News

Tesla Model Y vs Model 3 casting comparison shows that legacy auto’s ‘soil-your-pants’ moment is at hand

Back in April 2018, automotive teardown expert Sandy Munro mentioned that if Tesla had contracted an experienced automaker to produce the early-production Model 3’s body, the electric car maker would have “wiped the floor with everybody.” This is because from the suspension down, the Model 3 was a stellar piece of engineering, despite its body having several issues.

Its electric motors were compact, powerful, and cost effective; its batteries are the best in the industry, and its driving dynamics give the impression that the vehicle was riding on rails. Munro noted that if Tesla had hit a home run with the Model 3’s “dinosaur technologies” like its welds and casts, even veteran auto giants like Toyota would appropriately be “crapping their pants.”

It has been nearly two years since Munro mentioned those words during an appearance at YouTube’s Autoline After Hours. Tesla has changed a lot since then, and the company has even released its latest vehicle, the Model Y crossover. Sharing 75% of the Model 3’s parts, the Model Y is designed as a mass-market electric vehicle, and one that can be even more disruptive as its sedan sibling.

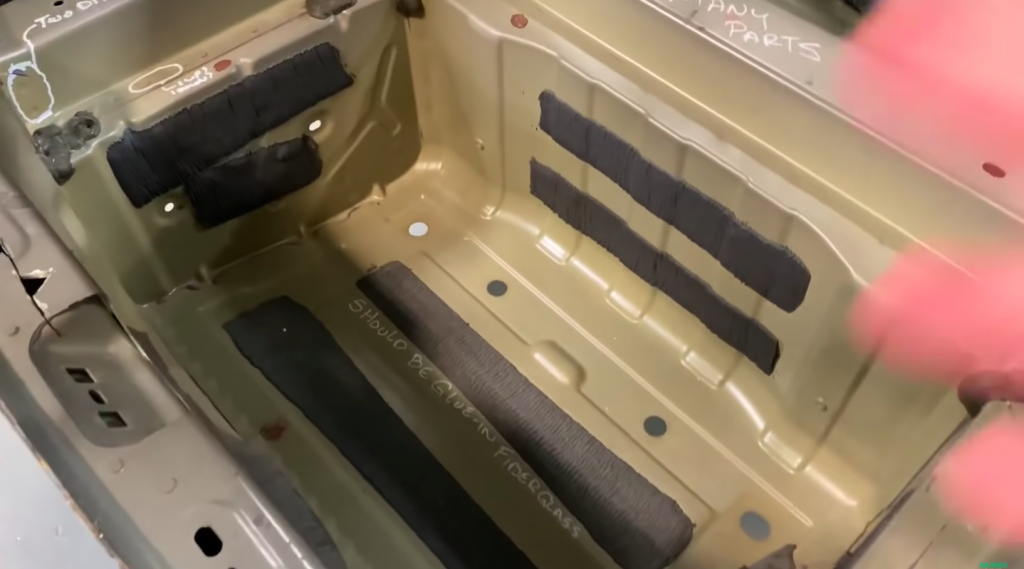

Munro, for his part, has acquired and started a teardown of the all-electric crossover. And based on his findings thus far, it appears that Tesla’s “dinosaur technologies” have improved vastly since the Model 3. This is most evident in the rear casting utilized on the two vehicles.

One look at the Model Y and Model 3’s rear casts shows that the two vehicles are already worlds apart in terms of build quality and design. Munro noted that he did not like the Model 3’s rear casting at all, since it was also over-engineered, with about 100 parts utilized for its rear trunk.

In a way, the Model 3’s rear casting represented the hubris that Elon Musk has admitted to in the past, as it showed Tesla essentially trying to fix something that is not necessarily broken. The result of this was a lot of challenges for Tesla, and a lot of issues with the early-production Model 3’s rear casting.

The Model Y is an entirely different animal. The all-electric crossover features what could only be described as a giant rear casting that is the complete antithesis of the Model 3’s. It has few parts, its welds are consistent, and it features a trunk tub that is similar to those utilized by the world’s best automakers. It’s pretty much what the Model 3 could have been if Tesla was more experienced when they started building the all-electric sedan.

