News

Lithium produced for Tesla’s batteries is less polluting than 31 cups of coffee: researcher

There are many criticisms of electric vehicles like Teslas, and one of them involves the notion that EVs require massive amounts of water to produce the lithium in their batteries. This idea, according to Dr. Maximilian Fichtner, who serves as the Director at the Helmholtz Institute for Electrochemical Energy Storage in Germany, is not accurate at all.

In a recent conversation with Tagesspiegel Background, the battery researcher stated that the production of electric car batteries is not as extreme as what EV critics would suggest. To produce the lithium needed for a 64 kWh battery pack, for example, Fichtner stated that about 3840 liters of water are evaporated according to usual calculation methods. This is roughly comparable to the production of 250 grams of beef, 30 cups of coffee, or half a pair of jeans, according to the researcher.

Explaining further, Fichtner stated that even before electric cars like Teslas became popular, lithium was already being used in large quantities in many industrial and chemical processes. Lithium-ion batteries are also widely used in mobile devices, which are universally accepted today. “I’m always surprised that the public never talks about lithium in laptops or mobile phones – but suddenly it’s a problem with the e-car,” the battery researcher said.

But the water consumption involved in the production of lithium for electric car batteries is just the tip of the iceberg. Fichtner estimates that a 64 kWh pack is likely in the middle of various variants of the Tesla Model 3 sedan, whose long-range versions can easily go beyond 450 km (280 miles) of range per charge. If one were to infer that an electric car battery pack can remain optimal with 2,000 full charging cycles, this could equate to a total distance of about 900,000 km. And that’s with estimates on existing battery technology.

With this in mind, it appears that Tesla’s lithium-ion batteries are actually less polluting than otherwise everyday items such as steak or the aforementioned 30 cups of coffee, since they have the potential to remain in service for a very long time. About 2,000 charging cycles, after all, would likely equate to years of average EV use.

Companies like Tesla are hard at work in improving their battery cells. This much is hinted at by Tesla executives such as CEO Elon Musk and President of Automotive Jerome Guillen, both of whom have noted that Tesla’s batteries are always evolving. Fichtner expects electric car batteries to have an average lifespan of 3,000 cycles by 2025, which would make EV batteries even more environmentally-friendly.

In his recent conversation with the publication, the researcher discussed one of the most sensitive topics surrounding battery production: cobalt. Cobalt has developed a very negative reputation due to the abhorrent conditions in cobalt mines in areas such as Congo. Fortunately, many automakers have since pledged to source the cobalt used in their EVs from areas that meet stringent standards. Tesla does this and more, with the electric car maker attempting to develop cobalt-free batteries in the near future.

For now, electric car makers are in a game of cobalt reduction, and in this sense, Tesla has a notable lead. The batteries used in Volkswagen’s well-received ID.3 hatchback, for example, contain about 12-14% cobalt. The Tesla Model 3, on the other hand, only contains about 2.9% cobalt as of 2018. Fichtner predicts that if things go well, cobalt-free batteries could enter the market as early as 2025.

Maximilian Fichtner received his Ph.D. in Chemistry/Surface Science with distinction and the Hermann Billing Award for his thesis in 1992. He currently serves as the professor for Solid State Chemistry at the Ulm University and Executive Director of the Helmholtz Institute Ulm for Electrochemical Energy Storage (HIU). He has also worked in collaboration with the German ministries of Economy and Research and Education, and has served as the Chair of the 1st International Symposium on Magnesium Batteries in 2016.

Elon Musk

Tesla engineers deflected calls from this tech giant’s now-defunct EV project

Tesla engineers deflected calls from Apple on a daily basis while the tech giant was developing its now-defunct electric vehicle program, which was known as “Project Titan.”

Back in 2022 and 2023, Apple was developing an EV in a top-secret internal fashion, hoping to launch it by 2028 with a fully autonomous driving suite.

However, Apple bailed on the project in early 2024, as Project Titan abandoned the project in an email to over 2,000 employees. The company had backtracked its expectations for the vehicle on several occasions, initially hoping to launch it with no human driving controls and only with an autonomous driving suite.

Apple canceling its EV has drawn a wide array of reactions across tech

It then planned for a 2028 launch with “limited autonomous driving.” But it seemed to be a bit of a concession at that point; Apple was not prepared to take on industry giants like Tesla.

Wedbush’s Dan Ives noted in a communication to investors that, “The writing was on the wall for Apple with a much different EV landscape forming that would have made this an uphill battle. Most of these Project Titan engineers are now all focused on AI at Apple, which is the right move.”

Apple did all it could to develop a competitive EV that would attract car buyers, including attempting to poach top talent from Tesla.

In a new podcast interview with Tesla CEO Elon Musk, it was revealed that Apple had been calling Tesla engineers nonstop during its development of the now-defunct project. Musk said the engineers “just unplugged their phones.”

