, these things happen with autonomous vehicles. We’ve seen Waymos get stuck at intersections in very strange scenarios at times:

Waymo turned into oncoming traffic on the way to work.

It sat there confused for 45 seconds with its hazards on.

Then it proceeded to back up into oncoming traffic.

And they’re about to let these guys on the freeway 😂 pic.twitter.com/ZLRKx2loo1

— Jake Glaser | LA Multifamily (@LAMultiBroker) January 31, 2025

It is proof that autonomous tech is still in a growth phase and engineers are still learning about its capabilities. Tesla and other companies will learn from these rare cases and become better companies, and offer safer technologies because of it.

Elon Musk

Elon Musk just revealed more about Tesla’s June Robotaxi launch

Tesla CEO Elon Musk gave more information about the Robotaxi launch in Austin set for June.

Tesla CEO Elon Musk just revealed more details about the company’s June Robotaxi launch, which will kick off in Austin.

As of right now, Tesla is still set to push out the first Robotaxi rides in Austin, Texas, in early June. These vehicles will be in short supply at first, as Musk says the company is purposely rolling out the fleet in a slow and controlled fashion to prioritize safety. There will be ten vehicles in the Robotaxi fleet to start.

Tesla Robotaxi deemed a total failure by media — even though it hasn’t been released

However, in an interview with CNBC on Tuesday afternoon, Musk also revealed some other new details, including where in Austin the vehicles will be able to go, how many Robotaxis we could see on public roads within a few months, and other information regarding Tesla’s Full Self-Driving suite.

A Controlled Rollout

Tesla has maintained for a few months now that the Robotaxi fleet will be comprised of between 10 and 20 Model Y vehicles in Austin.

The Cybercab, which was unveiled by the company last October, will not be available initially, as those cars will likely be produced in 2026.

Musk said during the CNBC interview that Tesla is doing a low-yield trial at first to initiate a safety-first mentality. It is important for Tesla to launch the Robotaxi fleet in a small manner to keep things in check, at least at first.

As confidence builds and the accuracy of the fleet is ensured, more vehicles will be added to the fleet.

Musk believes there will be 1,000 Robotaxis on the road “in a few months.”

Geofenced to Certain Austin Areas

Tesla will be launching the Robotaxi program in a geofenced fashion that gives the company the ability to control where it goes. Musk says that the areas the Robotaxis will be able to travel to are among the safest neighborhoods and areas in Austin.

This is yet another safety protocol that will ensure the initial riders are not put in dangerous neighborhoods.

Some might be disappointed to hear this because of Tesla’s spoken confidence regarding Robotaxi, but the initial rollout does need to be controlled for safety reasons. An accident or incident of any kind that would put riders’ lives in danger would be catastrophic.

No Driver, No Problem

As the company has rolled out an employee-only version of the Robotaxi program in Austin and the San Francisco Bay Area, some wondered whether the rides would be driverless, as these initial trials for Tesla workers were not. Employee rides featured a human in the driver’s seat to ensure safety.

Tesla says it has launched ride-hailing Robotaxi teaser to employees only

The company did not report whether there were any interventions or not, but it did state that the vehicles traveled over 15,000 miles through 1,500 trips.

Musk confirmed during the interview that there will be no driver in the vehicle when the Robotaxi program launches in June. This will be groundbreaking as it will be the first time that Tesla vehicles will operate on public roads without anyone in the driver’s seat.

Full Self-Driving Licensing

For more than a year, Tesla has indicated that it is in talks with another major automaker regarding the licensing of Full Self-Driving. Many speculated that the company was Ford, but neither it nor Tesla confirmed this.

Musk said today that Tesla has been in touch with “a number of automakers” that have inquired about licensing FSD. Tesla has yet to sign any deal to do so.

Here is the full interview with @elonmusk talking about Tesla and the Cybercab! pic.twitter.com/992njb0lPS

— Robin (@xdNiBoR) May 20, 2025

News

Tesla Full Self-Driving changes your perception of travel — long or short

Tesla Full Self-Driving will ruin controlling your vehicle manually.

Tesla does not tell you what Full Self-Driving will do to your perception of travel. Whether your next trip is a two-minute ride up the street to the grocery store or a 1,500-mile trip across multiple states, you’ll never look at driving the same way.