If the Model 3’s rear casting was an exercise in hubris, the Model Y’s rear cast is an exercise in humility. It showed that Tesla is flexible, and that it’s willing to learn, even if it meant abandoning its initial plans and starting from the ground up. Tesla evidently abandoned the early-production Model 3’s rear casting and trunk design. And it’s all the better for it.

A lot of this could be attributed to Elon Musk himself. Munro has noted in the past that he and the Tesla CEO had talked over the phone during his Model 3 teardown, where Musk explained the reasons behind some of the findings about the all-electric sedan. Munro’s firm later sent Tesla a pro bono list of over 200 suggestions that can improve the Model 3’s body.

These suggestions seem to have come to life in the Model Y. Granted, the teardown process for the all-electric crossover has only just begun. Still, several aspects of the vehicle, most notably its rear casting, shows that Tesla did learn from the Model 3, and it has become a much more mature automaker today. Other suggestions from the teardown expert were also applied to the Model Y’s other components, such as its wiring.

It should be noted that Tesla’s fast evolution is partly due to the company’s Silicon Valley startup roots. Startups are notorious for quick, drastic changes in direction, and workers at these companies are required to be tough and flexible. Tesla embodies this, making the company notoriously challenging to work for compared to conventional car companies like GM or Ford.

Yet despite this, Tesla has ranked consistently among the most attractive firms for engineering students. This is because in Tesla, conventional corporate bureaucracy is replaced with an open communication system that allows even interns to share their ideas with company executives. Some of the issues in the Model 3’s early production lines, for example, were addressed by interns, who were later hired full-time by Tesla.

The Model Y is a crossover, which means that it is competing in one of the fastest-growing segments in the auto industry today. With the Model Y, Tesla has the chance to make its biggest mark in the market yet. Fortunately, the electric car maker appears to have done its homework before it released its newest vehicle. One could even argue that Tesla released the Model Y at the perfect time. A mass-market all-electric vehicle that can disrupt the market of crossover SUVs requires a mature company, after all, and Tesla has only started to fit this bill recently.

Just two years ago, Munro mentioned that if the Model 3 had a properly-built body, veteran automakers like Toyota would be “crapping their pants” because of how outclassed they would be. With how the Model Y is turning out, it appears that legacy auto would be wise to keep some extra pairs of pants for the coming years, just in case.

Watch a deep dive into the Tesla Model 3 and Model Y’s rear casts in the video below.

Elon Musk

Celebrating SpaceX’s Falcon Heavy Tesla Roadster launch, seven years later (Op-Ed)

Seven years later, the question is no longer “What if this works?” It’s “How far does this go?”