Musk said in full:

“They were carpet bombing Tesla with recruiting calls. Engineers just unplugged their phones. Their opening offer without any interview would be double the compensation at Tesla.”

Interestingly, Apple had acquired some ex-Tesla employees for its project, like Senior Director of Engineering Dr. Michael Schwekutsch, who eventually left for Archer Aviation.

Tesla took no legal action against Apple for attempting to poach its employees, as it has with other companies. It came after EV rival Rivian in mid-2020, after stating an “alarming pattern” of poaching employees was noticed.

Elon Musk

Tesla to a $100T market cap? Elon Musk’s response may shock you

There are a lot of Tesla bulls out there who have astronomical expectations for the company, especially as its arm of reach has gone well past automotive and energy and entered artificial intelligence and robotics.

However, some of the most bullish Tesla investors believe the company could become worth $100 trillion, and CEO Elon Musk does not believe that number is completely out of the question, even if it sounds almost ridiculous.

To put that number into perspective, the top ten most valuable companies in the world — NVIDIA, Apple, Alphabet, Microsoft, Amazon, TSMC, Meta, Saudi Aramco, Broadcom, and Tesla — are worth roughly $26 trillion.

Will Tesla join the fold? Predicting a triple merger with SpaceX and xAI

Cathie Wood of ARK Invest believes the number is reasonable considering Tesla’s long-reaching industry ambitions:

“…in the world of AI, what do you have to have to win? You have to have proprietary data, and think about all the proprietary data he has, different kinds of proprietary data. Tesla, the language of the road; Neuralink, multiomics data; nobody else has that data. X, nobody else has that data either. I could see $100 trillion. I think it’s going to happen because of convergence. I think Tesla is the leading candidate [for $100 trillion] for the reason I just said.”

Musk said late last year that all of his companies seem to be “heading toward convergence,” and it’s started to come to fruition. Tesla invested in xAI, as revealed in its Q4 Earnings Shareholder Deck, and SpaceX recently acquired xAI, marking the first step in the potential for a massive umbrella of companies under Musk’s watch.

SpaceX officially acquires xAI, merging rockets with AI expertise

Now that it is happening, it seems Musk is even more enthusiastic about a massive valuation that would swell to nearly four-times the value of the top ten most valuable companies in the world currently, as he said on X, the idea of a $100 trillion valuation is “not impossible.”

It’s not impossible

— Elon Musk (@elonmusk) February 6, 2026

Tesla is not just a car company. With its many projects, including the launch of Robotaxi, the progress of the Optimus robot, and its AI ambitions, it has the potential to continue gaining value at an accelerating rate.

Musk’s comments show his confidence in Tesla’s numerous projects, especially as some begin to mature and some head toward their initial stages.