This past weekend, I was lucky enough to have a new Tesla Model Y for the weekend. Equipped with the company’s Hardware 4 computer, the latest software version, and all of the new Model Y’s improvements from the legacy iteration, I knew much of my weekend would be spent testing FSD, as I have never had an extended experience with it.

By the time the weekend was over and it was time to pick up my non-Tesla car, I realized I was not ready to let go. Having the car drive me around from location to location all weekend was something I truly enjoyed, but it was more than just a convenience thing. I felt impressed, relaxed, and even, in some instances, safer.

🚨 The final leg of our trip here: FSD did a great job of navigating through this parking lot and getting us onto a highway with a very short on-ramp (a very typical part of living and driving in Pennsylvania).

Also, Autopark did a great job! I would like to see it improve by… pic.twitter.com/OBefKZKDCo

— TESLARATI (@Teslarati) May 5, 2025

What Tesla Full Self-Driving Did Well

Now, before I truly begin, I do want to say that I don’t think I’ll ever feel safer than when I’m in ultimate control of the vehicle. However, a lot of things that give me stress during a drive were handled with relative ease by the car — and I was happy I didn’t have to deal with it.

One instance was merging onto a busy highway with a very short merge lane. Full Self-Driving took a no-holds-barred approach, taking the space it was given and grabbing a spot in the right lane quickly.

It was not willing to be passive, but it was also not willing to sacrifice safety. It will not wait for others to pull the trigger and go at intersections or four-way stops. If there are a few seconds of stagnation from the car and another driver in that instance, it will go, of course, proceeding safely.

It even did a handful of things I didn’t expect it to do. It would stay in the right lane if multiple on-ramps were approaching. I took it on a stretch of highway where three on-ramps are all within a mile of one another.

It passed a tractor-trailer just before we made it to the first of those three on-ramps. It stayed in that left lane after overtaking the 18-wheeler, as Driver Visualization showed more cars approaching to merge. It was one of those moments that, even though I have written about this topic for several years, was unbelievably impressive.

It not only drives people safely, but it is also considerate of other drivers, which is very impressive.

I was incredibly surprised to see my Fiancè have so much ease when it was operating.

🚨 Tesla Full Self-Driving takes my Fiancé and I to Target

Flawless drive! We’ll document the rest of our errands today! pic.twitter.com/TAx3mWmVgh

— TESLARATI (@Teslarati) May 4, 2025

I figured, just because she is not as familiar with what Tesla does to make FSD better and how it works, that she would be very on edge during our rides. This was the opposite. She felt comfortable enough to look away from the road while in the passenger seat. Scrolling her phone or looking out at the blooming flowers was what she did in the car. It was no different from when I’m driving, and I think that was what was most impressive to me.

Driving after FSD

I found that picking up my car and driving manually back home truly brought me back to real life. Everyone with a Tesla and Full Self-Driving says that when you go back to another car, you feel like you’re stuck in the past.

I really did feel that way. Not only because of the aesthetic of the interior, but just because I was doing something that I just realized could be done for me with the right vehicle.

🚨 100% the truth!

Once you go FSD, you never go back! https://t.co/uq7qkgAbtA pic.twitter.com/lUN3rT2Kkl

— TESLARATI (@Teslarati) May 8, 2025

While I love the car I own now, I’m still deciding whether I love it enough to keep it. To be completely honest, I have hopped around with the idea of trading in my car for the new Model Y. Whether I will or not truly depends on the next few weeks and how I feel, but I know that I will be considering it for the next few months easily.

-

News3 days ago

News3 days agoTesla debuts hands-free Grok AI with update 2025.26: What you need to know

-

Elon Musk1 week ago

Elon Musk1 week agoElon Musk confirms Grok 4 launch on July 9 with livestream event

-

Elon Musk5 days ago

Elon Musk5 days agoxAI launches Grok 4 with new $300/month SuperGrok Heavy subscription

-

News2 weeks ago

News2 weeks agoTesla Model 3 ranks as the safest new car in Europe for 2025, per Euro NCAP tests

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoxAI’s Memphis data center receives air permit despite community criticism

-

News5 days ago

News5 days agoTesla begins Robotaxi certification push in Arizona: report

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla reveals it is using AI to make factories more sustainable: here’s how

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla scrambles after Musk sidekick exit, CEO takes over sales