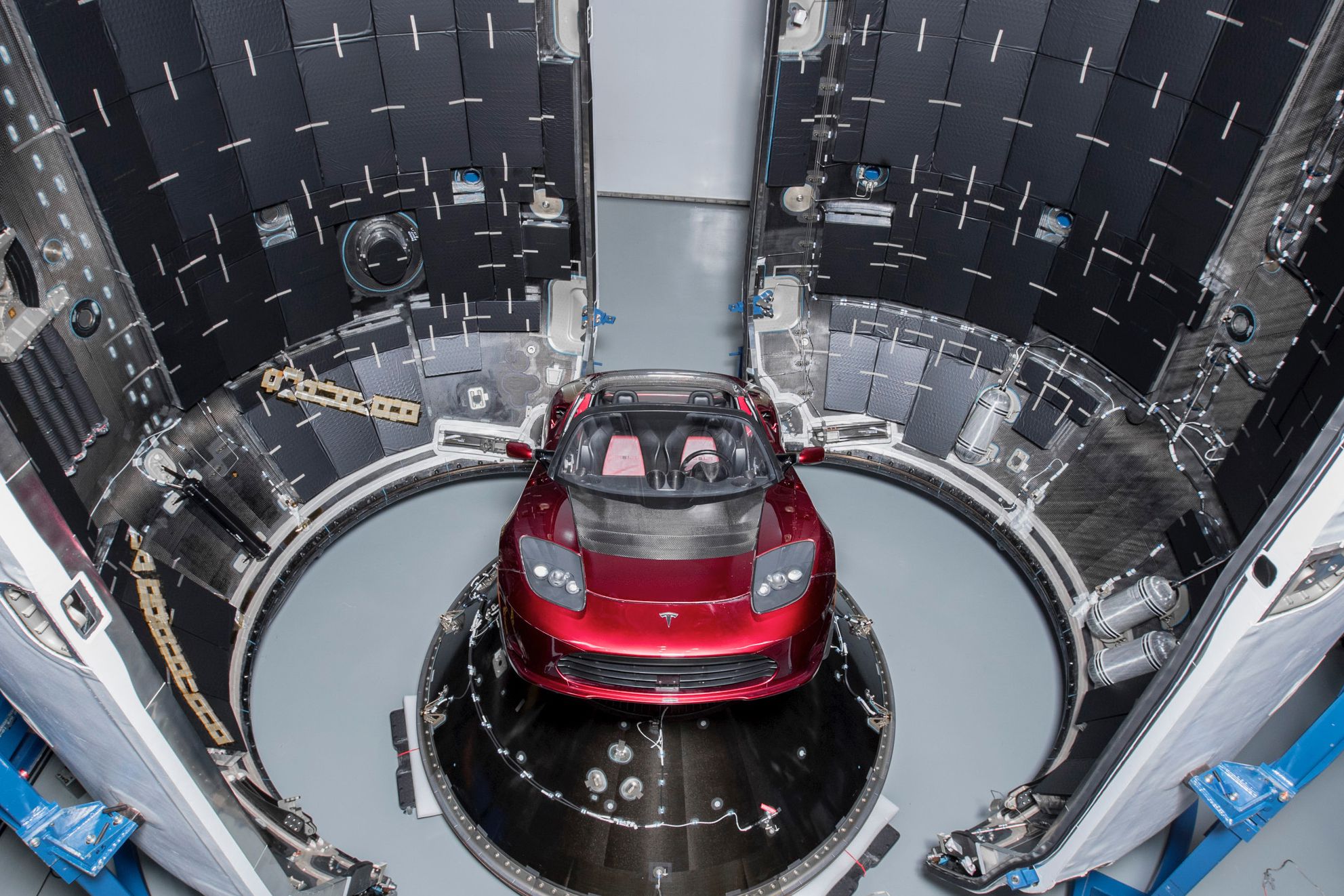

When Falcon Heavy lifted off in February 2018 with Elon Musk’s personal Tesla Roadster as its payload, SpaceX was at a much different place. So was Tesla. It was unclear whether Falcon Heavy was feasible at all, and Tesla was in the depths of Model 3 production hell.

At the time, Tesla’s market capitalization hovered around $55–60 billion, an amount critics argued was already grossly overvalued. SpaceX, on the other hand, was an aggressive private launch provider known for taking risks that traditional aerospace companies avoided.

The Roadster launch was bold by design. Falcon Heavy’s maiden mission carried no paying payload, no government satellite, just a car drifting past Earth with David Bowie playing in the background. To many, it looked like a stunt. For Elon Musk and the SpaceX team, it was a bold statement: there should be some things in the world that simply inspire people.

Inspire it did, and seven years later, SpaceX and Tesla’s results speak for themselves.

Today, Tesla is the world’s most valuable automaker, with a market capitalization of roughly $1.54 trillion. The Model Y has become the best-selling car in the world by volume for three consecutive years, a scenario that would have sounded insane in 2018. Tesla has also pushed autonomy to a point where its vehicles can navigate complex real-world environments using vision alone.

And then there is Optimus. What began as a literal man in a suit has evolved into a humanoid robot program that Musk now describes as potential Von Neumann machines: systems capable of building civilizations beyond Earth. Whether that vision takes decades or less, one thing is evident: Tesla is no longer just a car company. It is positioning itself at the intersection of AI, robotics, and manufacturing.

SpaceX’s trajectory has been just as dramatic.

The Falcon 9 has become the undisputed workhorse of the global launch industry, having completed more than 600 missions to date. Of those, SpaceX has successfully landed a Falcon booster more than 560 times. The Falcon 9 flies more often than all other active launch vehicles combined, routinely lifting off multiple times per week.