Elon Musk

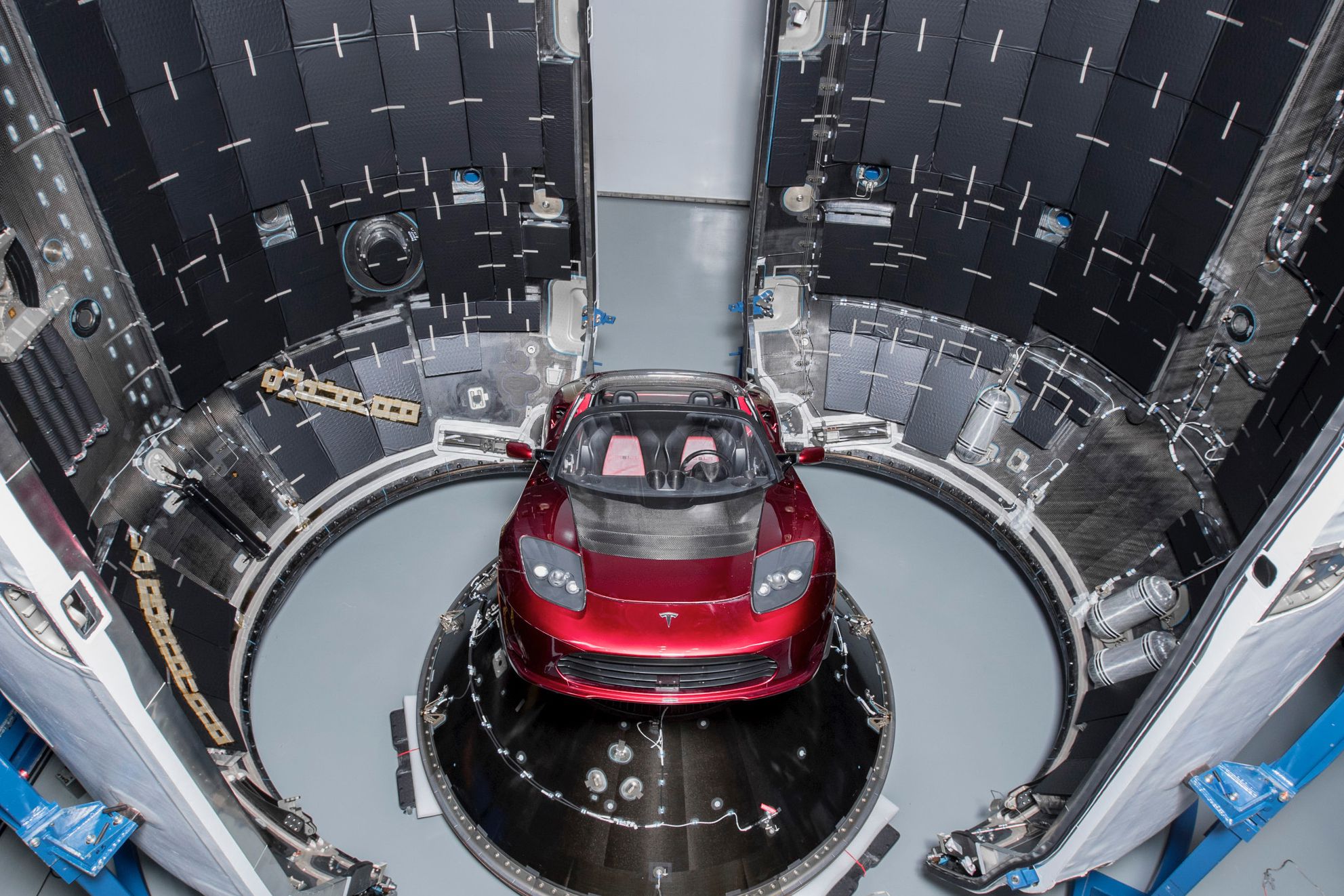

Celebrating SpaceX’s Falcon Heavy Tesla Roadster launch, seven years later (Op-Ed)

Seven years later, the question is no longer “What if this works?” It’s “How far does this go?”

When Falcon Heavy lifted off in February 2018 with Elon Musk’s personal Tesla Roadster as its payload, SpaceX was at a much different place. So was Tesla. It was unclear whether Falcon Heavy was feasible at all, and Tesla was in the depths of Model 3 production hell.

At the time, Tesla’s market capitalization hovered around $55–60 billion, an amount critics argued was already grossly overvalued. SpaceX, on the other hand, was an aggressive private launch provider known for taking risks that traditional aerospace companies avoided.

The Roadster launch was bold by design. Falcon Heavy’s maiden mission carried no paying payload, no government satellite, just a car drifting past Earth with David Bowie playing in the background. To many, it looked like a stunt. For Elon Musk and the SpaceX team, it was a bold statement: there should be some things in the world that simply inspire people.

Inspire it did, and seven years later, SpaceX and Tesla’s results speak for themselves.

Today, Tesla is the world’s most valuable automaker, with a market capitalization of roughly $1.54 trillion. The Model Y has become the best-selling car in the world by volume for three consecutive years, a scenario that would have sounded insane in 2018. Tesla has also pushed autonomy to a point where its vehicles can navigate complex real-world environments using vision alone.

And then there is Optimus. What began as a literal man in a suit has evolved into a humanoid robot program that Musk now describes as potential Von Neumann machines: systems capable of building civilizations beyond Earth. Whether that vision takes decades or less, one thing is evident: Tesla is no longer just a car company. It is positioning itself at the intersection of AI, robotics, and manufacturing.

SpaceX’s trajectory has been just as dramatic.

The Falcon 9 has become the undisputed workhorse of the global launch industry, having completed more than 600 missions to date. Of those, SpaceX has successfully landed a Falcon booster more than 560 times. The Falcon 9 flies more often than all other active launch vehicles combined, routinely lifting off multiple times per week.

Falcon 9 has ferried astronauts to and from the International Space Station via Crew Dragon, restored U.S. human spaceflight capability, and even stepped in to safely return NASA astronauts Butch Wilmore and Suni Williams when circumstances demanded it.

Starlink, once a controversial idea, now dominates the satellite communications industry, providing broadband connectivity across the globe and reshaping how space-based networks are deployed. SpaceX itself, following its merger with xAI, is now valued at roughly $1.25 trillion and is widely expected to pursue what could become the largest IPO in history.

And then there is Starship, Elon Musk’s fully reusable launch system designed not just to reach orbit, but to make humans multiplanetary. In 2018, the idea was still aspirational. Today, it is under active development, flight-tested in public view, and central to NASA’s future lunar plans.

In hindsight, Falcon Heavy’s maiden flight with Elon Musk’s personal Tesla Roadster was never really about a car in space. It was a signal that SpaceX and Tesla were willing to think bigger, move faster, and accept risks others wouldn’t.

The Roadster is still out there, orbiting the Sun. Seven years later, the question is no longer “What if this works?” It’s “How far does this go?”