Falcon 9 has ferried astronauts to and from the International Space Station via Crew Dragon, restored U.S. human spaceflight capability, and even stepped in to safely return NASA astronauts Butch Wilmore and Suni Williams when circumstances demanded it.

Starlink, once a controversial idea, now dominates the satellite communications industry, providing broadband connectivity across the globe and reshaping how space-based networks are deployed. SpaceX itself, following its merger with xAI, is now valued at roughly $1.25 trillion and is widely expected to pursue what could become the largest IPO in history.

And then there is Starship, Elon Musk’s fully reusable launch system designed not just to reach orbit, but to make humans multiplanetary. In 2018, the idea was still aspirational. Today, it is under active development, flight-tested in public view, and central to NASA’s future lunar plans.

In hindsight, Falcon Heavy’s maiden flight with Elon Musk’s personal Tesla Roadster was never really about a car in space. It was a signal that SpaceX and Tesla were willing to think bigger, move faster, and accept risks others wouldn’t.

The Roadster is still out there, orbiting the Sun. Seven years later, the question is no longer “What if this works?” It’s “How far does this go?”

Energy

Tesla launches Cybertruck vehicle-to-grid program in Texas

The initiative was announced by the official Tesla Energy account on social media platform X.

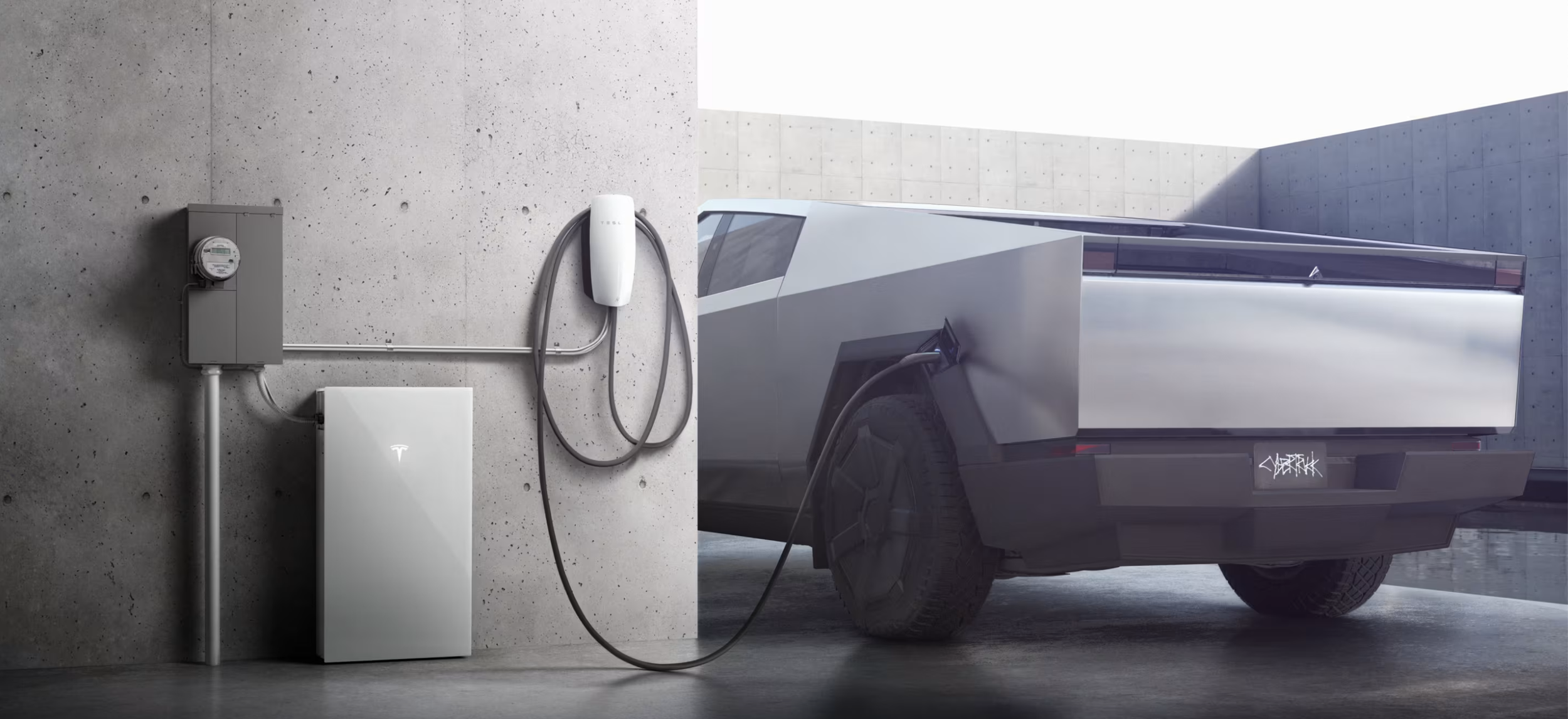

Tesla has launched a vehicle-to-grid (V2G) program in Texas, allowing eligible Cybertruck owners to send energy back to the grid during high-demand events and receive compensation on their utility bills.

The initiative, dubbed Powershare Grid Support, was announced by the official Tesla Energy account on social media platform X.

Texas’ Cybertruck V2G program

In its post on X, Tesla Energy confirmed that vehicle-to-grid functionality is “coming soon,” starting with select Texas markets. Under the new Powershare Grid Support program, owners of the Cybertruck equipped with Powershare home backup hardware can opt in through the Tesla app and participate in short-notice grid stress events.

During these events, the Cybertruck automatically discharges excess energy back to the grid, supporting local utilities such as CenterPoint Energy and Oncor. In return, participants receive compensation in the form of bill credits. Tesla noted that the program is currently invitation-only as part of an early adopter rollout.

The launch builds on the Cybertruck’s existing Powershare capability, which allows the vehicle to provide up to 11.5 kW of power for home backup. Tesla added that the program is expected to expand to California next, with eligibility tied to utilities such as PG&E, SCE, and SDG&E.

Powershare Grid Support

To participate in Texas, Cybertruck owners must live in areas served by CenterPoint Energy or Oncor, have Powershare equipment installed, enroll in the Tesla Electric Drive plan, and opt in through the Tesla app. Once enrolled, vehicles would be able to contribute power during high-demand events, helping stabilize the grid.

Tesla noted that events may occur with little notice, so participants are encouraged to keep their Cybertrucks plugged in when at home and to manage their discharge limits based on personal needs. Compensation varies depending on the electricity plan, similar to how Powerwall owners in some regions have earned substantial credits by participating in Virtual Power Plant (VPP) programs.

News

Samsung nears Tesla AI chip ramp with early approval at TX factory

This marks a key step towards the tech giant’s production of Tesla’s next-generation AI5 chips in the United States.

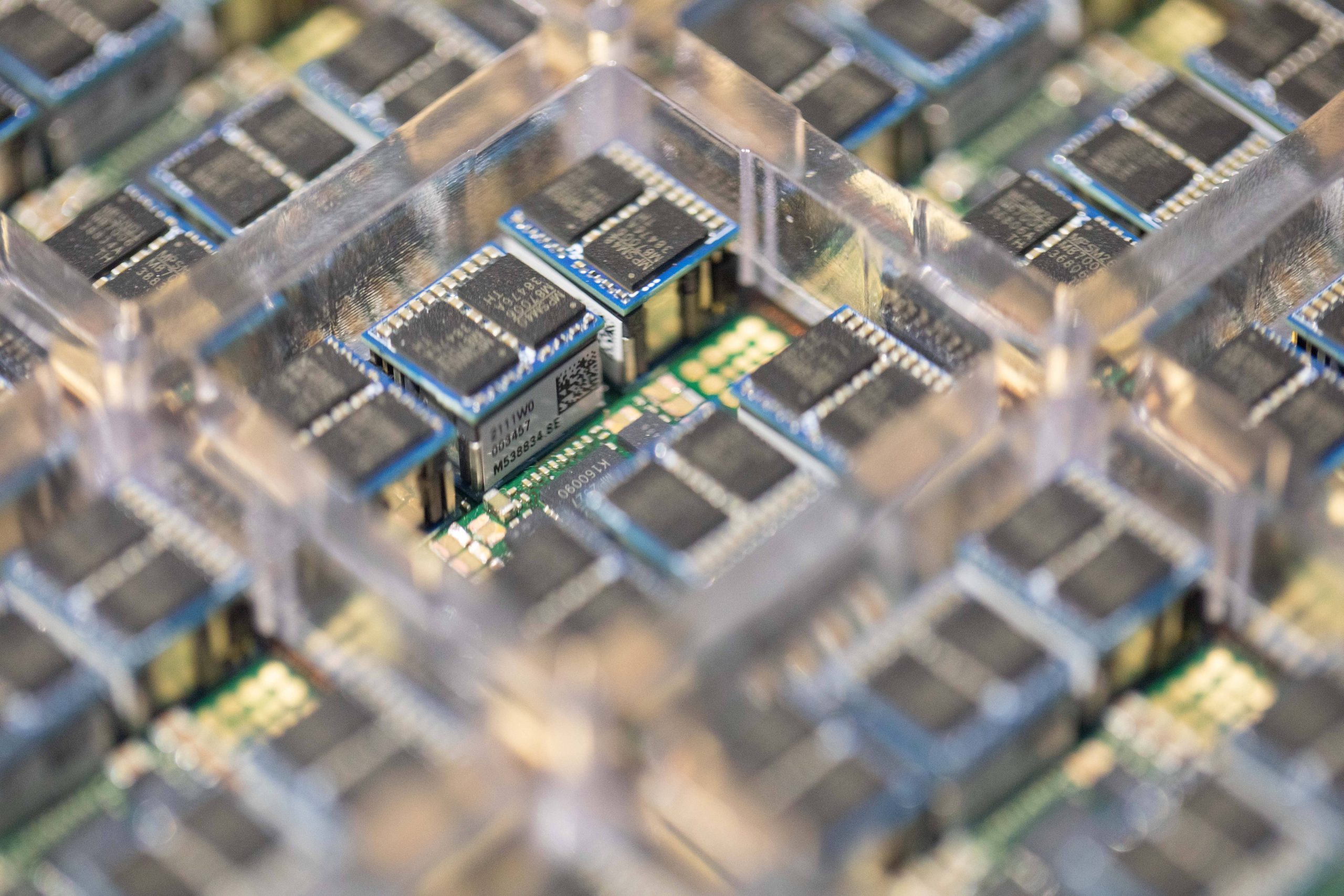

Samsung has received temporary approval to begin limited operations at its semiconductor plant in Taylor, Texas.

This marks a key step towards the tech giant’s production of Tesla’s next-generation AI5 chips in the United States.

Samsung clears early operations hurdle

As noted in a report from Korea JoongAng Daily, Samsung Electronics has secured temporary certificates of occupancy (TCOs) for a portion of its semiconductor facility in Taylor. This should allow the facility to start operations ahead of full completion later this year.

City officials confirmed that approximately 88,000 square feet of Samsung’s Fab 1 building has received temporary approval, with additional areas expected to follow. The overall timeline for permitting the remaining sections has not yet been finalized.

Samsung’s Taylor facility is expected to manufacture Tesla’s AI5 chips once mass production begins in the second half of the year. The facility is also expected to produce Tesla’s upcoming AI6 chips.

Tesla CEO Elon Musk recently stated that the design for AI5 is nearly complete, and the development of AI6 is already underway. Musk has previously outlined an aggressive roadmap targeting nine-month design cycles for successive generations of its AI chips.

Samsung’s U.S. expansion

Construction at the Taylor site remains on schedule. Reports indicate Samsung plans to begin testing extreme ultraviolet (EUV) lithography equipment next month, a critical step for producing advanced 2-nanometer semiconductors.

Samsung is expected to complete 6 million square feet of floor space at the site by the end of this year, with an additional 1 million square feet planned by 2028. The full campus spans more than 1,200 acres.

Beyond Tesla, Samsung Foundry is also pursuing additional U.S. customers as demand for AI and high-performance computing chips accelerates. Company executives have stated that Samsung is looking to achieve more than 130% growth in 2-nanometer chip orders this year.

One of Samsung’s biggest rivals, TSMC, is also looking to expand its footprint in the United States, with reports suggesting that the company is considering expanding its Arizona facility to as many as 11 total plants. TSMC is also expected to produce Tesla’s AI5 chips.